Prefabricated overhead soft heat preservation pipe system, manufacturing method and transportation and installation method

A production method and installation method technology, applied in the direction of thermal insulation, pipeline protection through thermal insulation, pipeline protection, etc., can solve the problems of wasted site, long construction time, increased management cost, etc., to reduce comprehensive energy consumption and improve energy utilization rate , the effect of fast construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

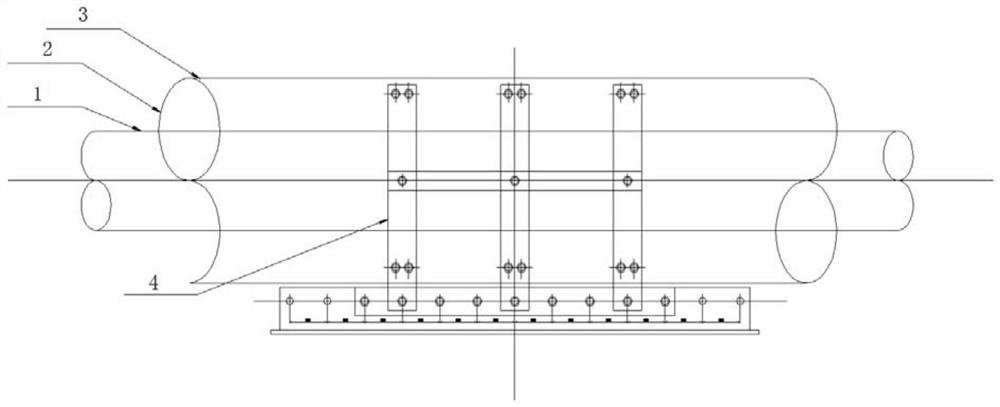

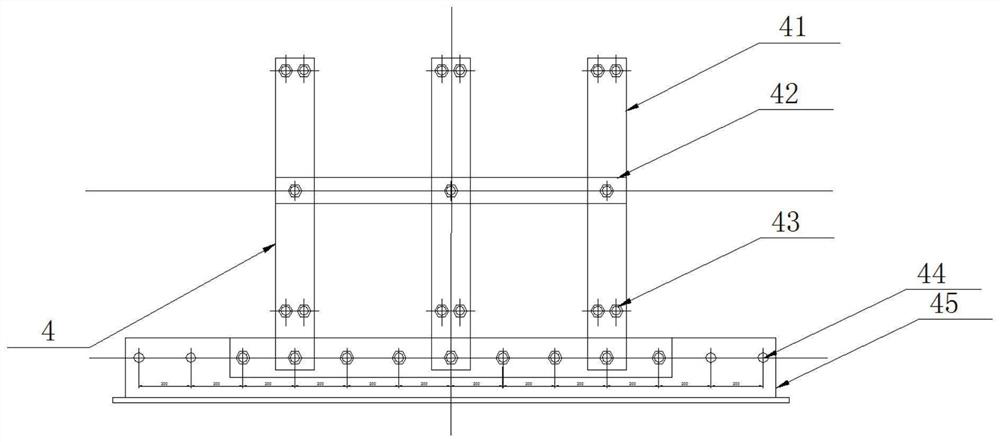

[0047] Take the working tube with a steam temperature of 400°C and a specification of DN600 as an example to illustrate. Such as Figures 1 to 4 , a prefabricated overhead soft thermal insulation pipe system, including a working pipe 1, a composite thermal insulation layer 2, an outer sheath 3 and a vertical heat insulation pipe support 4. There are multiple working tubes 1 and they are connected by coaxial welding. The vertical heat-insulating tube support 4 is installed on the corresponding working tube 1. The composite thermal insulation layer 2 wraps the corresponding parts of the working tube 1 and the vertical heat-insulating tube support 4. , the outer sheath 3 wraps the corresponding parts of the composite thermal insulation layer 2 and the vertical heat insulation pipe holder 4.

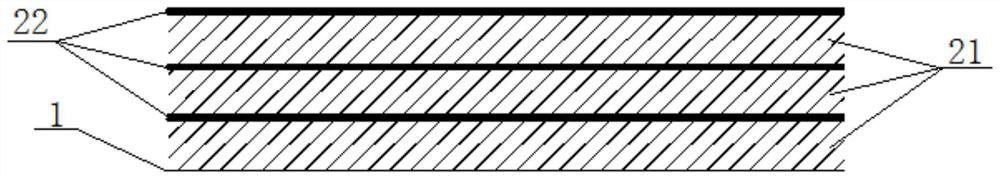

[0048] Composite thermal insulation layer 2 comprises thermal insulation layer 21 and reflective layer 22, and thermal insulation layer 21 and reflective layer 22 are alternately provided w...

Embodiment 2

[0068] Taking a working tube with a steam temperature of 300°C and a specification of DN600 as an example, the difference between this embodiment and the first embodiment is that the thickness of the aluminum foil in the reflective layer is 0.015mm, and the specification of the glass fiber cloth is 200g / m 2 , The temperature-resistant glue can withstand the high temperature of 300 ℃. The insulation layer 21 adopts the combination of aluminum silicate needle-punched blanket and glass wool.

Embodiment 3

[0070] The transmission speed of the headstock for pipe cutting and beveling is related to the nominal diameter of the working pipe, and the specific values are as follows:

[0071] Numbering Pipe Nominal Diameter (DNmm) Cutting head transmission speed / min 1 200 35 2 250 30 3 300 20 4 350 15 5 400 14 6 450 12 7 500 11 8 550 9 9 600 9 10 700 8 11 800 7

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com