Patents

Literature

39results about How to "Reduce material input" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Application of baby hamster kidney(BHK)-21 cell serum-free suspension culture technology in foot-and-mouth disease vaccine production

ActiveCN102178946AShort cycleIncrease productionMicroorganism based processesAntiviralsSerum igeSerum free

The invention discloses application of a baby hamster kidney(BHK)-21 cell serum-free suspension culture technology in foot-and-mouth disease vaccine production, which comprises the following steps of: 1) performing cell recovery; 2) performing reactor culture and cell amplification culture; and 3) inoculating foot-and-mouth disease virus seed venom and collecting the venom. A process for producing foot-and-mouth disease inactivated vaccines by culturing the BHK-21 cells through serum-free suspension culture and a step-by-step cell amplification method make the production period f the foot-and-mouth disease vaccines shortened and yield increased, and ensure stable quality and obvious benefit. The production process reduces the using amount of a culture medium, and the amount of the collected virus liquid is the culture medium consumption amount, while the culture medium consumption amount in a roller bottle production process is 2 times higher than the amount of the collected virus liquid, and bovine serum which is about 5 percent of the culture medium amount is needed.

Owner:马忠仁 +5

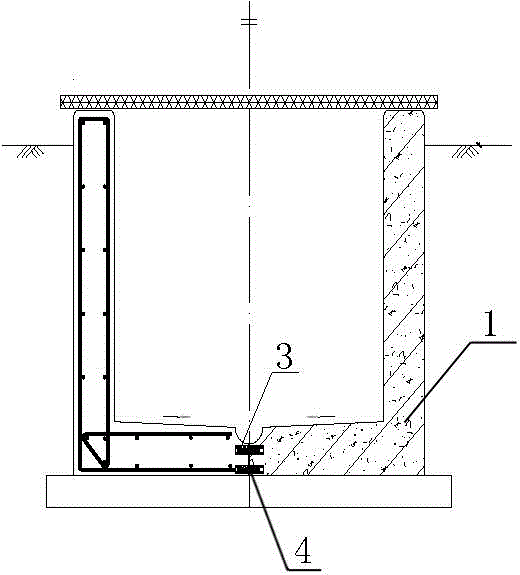

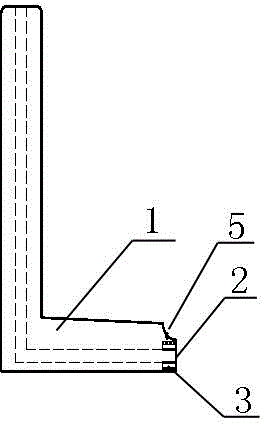

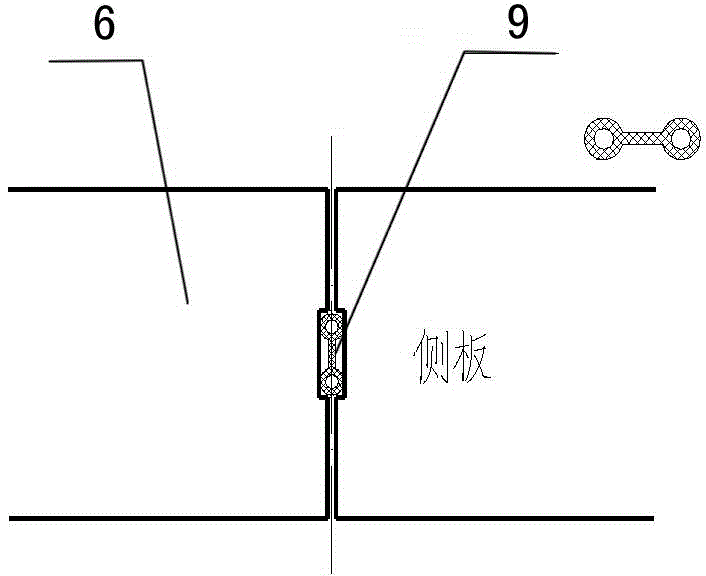

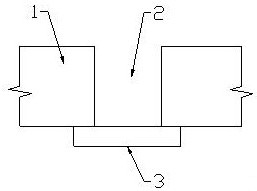

Reinforced concrete assembly type cable duct and manufacturing method

InactiveCN104466869AImprove the degree of factory processingImprove construction progressCable installations on groundArtificial islandsReinforced concreteEngineering

A reinforced concrete assembly type cable duct is formed by connecting sections of U-shaped duct bodies, each U-shaped duct body is formed by splicing two half L-shaped duct bodies in left-and-right symmetry, a plurality of steel bar connection sleeves arranged inwards respectively are correspondingly and transversely reserved on the spliced edges, at the spliced parts, of bottom plates, and when every two half L-shaped duct bodies are spliced together, short steel bars performing the functions of positioning and connecting are inserted in the steel bar connection sleeves corresponding to the two half L-shaped duct bodies. The manufacturing method comprises the steps of factory fabrication, positioning paying off, earth excavation, bedding layer construction, in-place hoisting, connecting joint pouring, cable support fixation, cable laying and cover plate laying. The reinforced concrete assembly type cable duct has the advantages of being convenient to convey, easy and convenient to splice, reliable in water resistance, smooth in water drainage, capable of being assembled on site and the like.

Owner:ZHEJIANG ELECTRIC POWER DESIGN INST

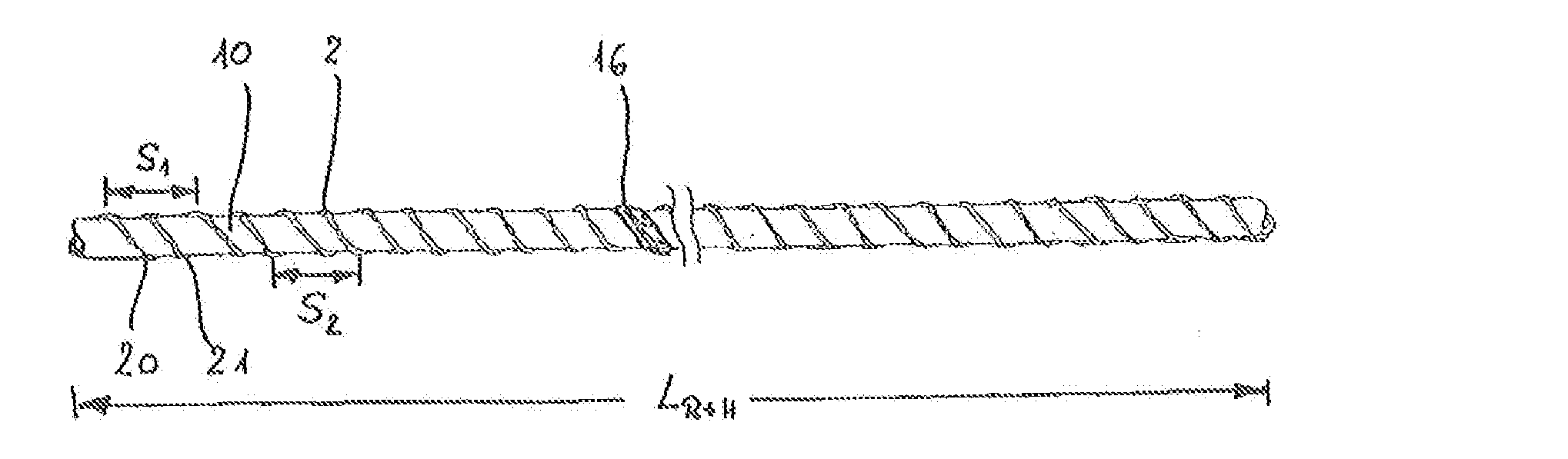

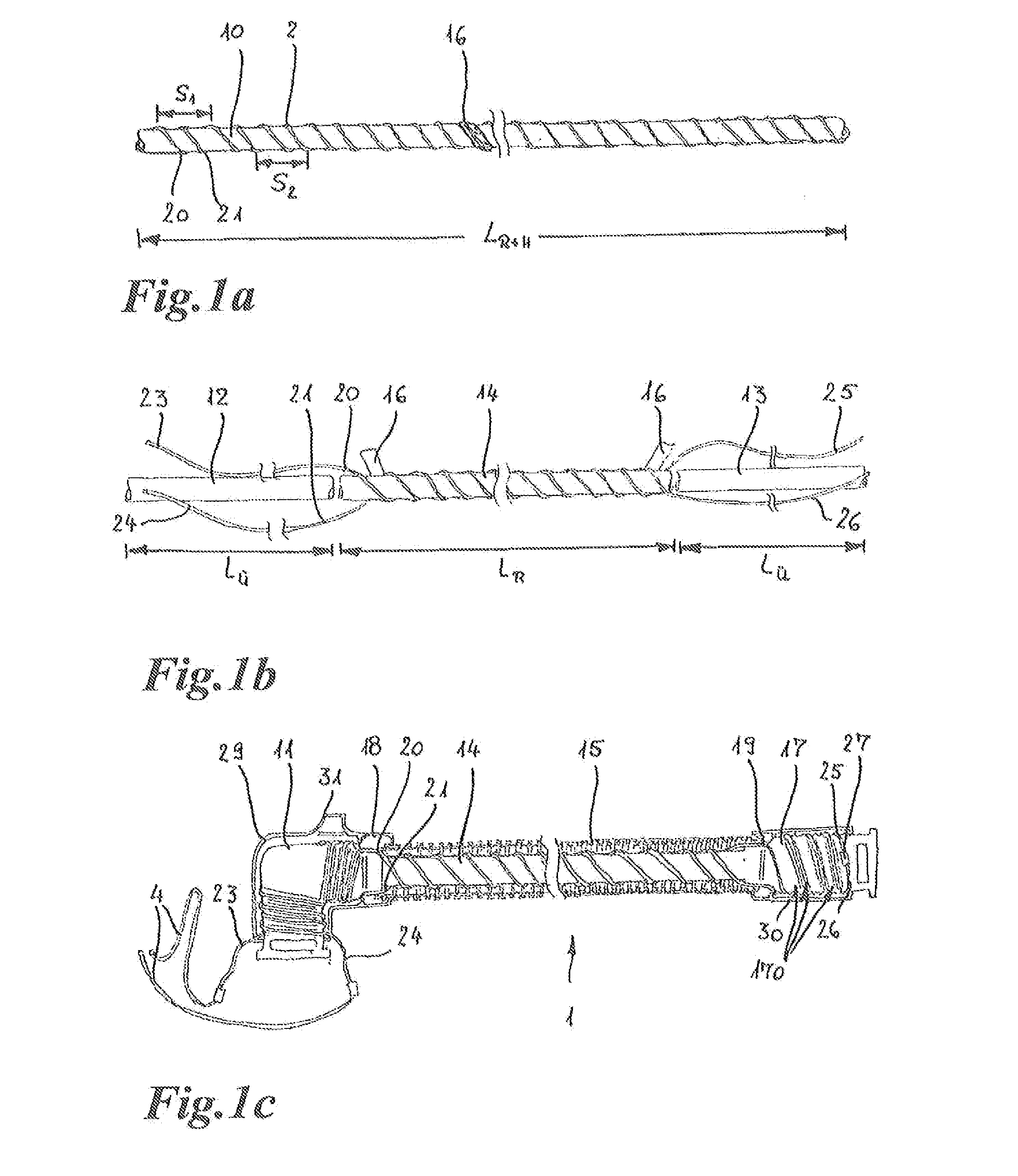

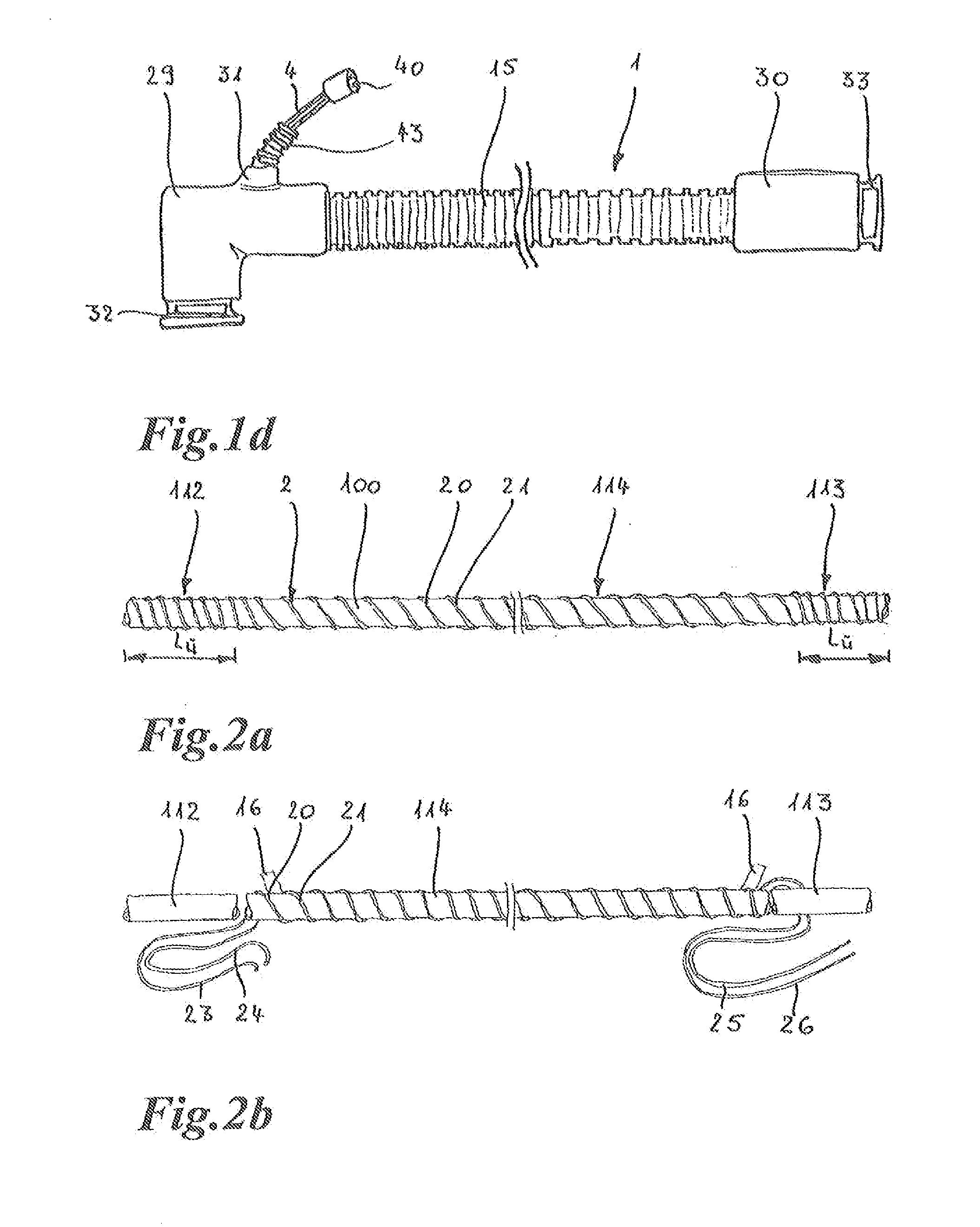

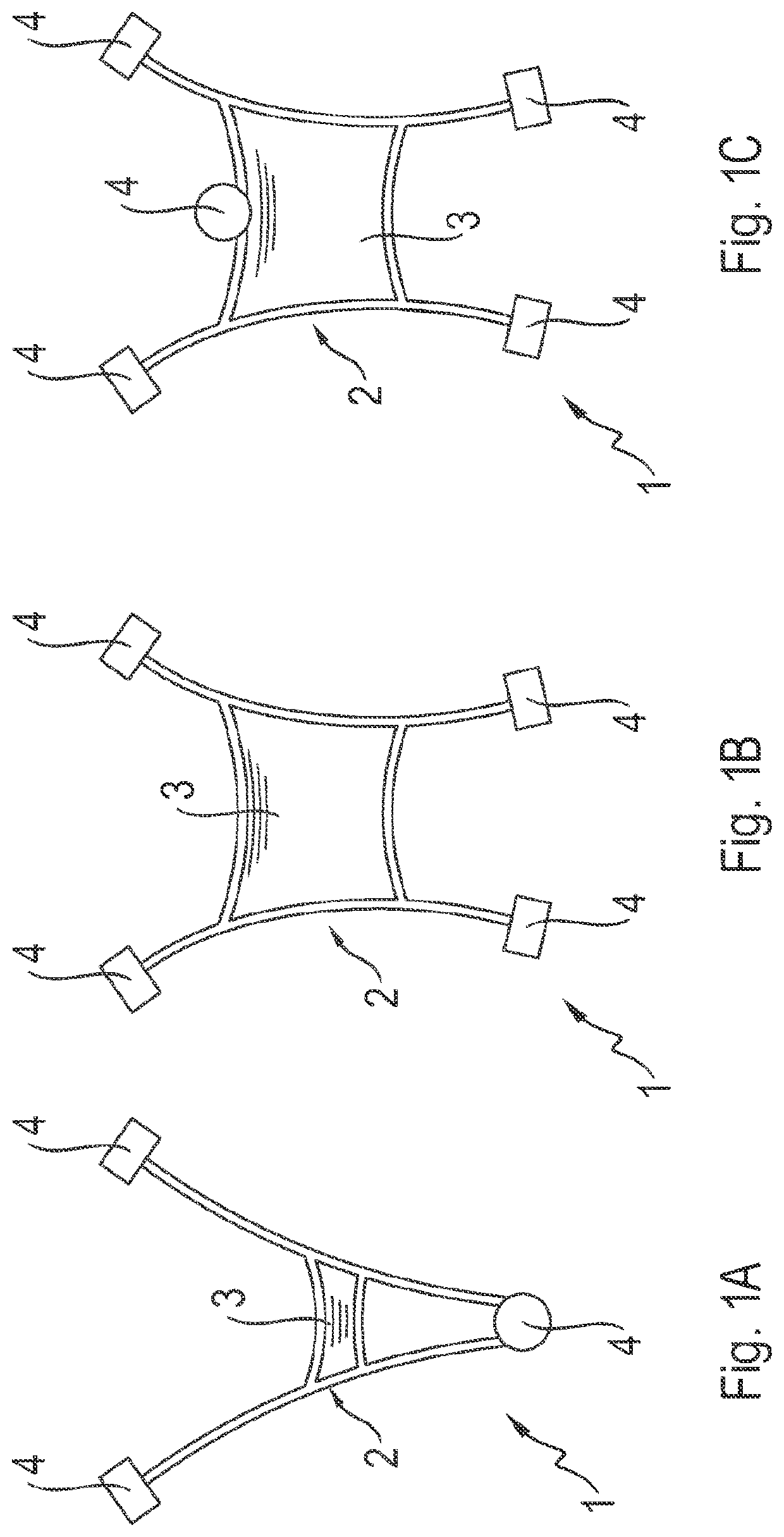

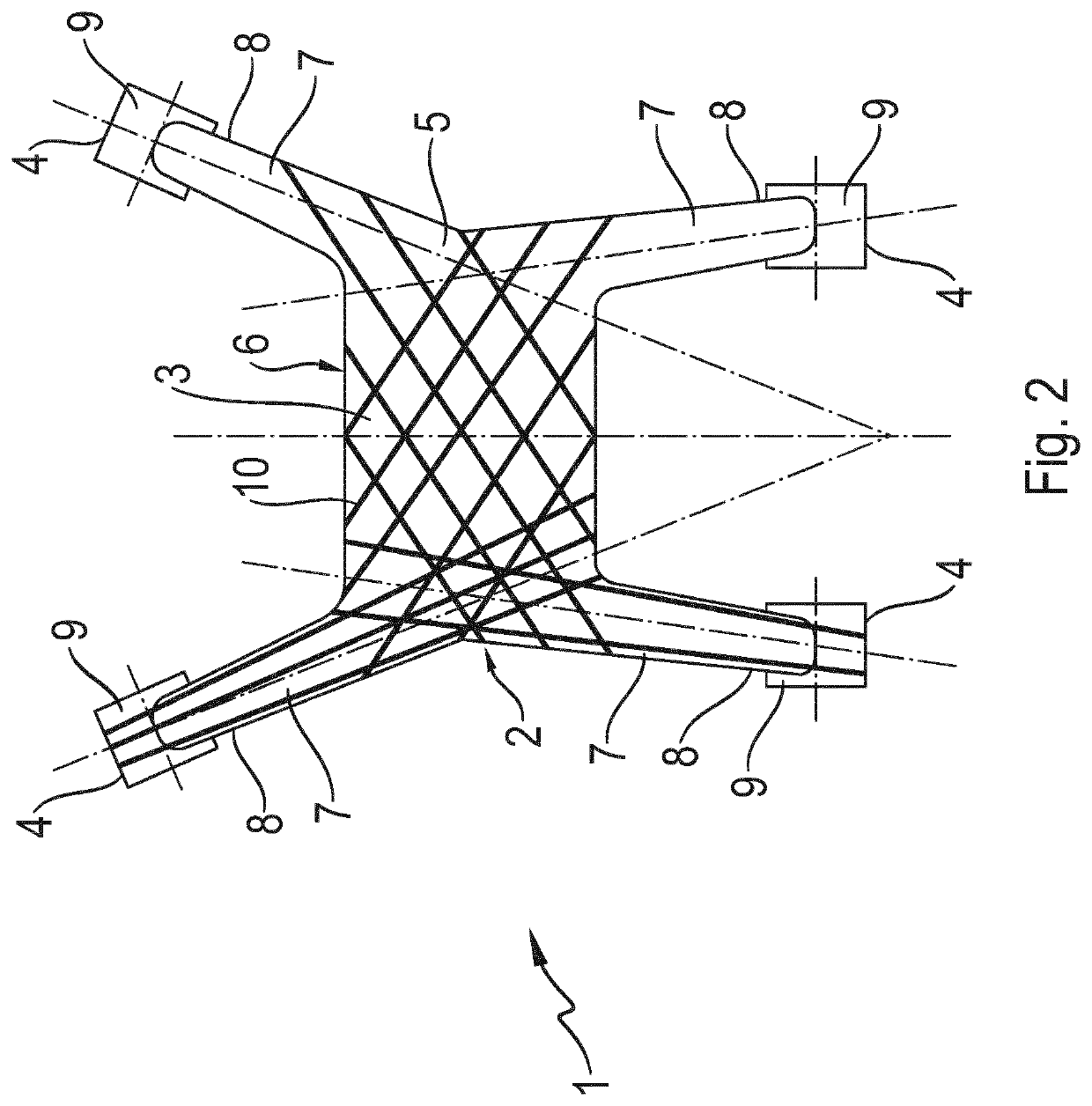

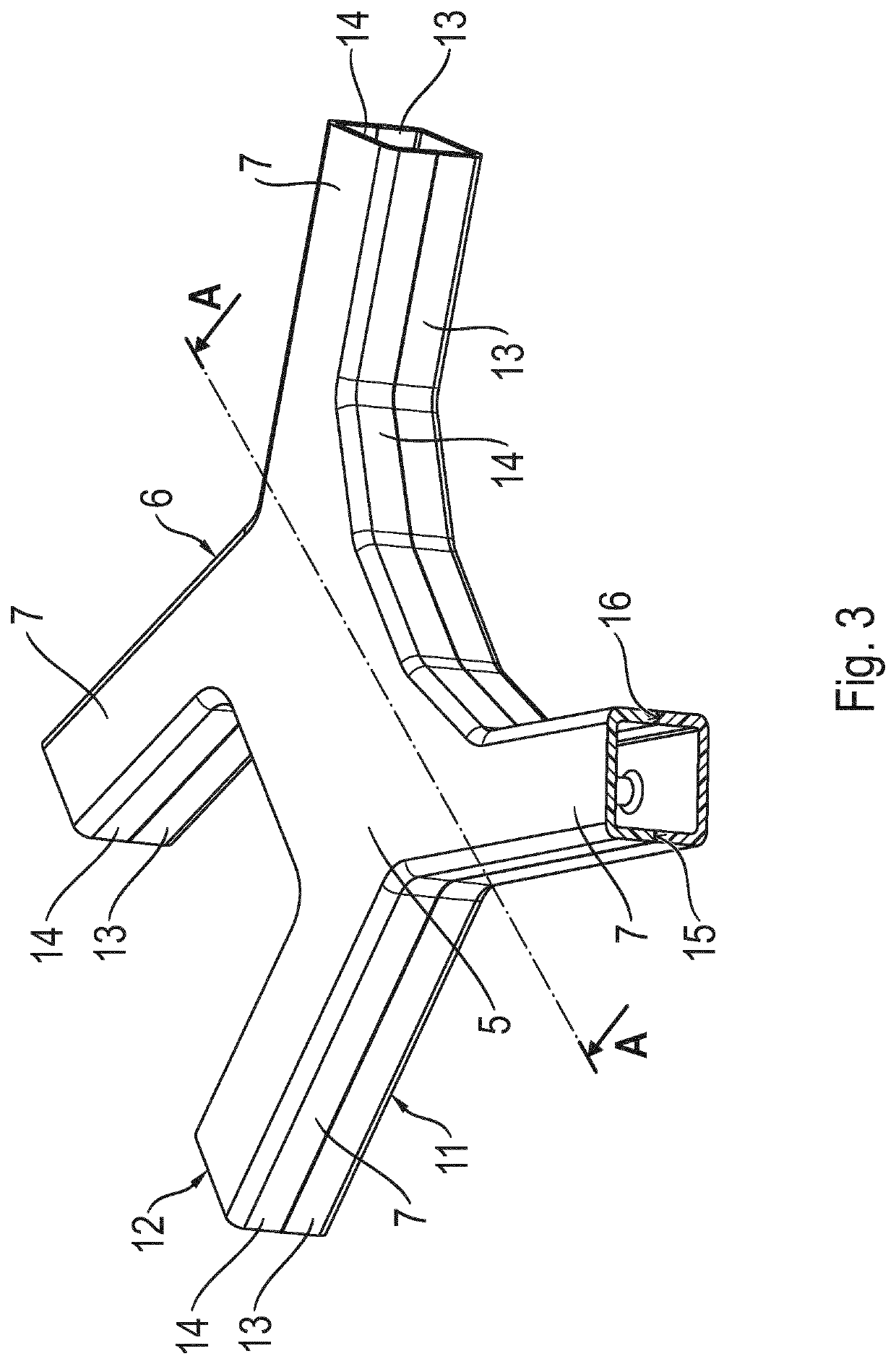

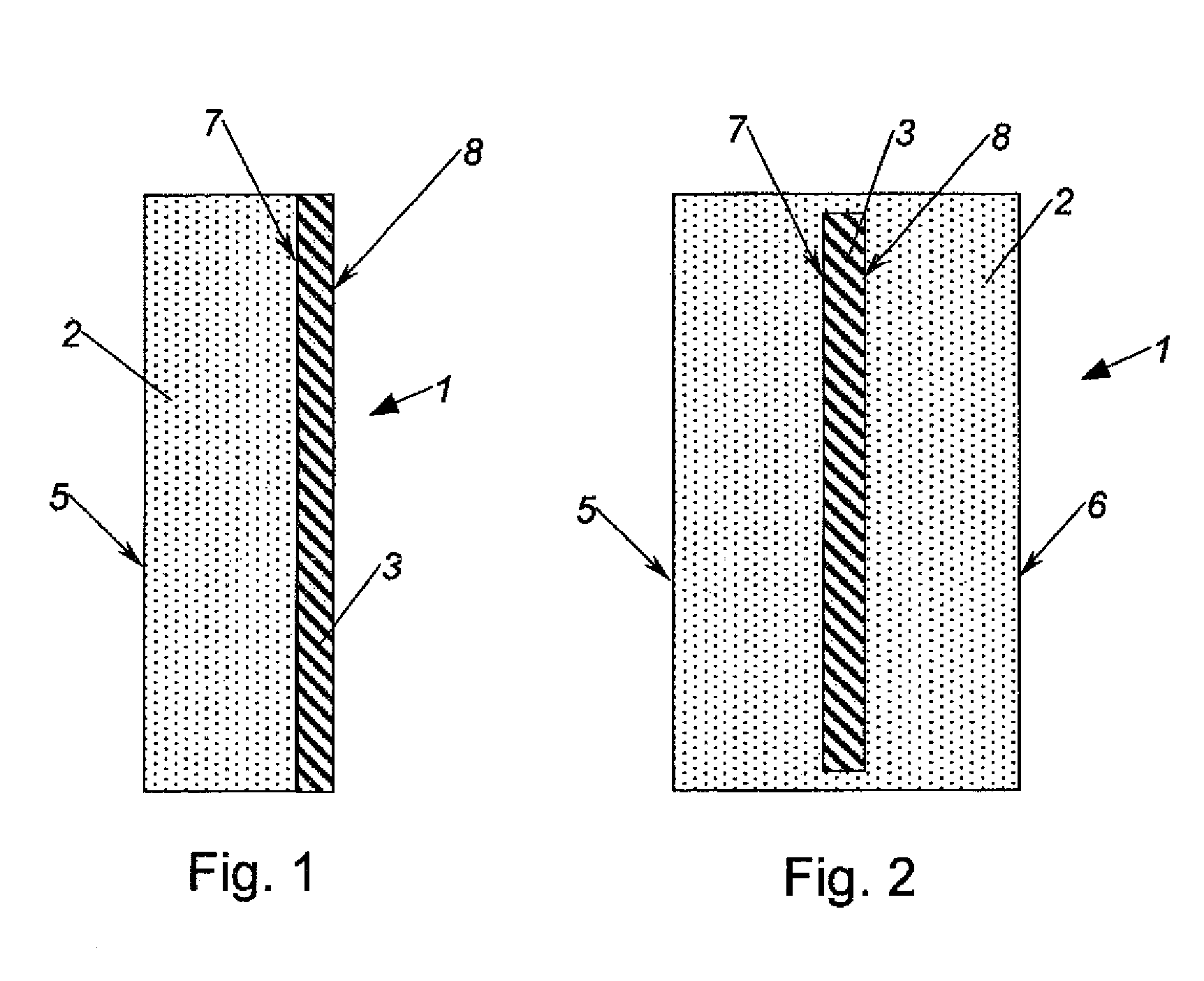

Heatable medium pipe and method for producing same

ActiveUS20130163970A1Less wall thicknessReduce material inputPipe heating/coolingMachines/enginesWrap aroundHeating element

A heatable medium pipe having at least one pipe connector and heating element, wherein the heating element has a few wires, in particular two wires, and said wires extend continuously along the medium pipe and along the at least one pipe connector. In a method for producing such a heatable medium pipe, the heating element is continuously wound around a tubular medium pipe and the heating element is pre-assembled on the medium pipe in that the heating element is fastened or fixed by at least one fastening element, the medium pipe is cut to a first length for the particular application, the length corresponding to the desired medium pipe length (IR) plus the heating element length (IH) required for wrapping around the at least one pipe connector and the transition area the fastening element is removed in the region outside the desired medium pipe length (IR), the heating element is unwrapped from the medium pipe section cut from the first length, the medium pipe is cut to the desired medium pipe length (IR) to form a second medium pipe section, the medium pipe section is connected to the at least one pipe connector as the medium pipe, and the heating element is at least wrapped around the at least one pipe connector.

Owner:VOSS AUTOMOTIVE

Collophanite flotation collecting agent prepared from rubber seed oil and method for preparing same

ActiveCN102205278ASimple production processReduce material inputFatty acids production/refiningFlotationFroth flotationSolubility

The invention relates to a collophanite froth flotation collecting agent, in particular to a method for preparing a collecting agent by processing and separating rubber seed oil as a main raw material. The method comprises the steps of: placing the rubber seed oil as the main raw material in a hydrolysis reaction kettle for medium-pressure hydrolysis, hydrolyzing to obtain mixed fatty acid, adding sodium sulfate as an electrolyte and sodium octylsulfate as an emulsifying agent, uniformly stirring, centrifugally separating to obtain two kinds of mixed fatty acid, adding sodium hydroxide for carrying out quaternization, and then adding an additive to obtain the collophanite froth flotation collecting agent. The invention has the advantages of simple process, low cost and no three-waste discharge. A prepared positive floatation collecting agent has the characteristics of good water-solubility, excellent resistance to low temperature, consumption reduction and the like. A prepared negative floatation collecting agent has the characteristics of good selectivity, chemical saving, high floatation speed and the like.

Owner:YUNNAN PHOSPHATE CHEM GROUP CORP

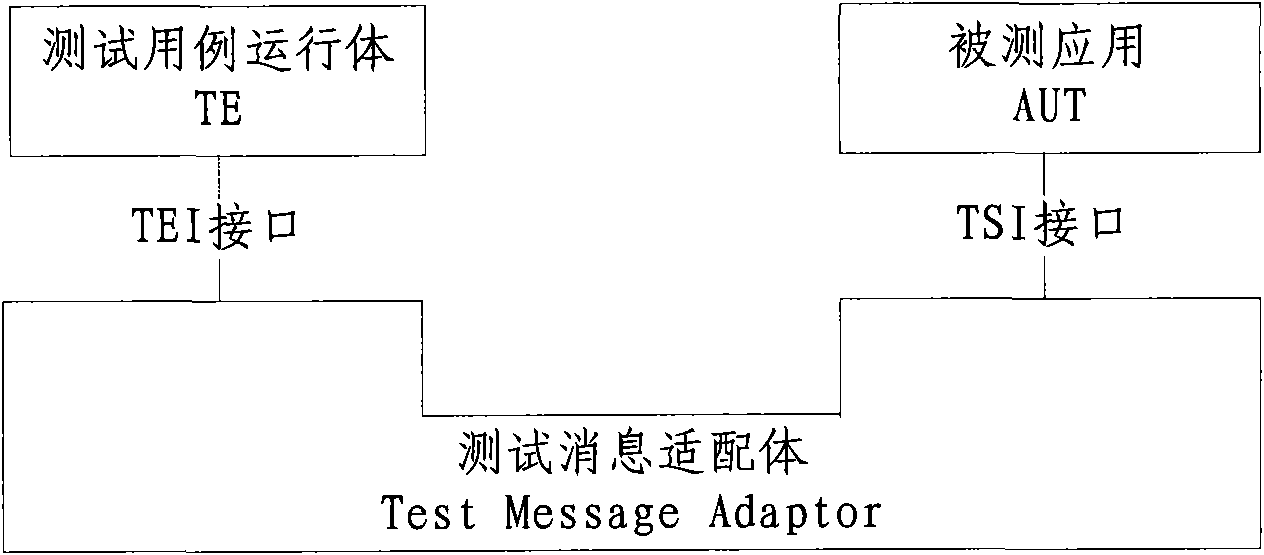

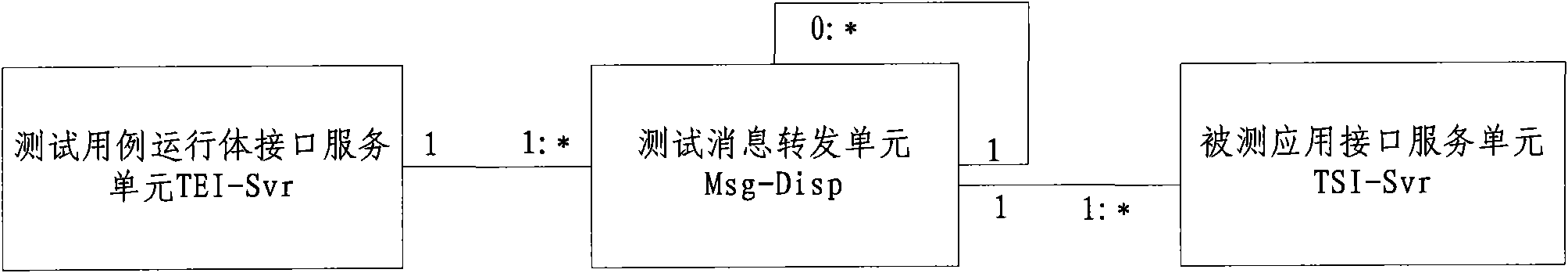

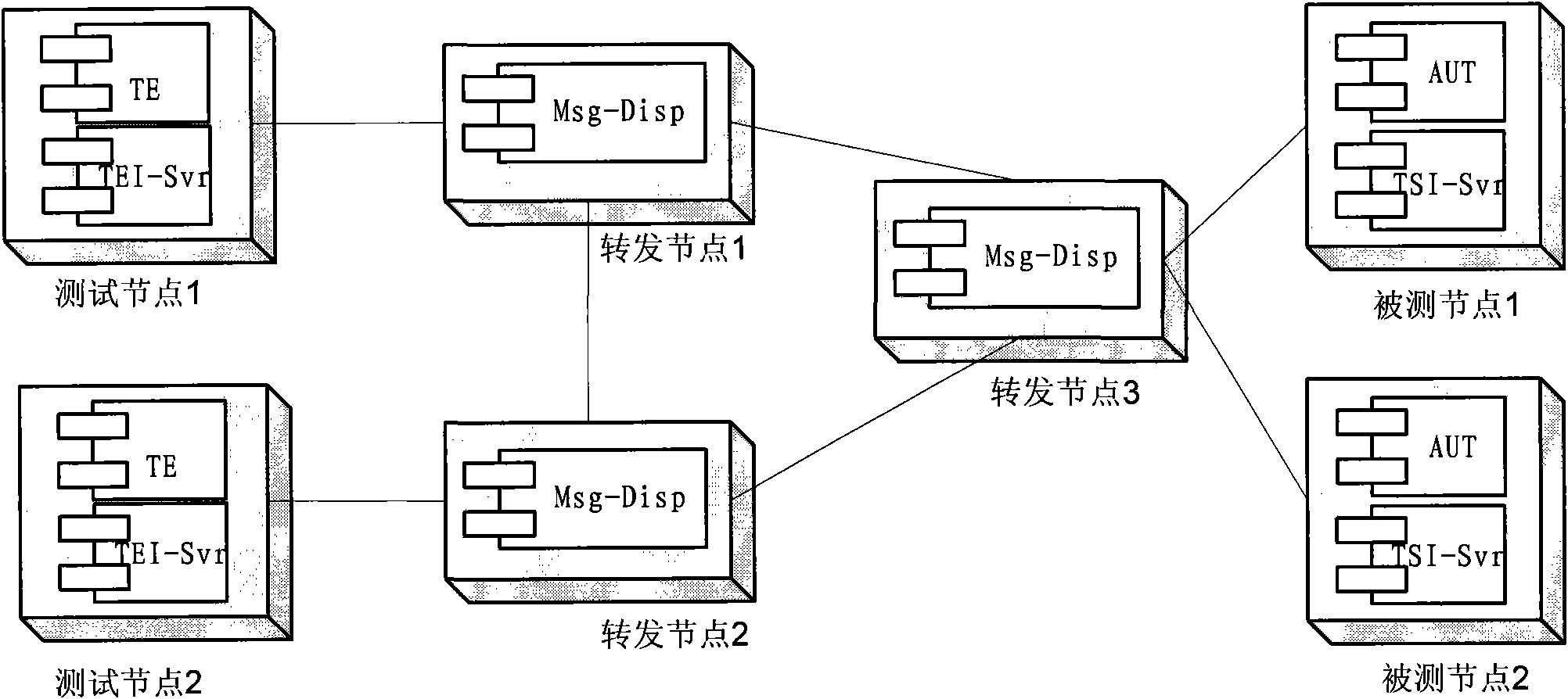

Reusable test message adapting method and system

ActiveCN101621419AReduce manpowerReduce material inputSoftware testing/debuggingData switching networksSpecific testComputer hardware

The invention relates to a reusable test message adapting method and a reusable test message adapting system related to an embedded system, which are used for overcoming a technical defect that a specific test message adaptor needs to be defined and realized for each test operator and a tested application when performing an embedded software test. The reusable test message adapting method and the reusable test message adapting system associate the test operator with the tested application by means of a standard interface through the test message adaptor, and describe a message format of the tested application in a standard mode, thereby reducing repeated definition of the test message adaptation layer, and having high code reuse ratio, strong universality and capability of being conveniently applied to test environments adopting different test tools for different tested applications.

Owner:DATANG MOBILE COMM EQUIP CO LTD

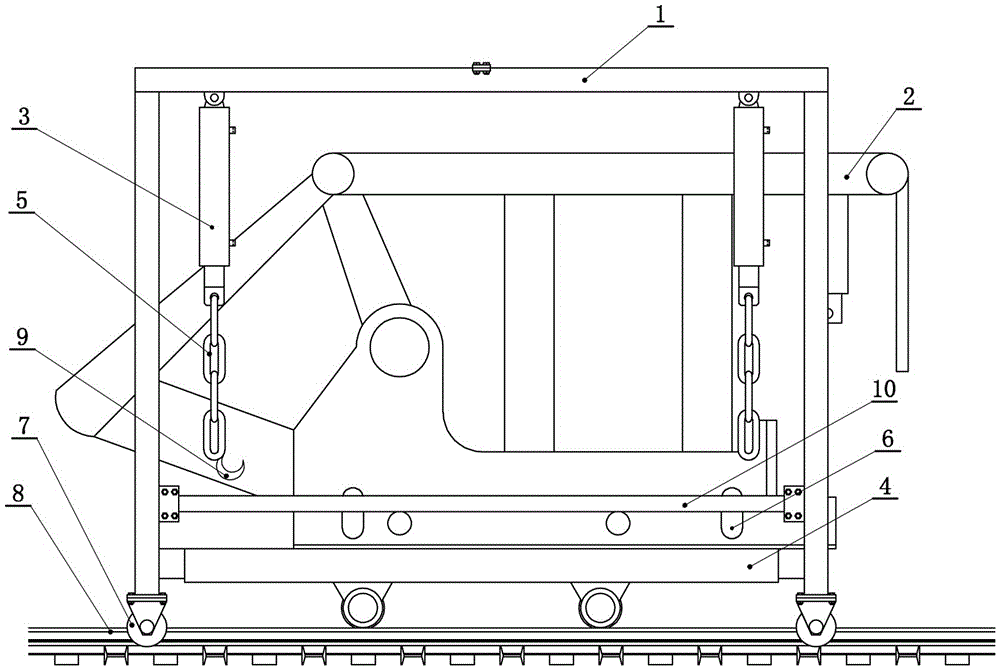

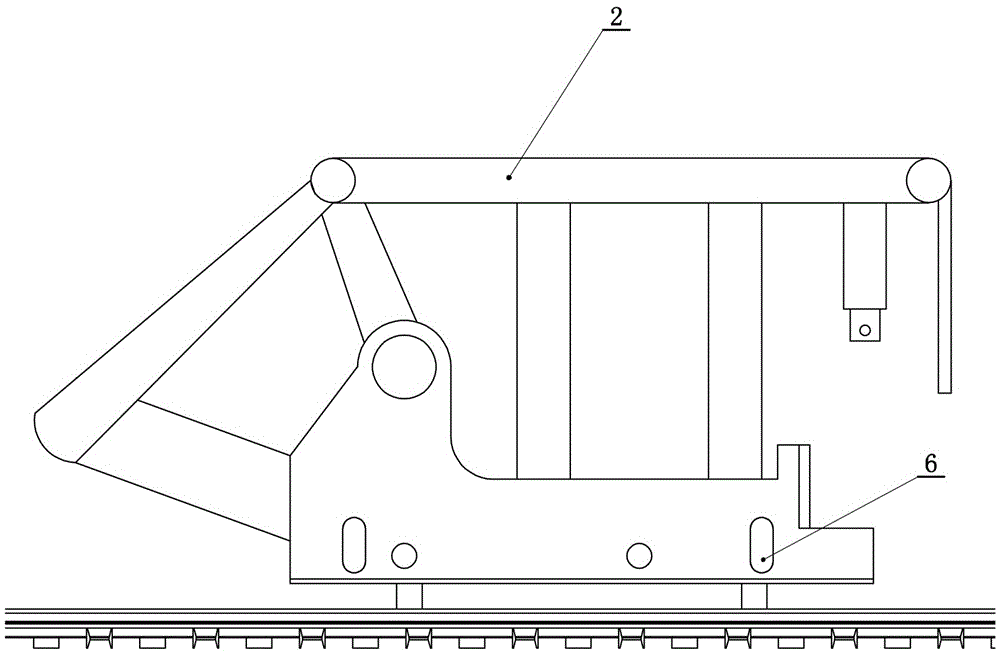

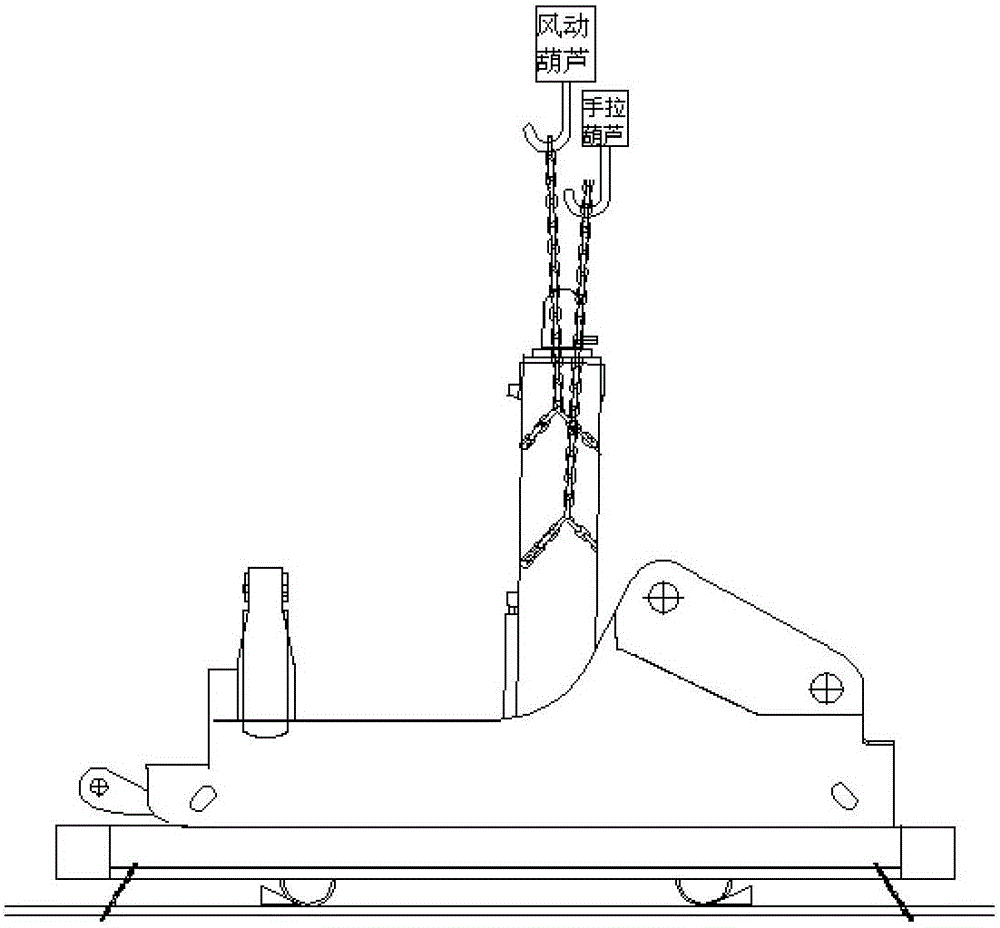

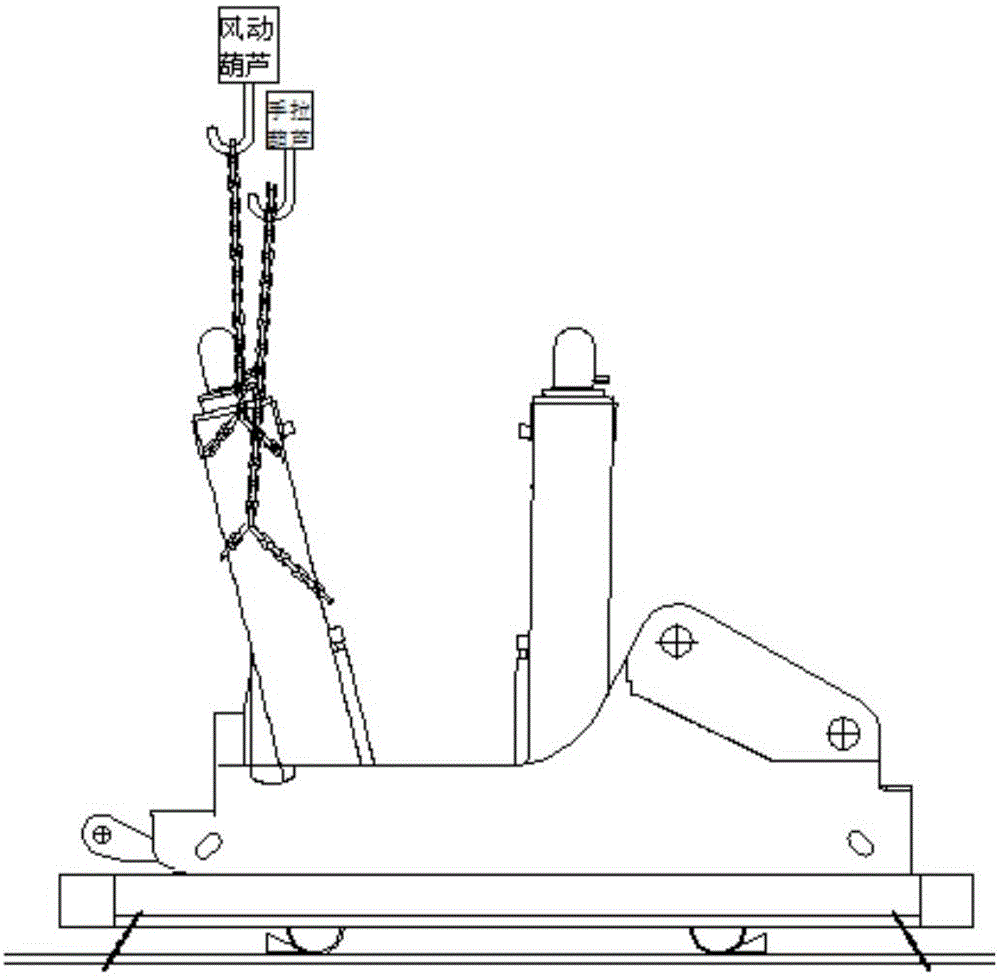

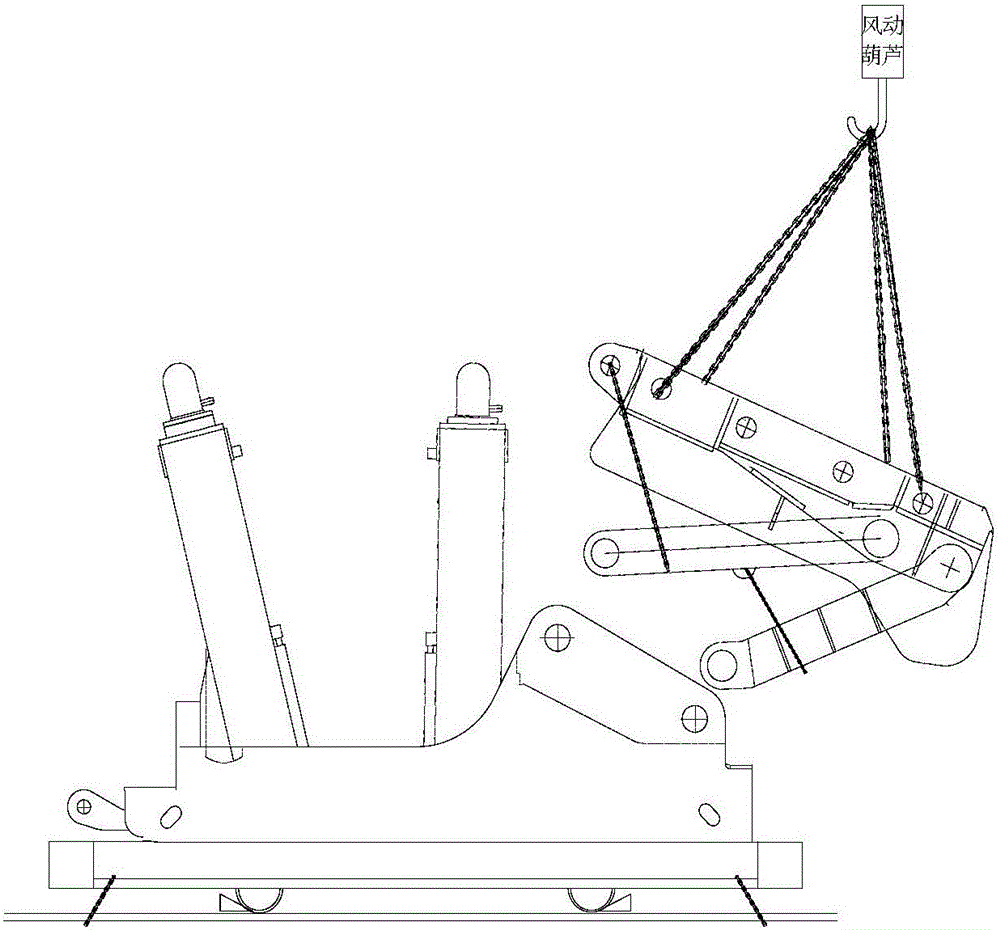

Hydraulic support loading and unloading device in roadway

InactiveCN105626120AReduce manpowerReduce material inputMine roof supportsEngineeringMechanical engineering

Owner:枣庄矿业(集团)付村煤业有限公司

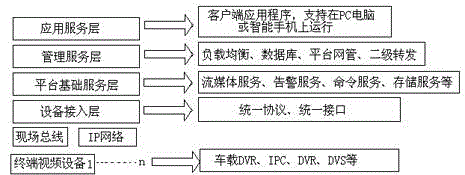

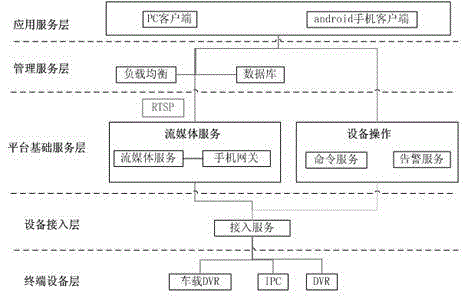

ICS streaming media platform system

ActiveCN102752666AMeet individual needsReduce material inputSelective content distributionService layerPersonalization

The invention relates to an ICS streaming media platform system which is characterized by adopting a hierarchical service-oriented system architecture and comprising an application service layer, a management service layer, a platform basic service layer and an equipment access layer. The system is compatible with multiple kinds of mainstream video terminal equipment on market; and the video terminal equipment from different factories is integrated to a uniform platform for management, thereby reducing the material investment and saving manpower resources. Meanwhile, the ICS streaming media platform meets various personalized needs of the users, and supports the functions of video browsing, history video replay and the like of the PC (personal computer) clients and mainstream smart phone clients.

Owner:CHINA YOUKE COMM TECH

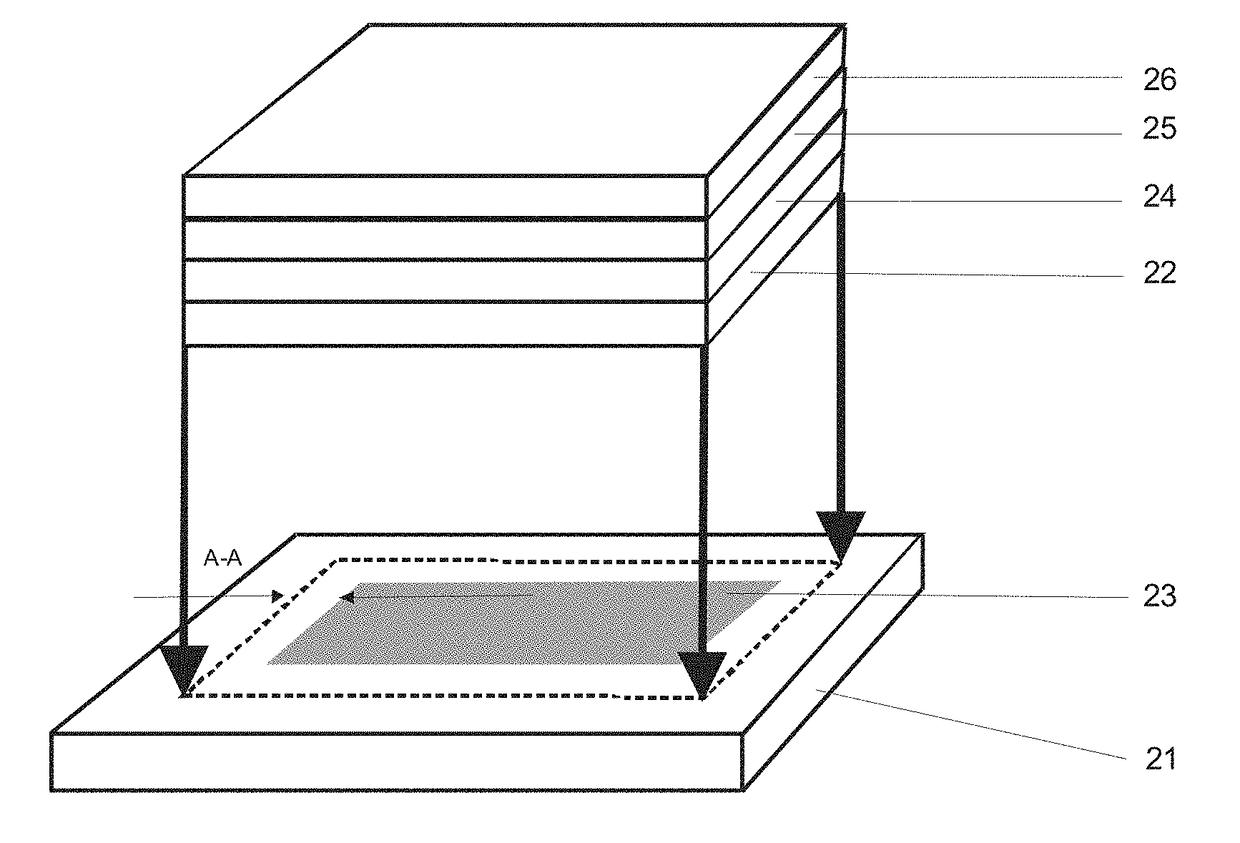

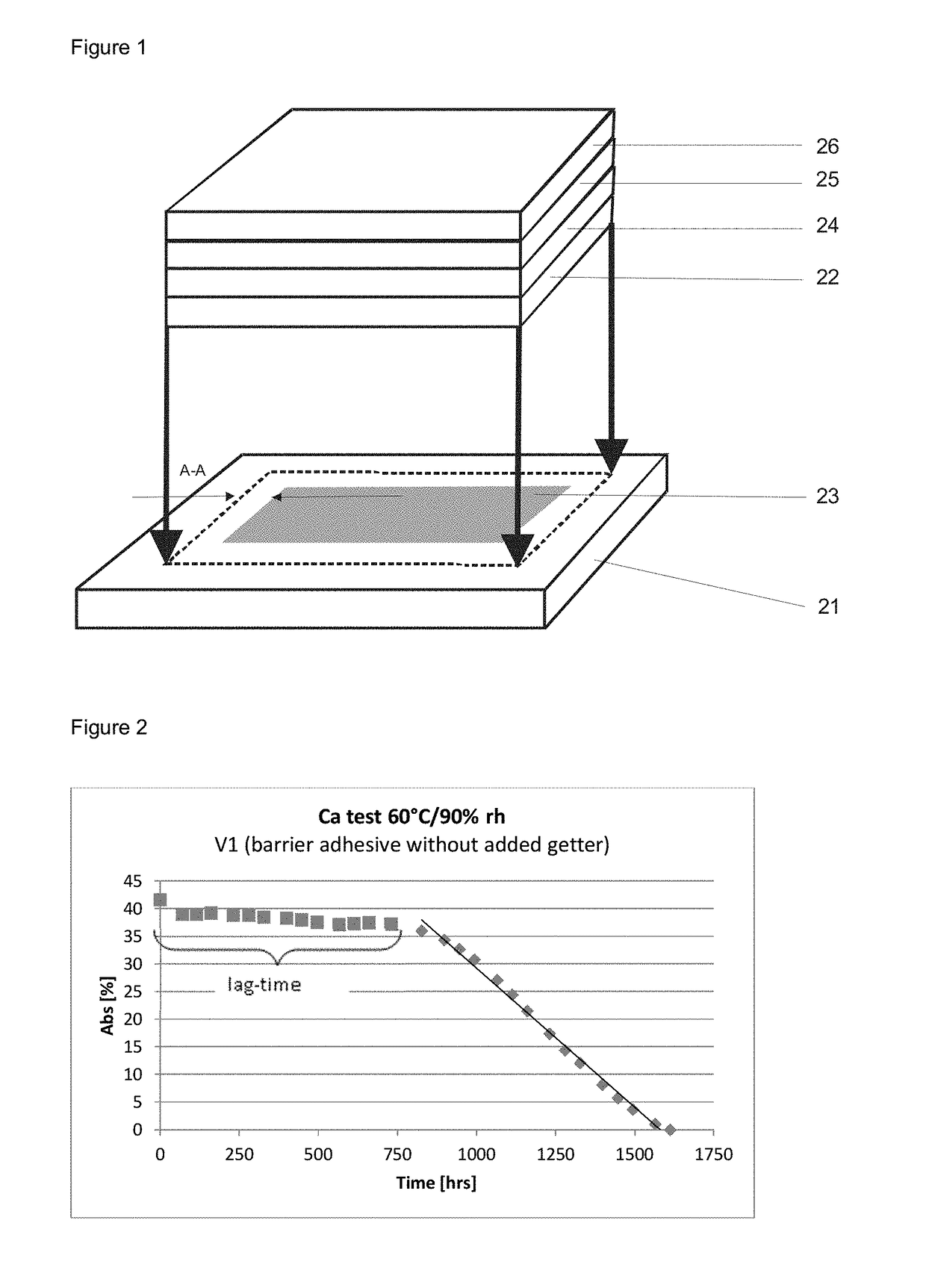

Oled-compatible adhesive masses having silane water scavengers

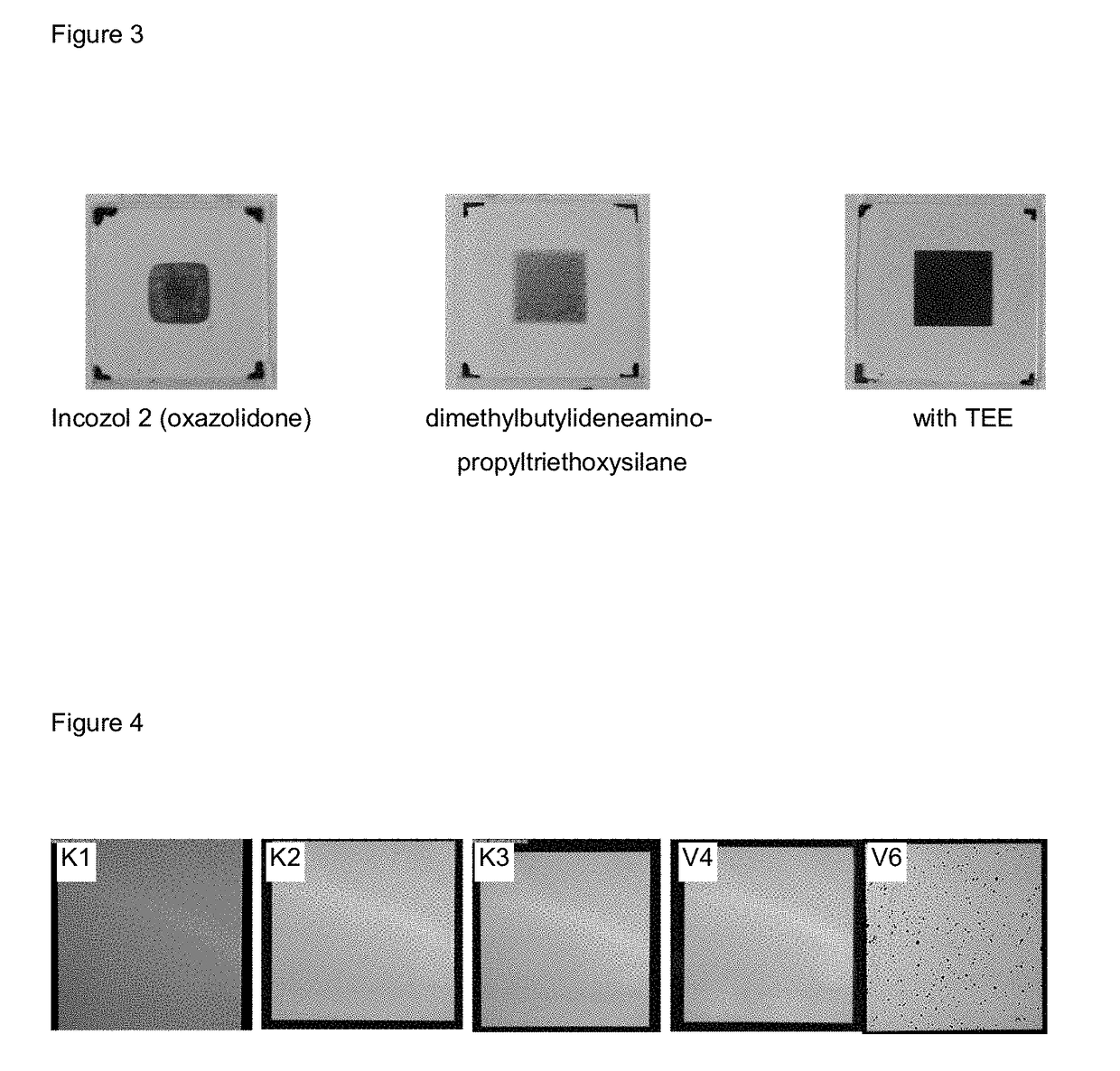

ActiveUS20170247582A1Improve adhesionEliminate the effects ofNon-macromolecular adhesive additivesSolid-state devicesElastomerScavenger

A barrier adhesive for the encapsulation of an (opto)electronic arrangement comprising an adhesive base composed of at least one reactive resin having at least one activatable group, at least one polymer, especially an elastomer, optionally at least one tackifying resin, where the adhesive base has a water vapour permeation rate after the activation of the reactive resin of less than 100 g / m2d, preferably of less than 50 g / m2d, especially less than 15 g / m2d, a transparent molecularly dispersed getter material and optionally a solvent, wherein the getter material is at least one silane having at least one alkoxy group and at least one activatable group.

Owner:TESA SE

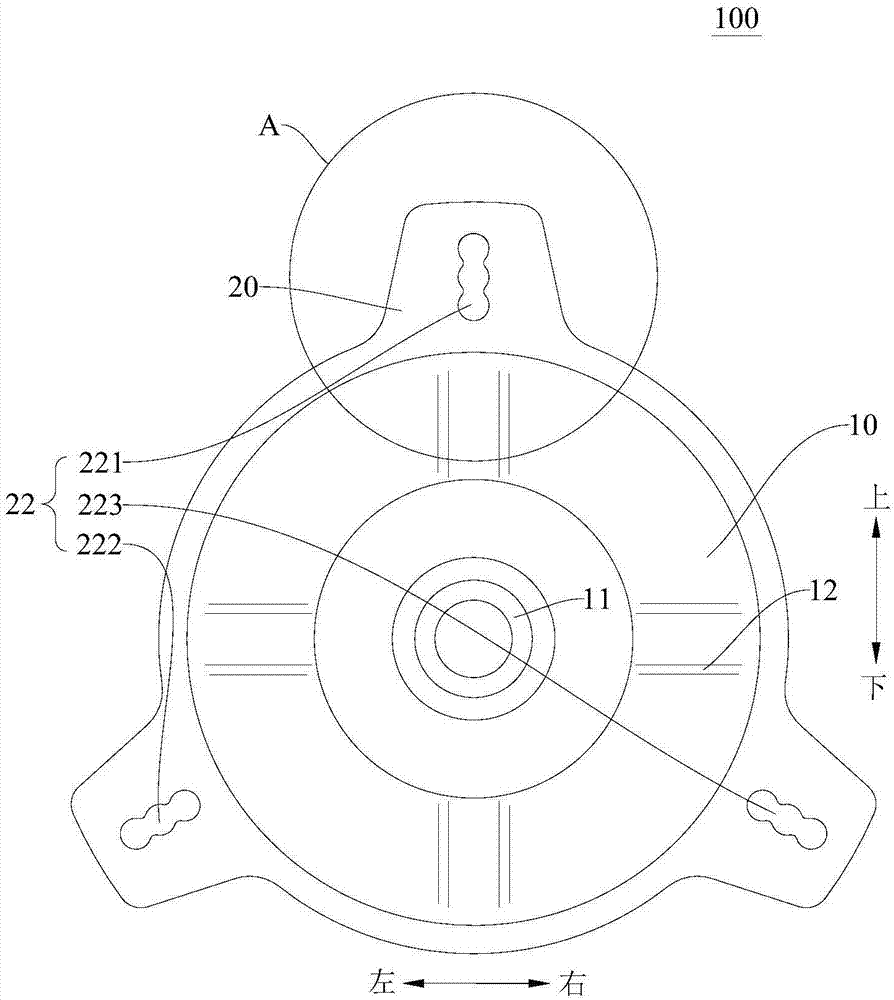

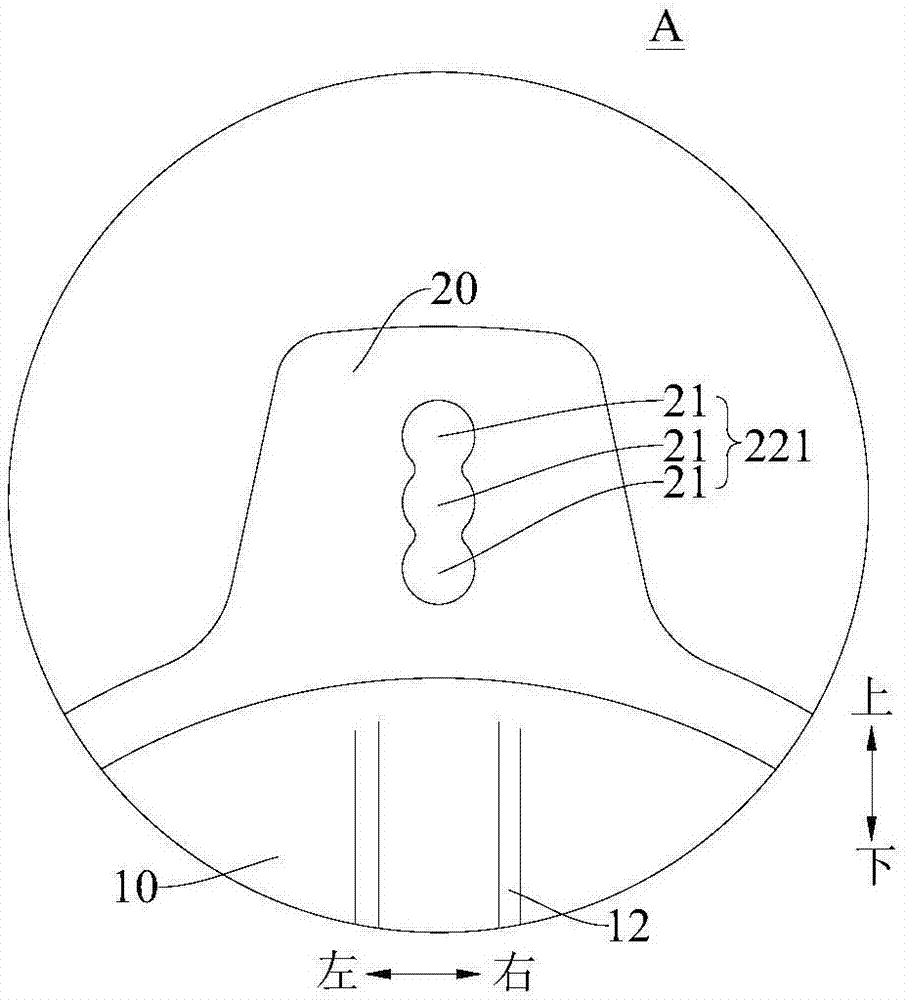

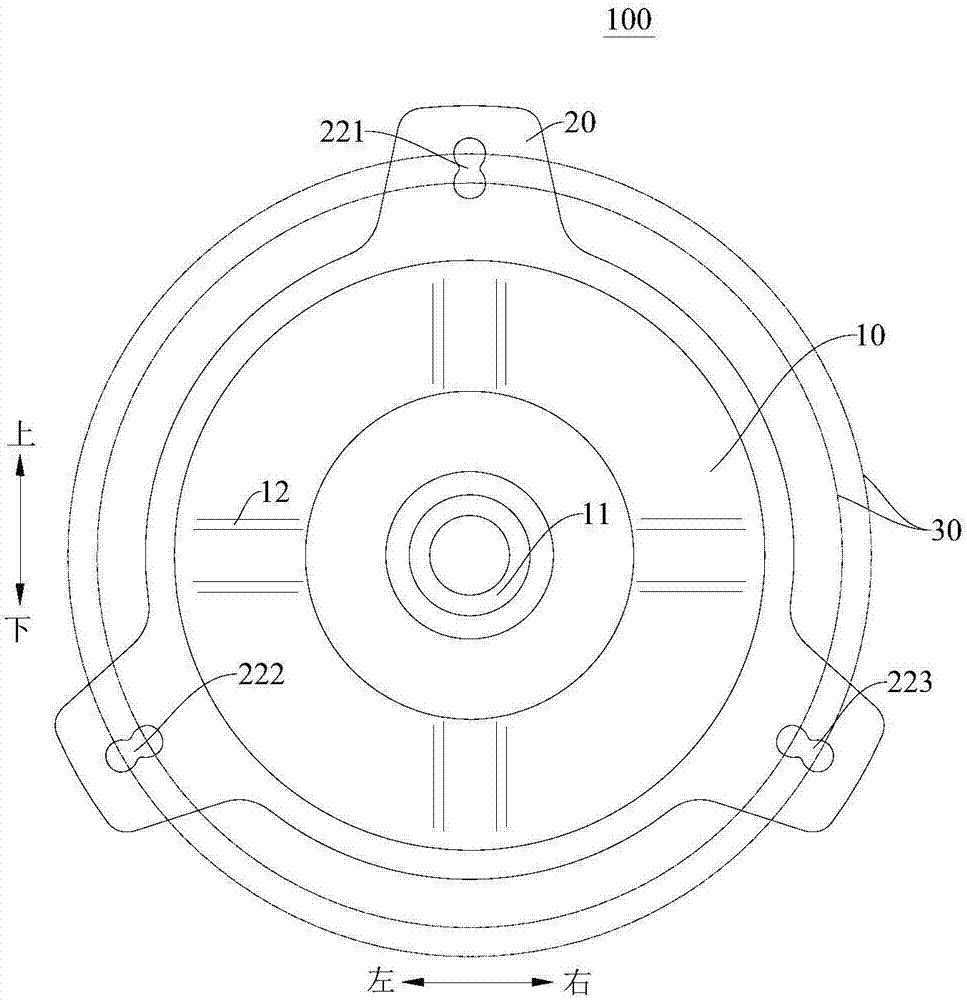

Motor end cover and motor equipped with same

InactiveCN106953445AReduce manufacturing costReduce procurement costsSupports/enclosures/casingsControl theory

The invention discloses a motor end cover and a motor with the same, wherein, the motor end cover is provided with multiple sets of installation holes, and the multiple sets of installation holes are arranged at intervals along the circumference of the motor end cover, each set The installation holes include a plurality of installation holes arranged along the radial direction of the motor end cover. According to the motor end cover of the embodiment of the present invention, the connection position between the motor end cover and the motor casing is adjusted by selecting installation holes at different distances from the central axis of the motor end cover. With the increase or decrease of the outer diameter of the motor casing, Choose the installation hole far away from or close to the body to improve the applicability of the motor end cover. Motors of various specifications and sizes use the same motor end cover. By increasing the single batch output or purchase quantity of the single machine end cover, the cost of the motor end cover is reduced. Production or procurement costs.

Owner:WELLING WUHU MOTOR MFG

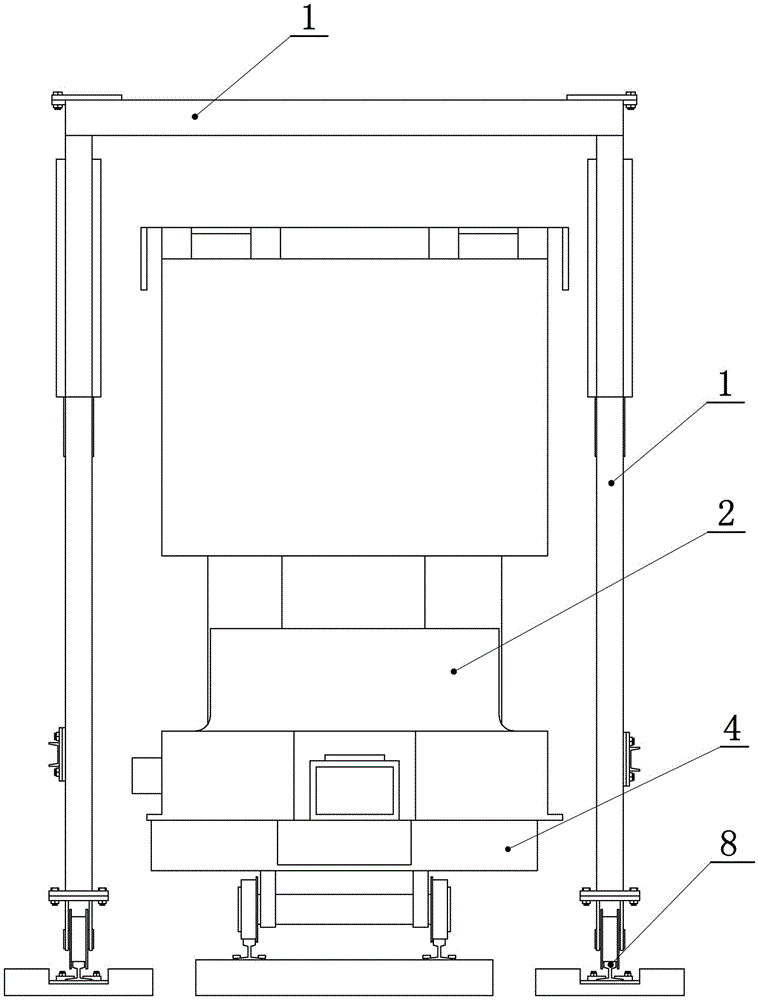

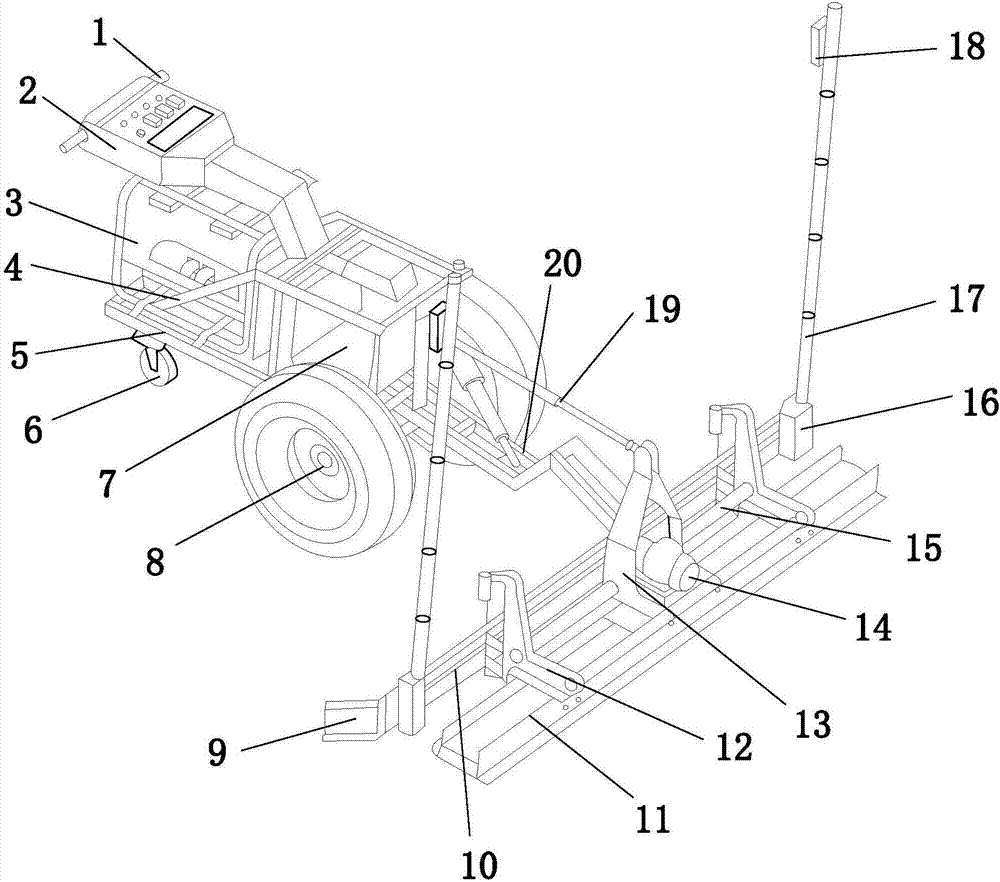

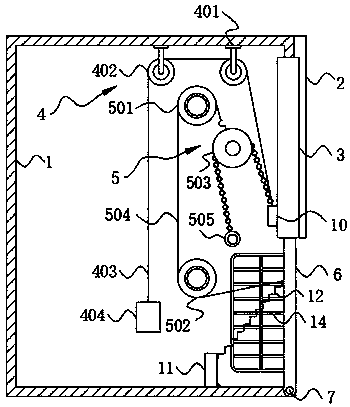

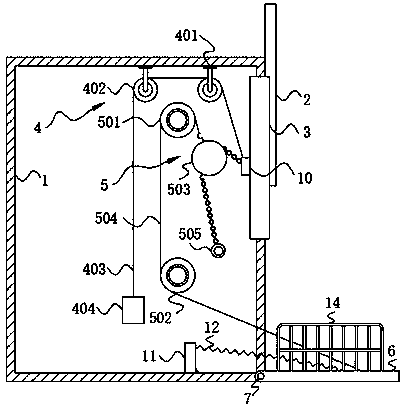

Hydraulic travelling crane and underground hydraulic bracket assembling system applying same

The invention belongs to construction and assembling equipment for hydraulic brackets of mines, and particularly relates to a hydraulic travelling crane and an underground hydraulic bracket assembling system applying the same. The hydraulic travelling crane comprises a fixed bracket, a sliding bracket and a hoisting unit, wherein the sliding bracket is arranged on the fixed bracket in a sliding way; the hoisting unit is arranged on the sliding bracket and comprises a sling, a movable pulley and a fixed pulley; the movable pulley is arranged in a reciprocating way; the fixed pulley is fixedly arranged or fixedly arranged in an adjustable manner relative to the sliding bracket; the upper end of the sling is fixedly connected with the sliding bracket; the sling bypasses the movable pulley and the fixed pulley in an S shape; and the lower end of the sling is used for connecting a to-be-hoisted component. The equipment can improve the work efficiency, save salary and material cost, increase the economic benefit, simplify the construction procedure, improve the construction efficiency, accelerate the construction progress and greatly improve the construction safety.

Owner:HUAINAN MINING IND GRP

Rapid construction vibration device based on municipal road project

InactiveCN107288013AReduced flatness errorFlatness is not affectedRoads maintainenceControl levelLaser transmitter

The invention discloses a rapid construction leveling device based on municipal road engineering. Vibration plate, leveling head, fixed protective end, vibration motor, limit rod, fixed base, support column, laser receiver, hydraulic rod, movable connection plate, laser emission port, laser emitter, first fixed disc, disc The fixed rod, the second fixed disc, the connecting ring plate, the buckle, the supporting foot, the bolt, and the footing can pave concrete in a large area as a whole and ensure the consistency of the ground elevation. The elevation is not controlled by the formwork, and there will be no cumulative error , The construction joints reduced in large-scale block construction greatly reduce the maintenance cost of the ground in the later stage; multiple operations are integrated together and completed by the machine at one time, improving work efficiency, saving labor, reducing labor and material input, and reducing construction procedures. Speed up construction progress.

Owner:泉州市西决三维科技有限公司

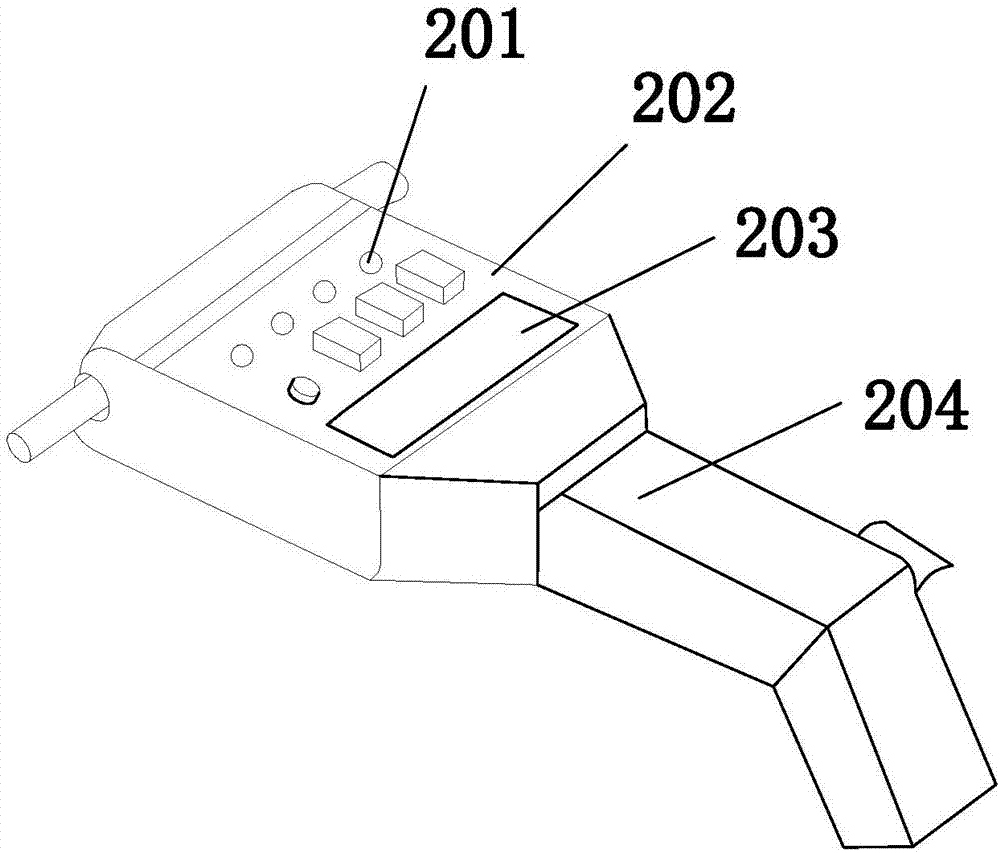

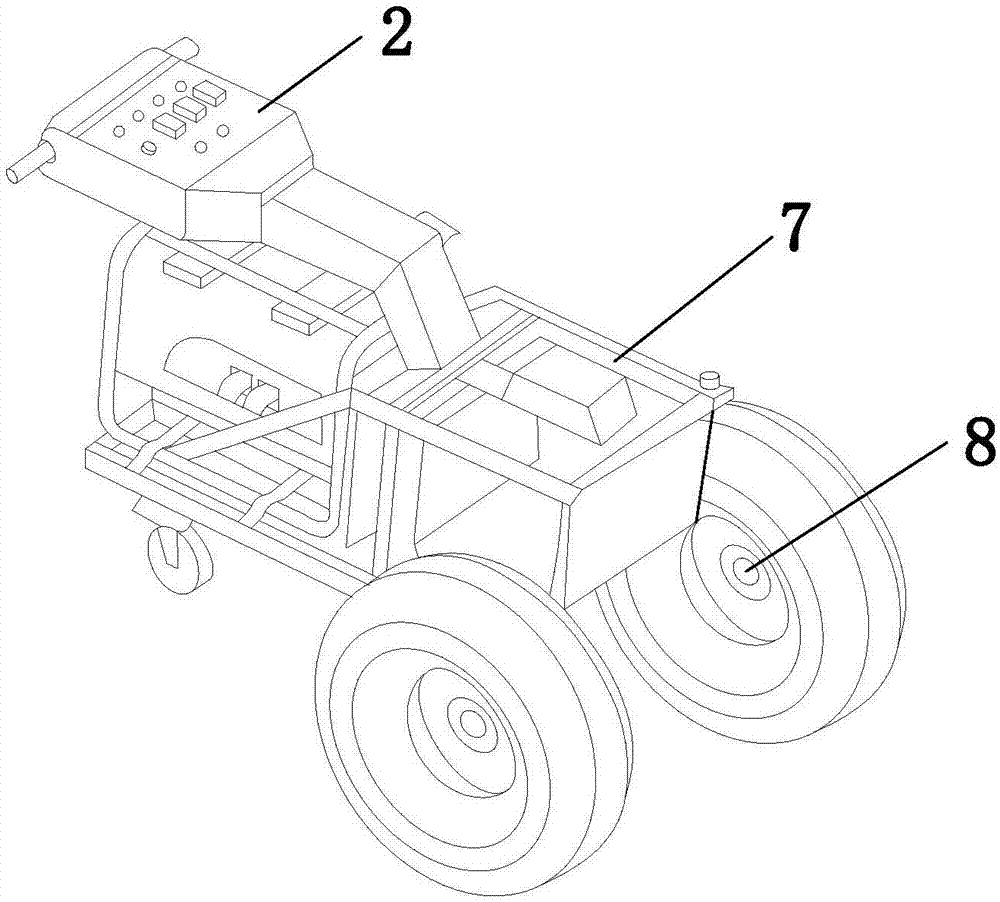

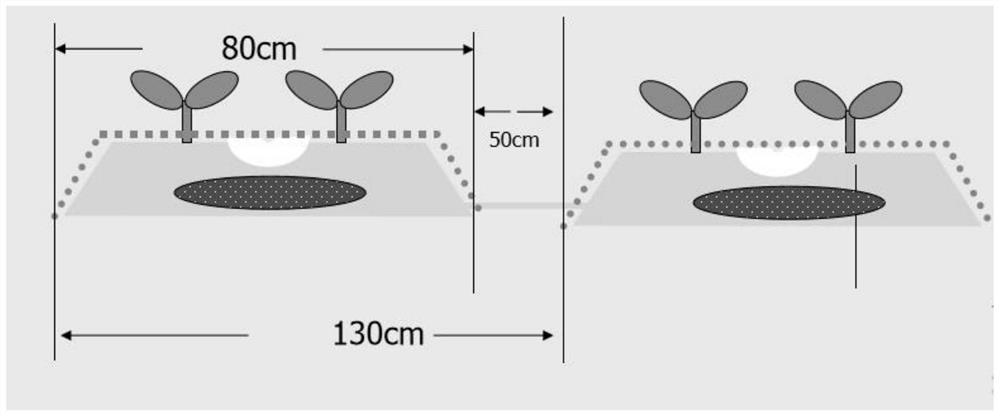

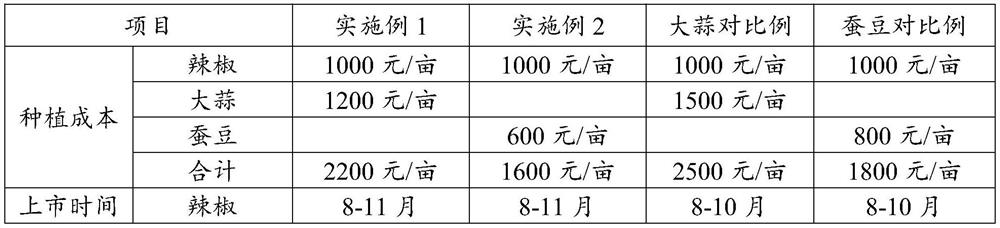

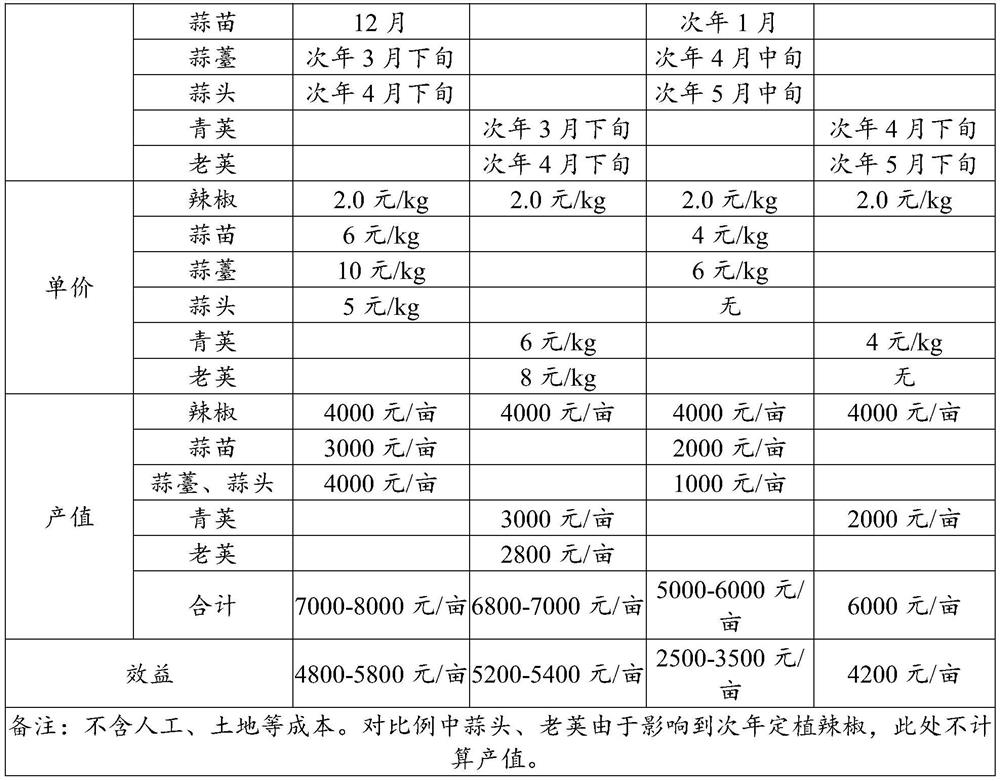

Efficient method for planting garlic/broad beans after harvesting pepper

InactiveCN111657075AGuaranteed time to marketReduce laborFabaceae cultivationBulb cultivationAllium sativumBroad beans

The invention discloses an efficient method for planting garlic / broad beans after harvesting pepper. A process comprises the following steps: in late April, conducting furrowing and bedding accordingto a specification of 120-130 cm in pepper planting land, applying an organic fertilizer and a compound fertilizer onto bed surfaces, mulching the bed surfaces with films, in early May, planting double rows of individual pepper seedlings in each bed surface mulched with the film, in June, conducting field management on the pepper seedlings, in August, harvesting green mature pepper and red maturepepper in time, after harvesting is conducted for two times, dressing 15-25 kg of the compound fertilizer per mu, from the end of September to the middle of October, sowing the garlic or the broad beans on the pepper bed surfaces, conducting drilling while conducting sowing, conducting earthing after sowing is conducted, from late November to the middle of December, dressing the compound fertilizer according to growth situations of the garlic or the broad beans, and harvesting garlic sprouts, young garlic shoots and garlic bulbs in sequence from late December to the middle of next April or harvesting green mature bean pods and old mature bean pods in sequence, conducting land preparation in time after harvesting is conducted in next late April, and repeating the process.

Owner:GUIZHOU SERICULTURE RES INST GUIZHOU PEPPER RES INST

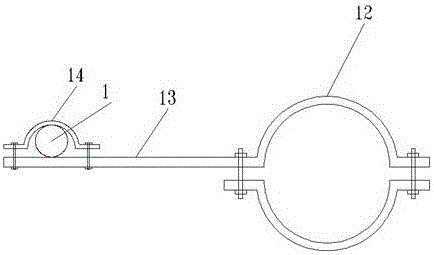

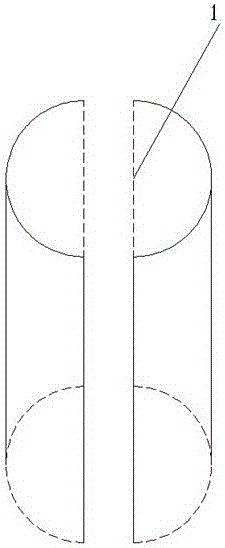

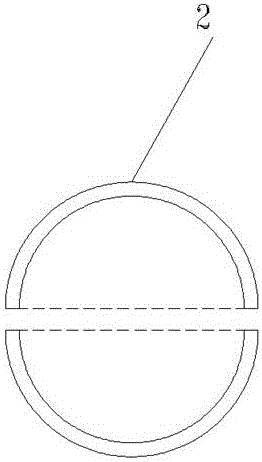

Fixing structure for detachable cable protection pipe

PendingCN106505504AImprove efficiencyIncrease costCable installations in underground tubesPetroleum engineering

The invention discloses a fixing structure for a detachable cable protection pipe, including a holt hoop iron I corresponding to a pole and towel pair. One end of the holt hoop iron is provided with an extension section. A cable protection pipe body is arranged at one side of the extension section. With the adoption of cooperation between the arc clamp loop and the extension section, the cable protection pipe body is tightly clamped. The fixing structure subversively changes the overall pipe-shaped structure of the original cable protection pipe, and the cable protection pipe is designed to have the detachable structure by a mode that one divides into two, so that in the installation or the later replacement process, the efficiency is greatly improved, and the cost is reduced. The fixing structure is easy to manufacture and strong in practicality.

Owner:GUIYANG POWER SUPPLY BUREAU OF GUIZHOU POWER GRID CO LTD

Method for rapidly cultivating rosa chinensis minima potted flowers by pinching for one time

ActiveCN107027461APromotes and accelerates rootingEnsure Physiological ConsistencyPlant cultivationCultivating equipmentsBudRapid prototyping

The invention discloses a method for rapidly cultivating rosa chinensis minima potted flowers by pinching for one time. The method comprises the steps of direct cutting in flowerpots and directional seedling growing for one time and pinching and trimming for one time in the seedling stage. Compared with a traditional multi-step potted flower cultivation method that seedlings are first cultivated and then potted, the production steps of seedling potting and transplanting, and combining and molding are reduced, damage and investment which are caused by seedling potting and transplanting are prevented, survival rates of the seedlings are increased, rooting and sprouting are ordered and consistent, and production cost is reduced. The number of flower branches and extension directions of foliage leaves can be directionally cultivated by the technologies of directional cutting and pinching and trimming for one time, the sprouting time of plant buds and consistency of flower branch growth are ensured, the potted flowers are promoted to the molded rapidly and fully, ornamental characteristics are largely improved, insect diseases are prevented, the ratio of high-quality potted flowers is significantly improved, the production cycle is as short as 60-85 days.

Owner:云南云秀花卉有限公司

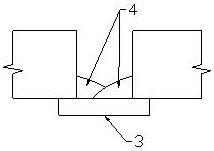

Single-wire submerged arc welding process for steel plate with thickness of 30-50mm

ActiveCN113305404AResolve parallelFusion wellArc welding apparatusWelding/soldering/cutting articlesEngineeringWeld seam

The invention relates to a single-wire submerged-arc welding process for a steel plate with a thickness of 30-50mm, which comprises the following steps of: pre-splicing a structure after derusting, and adopting an I-shaped groove with a welding seam gap of 25 mm; welding a steel liner on the back of the groove; using submerged-arc welding for backing welding, wherein H10Mn2 is matched with SJ101 welding flux, the diameter of a welding wire is 4.0 mm, the welding current is 450-500 (A), the voltage is 30-33 (V), and the welding speed is 37-44 (cm / min); adjusting a welding machine head to weld a right base and a left base respectively, to make the left base and the right base overlapped in the middle; using H10Mn2 matched with SJ101 welding flux for filling and capping welding, and using submerged-arc welding wires with the diameter of 4.0 for filling and capping, wherein the welding current ranges from 450-500 (A), the voltage ranges from 31-35 (V), and the welding speed ranges from 37-45 (cm / min); adjusting a welding machine head to perform left filling welding and right filling welding respectively, and alternately welding and overlapping filling welding seams left and right; carrying out cover surface rotary welding; and (6) removing welding equipment, and waiting for natural cooling of the weld seam. According to the welding process, the arc axis is parallel to the side wall during narrow gap welding, the weld seam and base metal are well fused, and the construction efficiency is improved.

Owner:二十二冶集团装备制造有限公司 +1

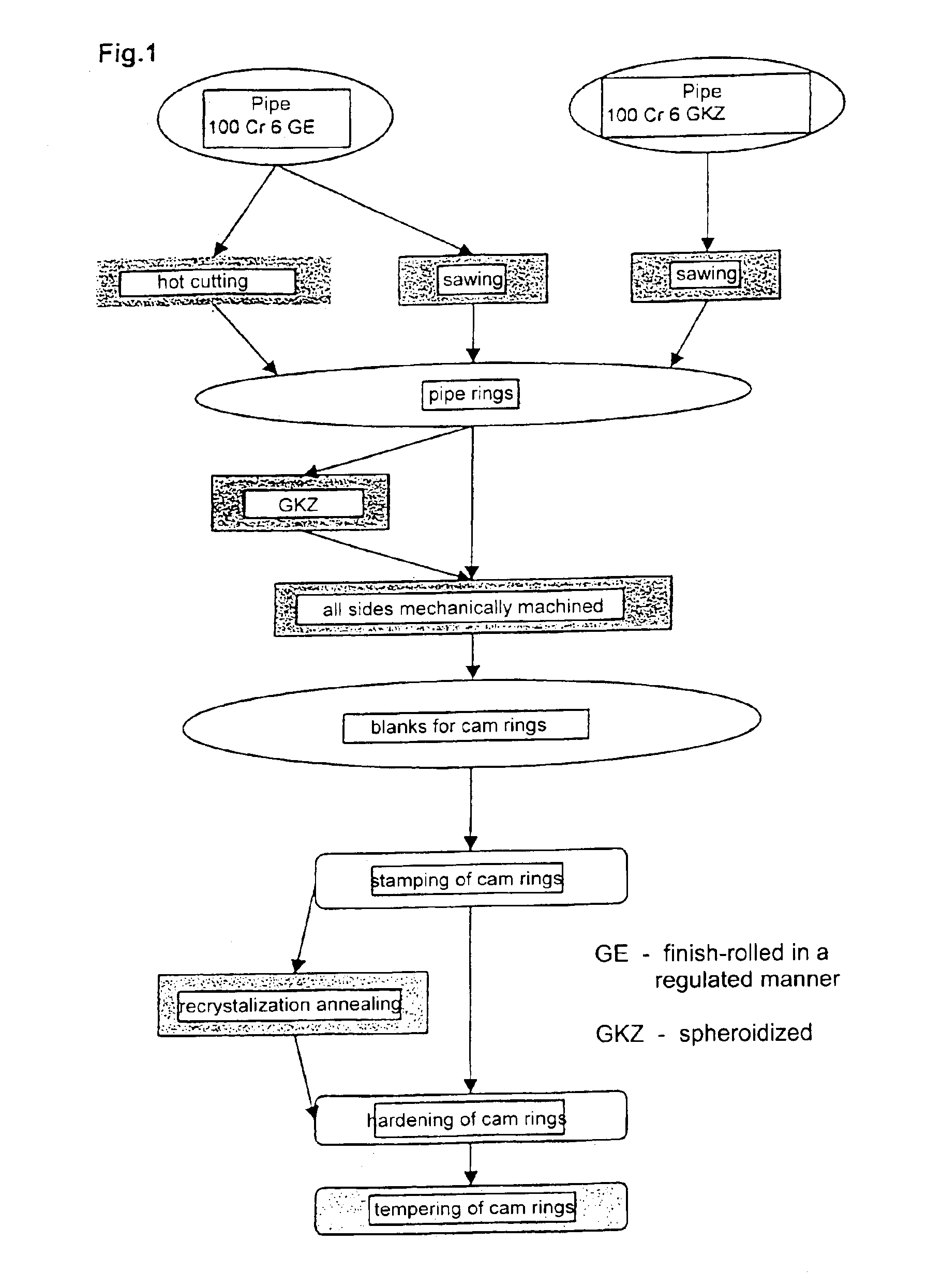

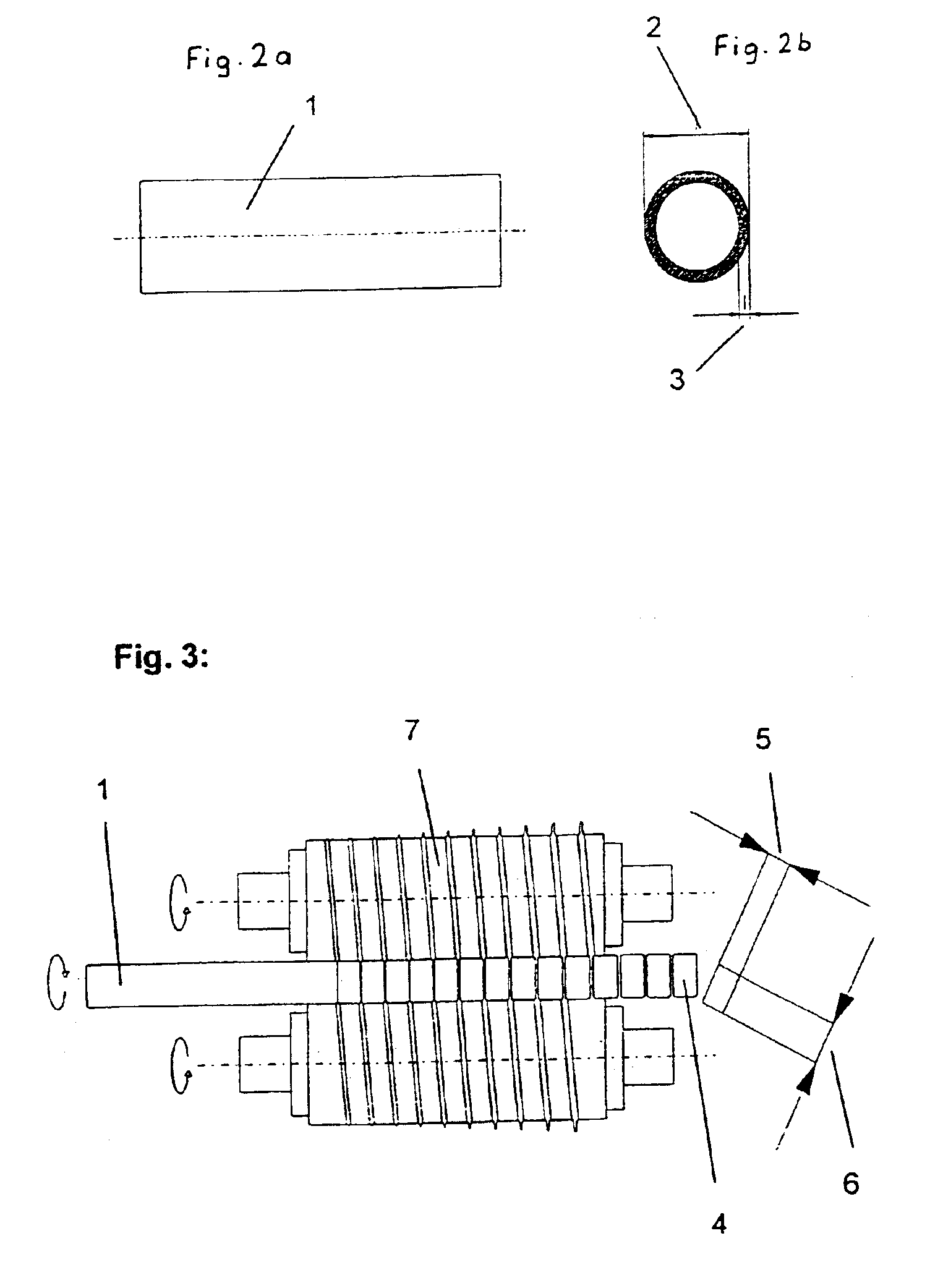

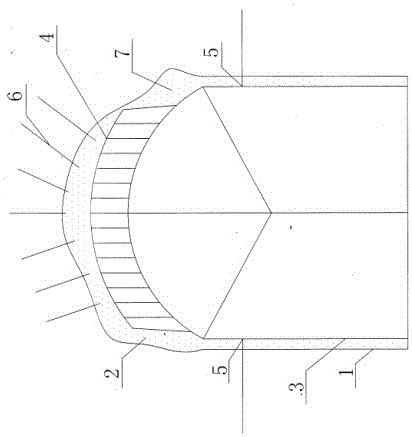

Method for producing metallic, non-rotationally symmetrical rings with a constant wall thickness over their circumference

The invention is directed to a method and a device for producing metal, non-rotationally symmetric rings with a constant wall thickness along their circumference, particularly cam rings, starting from a hot-rolled pipe from which individual portions are severed, mechanically machined and subsequently hardened and tempered. Ring blanks of equal width are severed from the pipe and are mechanically machined on all sides, and the non-rotationally symmetric shape is produced by cold forming, the pipe or the severed ring blank having a structure suitable for cold forming.

Owner:MANNESMANN ROHRENWERKE

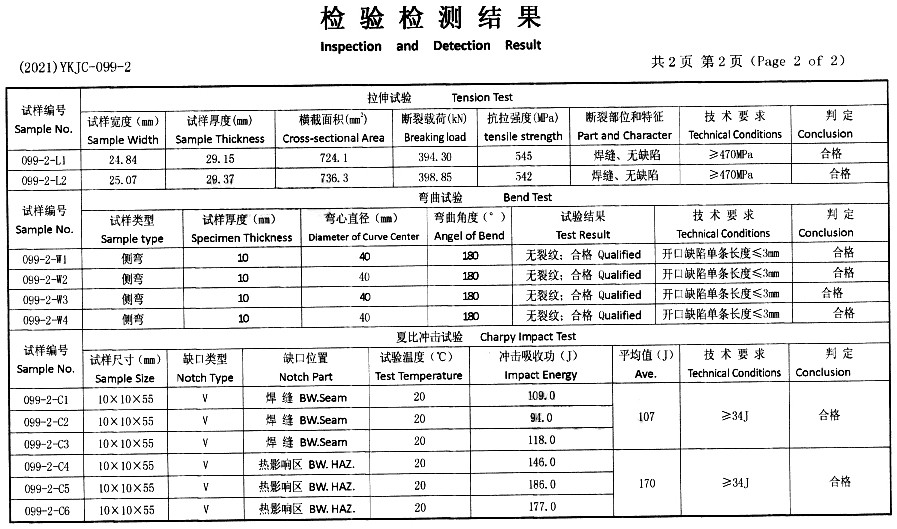

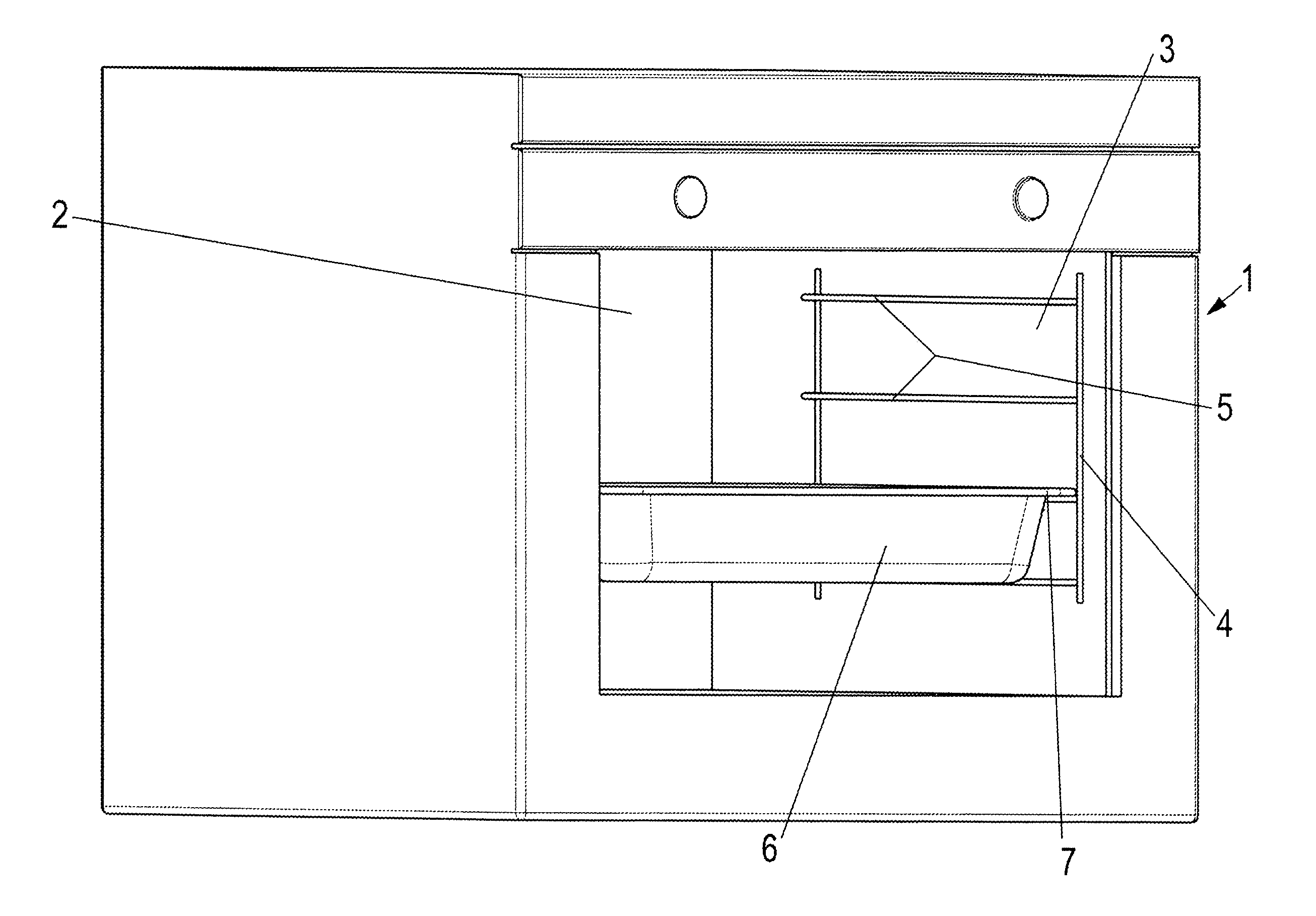

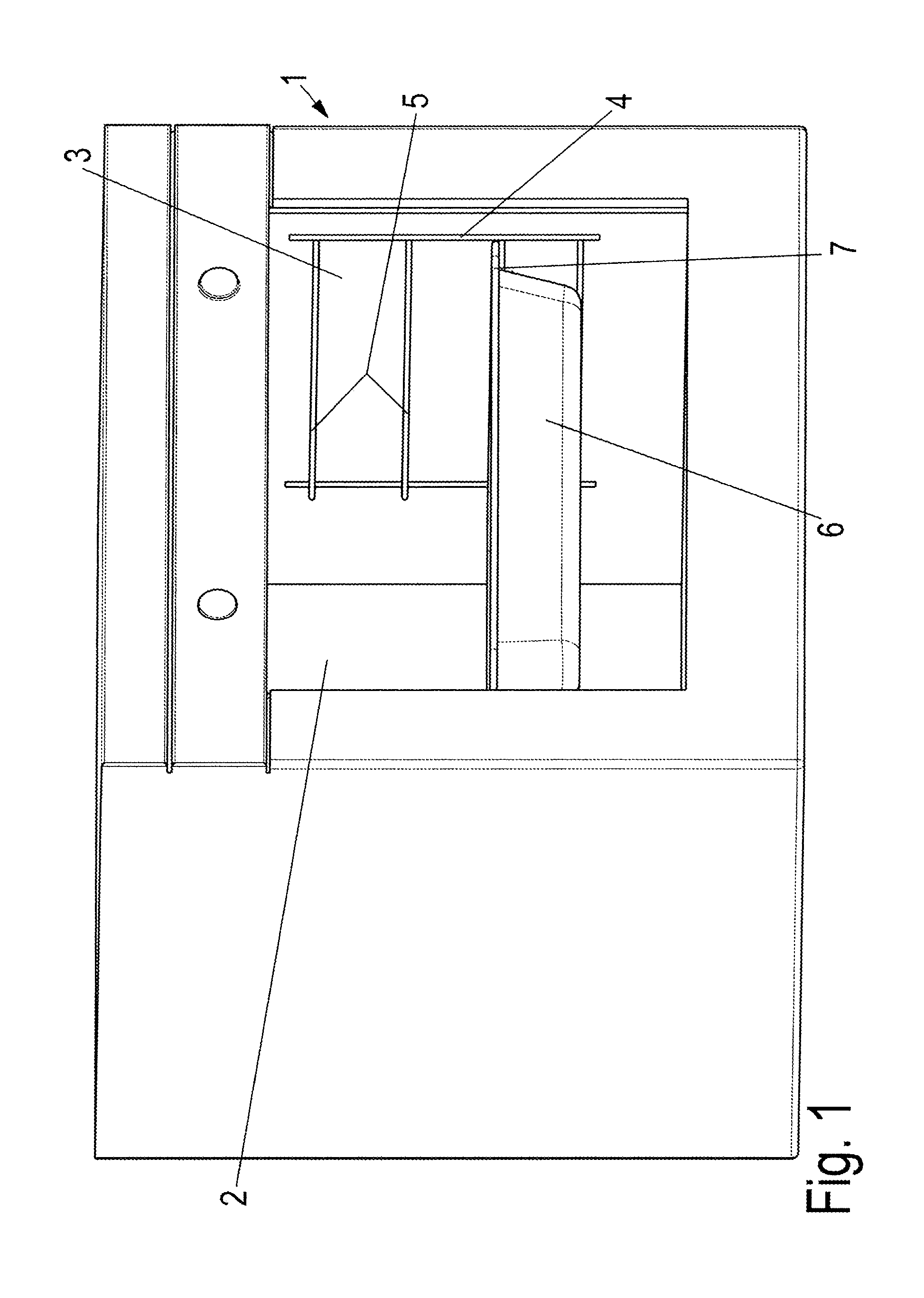

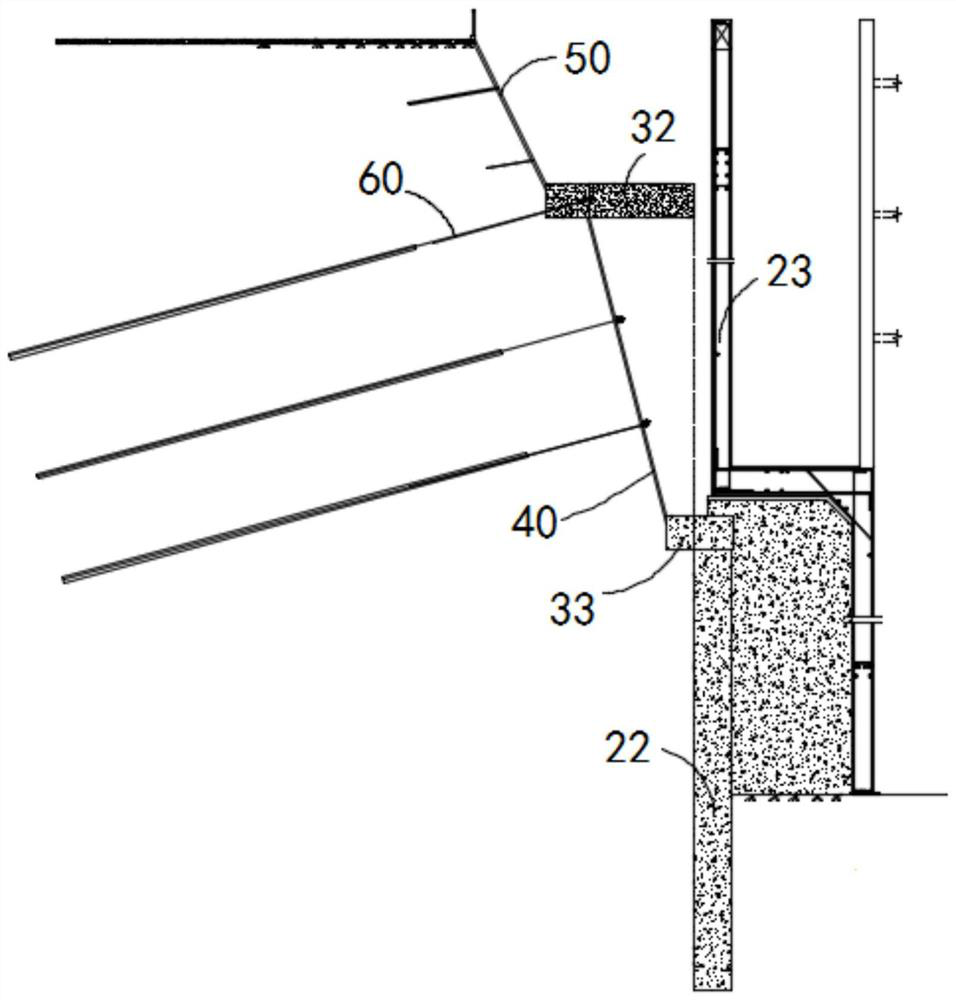

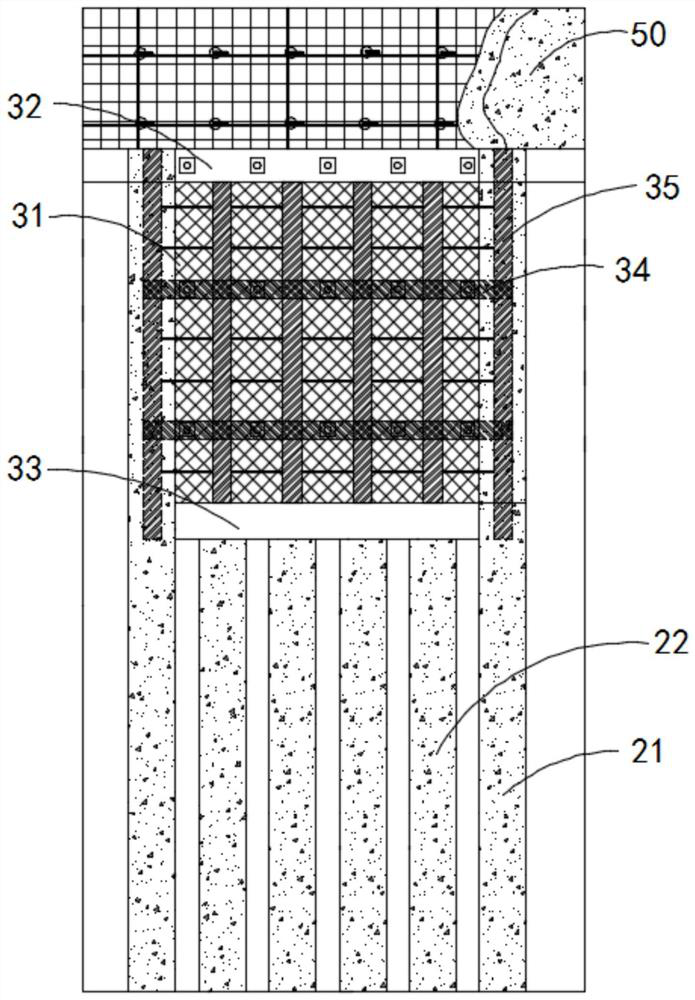

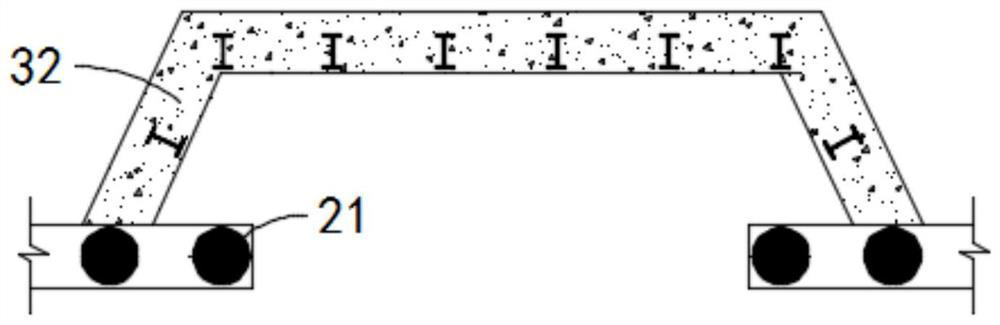

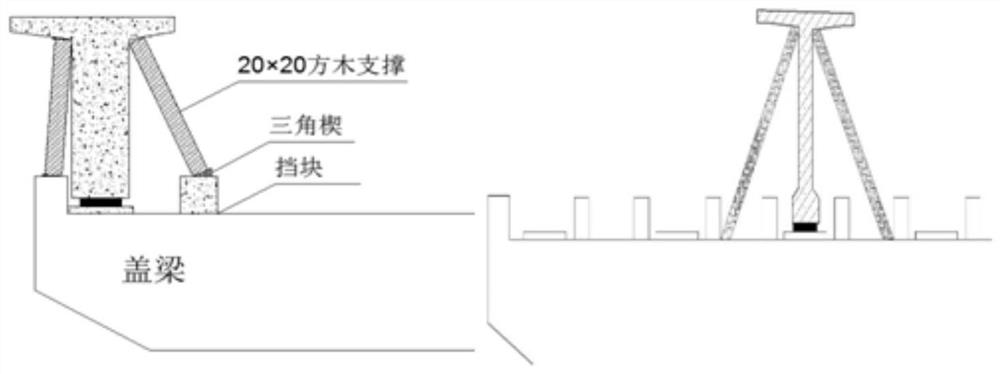

Side-top arch collapse cavity supporting system and method for super-large-section tunnel in plateau region

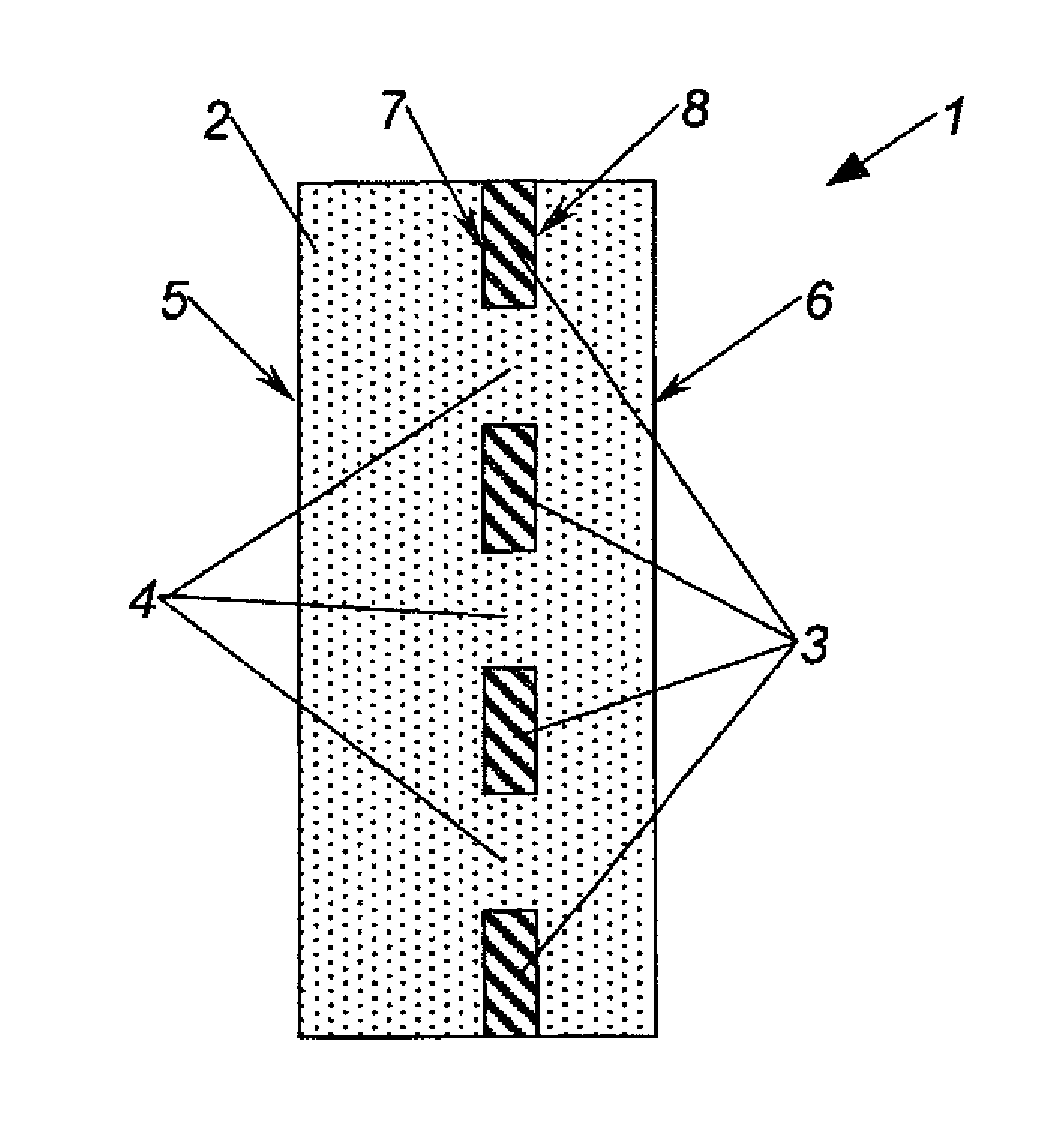

InactiveCN106640130AEasy to do on siteReduce material inputUnderground chambersTunnel liningClerestoryArch supports

The invention discloses a side-top arch collapse cavity supporting system and method for a super-large-section tunnel in a plateau region. The aim of primary supporting of a side-top arch collapse cavity in a portal of the super-large-section tunnel in the plateau region is achieved. According to the system, the arch top collapse cavity (2) is formed in the arch top of a large-section excavated portal outline (1); a main arch supporting system (3) is arranged under the arch top of the large-section excavated portal outline; an auxiliary arch supporting frame (4) is fixedly welded to a main arch frame of the main arch supporting system (3); an anchor cable supporting system (5) is arranged at the outer edge of the arch top collapse cavity (2); an anchor rod supporting system (6) is arranged on the top of the arch top collapse cavity (2); and the rock surface of the large-section excavated portal outline (1) and the rock surface of the arch top collapse cavity (2) are provided with primary supporting concrete jet layers (7). By means of the system and method, the aim of primary supporting of the super-large-section tunnel in a water-rich rock stratum in the plateau region is achieved, and the effects that field construction is easy, supporting is stable and the project period is shortened are achieved.

Owner:中铁二十一局集团第六工程有限公司

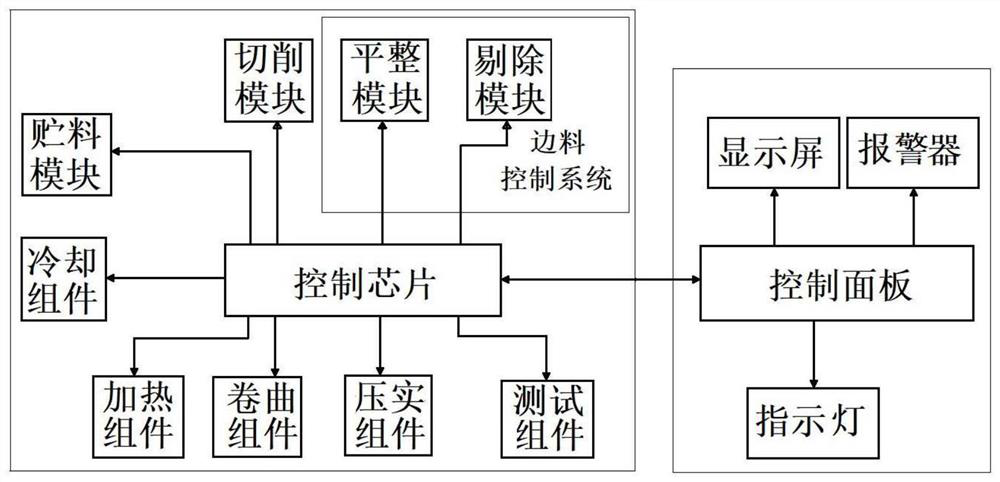

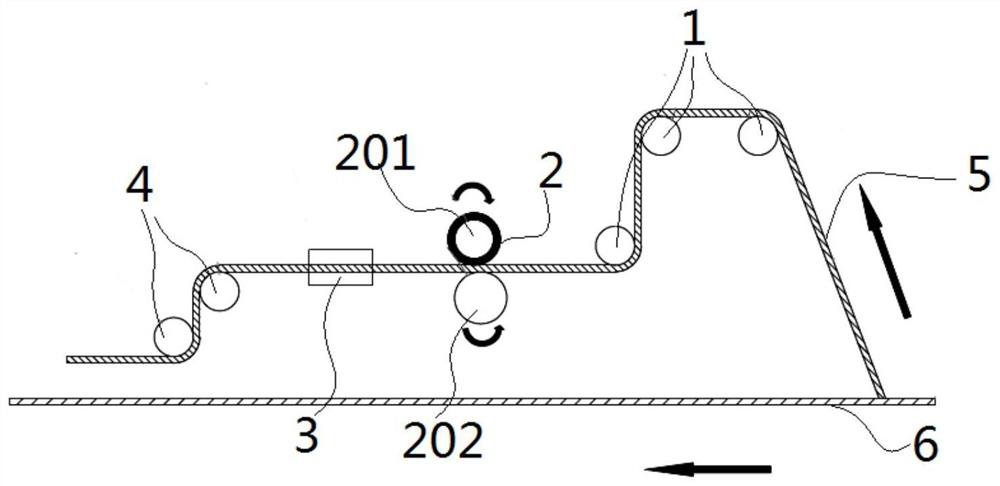

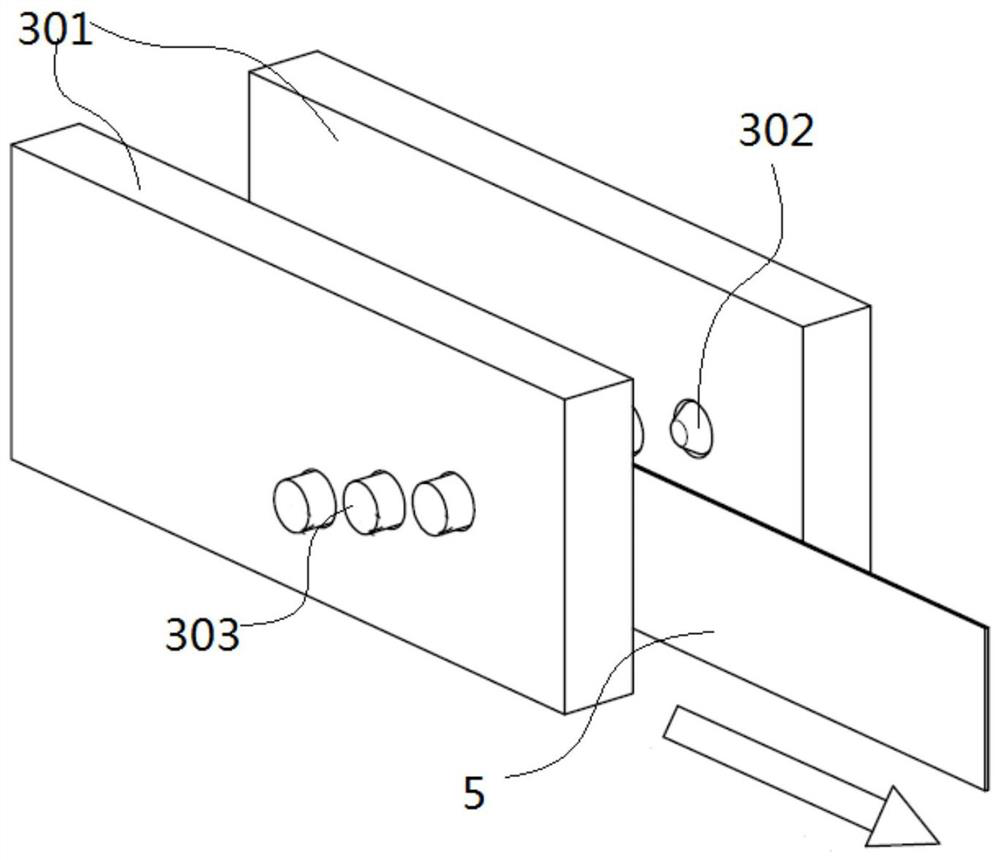

Rim charge control system and hose welding process thereof

PendingCN112092425AReduce material inputReduce Material ComplexityTubular articlesDrive motorEngineering

The invention discloses a rim charge control system and a hose welding process thereof. The rim charge control system is characterized in that a guide wheel used for guiding rim charges is arranged ona machine base; a leveling module is arranged at the tail end of the guide wheel; a removing module, a width recognition and removing module and a leading-out wheel are arranged at the tail end of the leveling module; the leveling module comprises a driving motor, an upper rubber roller and a lower rubber roller; the driving motor is in driving connection with the upper rubber roller; and a partbetween the upper rubber roller and the lower rubber roller is used for extruding and leveling rim charges. The application is suitable for bonding production operation of composite hoses of various sheet types, and other additional materials are not required; and edge cutting rim charges generated in the pipe manufacturing process are synchronously welded to the inner side of the edge seam of a hose, without being affected by the sheet types. The material investment and the material complexity in the composite hose manufacturing process are reduced, and the production cost is reduced; the rimcharges are used for filling, welding and fixing edge seam areas of the formed sheets at the angle of 60 to 120 degrees, so that the welding strength of the edge seams is improved; and meanwhile, theappearance of a welded finished product has no overlapping trace.

Owner:ESSEL PACKAGING GUANGZHOU LTD

Turnover turning plate tool for construction elevator

PendingCN107804770AImprove channel setupSimple structureElevatorsBuilding liftsBlock and tackleControl theory

The invention provides a turnover turning plate tool for a construction elevator. The turnover turning plate tool comprises a suspension cage, an elevator door, a sliding rail, an elevator door pulleyblock, a turning plate pulley block and a turning plate, wherein the sliding rail is fixedly mounted at the upper part of the front side of the suspension cage; fixing pins are fixedly mounted at thelower part of the front side of the suspension cage; the fixing pins are in hinged connection with the rear end of the turning plate; the sliding rail is in sliding fit with sliding blocks; the sliding blocks are in bolted connection with one end of a support plate; the other end of the support plate is in bolted connection with the elevator door; supporting blocks are fixedly mounted on the rearside of the elevator door; and the supporting blocks are fixedly connected with the elevator door pulley block and the turning plate pulley block. The turnover turning plate tool for the constructionelevator has the benefits as follows: the structure is simple, the installation is convenient, the conventional method of building passages to allow the construction elevator to go to all floors is improved, the problem that the construction elevator is at an excessively large distance from the structure edge when going to the passages of all floors is effectively solved, the efficiency is increased, the human and material input are reduced, the application range is wide, and the turning over is realized.

Owner:CHINA CONSTR EIGHTH ENG DIV

Multi-Point Link for an Undercarriage of a Vehicle

PendingUS20220212511A1Improve adaptabilitySpeed up the processConnecting rodsPivoted suspension armsMechanical engineeringRolling chassis

Owner:ZF FRIEDRICHSHAFEN AG

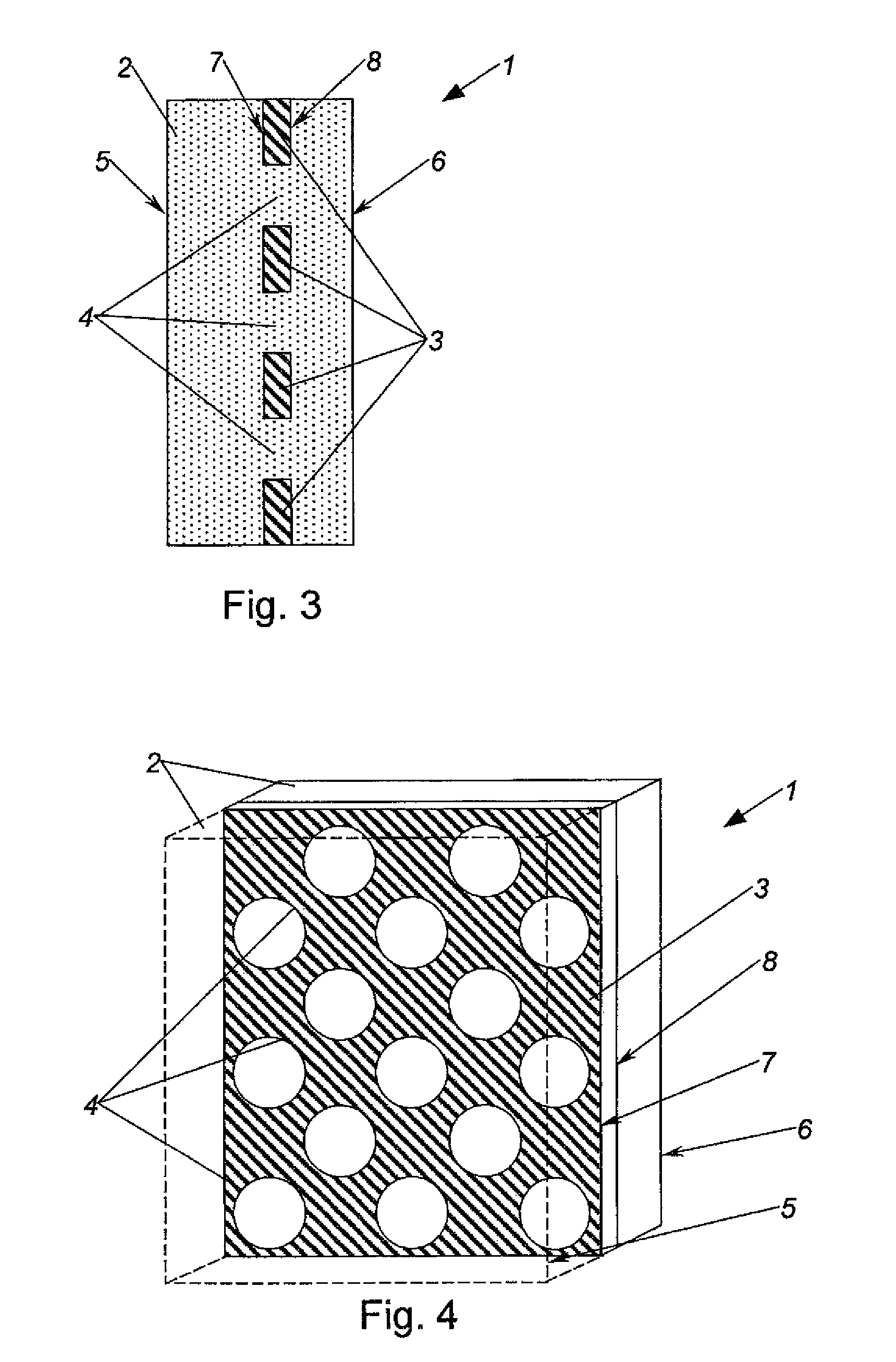

Sound protection component

InactiveUS9538267B2Reduce thicknessEasy to adjustTransducer detailsNoise reduction constructionEngineeringSupport design

Owner:KIRCHDORFER FERTIGTEILHOLDING GMBH

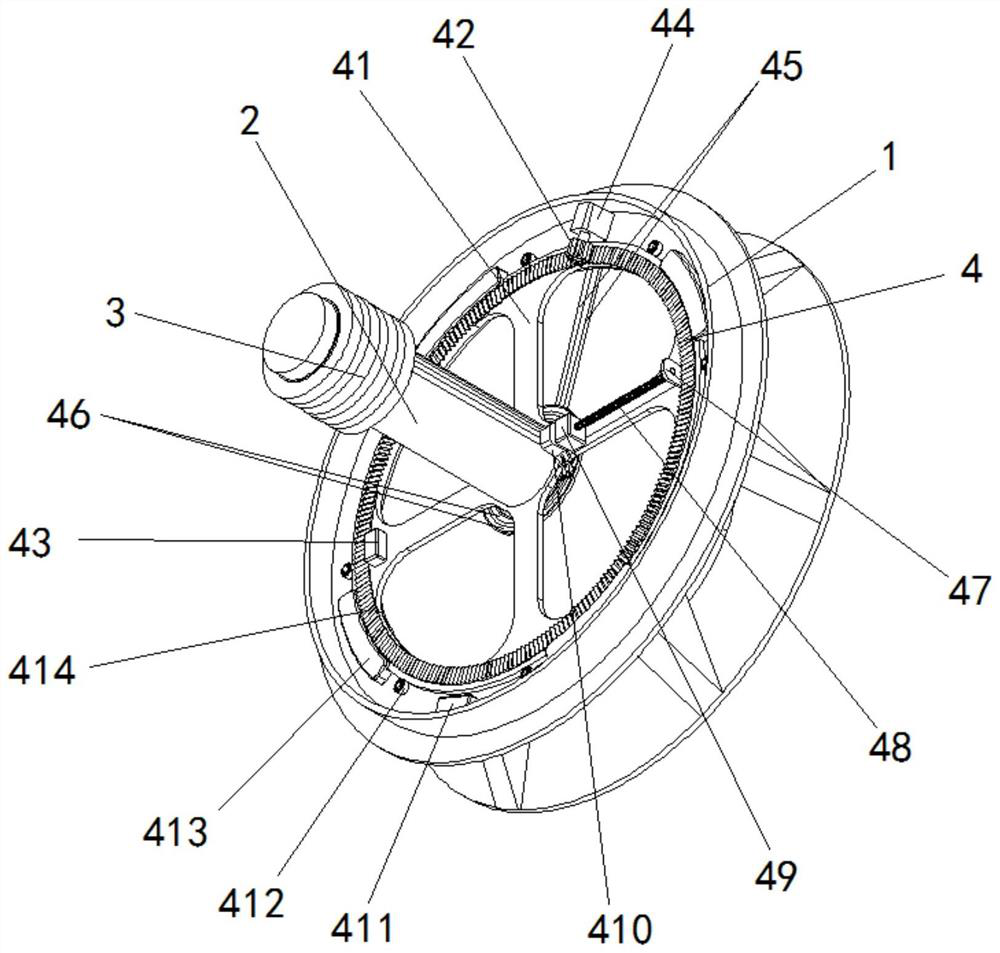

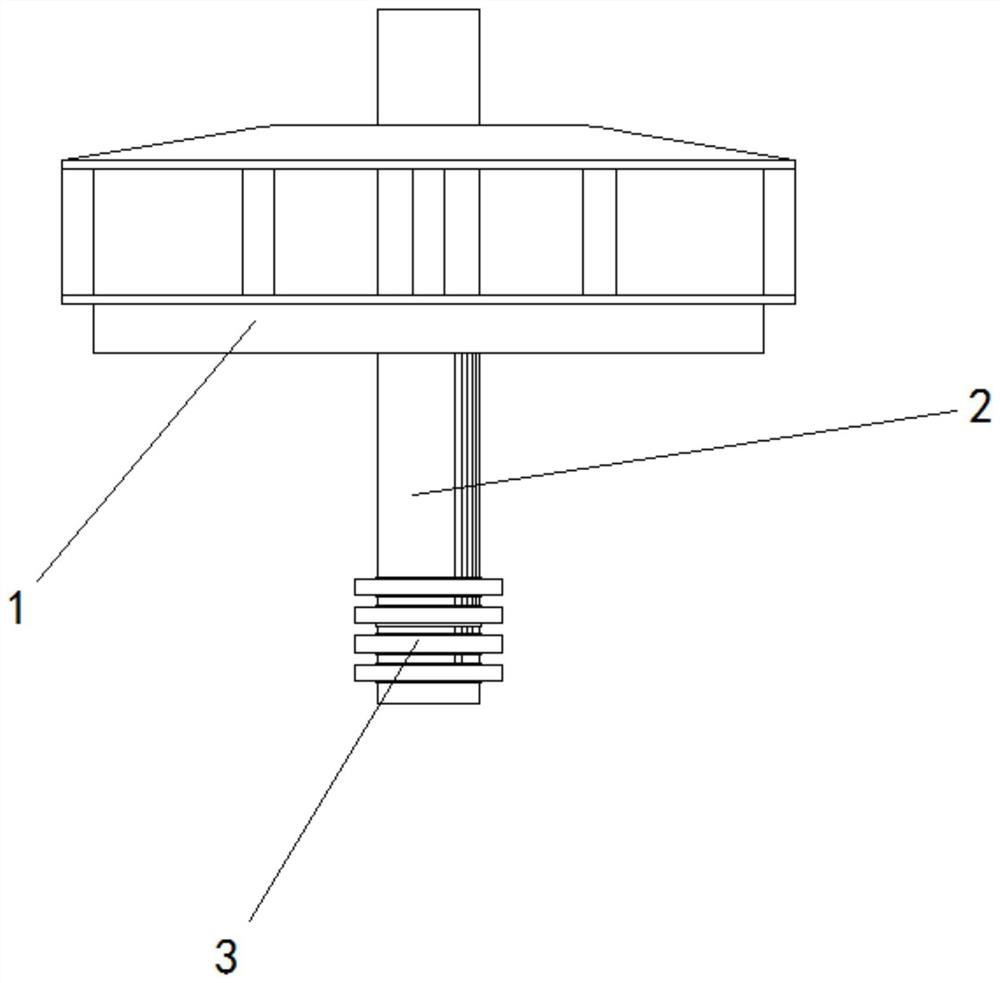

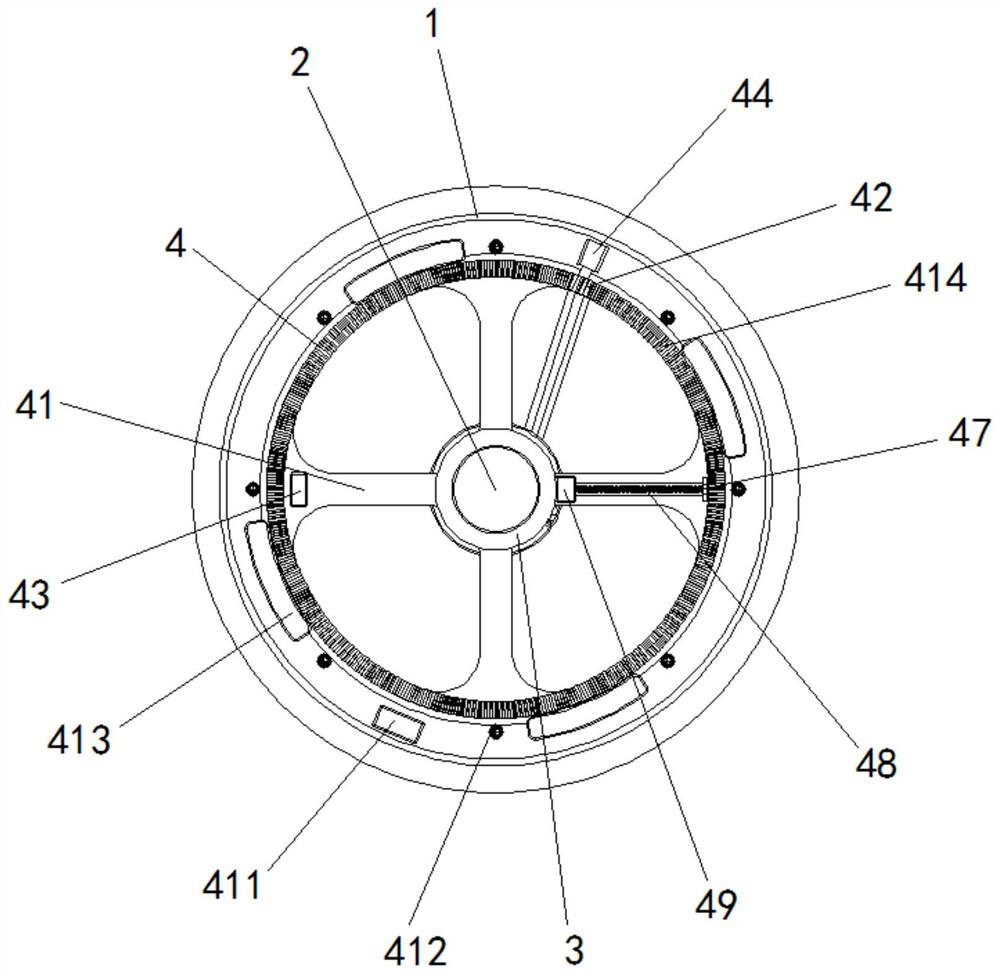

Non-stop dynamic balance real-time continuous correction device

PendingCN114720053AAvoid damageAvoid running sickStatic/dynamic balance measurementGear wheelDynamic balance

The invention relates to a non-stop dynamic balance real-time continuous correction device which comprises a shell and a rotating shaft, a shaft hole is formed in the center of the shell, when the device is installed on the end face of an equipment rotor, the rotating shaft of equipment can directly penetrate through the shaft hole, a power supply sliding ring is fixedly installed on the outer side of the rotating shaft, and a correction assembly is arranged on the inner side of the shell. The correcting assembly comprises a rotating disc with one end rotationally connected with the inner side of the shell, a gear ring is fixedly connected to the outer side of the rotating disc, an angle adjusting self-locking motor is fixedly connected to the inner side of the shell, and a gear with one end meshed with the gear ring is fixedly connected to an output shaft of the angle adjusting self-locking motor. According to the non-stop dynamic balance real-time continuous correction device, when dynamic balance deviation occurs, equipment does not need to be shut down, real-time correction can be achieved when the equipment is running, the situation that the equipment runs with faults due to the fact that the equipment cannot be shut down is avoided, and therefore damage to equipment bearings and accessories due to vibration caused by unbalance is effectively avoided; therefore, the service life of the equipment is prolonged, and the stability of the equipment during operation is maintained.

Owner:山东森杰电机有限公司

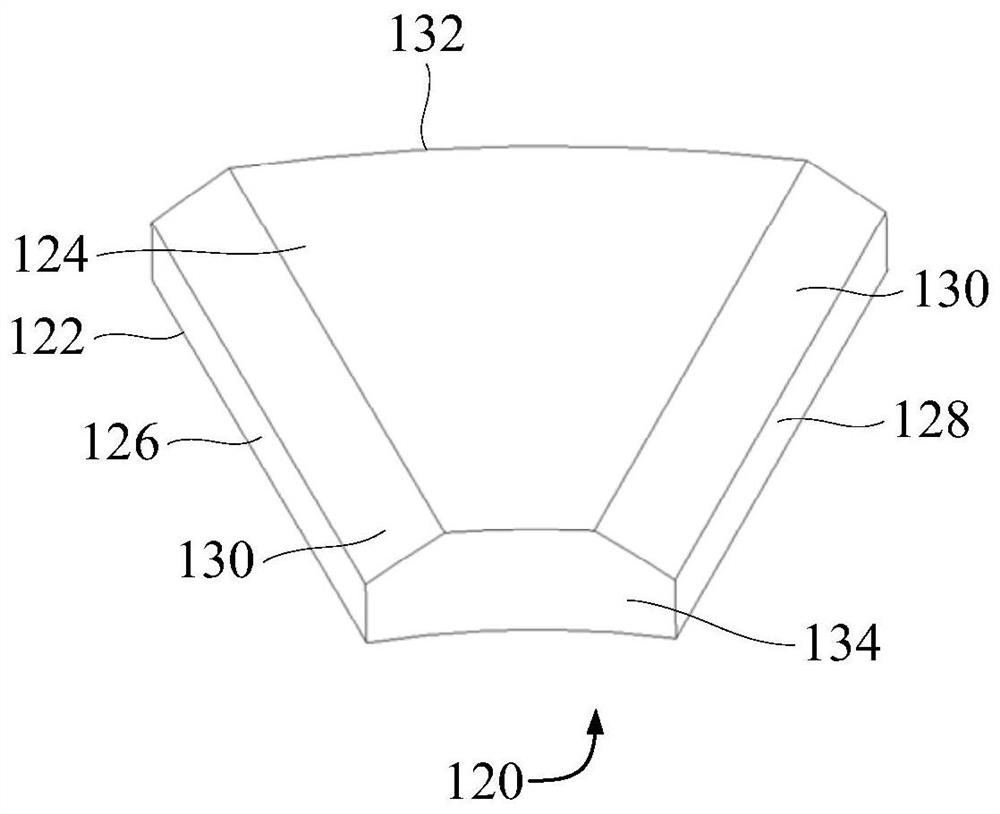

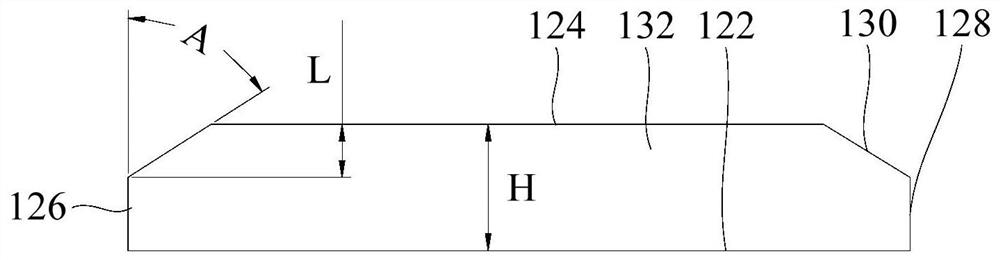

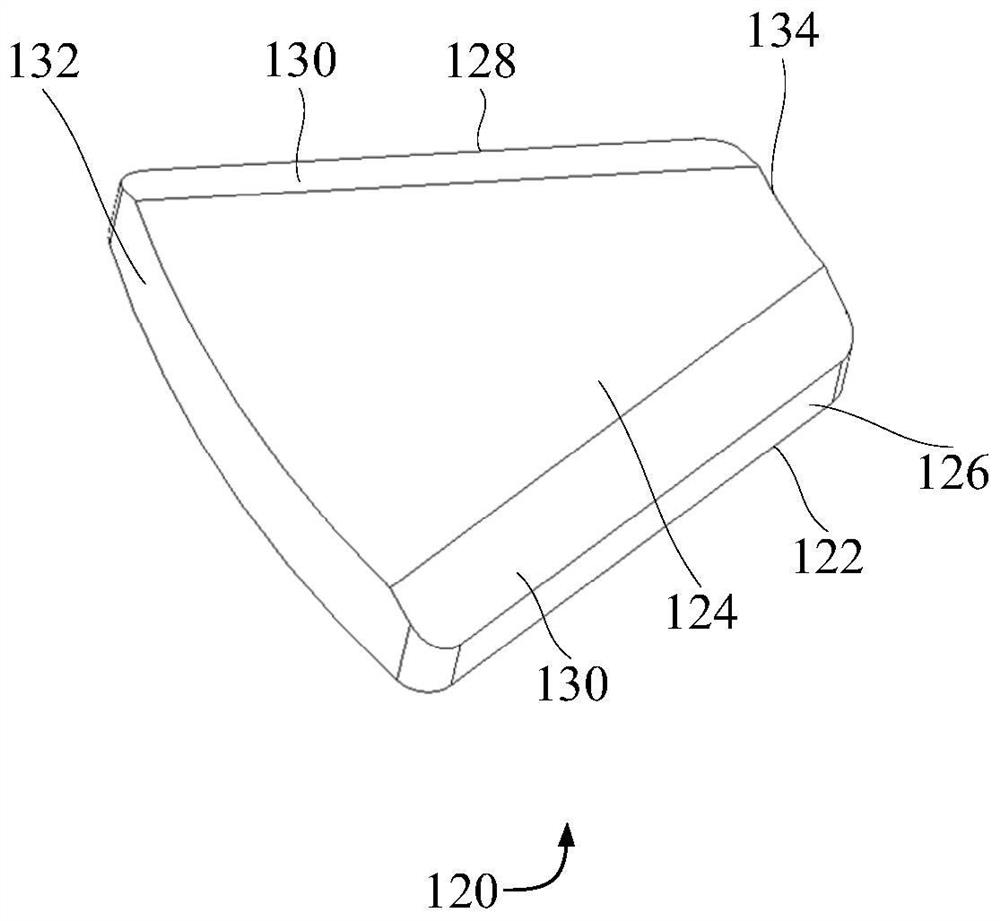

Permanent magnet, rotor assembly and motor

PendingCN112865371AReduce Flux LeakageReduce material inputMagnetic circuit rotating partsPermanent magnetsElectric machineryEngineering

The invention provides a permanent magnet, a rotor assembly and a motor. The permanent magnet is applied to the motor and comprises a first end surface, a second end surface, a first side surface, a second side surface and a transition surface, wherein the first end surface and the second end surface are opposite and are arranged at an interval; the first side surface and the second side surface are located between the first end surface and the second end surface, the first side surface and the second side surface are oppositely arranged, and the first side surface and the second side surface are suitable for extending in the direction from the middle to the edge of a rotor core of the motor; the transition surface is located between the first side surface and the second end surface, and / or the transition surface is located between the second side surface and the second end surface; the distance from the transition surface to the first end surface is less than the distance from the first end surface to the second end surface. According to the invention, reduction of back electromotive force harmonics, cogging torque and torque pulsation is facilitated.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG +1

A method of quickly cultivating miniature roses in potted plants

ActiveCN107027461BPromotes and accelerates rootingEnsure Physiological ConsistencyFlowers cultivationCultivating equipmentsInsect diseaseRapid prototyping

The invention discloses a method for rapidly cultivating rosa chinensis minima potted flowers by pinching for one time. The method comprises the steps of direct cutting in flowerpots and directional seedling growing for one time and pinching and trimming for one time in the seedling stage. Compared with a traditional multi-step potted flower cultivation method that seedlings are first cultivated and then potted, the production steps of seedling potting and transplanting, and combining and molding are reduced, damage and investment which are caused by seedling potting and transplanting are prevented, survival rates of the seedlings are increased, rooting and sprouting are ordered and consistent, and production cost is reduced. The number of flower branches and extension directions of foliage leaves can be directionally cultivated by the technologies of directional cutting and pinching and trimming for one time, the sprouting time of plant buds and consistency of flower branch growth are ensured, the potted flowers are promoted to the molded rapidly and fully, ornamental characteristics are largely improved, insect diseases are prevented, the ratio of high-quality potted flowers is significantly improved, the production cycle is as short as 60-85 days.

Owner:云南云秀花卉有限公司

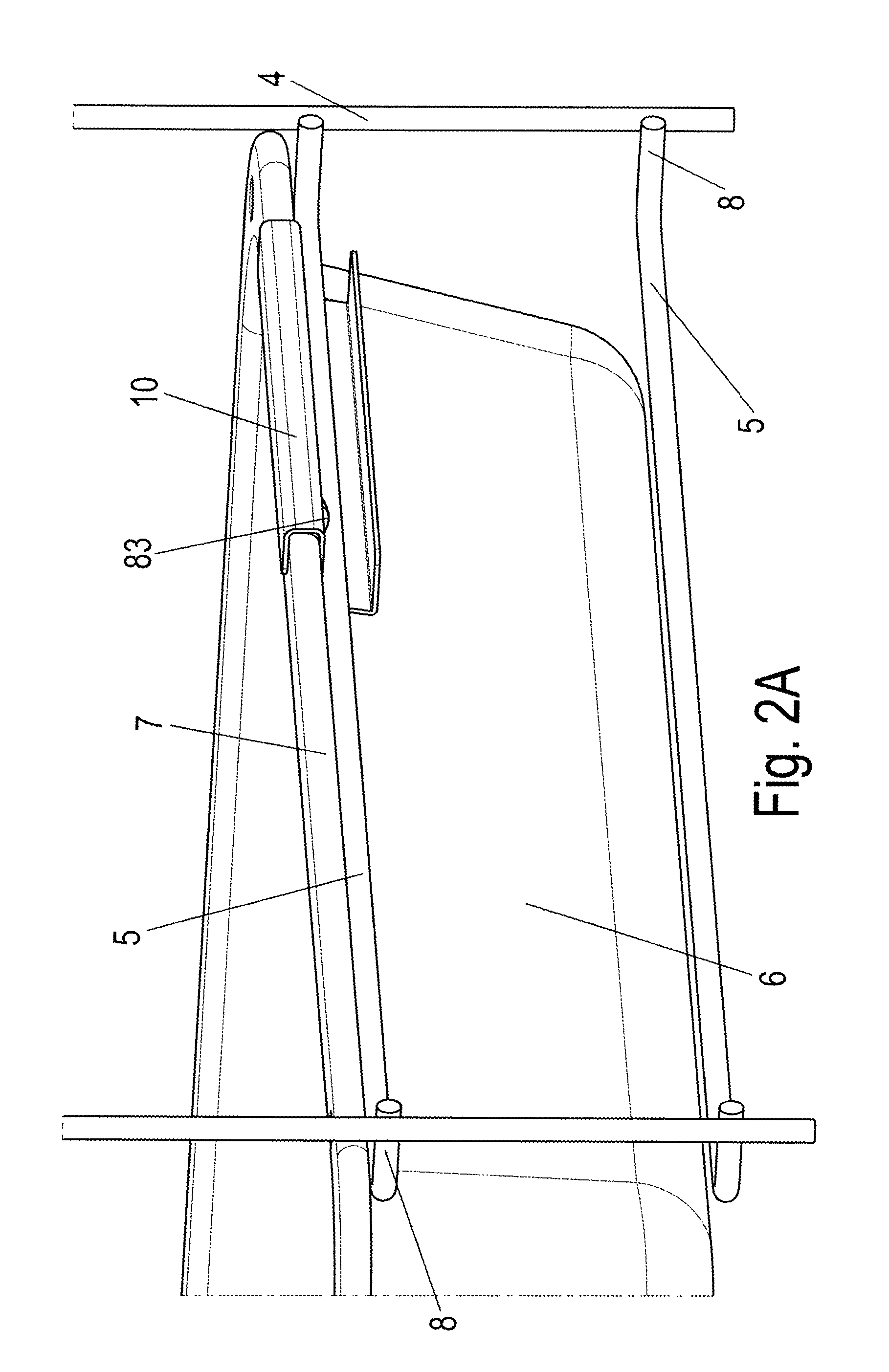

Guide device

InactiveUS20110197875A1Easy to manufactureLower average energyDomestic stoves or rangesStoves/ranges shelves or racksProtection mechanismEngineering

A guide apparatus for a baking oven. The guide apparatus includes a baking support including a projecting edge on opposite sides of the baking support. Further included is a side wall of the oven and a plurality of horizontal bars mounted on the side wall. The horizontal bars form at least one baking level and support the projecting edges of the baking support. Also included is at least one holding means provided on the baking support, which holding means engages beneath one of the plurality of horizontal bars and forms a tilt protection mechanism.

Owner:PAUL HETTICH

Deep Foundation Pit Large Slope Upside-Down Steel Bolt-spray Support Structure and Its Construction Method

ActiveCN112281862BAchieve early unloadingSmall amount of workExcavationsBulkheads/pilesArchitectural engineeringStructure support

The invention discloses a large-slope upside-down steel anchor-spray support structure for a deep foundation pit, which supports the support pit formed by excavating the basement in the foundation pit at a position to be protruded. The support structure includes: A first support pile and a second support pile, the second support pile is correspondingly arranged at a corresponding position of the support pit and the elevation of the second support pile is lower than the first support pile; The crown beam on the top of the first support pile; the upper support beam on the inner wall of the support pit, the upper support beam is supported on the inner wall of the support pit and the upper support The end of the beam protrudes from the support pit and is fixedly connected to the crown beam on the first support pile; the protective plate is arranged at the bottom of the upper support beam and is attached to the inner wall of the support pit ; the lower support beam on the second support pile, the lower support beam is provided with a certain distance from the inner wall of the support pit, and the lower support beam and the upper support beam pass through The protective plate is fixedly connected.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Shell-making method capable of improving sand clearing efficiency of casting

InactiveCN111001759ASave materialReduce material inputFoundry mouldsFoundry coresProcess engineeringGrout

The invention discloses a shell-making method capable of improving sand clearing efficiency of a casting. The shell-making method is characterized in that each hole of a slot hole or a cavity is plugged by a sealing part after 4-5 layers of shells are guaranteed to be made for a casting with the cavity or the slot hole during shell-making, and a next layer of the shells is continuously made, so that slurry and sand of making the next layer do not enter the cavity and the slot hole; the inner shell of the cavity or the slot hole is relatively thin, so that sands in the cavity or the slot hole are easily cleared at a later period as long as molten steel does not leak, and therefore, acid-soaking and fierce-hitting are not needed. According to the shell-making method disclosed by the invention, materials are saved, and sand plugging or slurry filling does not need to perform in the cavity or the slot hole, so that material investment and manual investment are reduced; and the sealing partfor sealing is adopted to replace a slurry filling process, so that no more mortar is in the cavity or the slot hole, and the cavity or the inner cavity of the slot hole does not need to clear at a later period, and therefore, acid-soaking and fierce-hitting are not needed, and clearing is easier.

Owner:HUZHOU NANFENG MACHINERY MFG

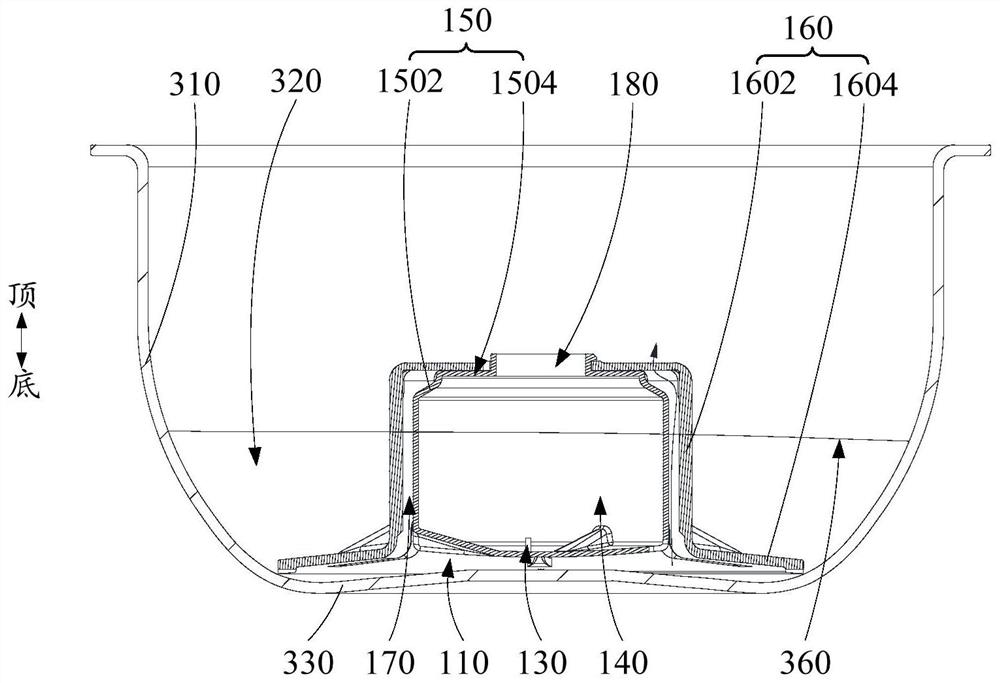

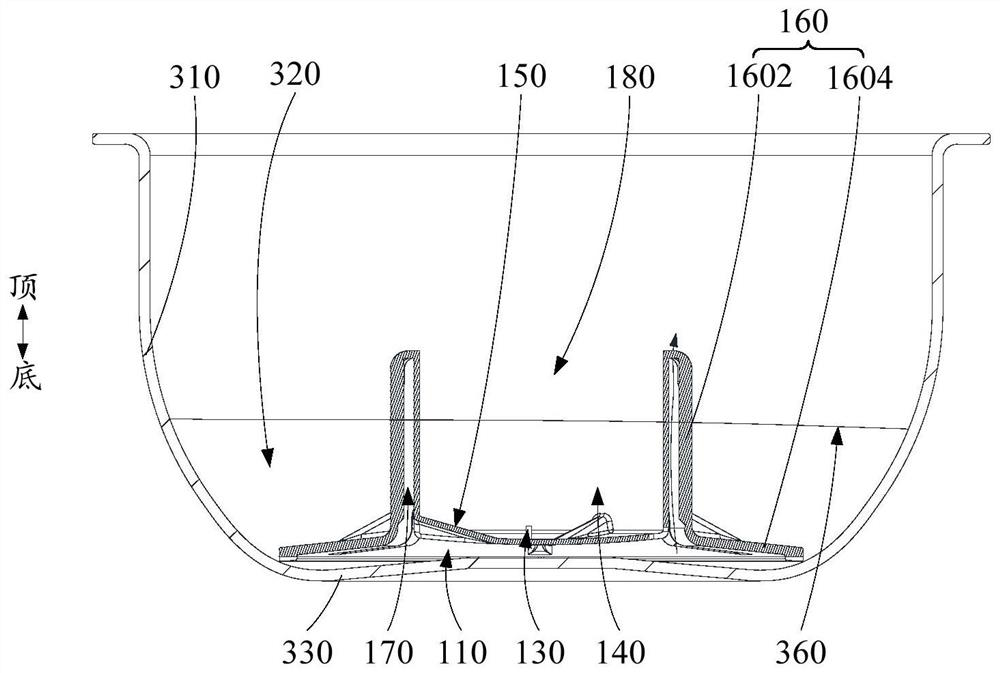

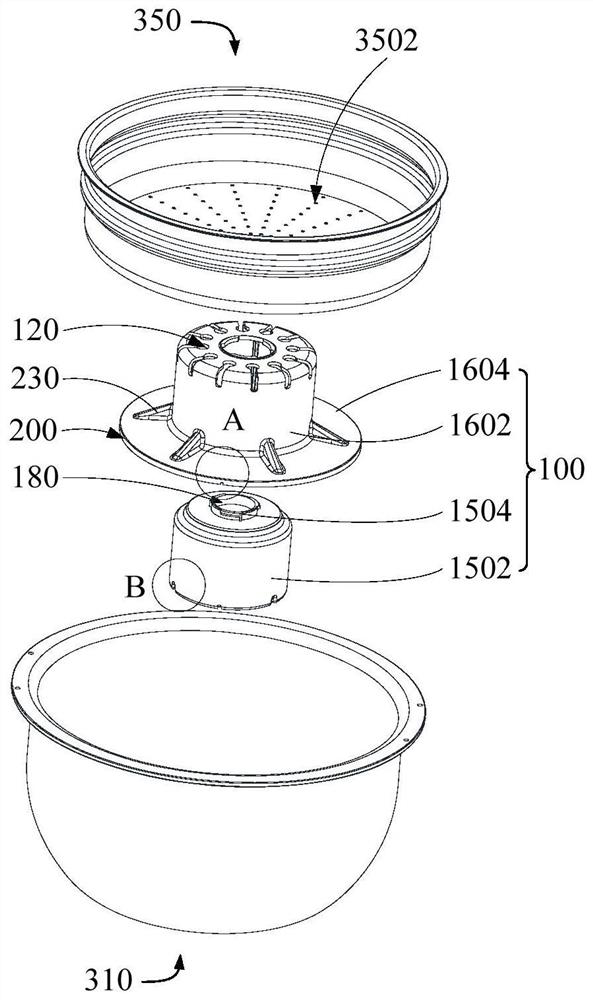

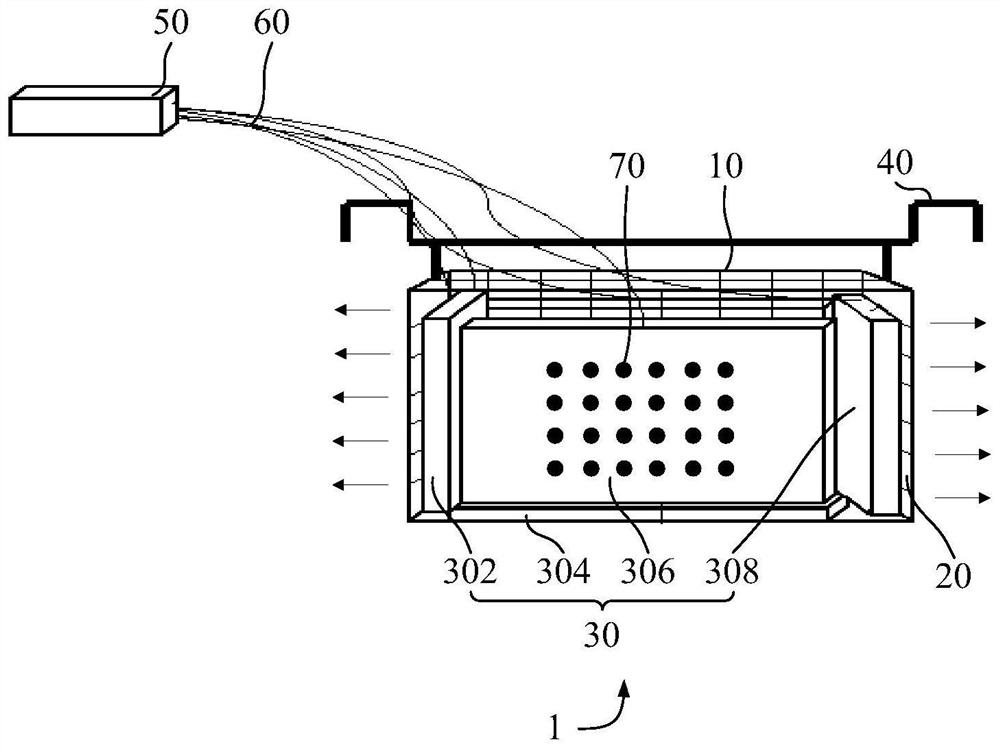

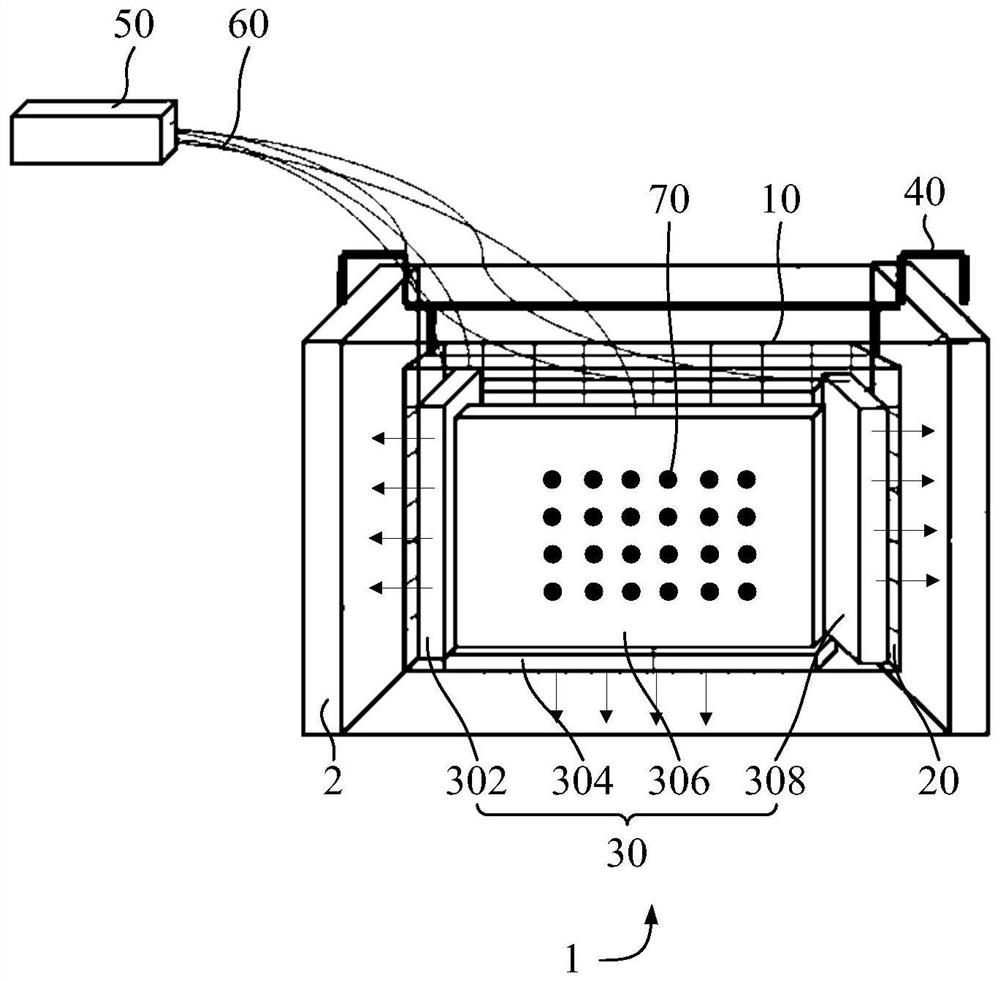

Household appliance

PendingCN113142967AReduce material inputReduce manufacturing costCooking insertsCooking vessel constructionsHome useThermodynamics

A household appliance is provided. The household appliance comprises a container; wherein an isolator is arranged in the container, and an exhaust port and a liquid level limiting surface are formed on the isolator; a first chamber is defined between a liquid level limiting surface and a part of an inner surface of the container, and the first chamber is communicated with the exhaust port; and at least part of the liquid level limiting surface is opposite to a part of the inner surface of the container. According to the household appliance, a structure of the household equipment is reasonably arranged, so the medium is gathered in the first chamber, the first chamber limits the amount of the medium located in the first chamber, and the amount of the medium to be heated is slightly influenced by the medium amount and the medium temperature of the external area of the isolator; through heating the medium in the first chamber, the time for a medium to boil from normal temperature and generate relatively stable steam can be greatly shortened, and the temperature rise of the medium in the external area of the isolator is very small, so a purpose of quickly generating high-temperature steam can be achieved, and energy loss is avoided.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

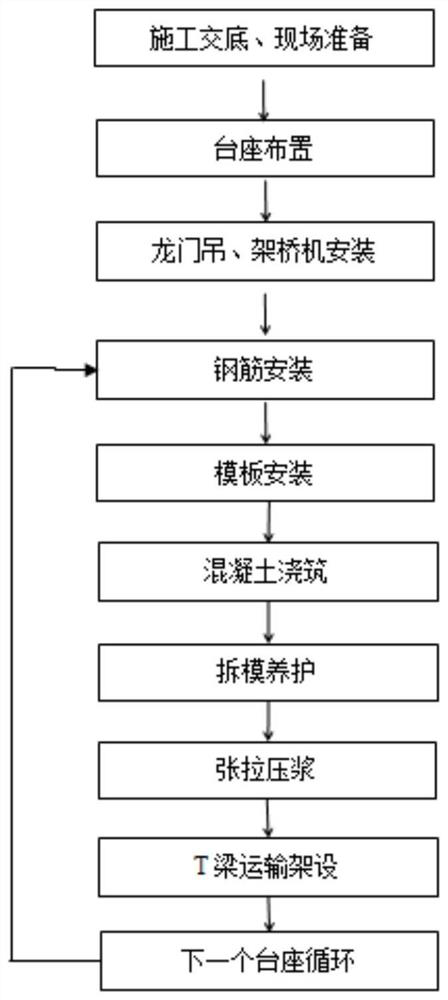

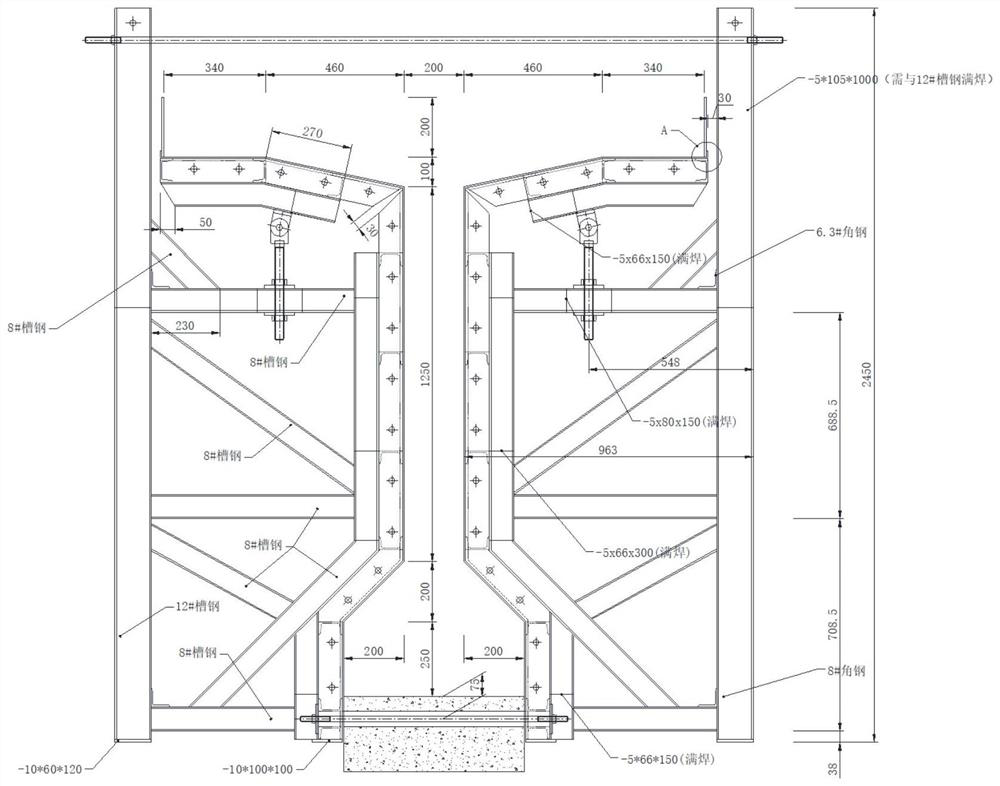

Construction method for prefabricating and installing T beam in bridging tunnel

PendingCN114851374AShorten the construction periodReduce shipping costsCeramic shaping plantsHydro energy generationProduction lineT-beam

The invention discloses a construction method for prefabricating and installing a T-beam in a bridging tunnel. The construction method comprises the steps that firstly, a construction site is prepared, and an assembly line system is arranged; reasonably designing a production line layout diagram according to a construction technology disclosure process sequence; each production line is provided with a pedestal arrangement area, a steel bar manufacturing area, a beam manufacturing area, a maintenance area, a primary tensioning area, a maintenance area, a secondary tensioning area and a beam storage area. A gantry crane and a bridge girder erection machine are entrusted to be manufactured by professional manufacturers, and the sizes of the gantry crane and the bridge girder erection machine are limited due to limitation of the height and the width of a tunnel. According to the method, the T-beam is prefabricated in the tunnel, the situation that the T-beam is prefabricated from a farther beam yard and transported to the site for installation is avoided, the construction period is shortened, the transportation cost is reduced, meanwhile, the safety risk is reduced, the beam plates are prefabricated in the tunnel, and due to the fact that sunlight in the tunnel is little and the water loss speed is low, T-beam maintenance is easier compared with outdoor conditions; the time for the concrete to reach the design strength is greatly shortened, and the T-beam tension grouting time is averagely shortened by 1-2 days.

Owner:THE FOURTH CONSTR OF YUNNAN ARCHITECTURAL ENG GROUP

cleaning supplies

ActiveCN111715612BReduce material inputEasy to useCleaning using liquidsMaintenance careMechanical engineering

The invention provides a cleaning device, comprising: a shell; a hollowed-out area arranged on the inner wall of the shell; an ultrasonic device detachably arranged in the shell, and an output part of the ultrasonic device is set correspondingly to the hollowed-out area. The present invention rationally arranges the structure of the cleaning equipment, so that when using the cleaning equipment to clean and maintain the device to be cleaned (such as the liquid medicine tank), the ultrasonic wave emitted by the output part of the ultrasonic device reaches the working surface of the liquid medicine tank through the hollow area, and then the working The dirt on the surface of the surface is knocked down, and then the effective cleaning of the liquid medicine tank is realized, which greatly enhances the cleaning effect of the liquid medicine tank. At the same time, the structural setting realizes the purpose of automatic cleaning and maintenance of the device to be cleaned, avoids manual input, and reduces maintenance costs.

Owner:CHONGQING FOUNDER HI TECH ELECTRONICS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com