Production of cavity molding shell member for cast-in-situs concrete

一种制作方法、空腔模的技术,应用在建筑构件、模具、制造工具等方向,能够解决整体强度和刚度差、空腔模壳构件破裂等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0068] A method for manufacturing a cavity formwork member for cast-in-place concrete, characterized in that:

[0069] (1), making an open cavity formwork in the mould;

[0070] (2), make slurry lower bottom 3 at lower bottom mold;

[0071] (3), before the lower bottom (3) slurry is solidified and hardened, the opening edge of the pre-made open cavity formwork and the lower bottom slurry are bonded into a whole;

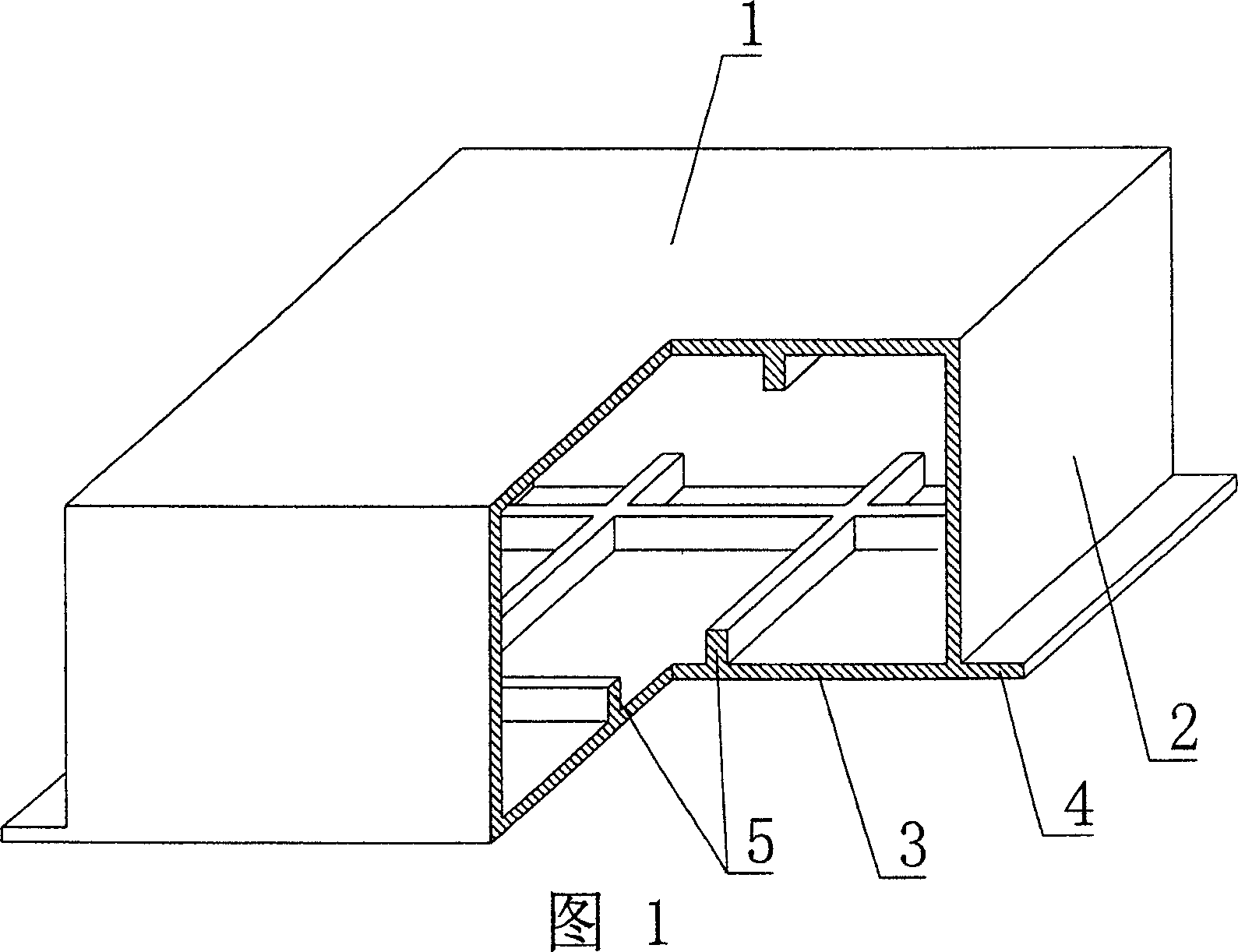

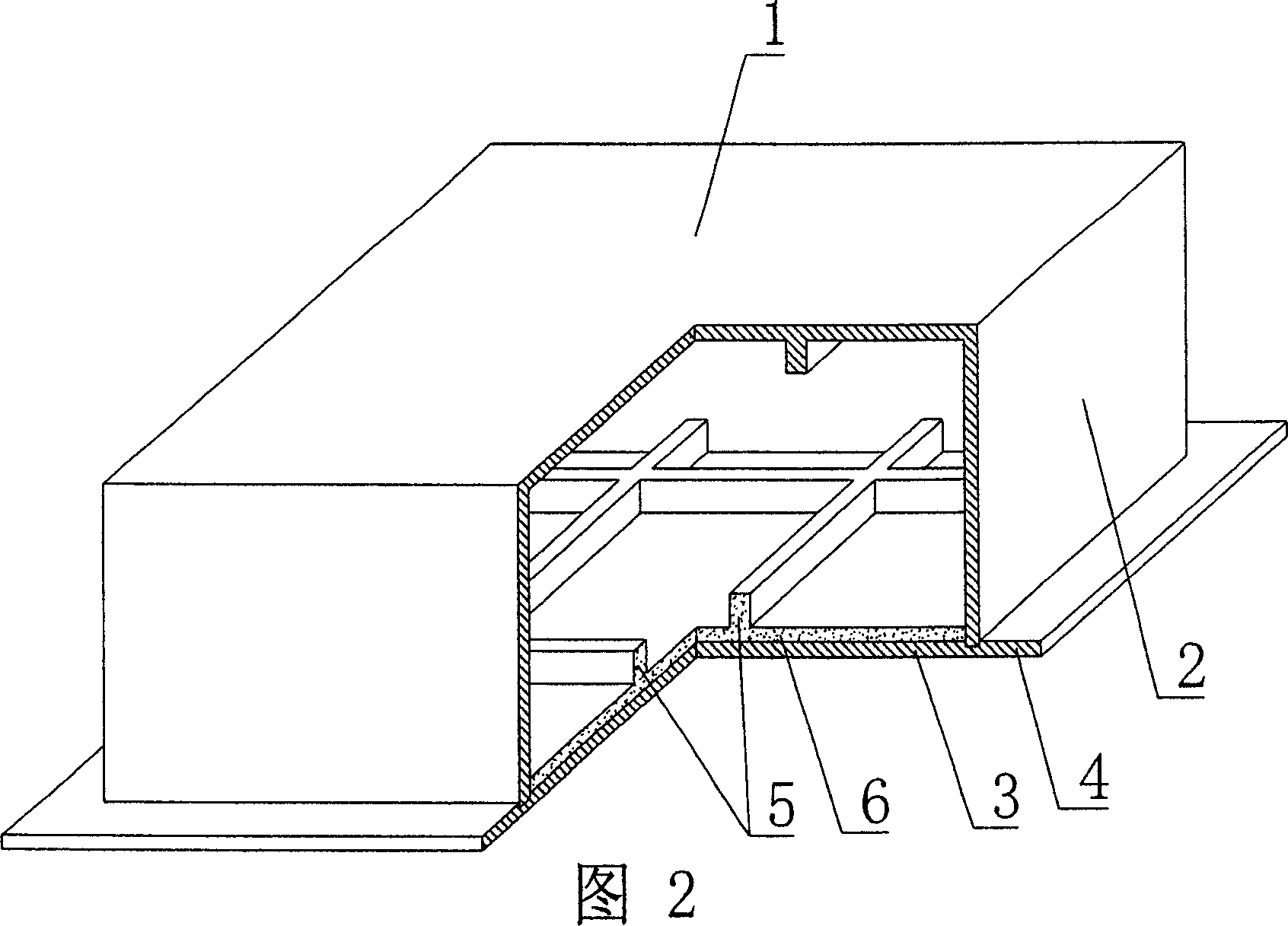

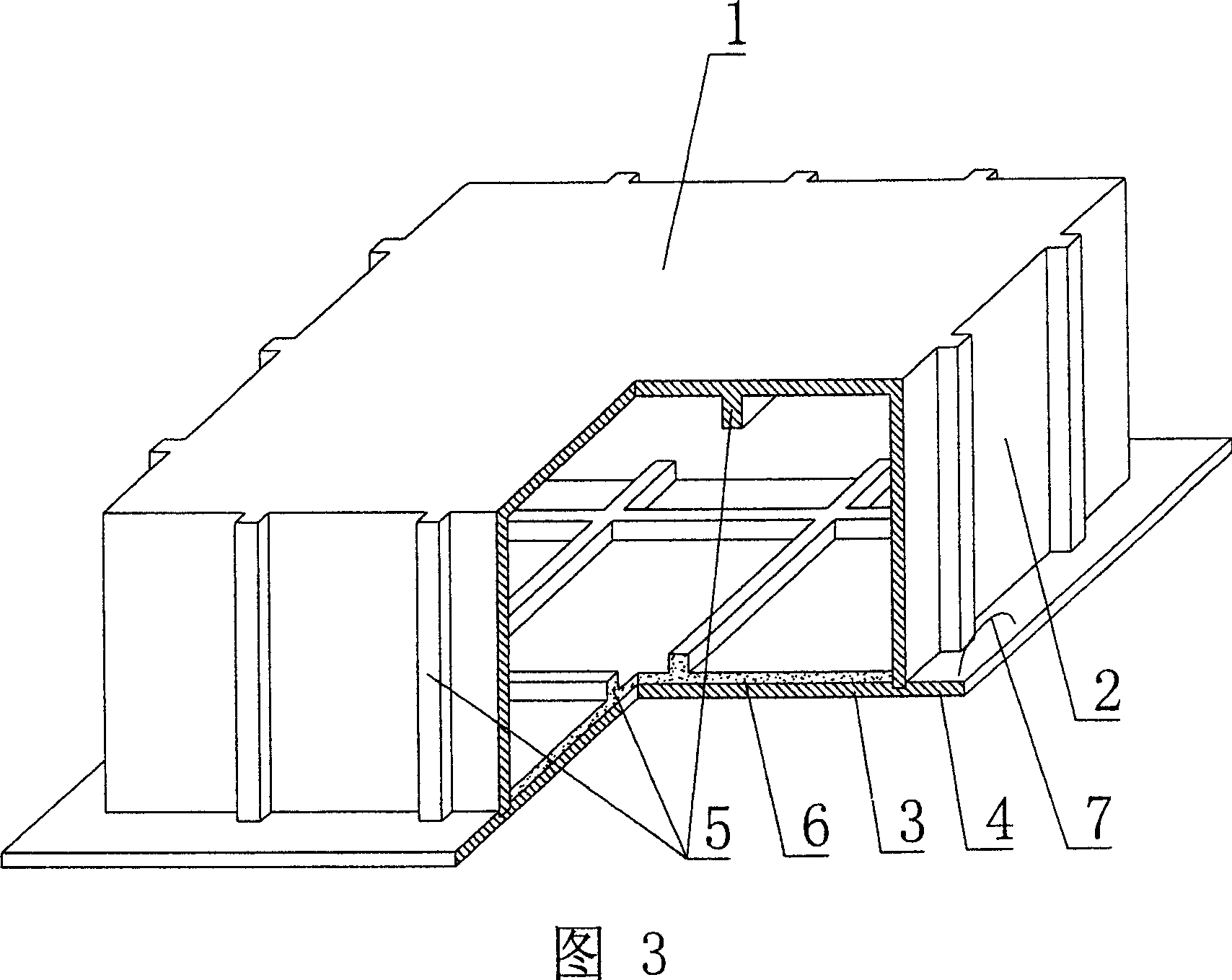

[0072] (4), maintenance demoulding. In the accompanying drawings, 1 is an upper plate, 2 is a surrounding side wall, 3 is a lower bottom, 4 is a pick plate, and 5 is a reinforcing rib. In the following drawings, those with the same number have the same description.

[0073] Another manufacturing method of a cavity formwork member for cast-in-place concrete, characterized in that:

[0074] (1), in the mould, make one layer of cementing mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com