Prefabricated thermal insulation exterior wall and method for producing the same

A production method and technology of thermal insulation wall panels, which are applied in the field of building exterior walls and can solve problems such as poor thermal insulation of walls, easy cracking of walls, and water seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

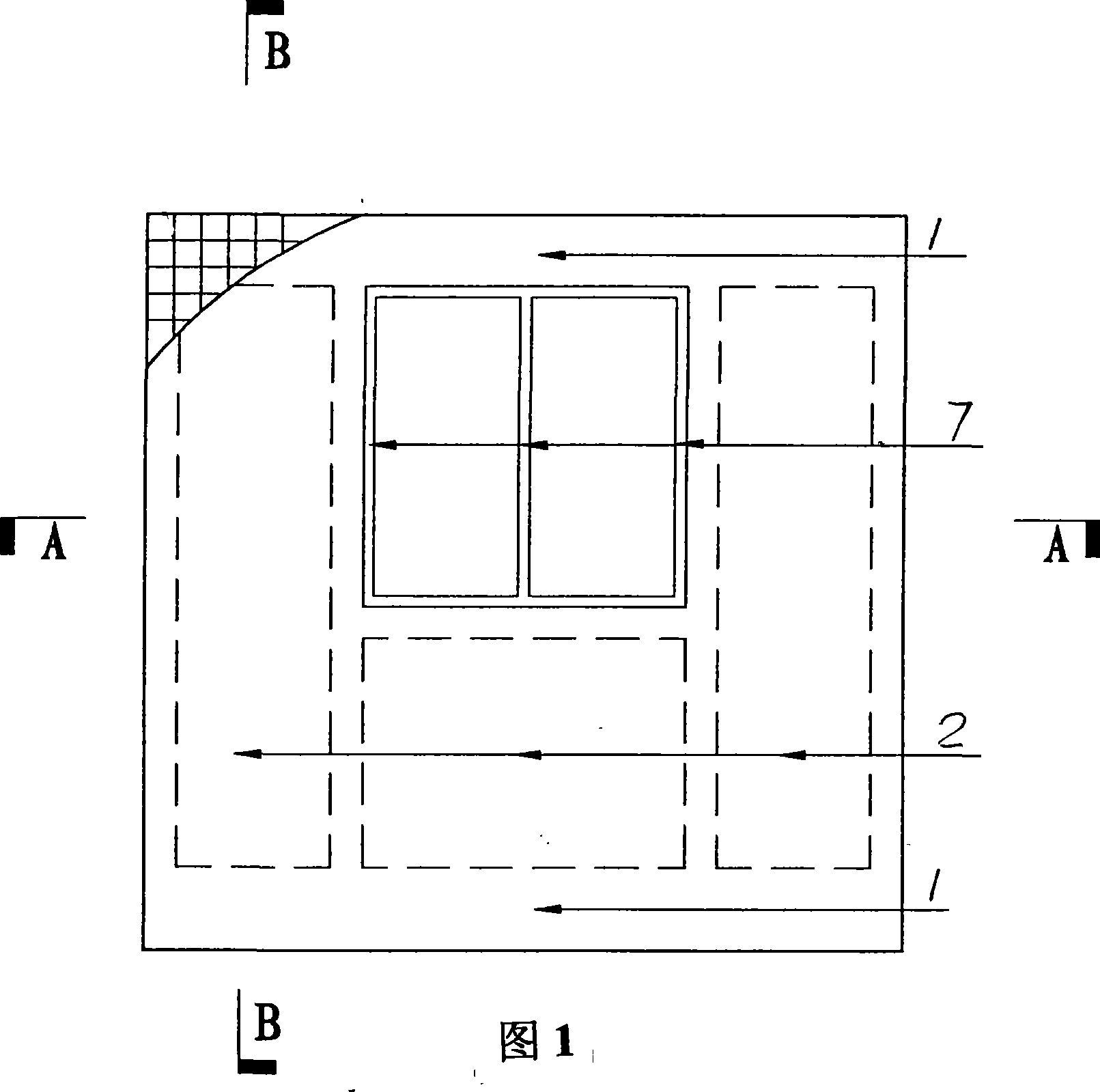

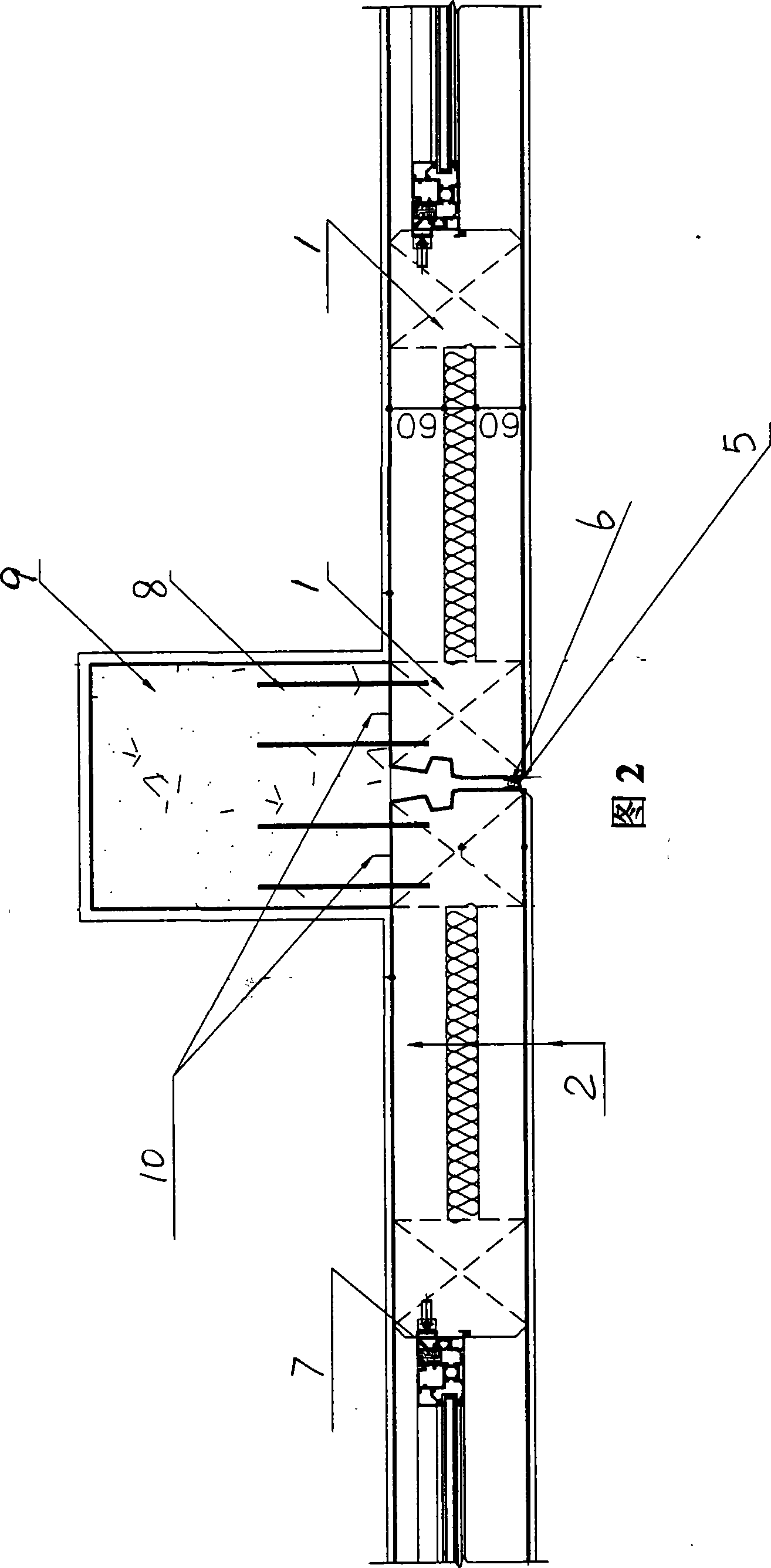

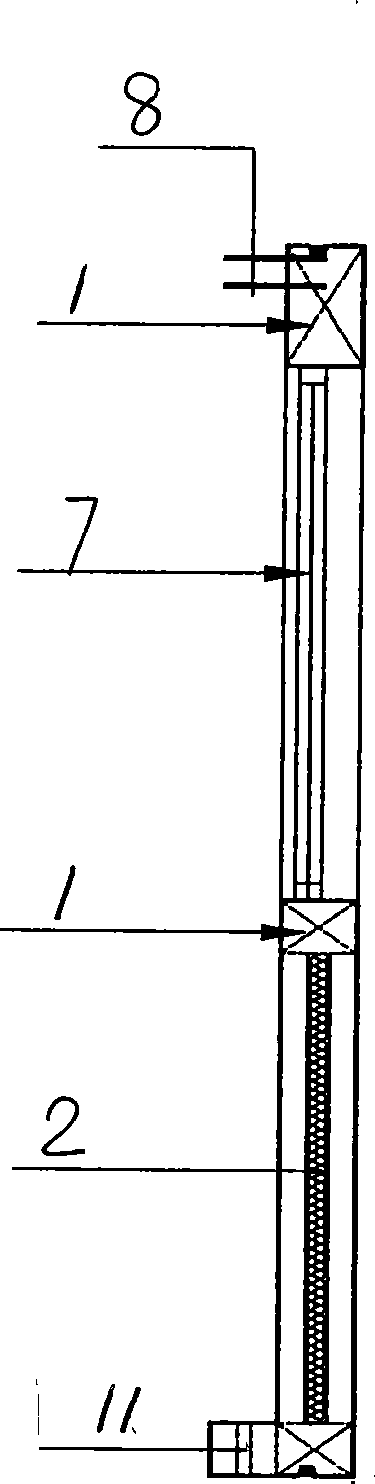

[0019] The solid wallboard 1 of the present invention is connected with the sandwich wallboard 2, the sandwich wallboard has at least three layers, the inner and outer layers are concrete boards 3, and the middle layer is a thermal insulation board 4. The concrete slab is 70mm thick, and the insulation board is extruded polystyrene insulation board. The gap between the prefabricated thermal insulation wall panels and the prefabricated thermal insulation wall panels is 20 mm, and the gap is filled with waterproof sealing material 5 and polystyrene rods 6 for waterproof lining materials, wherein the waterproof sealing material is silica gel. The solid wall panels are connected to the door and window frames 7, and the periphery of the solid wall panels is provided with reserved parts or reserved sockets, the reserved parts are reserved steel bars, reserved hanging nails or connectors, and the height of the prefabricated thermal insulation wall panels It is 3600mm and the height i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com