Assembled hybrid structure system applicable to high-rise residential building

A technology of high-rise residential buildings and mixed structures, which is applied to residential buildings, building components, special structures, etc. It can solve the problems of large wet work workload on site, inconvenient layout of lateral force-resistant components, and difficult handling of steel column feet, etc., and achieves reduction Wet work, low noise, and improved structural rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further understand the content of the invention, features and effects of the present invention, the following examples are given hereby, and detailed descriptions are as follows in conjunction with the accompanying drawings:

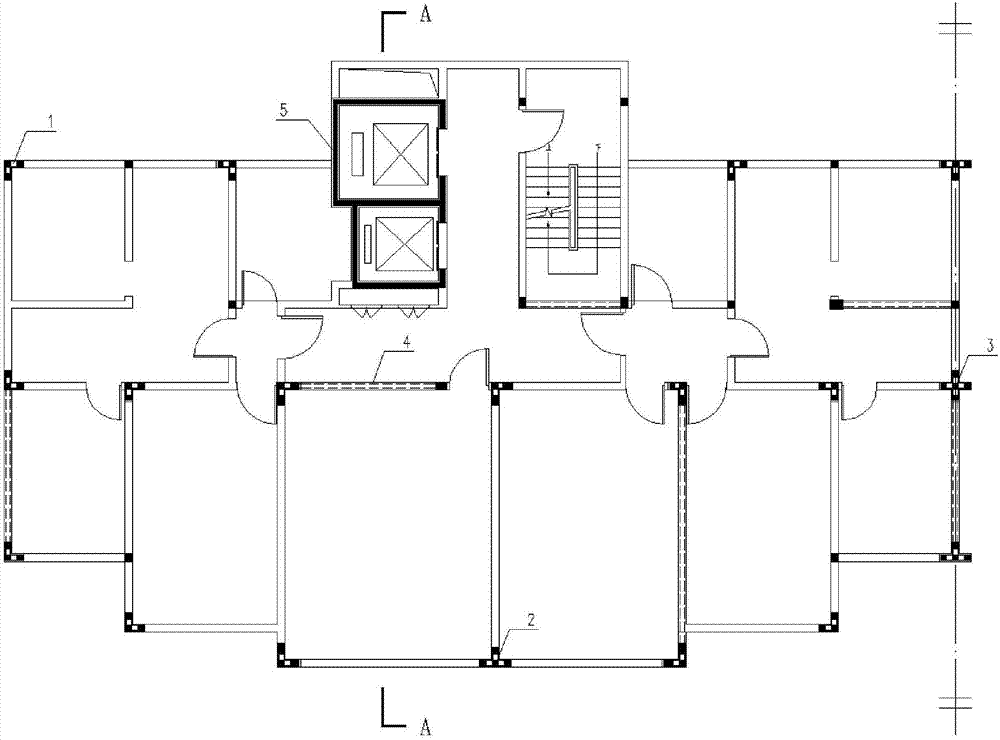

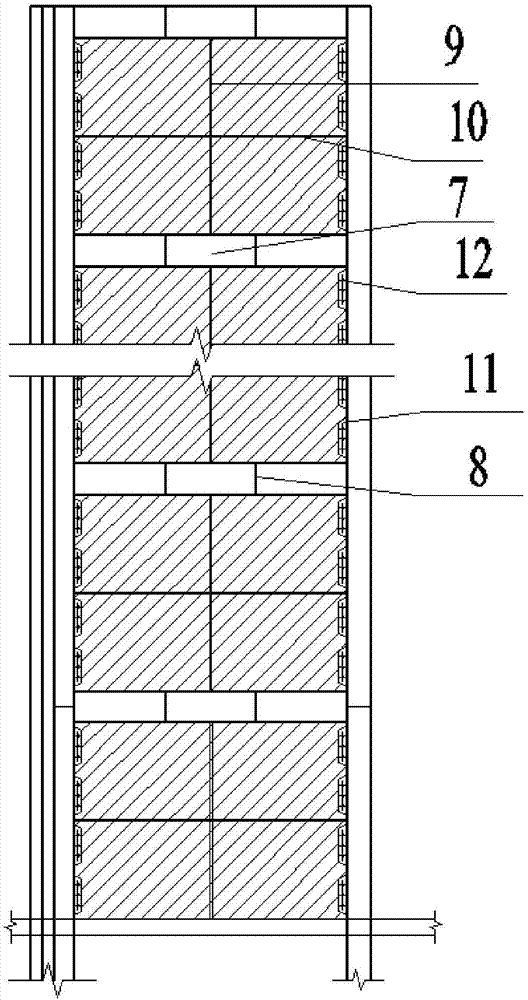

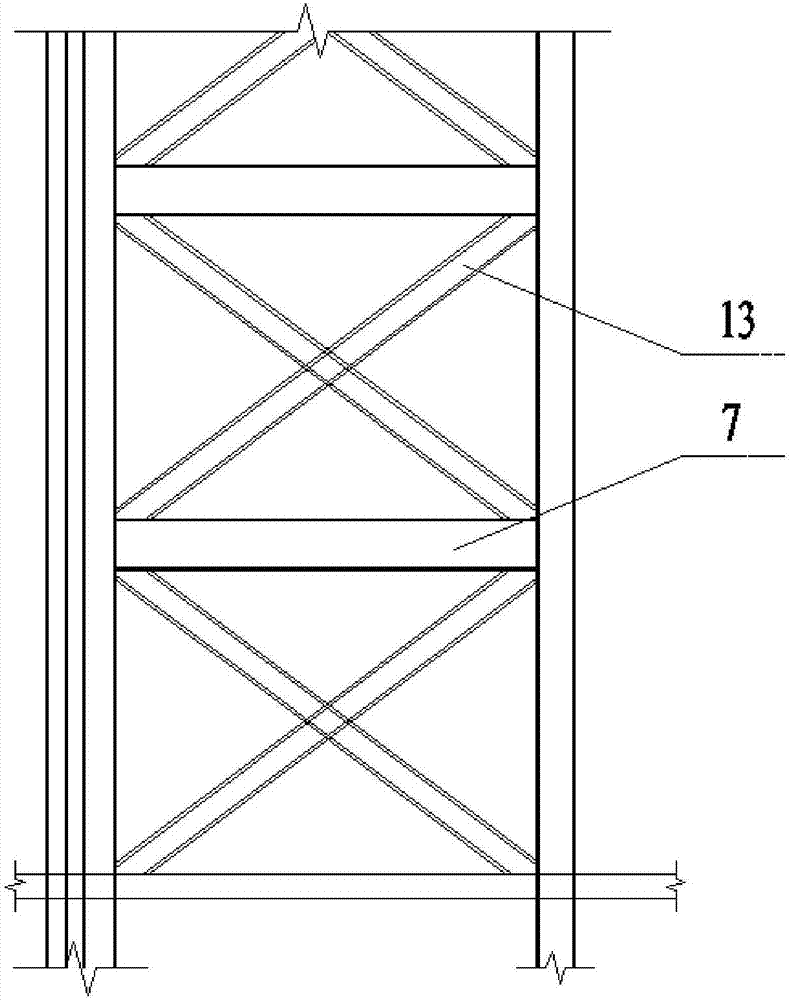

[0027] See figure 1 - Figure 8 , a prefabricated hybrid structure system suitable for high-rise residential buildings, including steel frame columns 6, steel beams 7, support structures 4 and prefabricated core tubes 5, the steel frame columns 6 are composed of tubular concrete combined special-shaped columns and steel tube concrete columns According to the arrangement of the positions of the side column 19 and the center column 20, the concrete-filled steel pipe composite special-shaped column in this embodiment is divided into an L-shaped concrete-filled steel pipe composite special-shaped column 1, a T-shaped composite steel pipe concrete-shaped special-shaped column 2, and a cross-shaped steel pipe concrete composite special-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com