Construction method for thermal insulating sandwich concrete external wall panel with steel beams and steel columns

A technology of thermal insulation concrete and construction method, which is applied in the processing of building materials, construction, building structure, etc., can solve the problems of slow construction speed, complex process, large on-site construction workload, etc., to achieve fast construction speed and reduce wet work. , the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

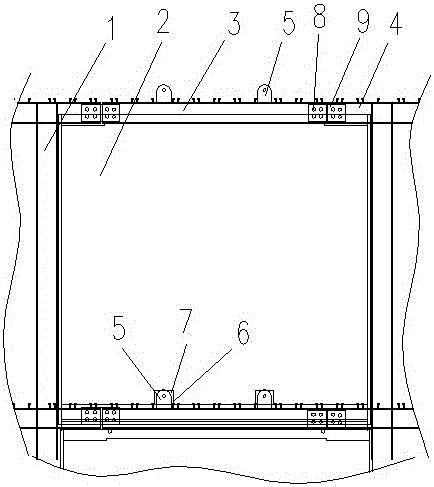

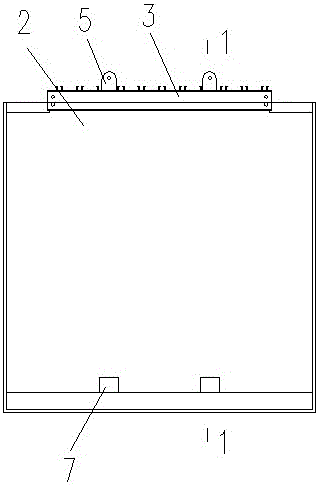

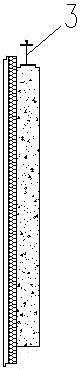

[0028] The present invention is described in detail below with reference to accompanying drawing and embodiment:

[0029] attached Figure 1-4 It can be seen that a construction method of a sandwich thermal insulation concrete exterior wall panel and steel beams and steel columns comprises the following steps:

[0030] The steel column 1 is hoisted in place, and the steel column, steel beam axis and wall installation control line pop up on the floor;

[0031] Sandwich thermal insulation concrete exterior wall panel 2 hoisting;

[0032] Adjust the verticality of the sandwich insulation concrete exterior wall panel 2;

[0033] The steel beam 3 of the sandwich thermal insulation concrete exterior wall plate is connected with the steel column corbel 4 by bolts;

[0034] The lifting lug 5 of the steel beam of the lower sandwich thermal insulation concrete external wall panel is inserted into the reserved opening 6 of the upper sandwich thermal insulation concrete external wall p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com