Detachable steel-concrete composite beam adopting conical nut and bolt connectors

A technology of connectors and bolts, which is applied in the field of detachable steel-concrete composite beams, can solve problems such as construction dust, and achieve the effects of saving resources, enhancing bonding, and facilitating recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

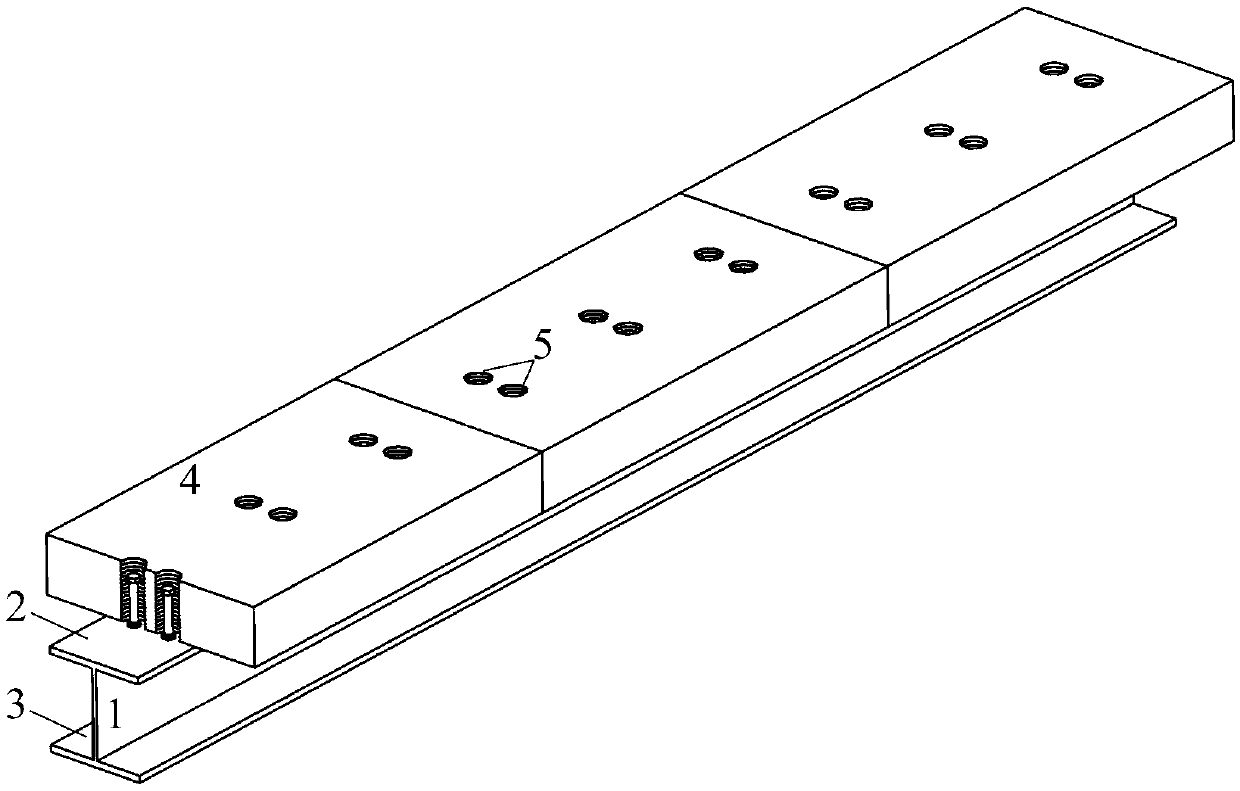

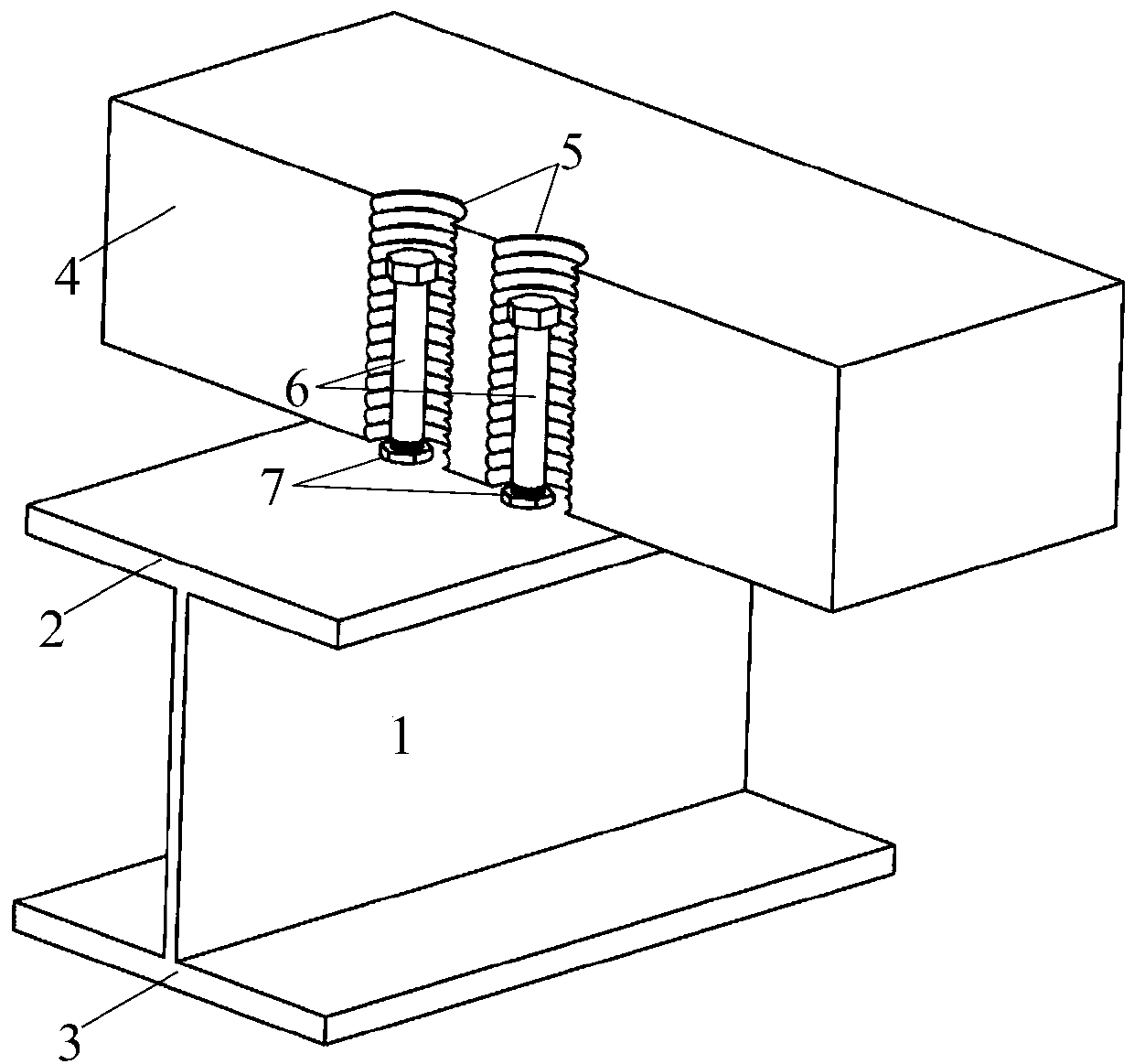

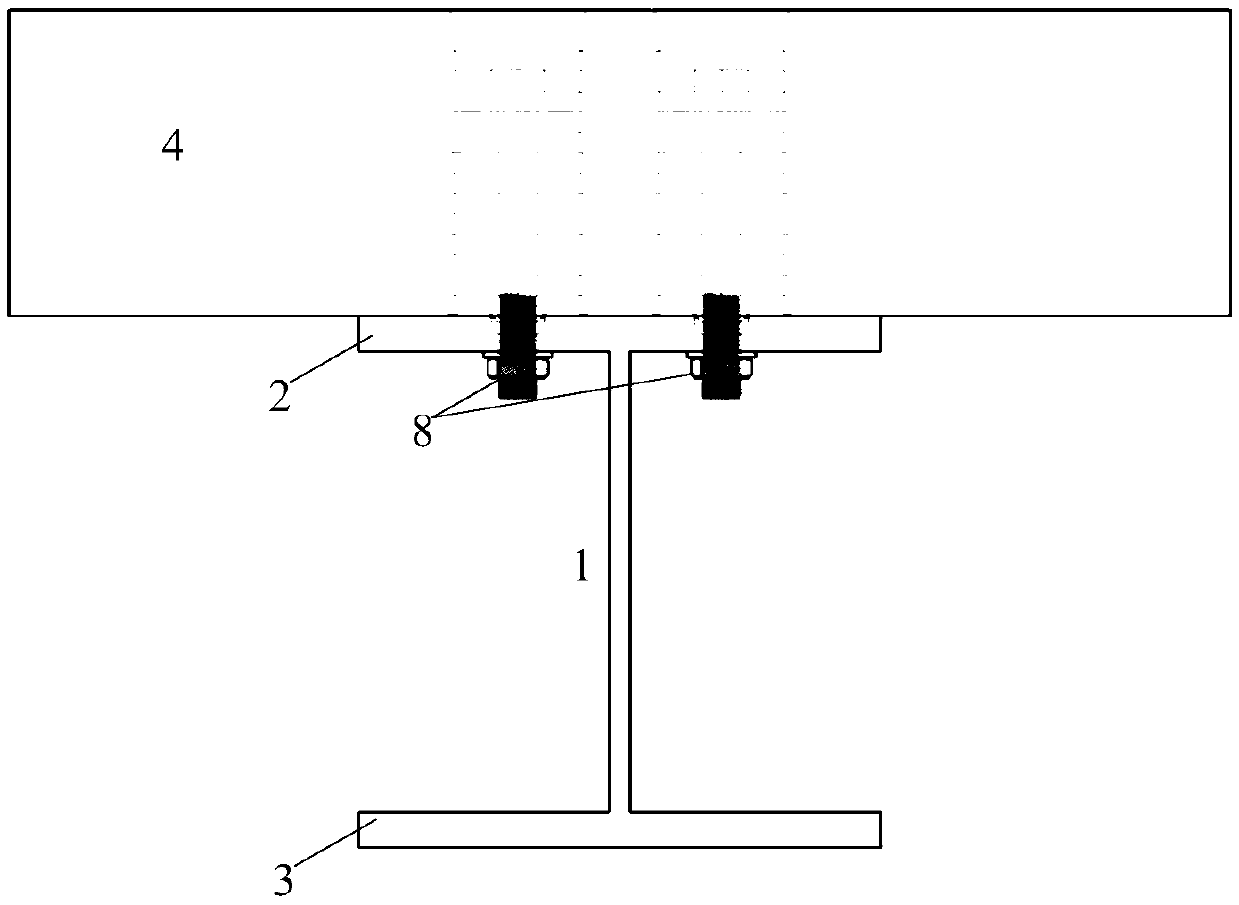

[0022] As shown in the accompanying drawings, a detachable steel-concrete composite beam using a tapered hexagonal lock nut bolt connection of the present invention includes an I-beam 1, and on the upper flange of the I-beam 1 2 is installed with a prefabricated concrete slab 4, and two rows of mounting holes on the left and right are respectively opened along the vertical direction on the prefabricated concrete slab 4, and the two rows of mounting holes on the left and right are respectively connected with the left and right sides of the web of the I-beam Correspondingly arranged on both sides, a bellows sleeve 5 is pre-embedded in each installation hole, and positioning holes are respectively opened on the upper flange 2 of the I-beam 1 and corresponding to each installation hole. Holes 10, bolt shear connectors are installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com