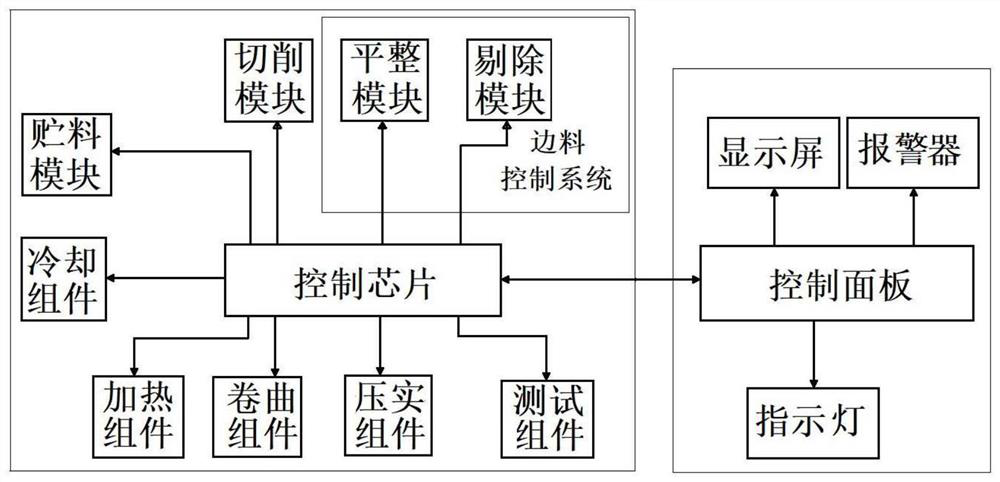

Rim charge control system and hose welding process thereof

A control system and welding process technology, applied in the direction of tubular objects, other household appliances, household appliances, etc., can solve the problems of difficult processing of stepped structures, damage to the pattern layer, and high production costs, reducing the complexity of materials and reducing materials. The effect of investment and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example 1

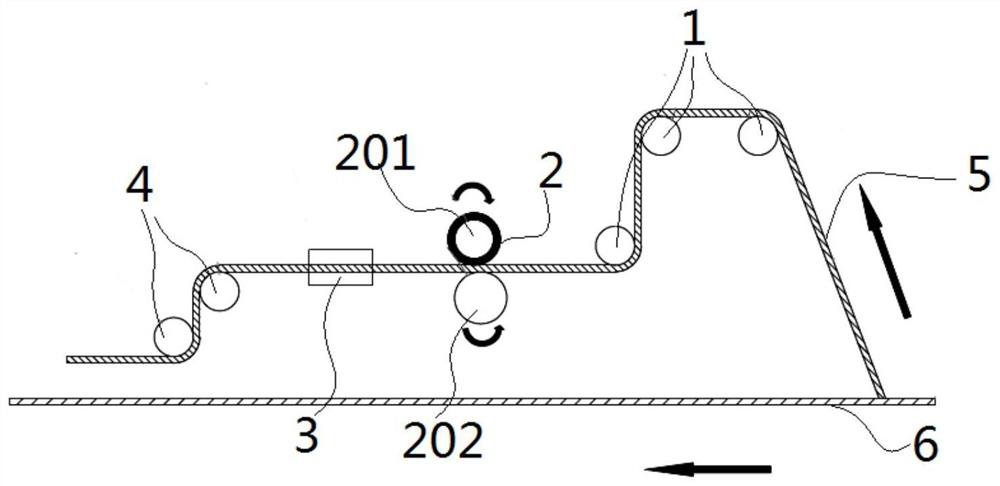

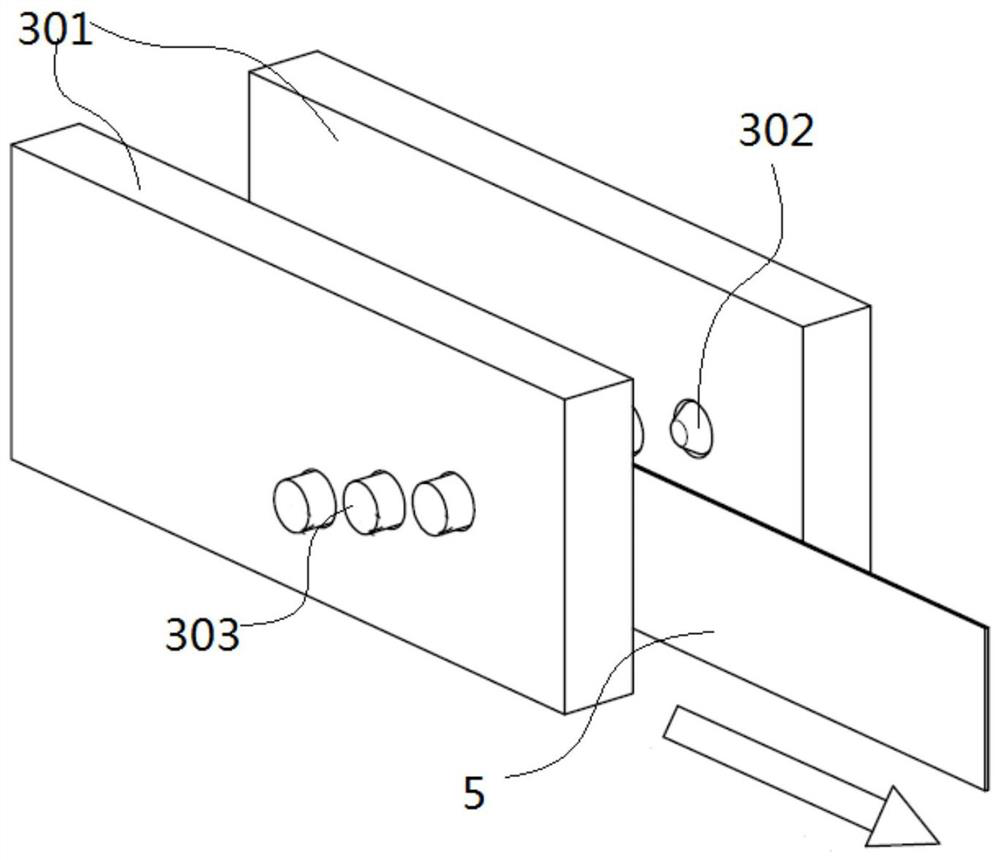

[0046] Specific example 1: PBL all-plastic transparent composite hose: 350um PBL all-plastic sheet, the diameter of the hose is 35mm, the width of the trimmed edge material and wire is 5mm, and the edge-cutting of the sheet is carried out along the running direction of the equipment. Welding, at the same time, add the edge wire to the inner side of the hose, adjust the welding energy, so that the thickness of the edge wire with a thickness of 350um after heat melting is 280um-175um. The finished hose passes the hose performance test: 2bar compressed air is added to the hose to keep the pressure constant for 30 seconds, and there is no cracking at the joint of the hose sheet.

specific example 2

[0047] Specific example 2: High-gloss composite hose: Select the high-brightness composite sheet with a thickness of 395um, a hose diameter of 50mm, and a width of 5mm for the trimmed edge material and wire. Diagonal welding, at the same time, welding the edge wire on the inner side of the hose, adjusting the welding energy, so that the thickness of the edge wire with a thickness of 395um after heat melting is 316u-198um. The finished hose passes the hose performance test: 2bar compressed air is added to the hose to keep the pressure constant for 30 seconds, and there is no cracking at the joint of the hose sheet.

[0048] This application is suitable for the bonding production operation of various composite hoses, without adding other materials, reducing the material input and material complexity in the process of making composite hoses, further ensuring quality and reducing production costs; controlled by the side material control system The width and position of the edge ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com