Steel frame whole exterior wall board

A steel frame and exterior wall technology, applied in building components, buildings, building structures, etc., to achieve the effect of improving building assembly rate, reducing building construction, and convenient and quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

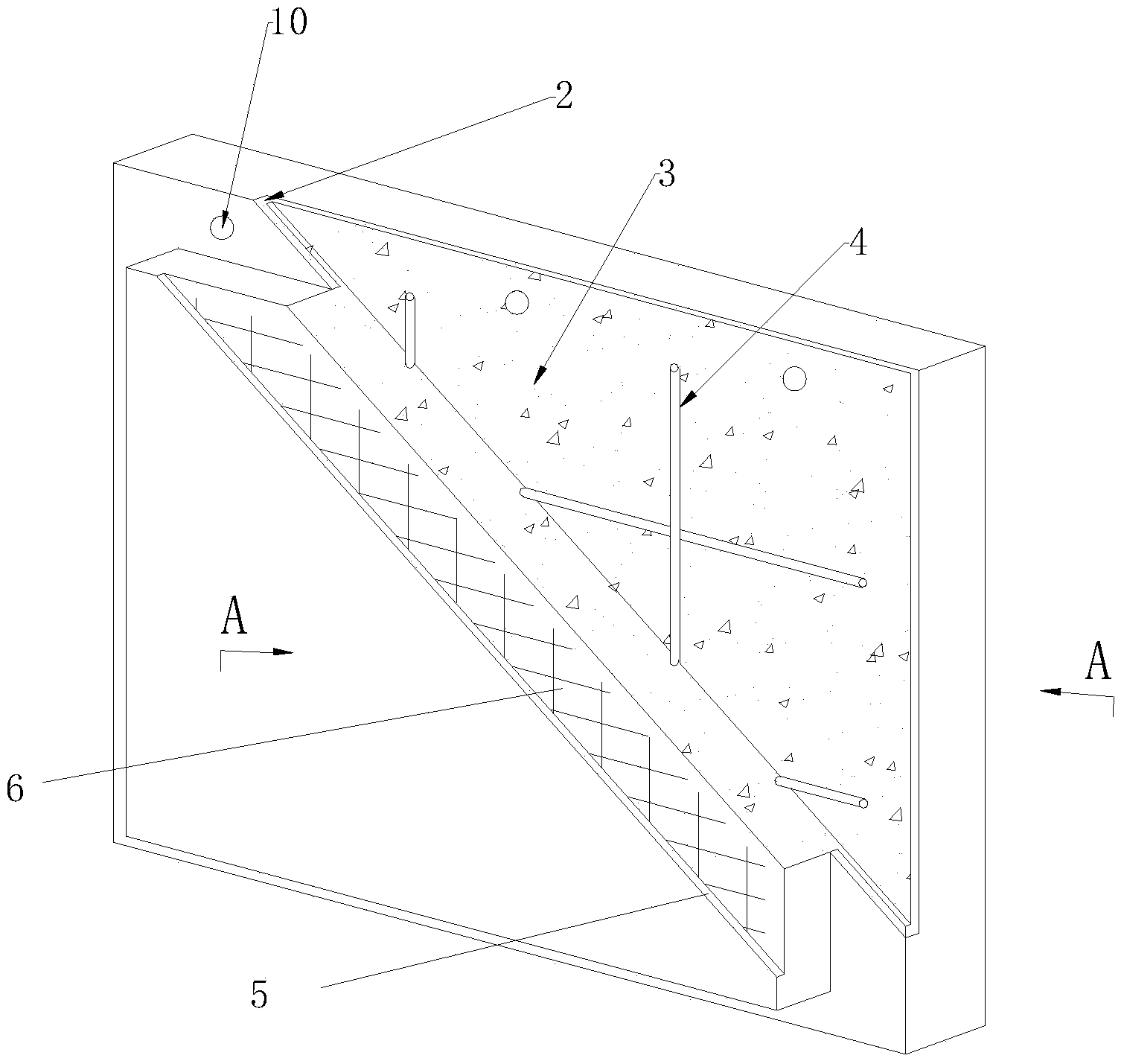

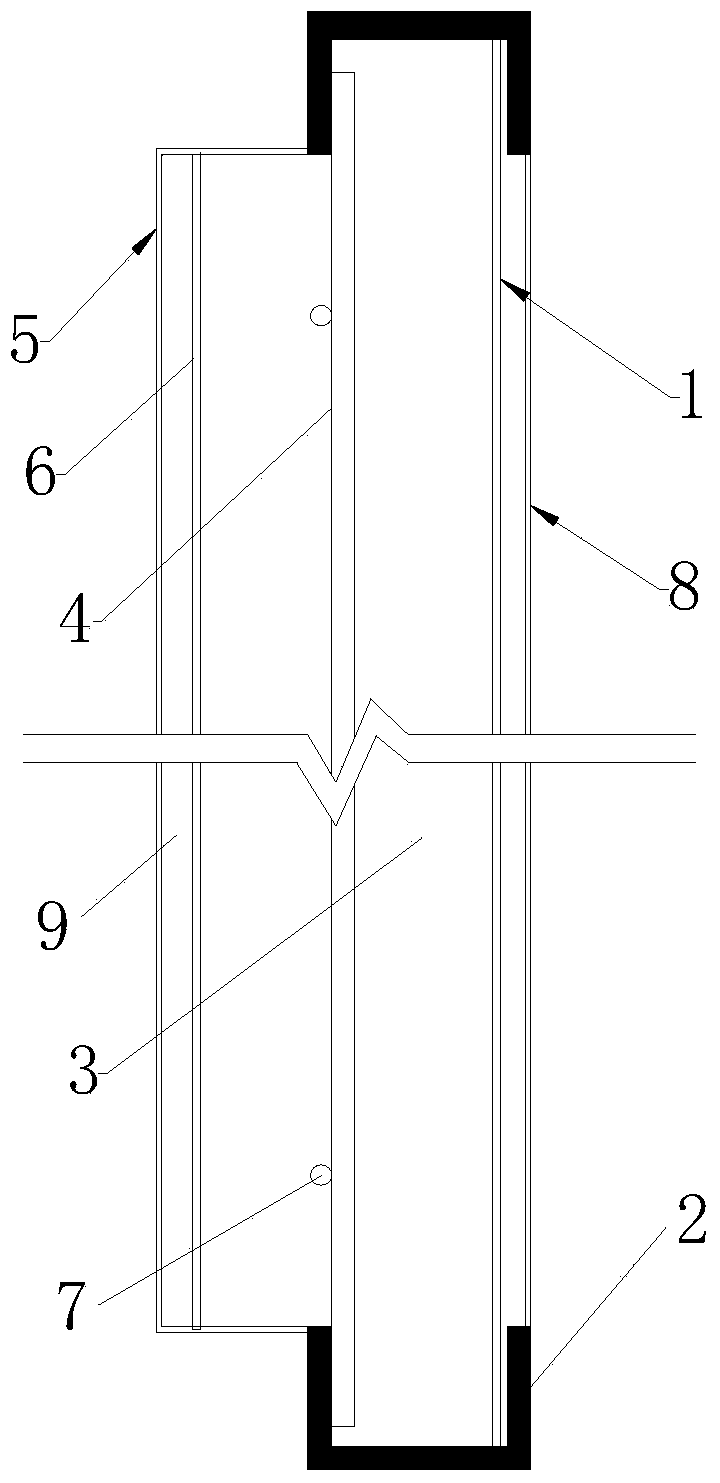

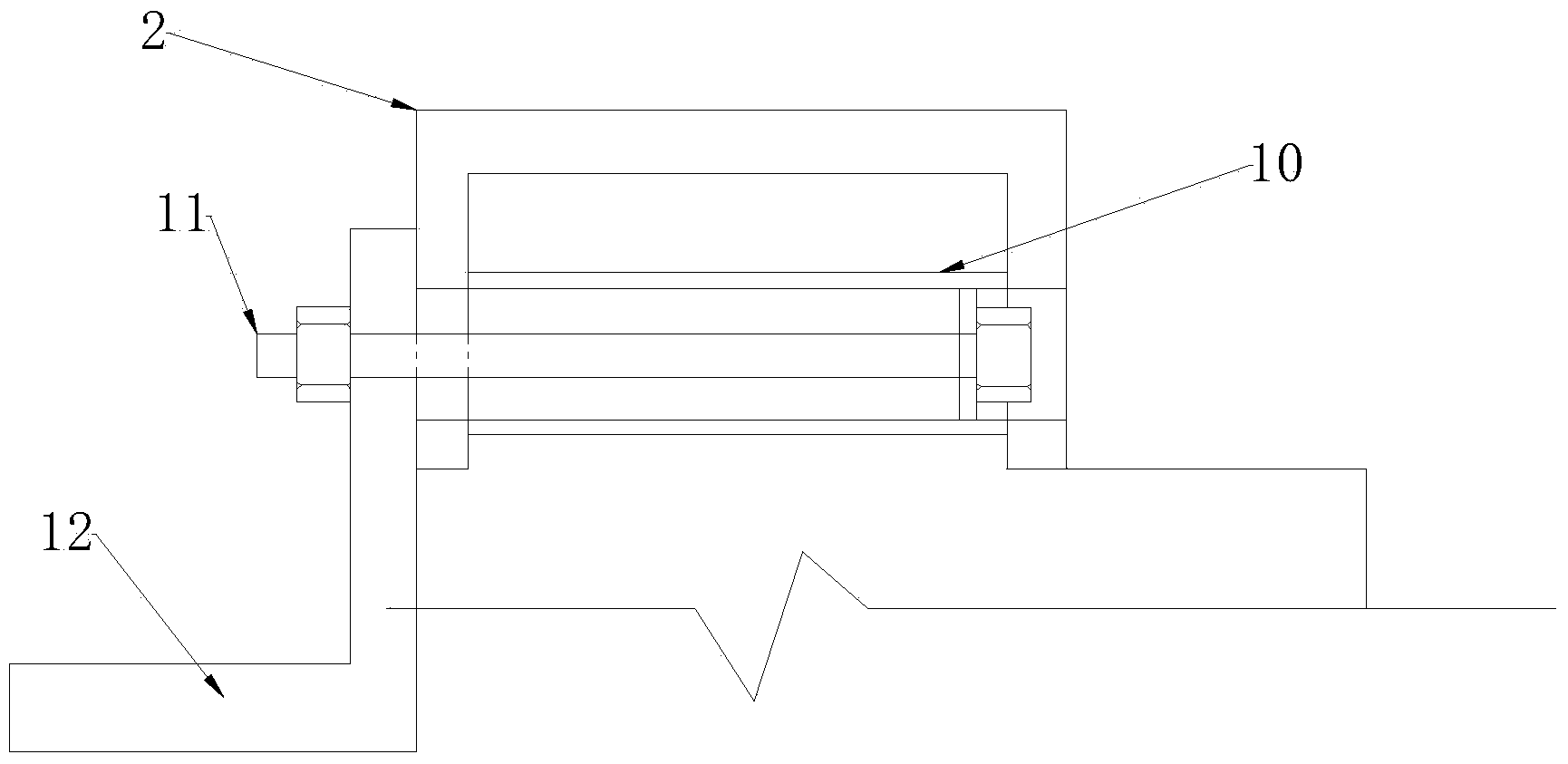

[0035] Under normal circumstances, the construction of the large U-shaped steel frame external wall will start after the construction of the main structure is completed. Firstly, install the external wall slab, and connect the external wall slab to the main body by bolts through connecting ears or connectors as required. Then push into the silicone weather-resistant glue 16 at the U-shaped steel frame position between the two outer wall slabs. Reserve the benzene board grooves for the two external wall slabs during prefabrication, paste a benzene board during construction, paste glass fiber mesh cloth on the outside of the benzene board, and finally spray waterproof mortar, the steel frame is inside the benzene board, and the benzene board acts as a break Bridge role.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com