Rotatable pre-embedded external member and prefabricated assembly type wall structure

A wall structure, prefabricated assembly technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of complex structure of embedded connectors, inconvenient wall assembly and construction, inconvenient transportation and storage, etc. Convenient construction, strong overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

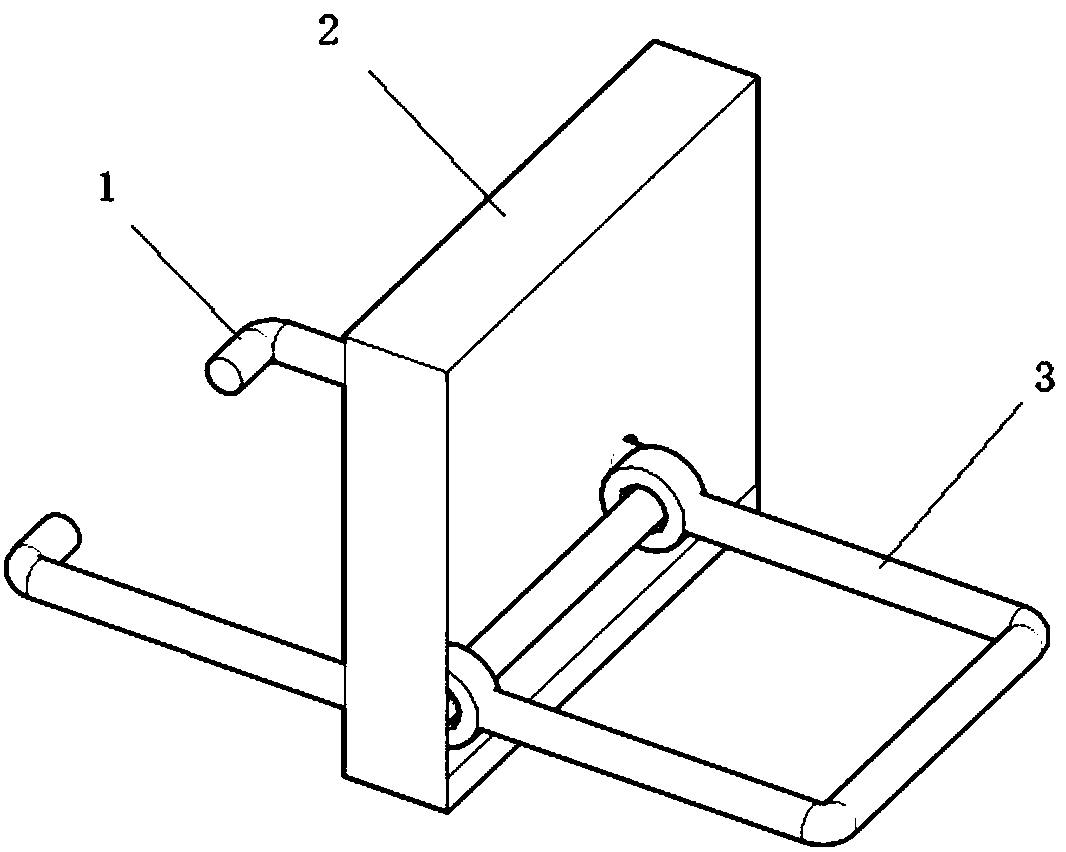

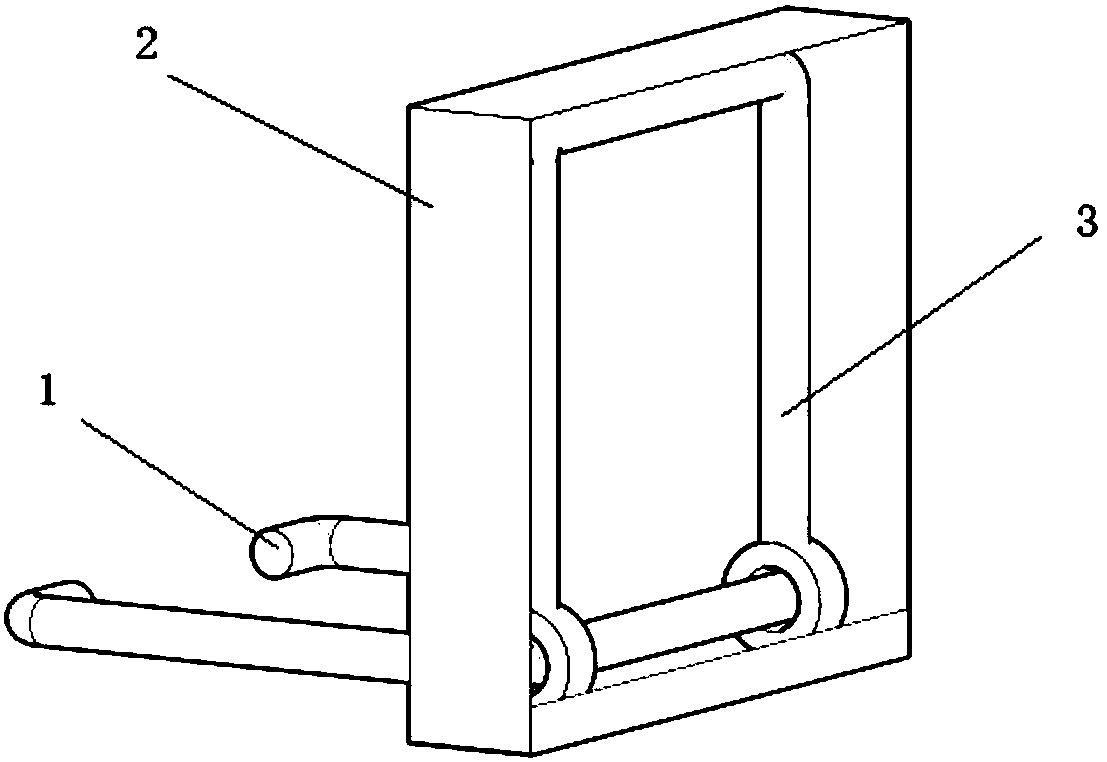

[0036] Such as Figure 1-9 As shown, the embodiment of the present invention provides a rotatable pre-embedded kit, which includes a pre-embedded C-shaped anchor bar 1 , a pre-embedded sleeve box 2 and a U-shaped bar 3 .

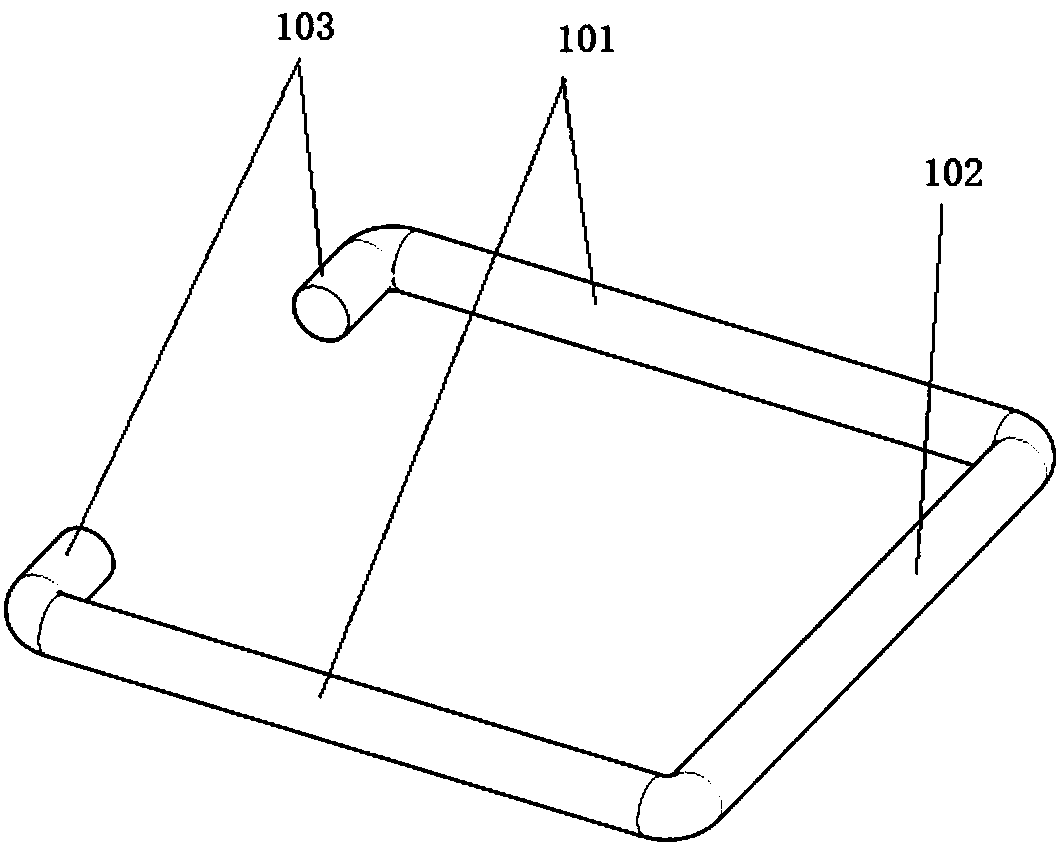

[0037] Wherein, the pre-embedded C-shaped anchoring steel bar 1 includes two first vertical parts 101 and a first transverse connection part 102 connecting the top ends of the two first vertical parts 101, and the pre-embedded casing 2 is a rectangular box with an open end, The U-shaped steel bar 3 includes two second vertical portions 301 and a second transverse connecting portion 302 connecting top ends of the two second vertical portions 301 .

[0038] The first transverse connecting portion 102 is arranged in the embedded casing 2, and the embedded casing 2 is provided with two through holes 201 corresponding to the first vertical portion 101, and the two first vertical portions 101 respectively pass through Two through holes 201 are provided outside th...

Embodiment 2

[0047] Such as Figure 10-11 As shown, the embodiment of the present invention provides a prefabricated assembled wall structure, including two shear walls 7A and 7B with a gap between them, on the opposite wall formwork between the two shear walls 7A and 7B Correspondingly, there are a plurality of embedded sets 6A and 6B arranged sequentially from top to bottom. The embedded sets 6A and 6B are the rotatable embedded sets described in the first embodiment above, wherein the embedded sets in the embedded sets The C-shaped anchoring steel bar and the embedded box are arranged in the shear wall, and the U-shaped steel bar is rotatably arranged outside the shear wall. In the gap region between the two shear walls 7A and 7B there is a cast-in-place concrete strip 8 .

[0048] In the prefabricated wall structure of the embodiment of the present invention, pre-embedded sets 6A and 6B are respectively arranged on the wall templates facing each other between the two shear walls 7A an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com