Assembled steel-concrete composite structure metro station and assembling method

A hybrid structure and subway station technology, applied in underwater structures, infrastructure engineering, water conservancy projects, etc., can solve problems such as low industrialization, noise pollution, and poor on-site operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

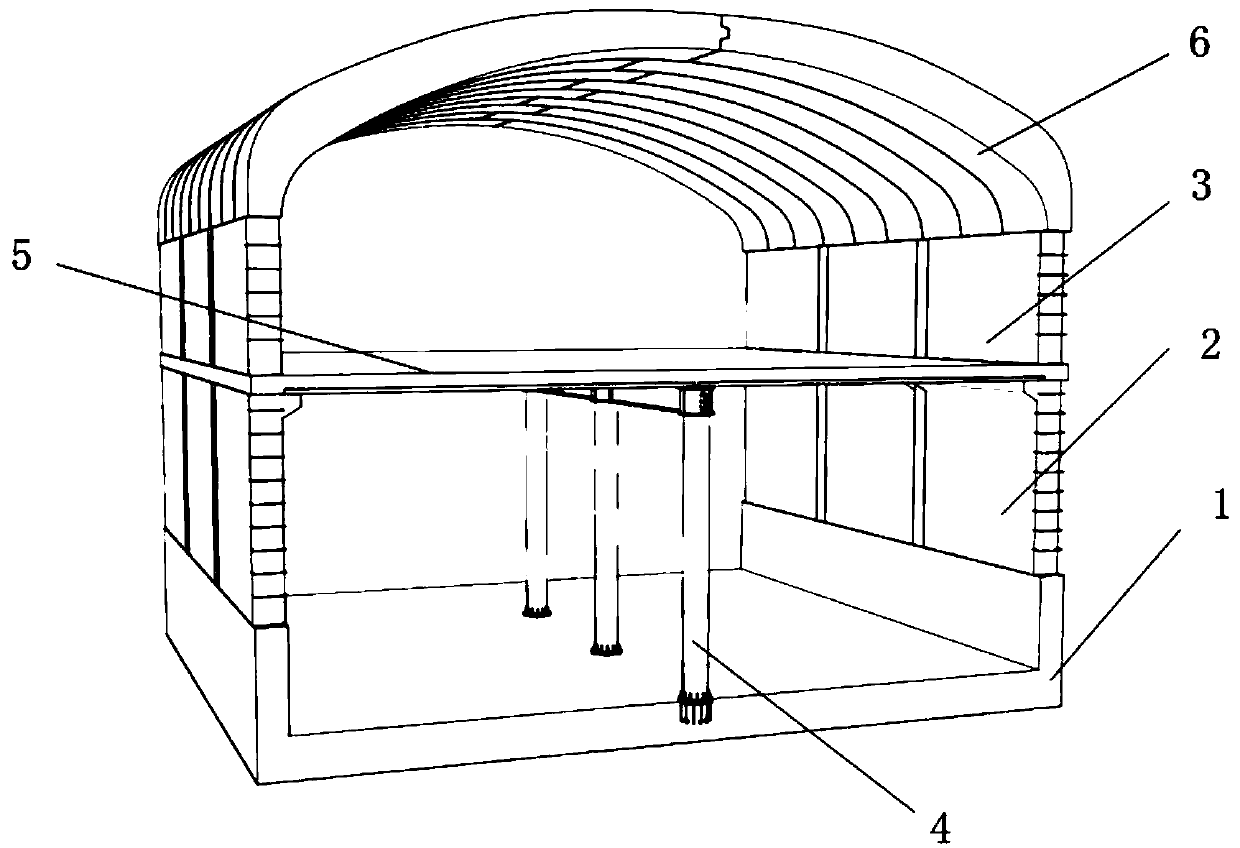

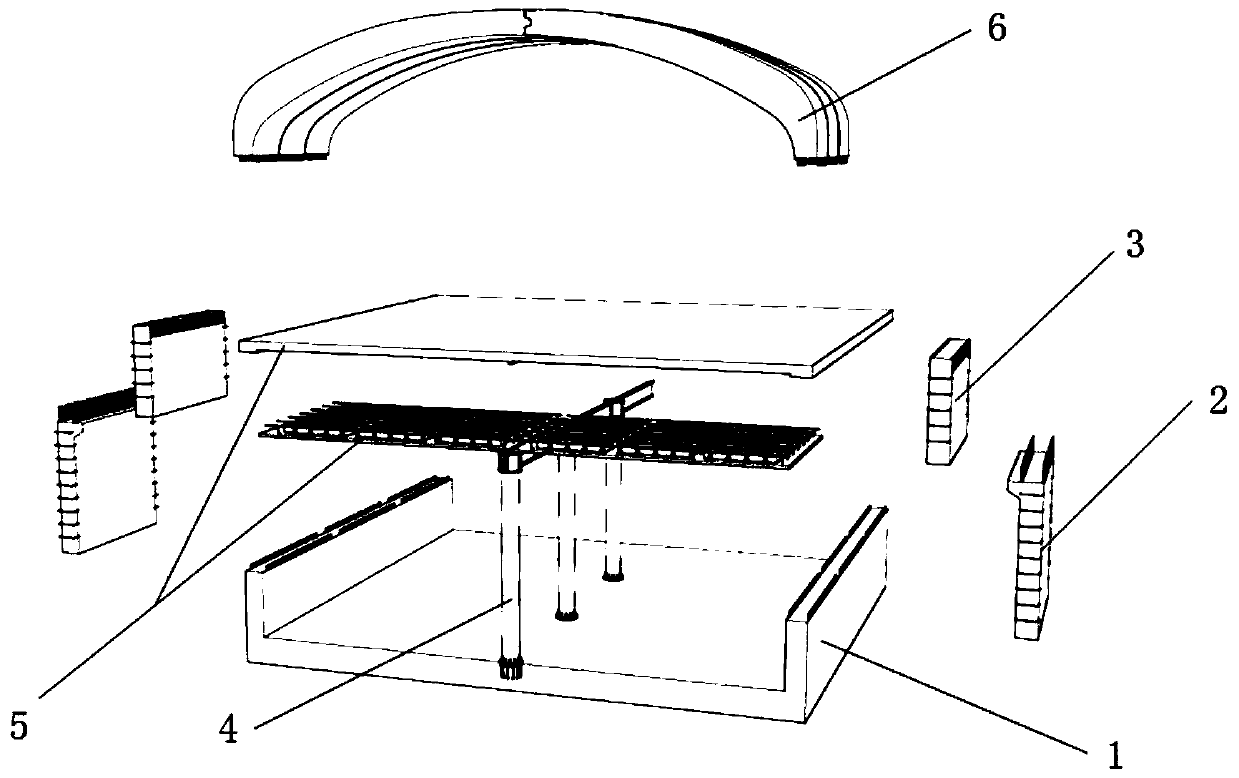

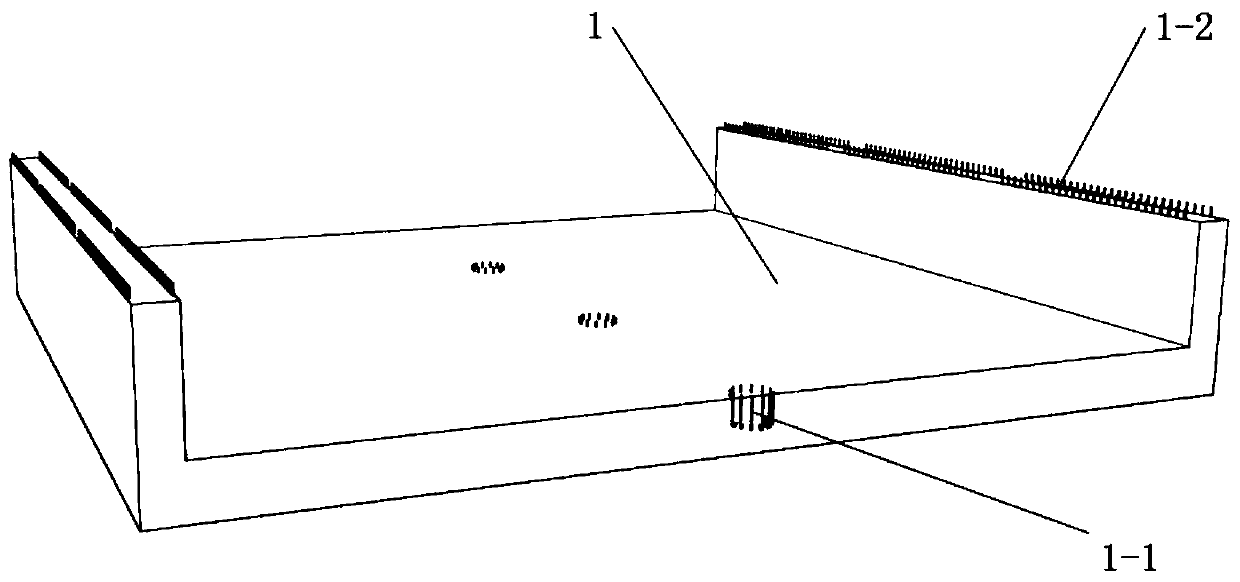

[0078] combined with Figure 1 to Figure 11 Illustrate the specific embodiment of the present invention: the assembled steel-concrete mixed structure subway station of a kind of arch structure of the present invention, as figure 1 with figure 2 As shown, it includes bottom plate 1, side wall 2 of the lower second floor, side wall 3 of the next floor, steel pipe concrete composite beam, laminated floor 5 and roof 6. The side wall 2 of the second floor is provided with the side wall 3 of the next floor, and the superimposed floor 5 is horizontally arranged between the side wall 2 of the lower second floor and the side wall 3 of the next floor, and a steel pipe is arranged between the superimposed floor 5 and the bottom plate 1 Concrete composite beams, the top plate 6 is arranged on the side wall 3 of the next layer and is located above the laminated floor slab 5, the top plate 6 includes a long vault member 6-1 and a short vault member 6-2, and a long vault member 6-1 Cooper...

specific Embodiment approach 2

[0103] combined with Figure 3 to Figure 10 , Figure 12 and Figure 13 Illustrate another specific embodiment of the present invention: the assembled steel-concrete mixed structure subway station of a kind of rectangular structure of the present invention, as Figure 12 As shown, it includes bottom plate 1, side wall 2 of the lower second floor, side wall 3 of the next floor, steel pipe concrete composite beam, laminated floor 5 and roof 6. The side wall 2 of the second floor is provided with the side wall 3 of the next floor, and the superimposed floor 5 is horizontally arranged between the side wall 2 of the lower second floor and the side wall 3 of the next floor, and a steel pipe is arranged between the superimposed floor 5 and the bottom plate 1 Concrete composite beam, the roof 6 is arranged on the side wall 3 of the next layer and is located above the laminated floor 5, the roof 6 includes a roof member 6-3, the structure of the roof member 6-3 is the same as that of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com