Wastewater processing system during production of HIV (Human Immunodeficiency Virus) prevention medicament

A wastewater treatment system and wastewater technology, applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. and other problems, to achieve the effect of improving biodegradability, improving removal effect, and reducing the number of times of material lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

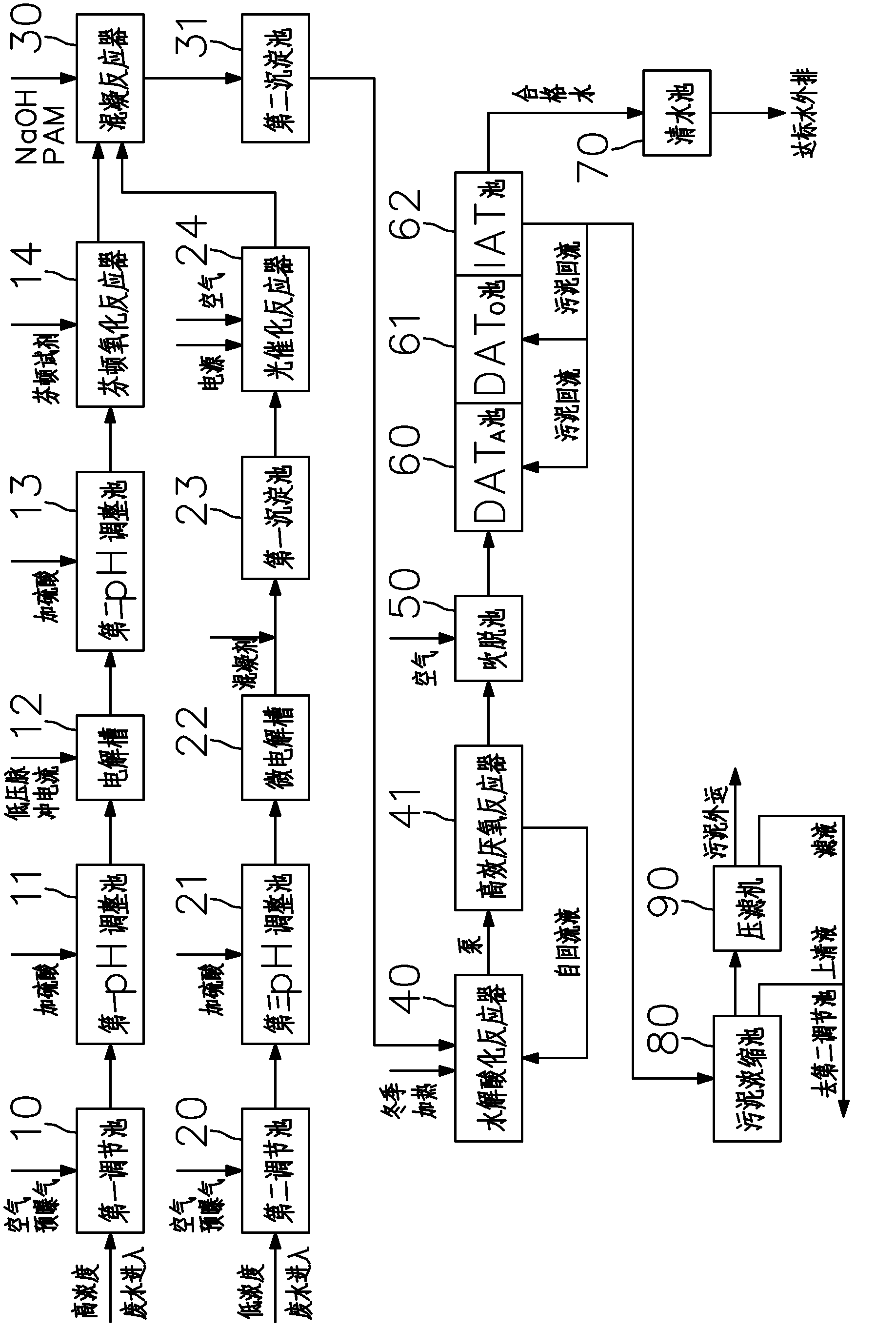

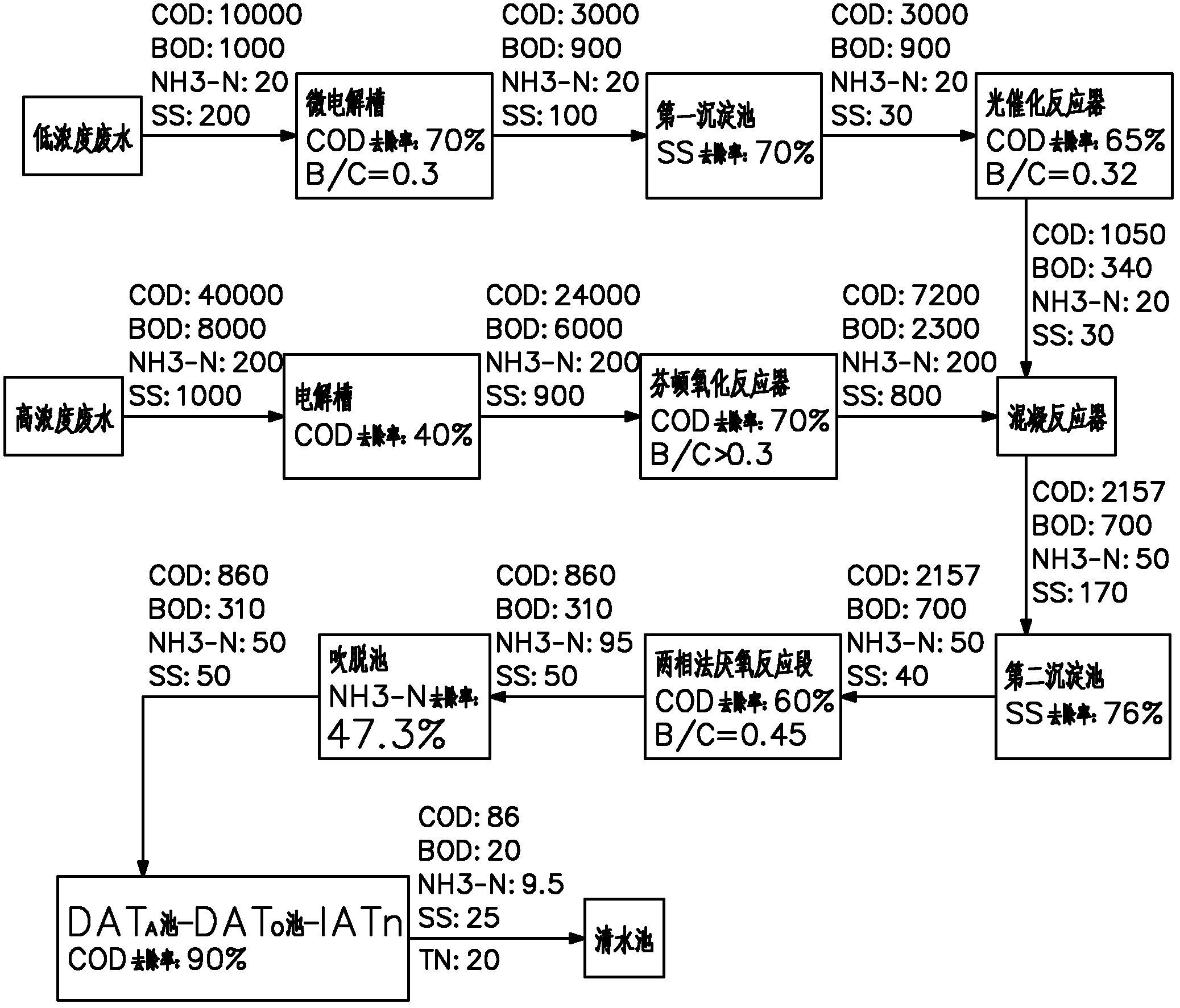

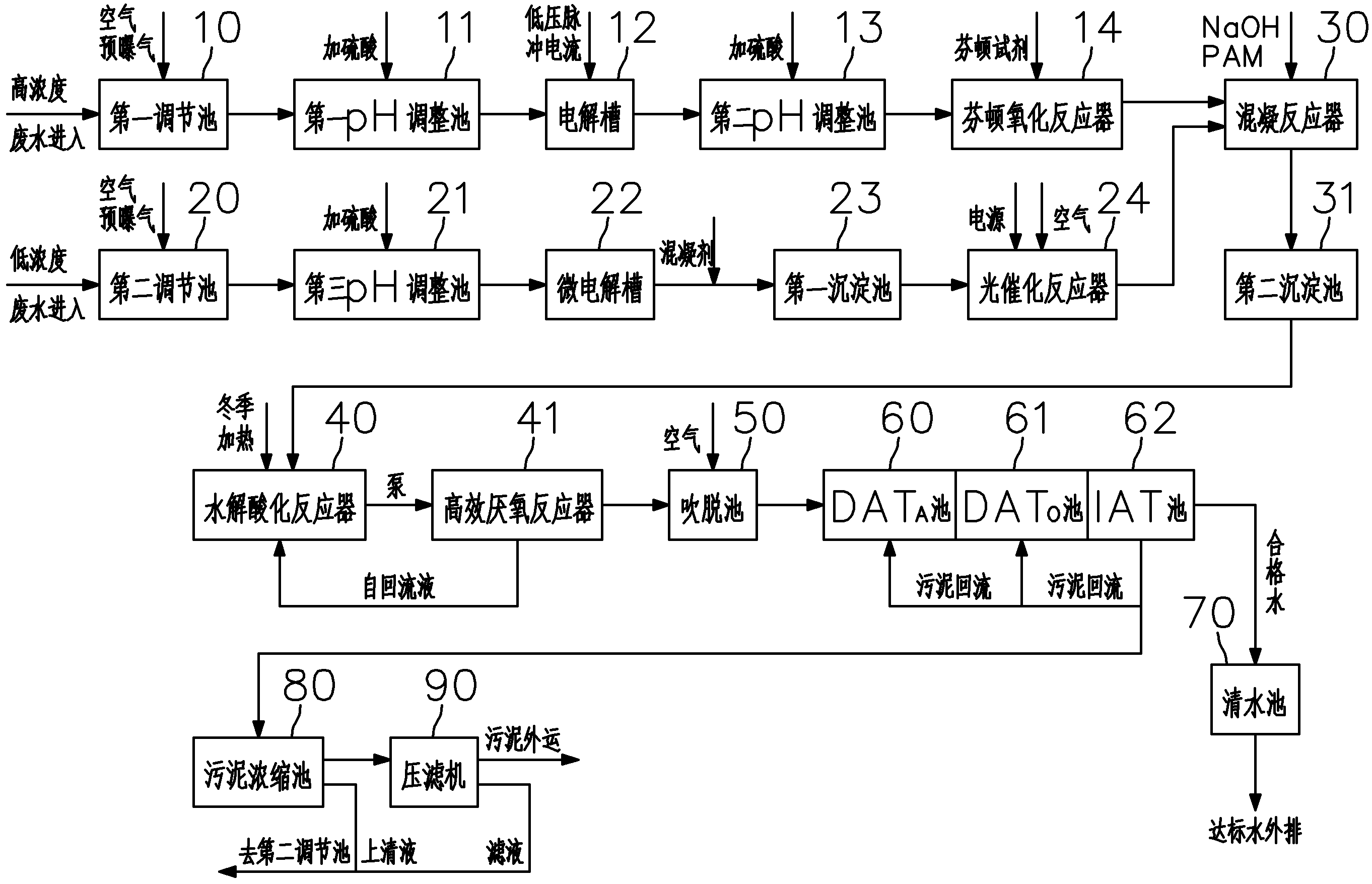

[0055] Such as figure 1 , 2 As shown, high concentration wastewater (COD cr =4.0×10 4 mg / L) flow rate is 4m 3 / h, the high-concentration waste water first continuously enters the first adjustment tank 10, adopts air pre-aeration in the first adjustment tank 10 to homogenize and prevent sedimentation, then pumps it into the first pH adjustment tank 11, and the first pH adjustment A certain amount of sulfuric acid is added to the pool 11 to adjust the pH value of the wastewater to 4.5, and then the wastewater enters the electrolytic cell 12 by itself; the electrolytic cell 12 uses pulsed direct current to electrolytically oxidize the wastewater entering it. The width is 3.5×10 -4 s, the power-off time is 3.5~6.0×10 -4 s, the peak current is 100-135A, in the electrolytic cell, the refractory pollutants in high-concentration wastewater are preliminarily removed and degraded, among which COD cr The removal rate reaches about 40%, and the B / C value is increased to 0.25; then t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com