Guide device

a technology of guide device and guide rod, which is applied in the direction of lighting and heating apparatus, domestic heating details, domestic heating, etc., can solve the problems of high material input, comparatively complex guide and side grates, and large input of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

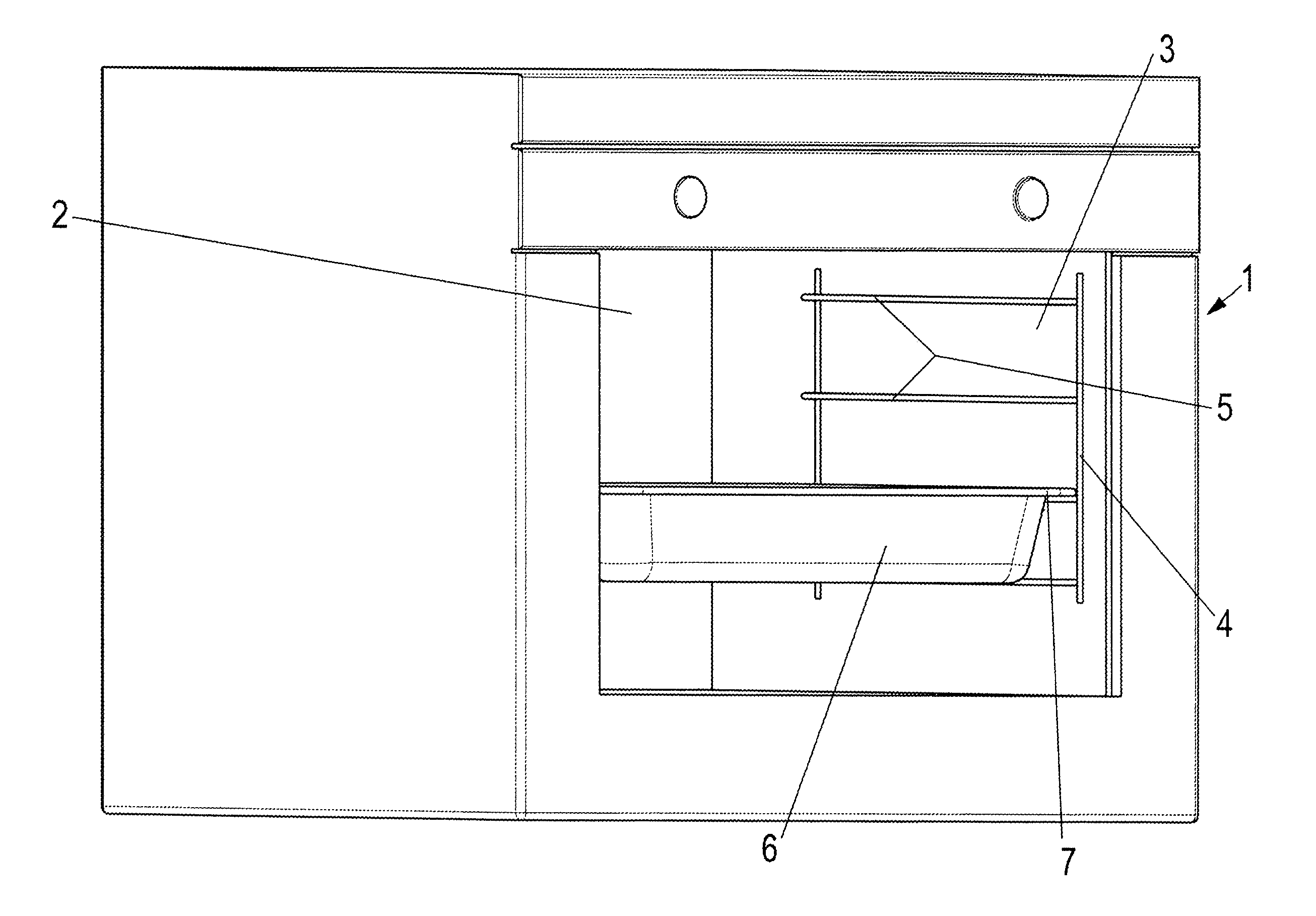

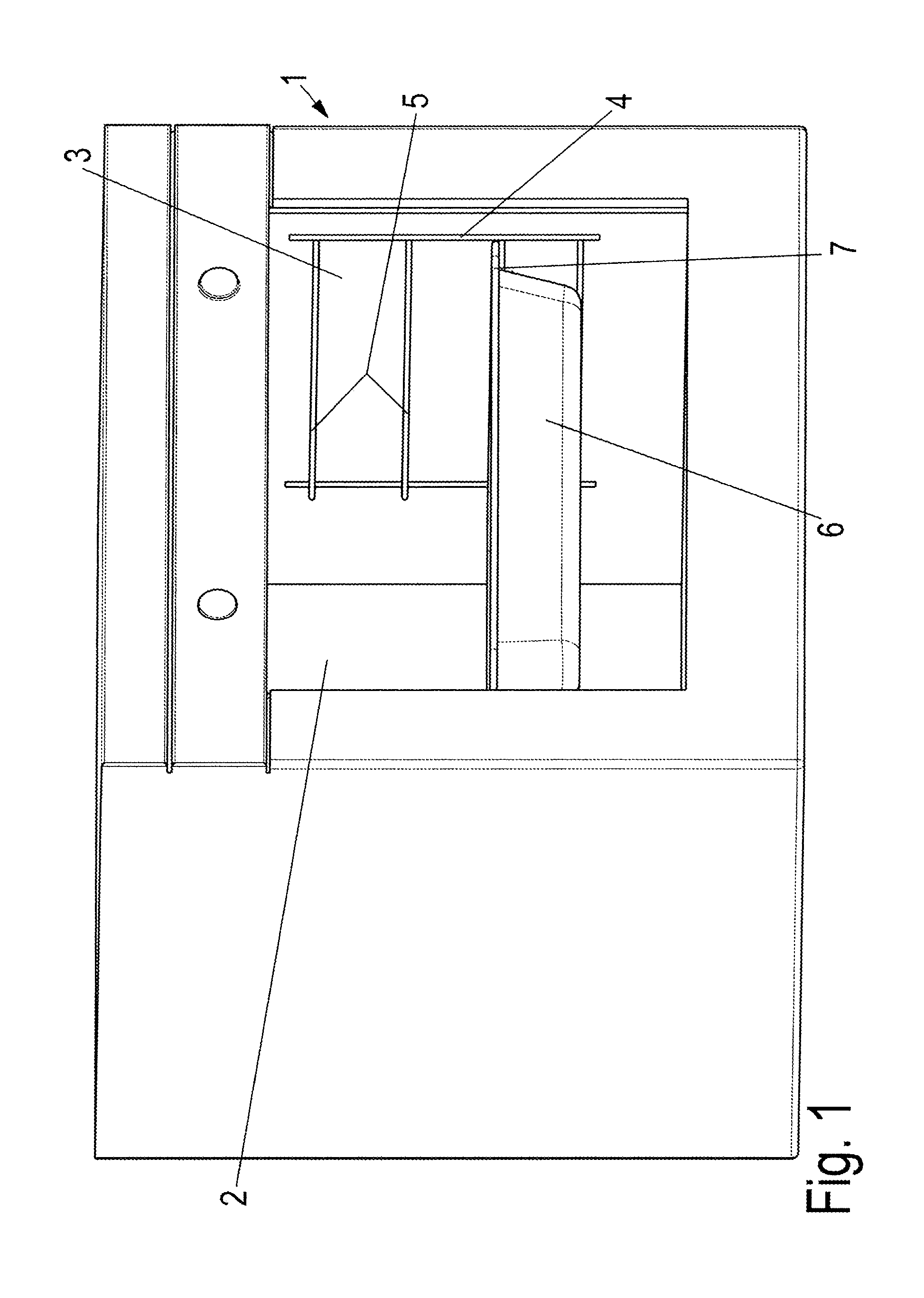

A baking oven 1 comprises a heatable interior space 2 which comprises a side grate 4, of a guide apparatus, according to the present disclosure, on opposite side walls 3. The side grate 4 is fixed via fastening means (not shown) to the side wall 3 and comprises a plurality of horizontal bars 5 which are fixed at opposite ends to vertical bars. Each horizontal bar 5 forms a baking level and is used for supporting a baking support 6 which is arranged or configured, for example, as a baking tray and which baking support 6 comprises a laterally protruding edge 7.

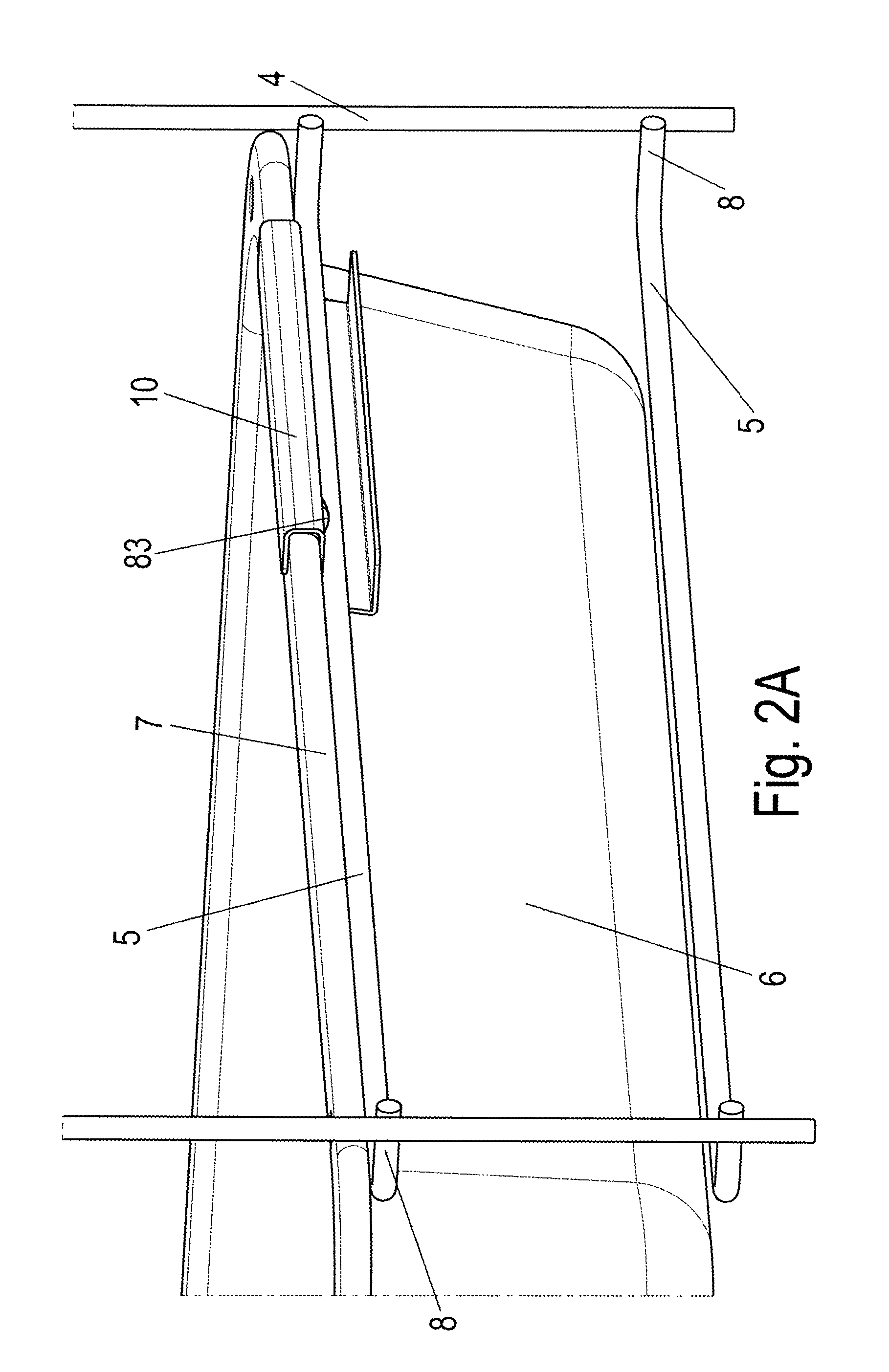

As is shown in an embodiment of the present disclosure in FIGS. 2A and 2B, the laterally protruding edge 7 of the baking support 6 is provided with a holding means 10 in the form of a strip-like bent sheet in a rear region adjacent to a rear wall of the baking oven 1. The holding means or sheet 10 is arranged in a virtually S-shaped manner in its cross section. The holding means 10 comprises a first U-shaped receiver which is de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com