Fixed model quasi-non-combustible high thermal-resistance decoration integral composite template

A composite formwork, high thermal resistance technology, applied in the fields of decoration, thermal insulation, building exterior wall formwork, and fire protection, can solve the problems of easy cracking and leakage of board seams, high production and installation costs, and difficulty in control, so as to reduce project cost and product quality. The effect of quality assurance and water absorption improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

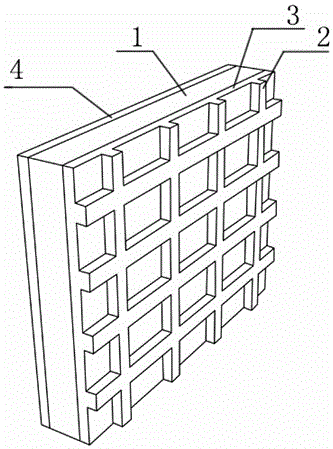

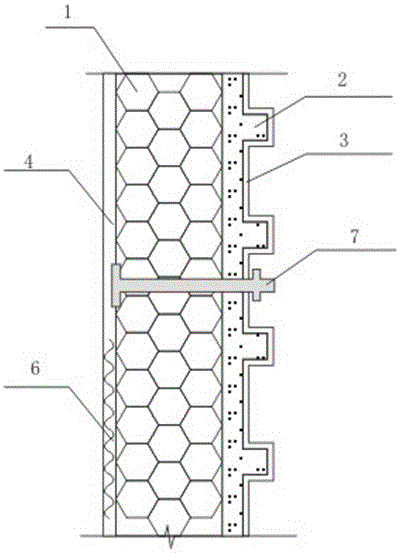

[0018] Example 1, see figure 1 , 2 , Extrusion molding technology or cutting technology is used on the production line of the factory to make the insulation layer 1 with horizontal ribs or vertical and horizontal ribs 2 on the inner side, and the insulation layer 1 is placed on the production line of the equipment, and the Facing up, use spraying equipment to evenly spray ceramic glaze or resin glue on the surface with a thickness of 0.1-2mm to form a protective layer 3. After curing and drying, use a turning machine to turn the insulation layer 1 by 180 degrees, and turn the belt horizontally. Ribs or vertical and horizontal ribs 2 face down; spread steel wire mesh or mortar sheet and glass brazing mesh cloth 6 on the surface of insulation board 1, and use spraying equipment to evenly spray ceramic glaze or resin glue on the surface of insulation board 1 to form a thickness Finishing layer 4 of 0.2-5mm;

[0019] The insulation layer 1 and the composite decorative panel 4 ar...

Embodiment 2

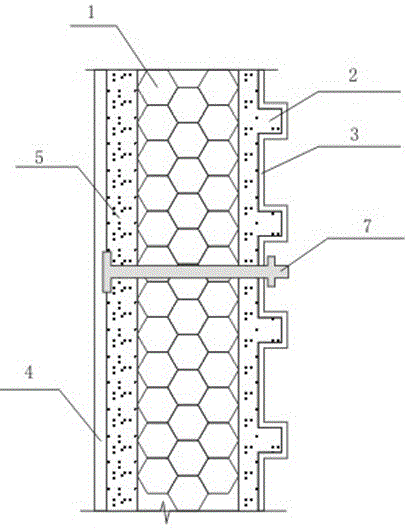

[0020] Example 2, see figure 2 , same as embodiment 1, the difference is that a lightweight fly ash board or cement fiber board layer 5 is pasted between the outer side of the insulation layer 1 and the facing layer 4, and the lightweight fly ash board or cement fiber board layer 5 and the facing Layer 4 is an integral structure.

[0021] The quasi-non-combustible and high thermal resistance decorative integrated composite formwork of the present invention uses the thermal insulation layer and composite decorative panel that have been manufactured in the factory in advance to form an integrated thermal insulation layer and composite decorative panel in the factory, with high bonding strength. The quality is guaranteed, the thickness of the insulation layer can be adjusted according to the energy-saving design requirements, and various performance indicators such as bonding strength meet the standard requirements, which is in line with the industrial development direction of f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com