Scrap edge distribution device and distribution method

A technology for distributing devices and waste materials, which is applied in the directions of transportation and packaging, loading/unloading, etc., and can solve the problem of low efficiency of waste edge collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

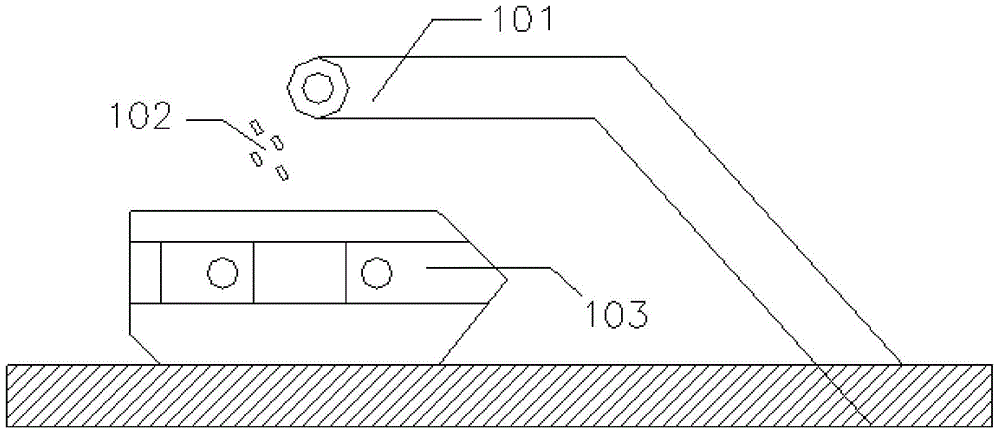

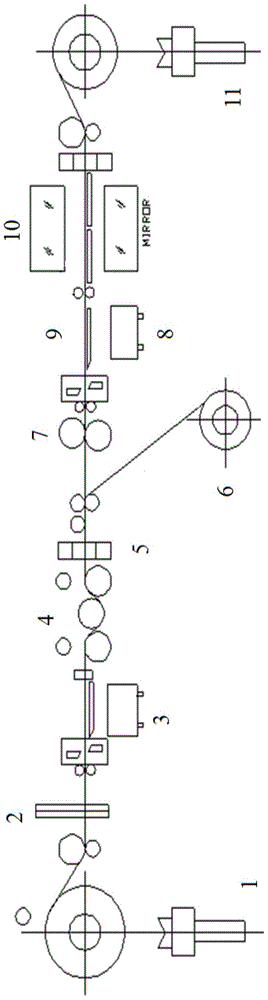

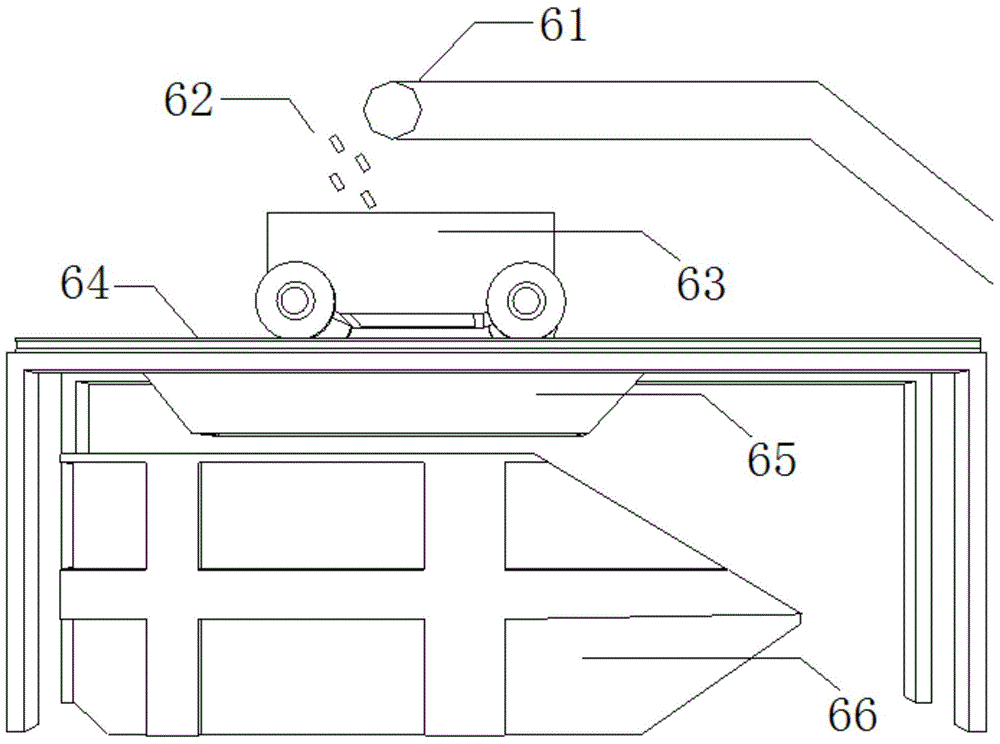

[0018] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0019] Since the cut waste edges cannot be evenly stacked in the waste edge collection bucket, only a small amount of waste edges can be placed in the waste edge collection bucket, which not only affects the production capacity of the unit, but also increases the number of lifting and transportation of the waste edge collection bucket. The present invention calculates the amount of waste transported by the waste transport belt through the operating speed of the unit and the amount of trimming, and then controls the moving speed of the cloth trolley to realize that the waste can be evenly placed in the waste hopper, which solves the problem of low utilization rate of the waste hopper For this problem, reduce the number of times the finishing unit lifts the waste hopper, increase the operating rate and increase the output.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com