Vitrified micro bubble composite rock wool fireproof insulating plate and manufacturing method thereof

A fire-proof insulation board and vitrified micro-bead technology, which is applied in the directions of heat preservation, fire prevention, building components, etc., can solve the problems of cumbersome construction process, containing toxic substances, poor environmental protection performance, etc. The effect of increasing the fire rating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

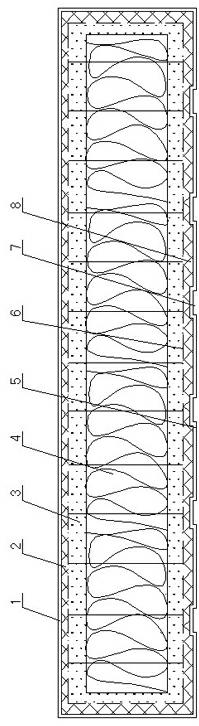

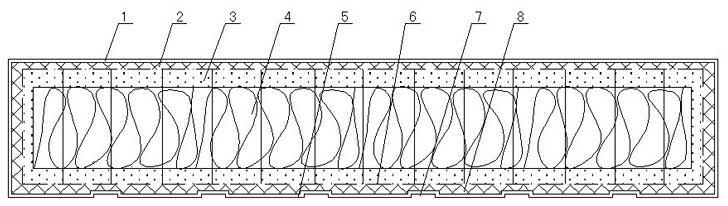

[0036] This embodiment is a vitrified microbead composite rock wool fireproof insulation board, its structure is as follows figure 1 , The vitrified microbead composite rock wool fireproof insulation board is a seven-layer structural board with the rock wool board as the base layer, and the vitrified microbead layer 3 is consolidated on the outer surface of the rock wool board 4 . The upper surface of the vitrified bead layer 3 is consolidated with an alkali-resistant mesh cloth layer to form an upper alkali-resistant mesh cloth layer 2 . The lower surface of the vitrified bead layer 3 is also consolidated with an alkali-resistant mesh cloth layer to form the lower alkali-resistant mesh cloth layer 8, and the two layers of alkali-resistant mesh cloth layers 2 and 8 use a special sewing machine and a mesh cloth connecting line 6. The rock wool board 4, the vitrified bead layer 3 and the upper and lower alkali-resistant mesh cloth layers are sewn together to form a connection re...

Embodiment 2

[0043] A method for making vitrified bead rock wool fireproof and thermal insulation composite board, which is carried out according to the following steps

[0044] ⑴Preparation of vitrified microbead insulation slurry, the weight ratio is: cement 42.5R150kg, vitrified microbeads 125kg, Wacker dispersible rubber powder 10kg, hydroxypropyl methylcellulose 2.5kg, Wacker phobic Water silicone 2.0kg, Class II fly ash 50kg, PP fiber 0.7kg, ash calcium 30kg, the water-cement ratio of the slurry is 1:1.2.

[0045] The particle size of vitrified microbeads is 0.5-1.5㎜, the bulk density is 80-120kg / m3, the thermal conductivity is 0.028-0.048w / m.k, the vitrification rate of beads is more than 95%, the water absorption rate is less than 35%, and the refractoriness is 1280℃~1360℃, operating temperature 800℃;

[0046] ⑵. Select the finished hydrophobic rock (mineral) wool board, which requires density ≥ 150㎏ / m3, width 600㎜, length 1200㎜, thickness 50㎜ as the substrate, and coat the top, b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com