Prefabricated highway intercepting ditch and manufacturing method thereof

A prefabricated assembly and manufacturing method technology, applied in the field of intercepting ditches, can solve the problems of high cost, waste of building materials, and long construction period, and achieve the effects of reducing the discharge of construction waste, saving building materials, and reducing the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] During specific implementation, there are many reinforced concrete components to be removed. The present invention takes the reinforced concrete support of the foundation pit support structure as an example, and the manufacturing methods of other reinforced concrete components are similar to the reinforced concrete support.

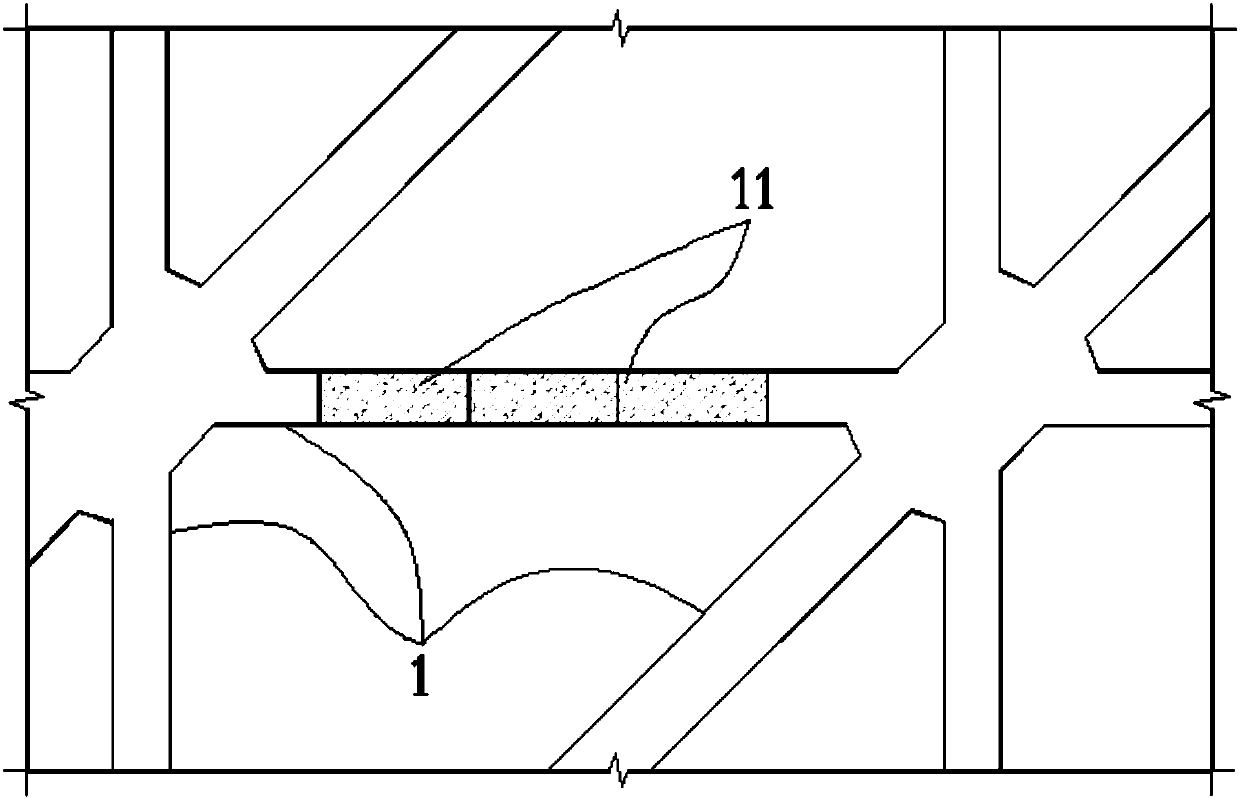

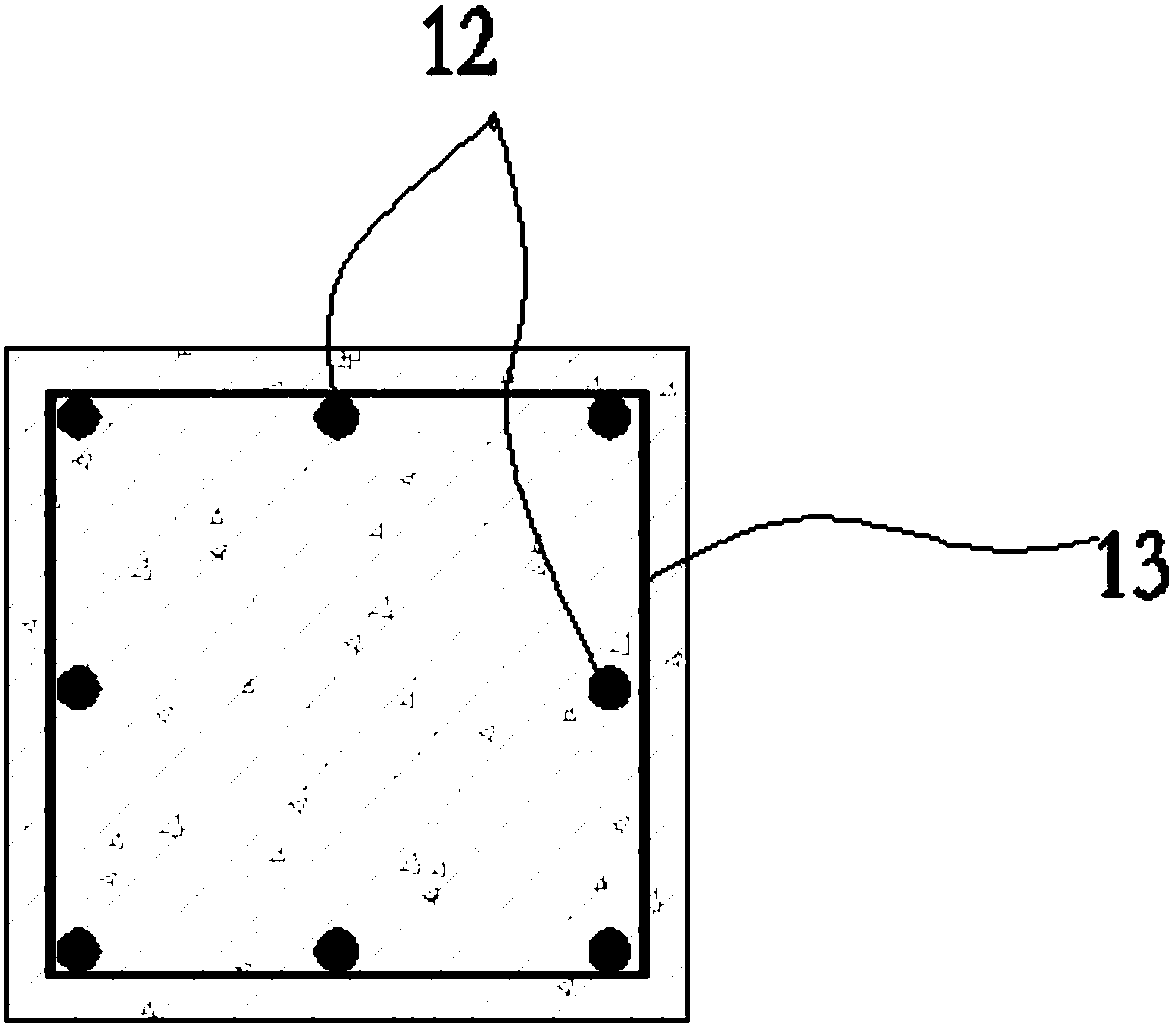

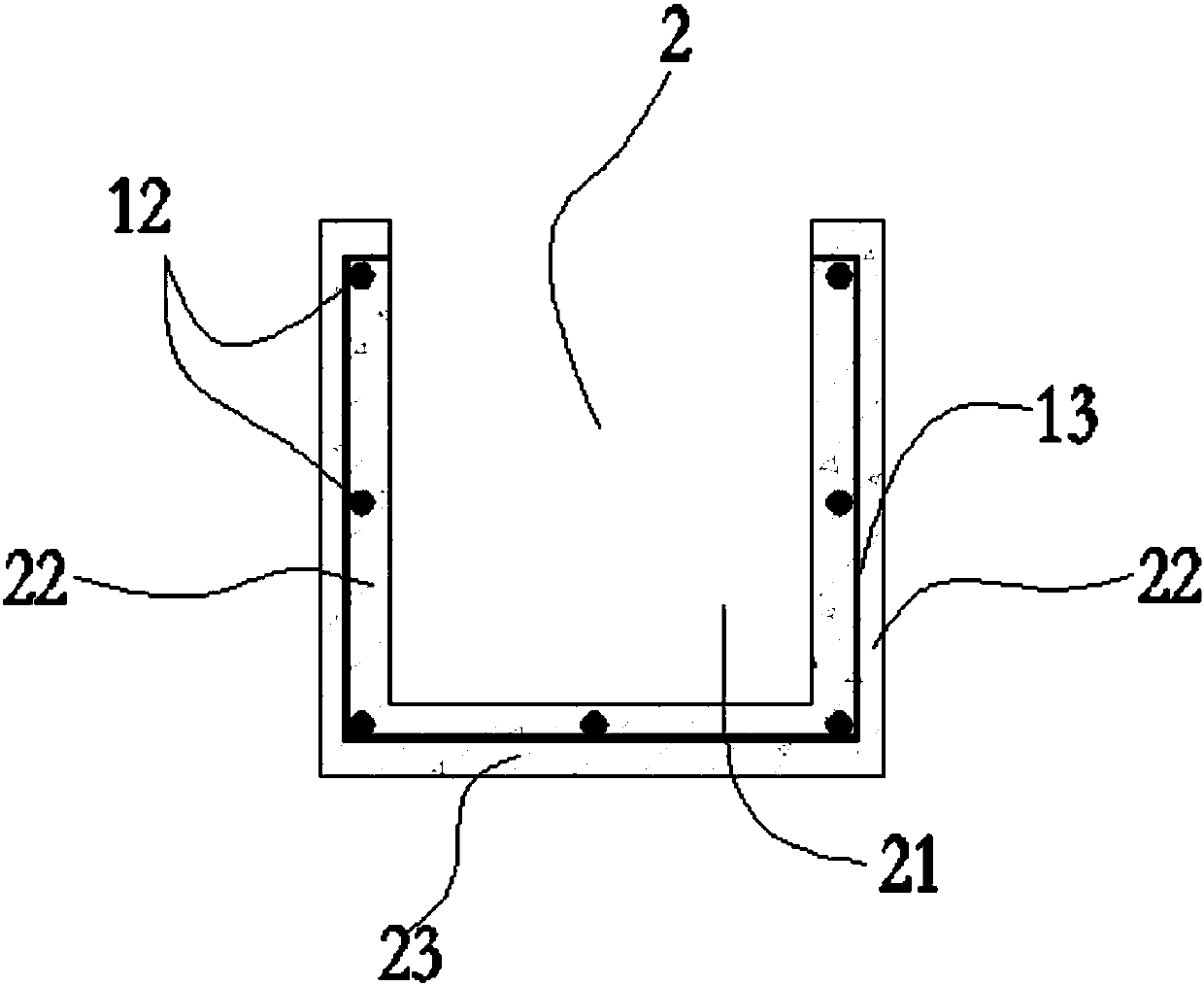

[0028] Such as Figure 1-7 As shown, a prefabricated assembled highway intercepting ditch, the intercepting ditch 2 is a U-shaped structure, including the intercepting ditch bottom plate 23 and the intercepting ditch side wall 22, the intercepting ditch bottom plate 23 and the intercepting ditch side The wall 22 is integrally formed. The intercepting ditch 2 is a reinforced concrete structure. The interior of the intercepting ditch 2 includes longitudinally stressed steel bars 12 and stirrups 13. The botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com