Ultrahigh and huge steel structure vibration attenuation integrated system

An integrated system and steel structure technology, applied in the direction of building components, building types, earthquake resistance, etc., can solve the problems of slow construction speed, waste of structural materials and social resources, reduce wind loads, etc. Low steel content, improving the effect of structural wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

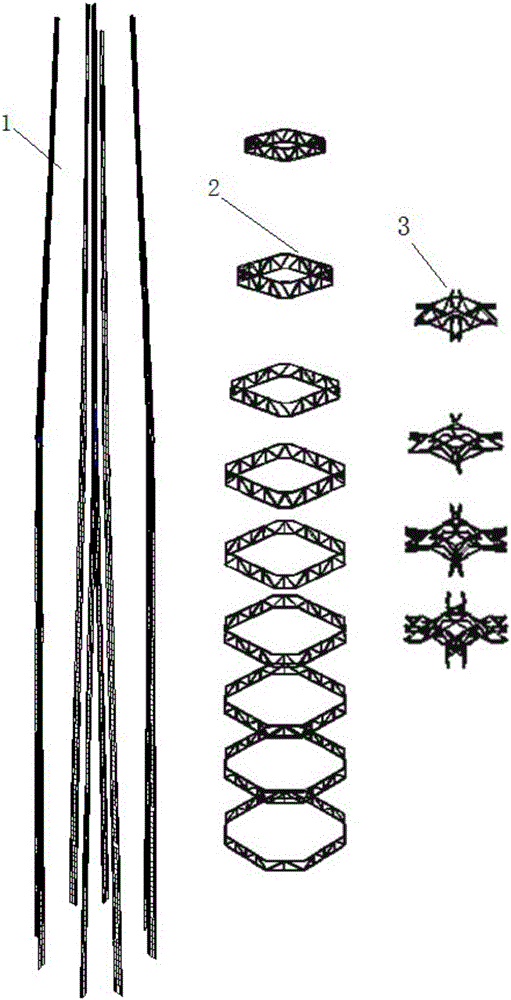

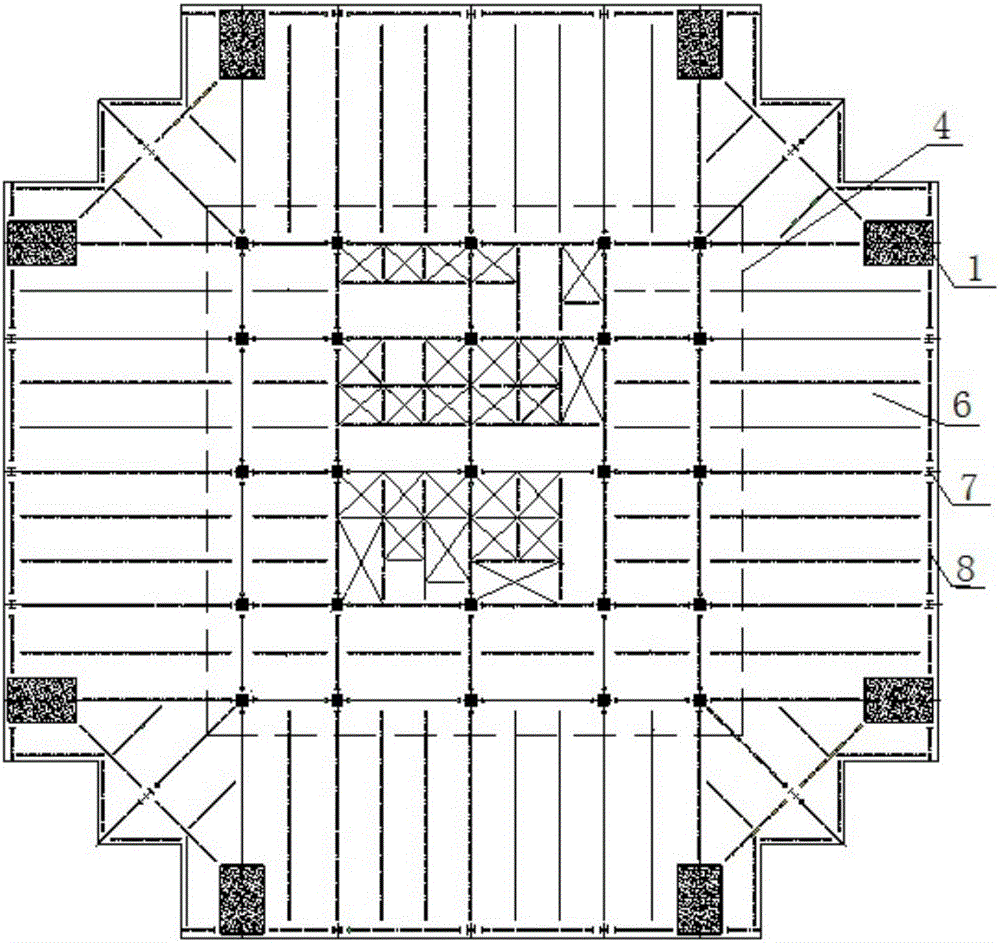

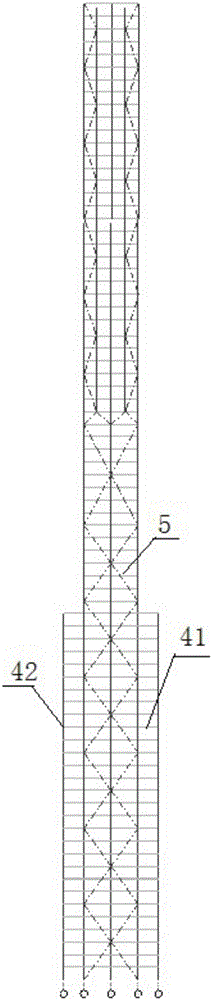

[0035] An ultra-high giant steel structure vibration reduction integrated system, such as Figure 1~3 As shown, it is applied to super high-rise buildings, including super-high giant steel structure units and vibration-damping equipment units set on super-high giant steel structure units. The secondary structure on the unit is composed of sub-units, and the sub-units of the main structure include a giant steel frame and a steel core tube 4 ( figure 2 Within the range of the dotted line frame), the giant steel frame is composed of a plurality of giant columns 1 and ring-belt trusses 2 arranged on the giant columns 1, and the shock-absorbing equipment unit includes a viscous damping mechanism 10 or / and a tuned vibration-damping mechanism.

[0036] The belt truss 2 of the giant steel frame is arranged on the equipment floor or the refuge floor of a super high-rise building, occupying a floor height of 1 to 2 floors, and a section is formed between two adjacent belt trusses 2, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com