Construction method for prefabricating and installing T beam in bridging tunnel

An in-tunnel and bridging technology, used in manufacturing tools, ceramic molding machines, ceramic molding workshops, etc., can solve the problems of difficult to guarantee construction period and transportation safety, limited bridges and tunnel sites, and high proportion of bridges and tunnels. Manpower, reduce transportation costs, save economic and environmental protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

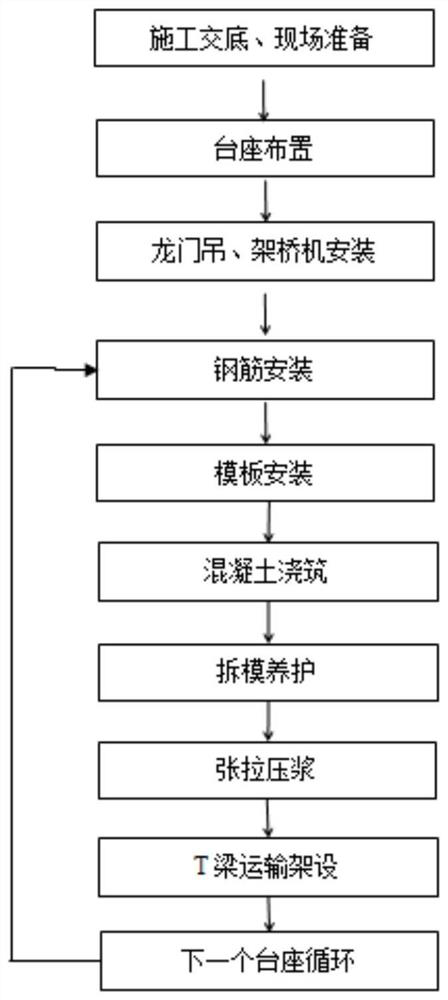

[0047] like Figure 1-4 As shown, the construction method of prefabrication and installation of T beams in the bridge tunnel includes the following steps:

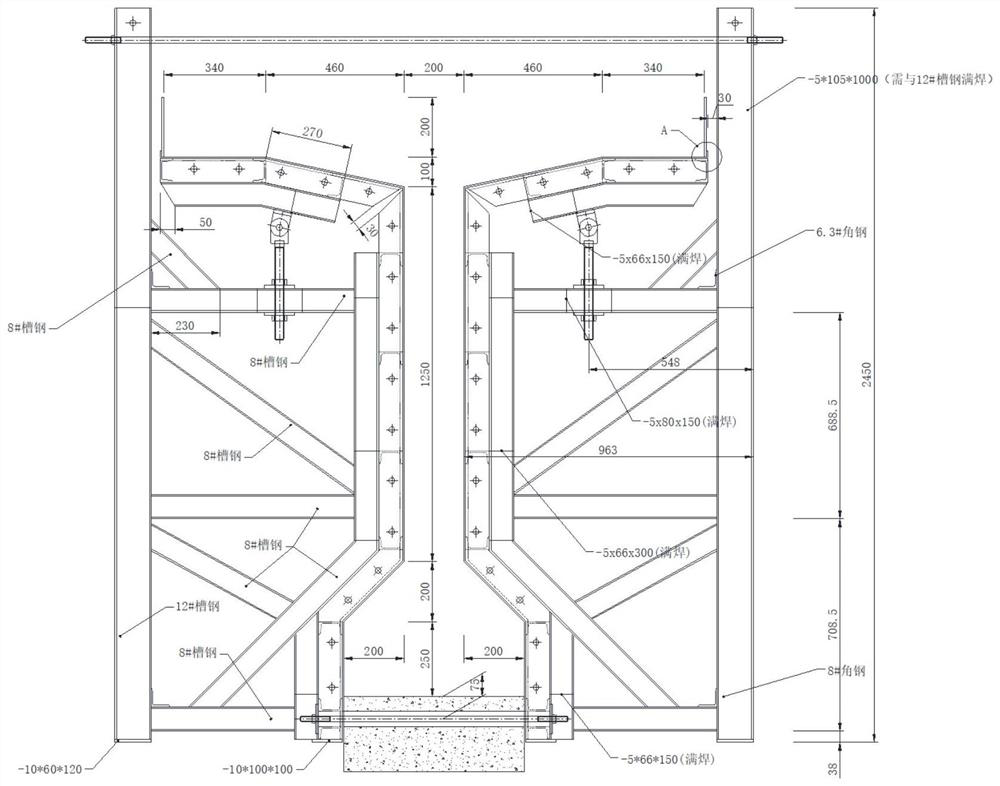

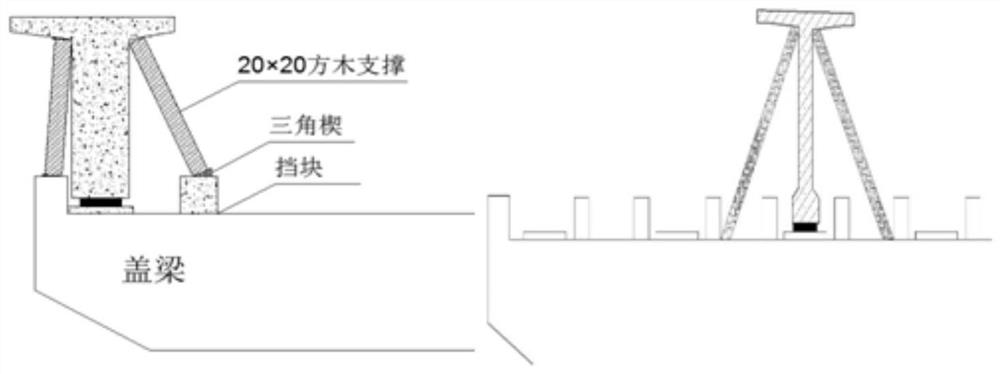

[0048] Step 1: Prepare the construction site and arrange the assembly line system; according to the construction technology and the process sequence, rationally design the production line layout; each production line is set up with a pedestal layout area, a steel bar production area, a beam making area, a maintenance area, and a preliminary tension area. Maintenance area, secondary tension area, beam storage area; gantry cranes and bridge erection machines are commissioned to manufactur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com