Permanent magnet, rotor assembly and motor

A technology of permanent magnets and components, applied in the direction of magnetic circuit rotating parts, magnets, magnetic objects, etc., can solve the problems of unreasonable permanent magnet structure setting, motor back EMF harmonics, cogging torque and torque ripple, and rotor Partial saturation of components and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

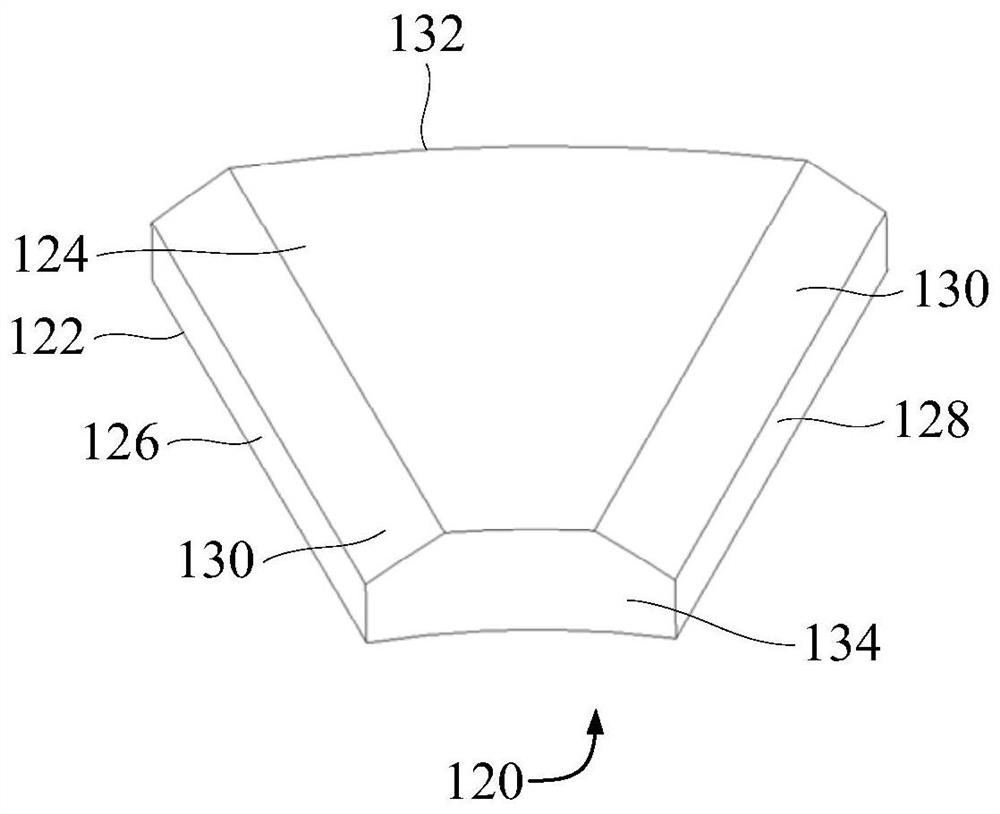

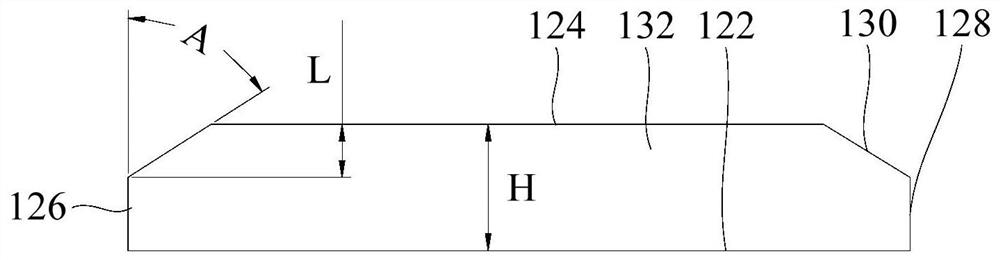

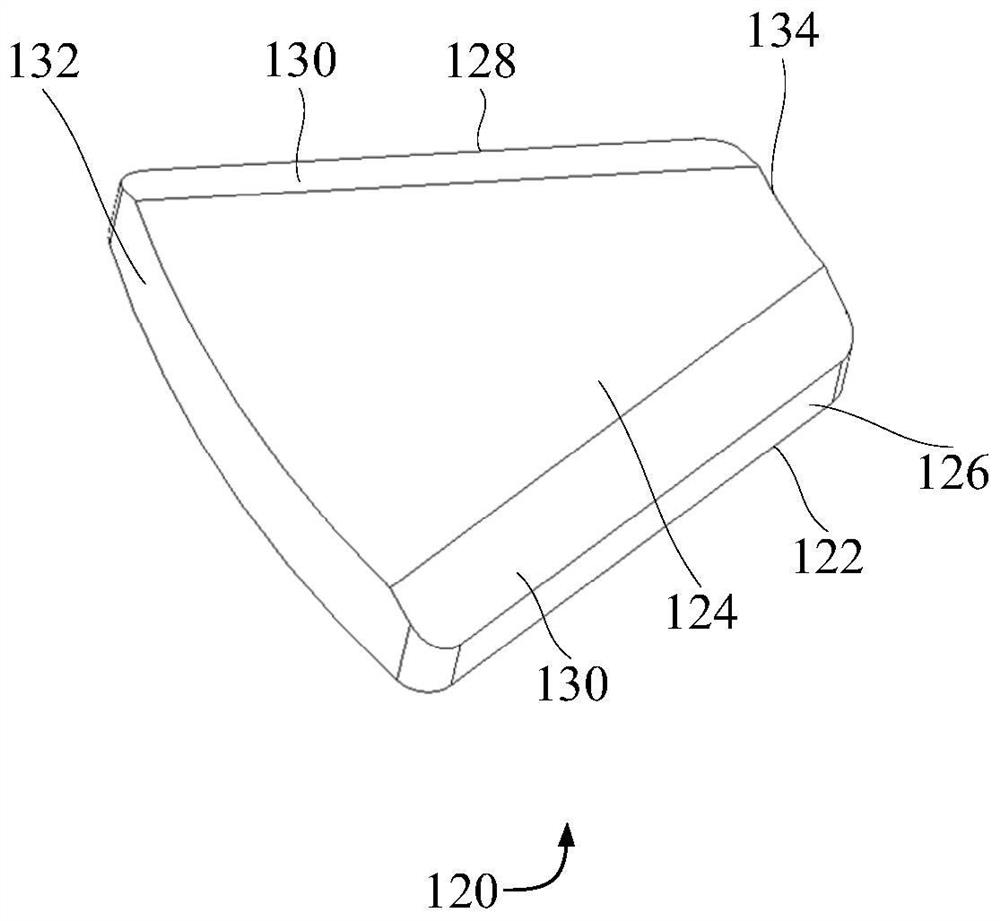

[0052] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, the embodiment of the first aspect of the present invention proposes a permanent magnet 120 for the motor 200, the permanent magnet 120 includes a first end surface 122, a second end surface 124, a first side surface 126, a second side surface 128 and a transition surface 130, the first end surface 122 is opposite to the second end surface 124 and arranged at intervals, the first side surface 126 and the second side surface 128 are both located between the first end surface 122 and the second end surface 124, and the first side surface 126 and the second side surface 128 are oppositely arranged , and the first side 126 and the second side 128 are suitable for extending along the direction from the middle of the rotor core 110 of the motor 200 to the edge, the transition surface 130 is located between the first side 126 and the second end surface 124, and / or the transiti...

Embodiment 2

[0059] On the basis of Embodiment 1, Embodiment 2 provides a permanent magnet 120 for a motor 200. The permanent magnet 120 includes a first end surface 122, a second end surface 124, a first side surface 126, a second side surface 128 and a transition surface 130, the first end surface 122 is opposite to the second end surface 124 and arranged at intervals, the first side surface 126 and the second side surface 128 are both located between the first end surface 122 and the second end surface 124, and the first side surface 126 and the second side surface 128 are oppositely arranged , and the first side 126 and the second side 128 are suitable for extending along the direction from the middle of the rotor core 110 of the motor 200 to the edge, the transition surface 130 is located between the first side 126 and the second end surface 124, and / or the transition The surface 130 is located between the second side surface 128 and the second end surface 124 , and the distance from t...

Embodiment 3

[0068] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, on the basis of Embodiment 1 or Embodiment 2, Embodiment 3 provides a permanent magnet 120 for the motor 200. The permanent magnet 120 includes a first end face 122, a second end face 124, a first side face 126, The second side surface 128 and the transition surface 130, the first end surface 122 is opposite to the second end surface 124 and arranged at intervals, the first side surface 126 and the second side surface 128 are located between the first end surface 122 and the second end surface 124, the first side surface 126 Set opposite to the second side 128, and both the first side 126 and the second side 128 are adapted to extend from the middle of the rotor core 110 of the motor 200 to the edge, and the transition surface 130 is located between the first side 126 and the second end 124 and / or the transition surface 130 is located between the second side surface 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com