Microsatellite quality characteristic bidirectional testing equipment and method

A technology for quality characteristics and testing equipment, applied in the testing of mechanical equipment, machine/structural components, static/dynamic balance testing, etc., to achieve the effect of reducing volume and mass, reducing impact, and improving test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

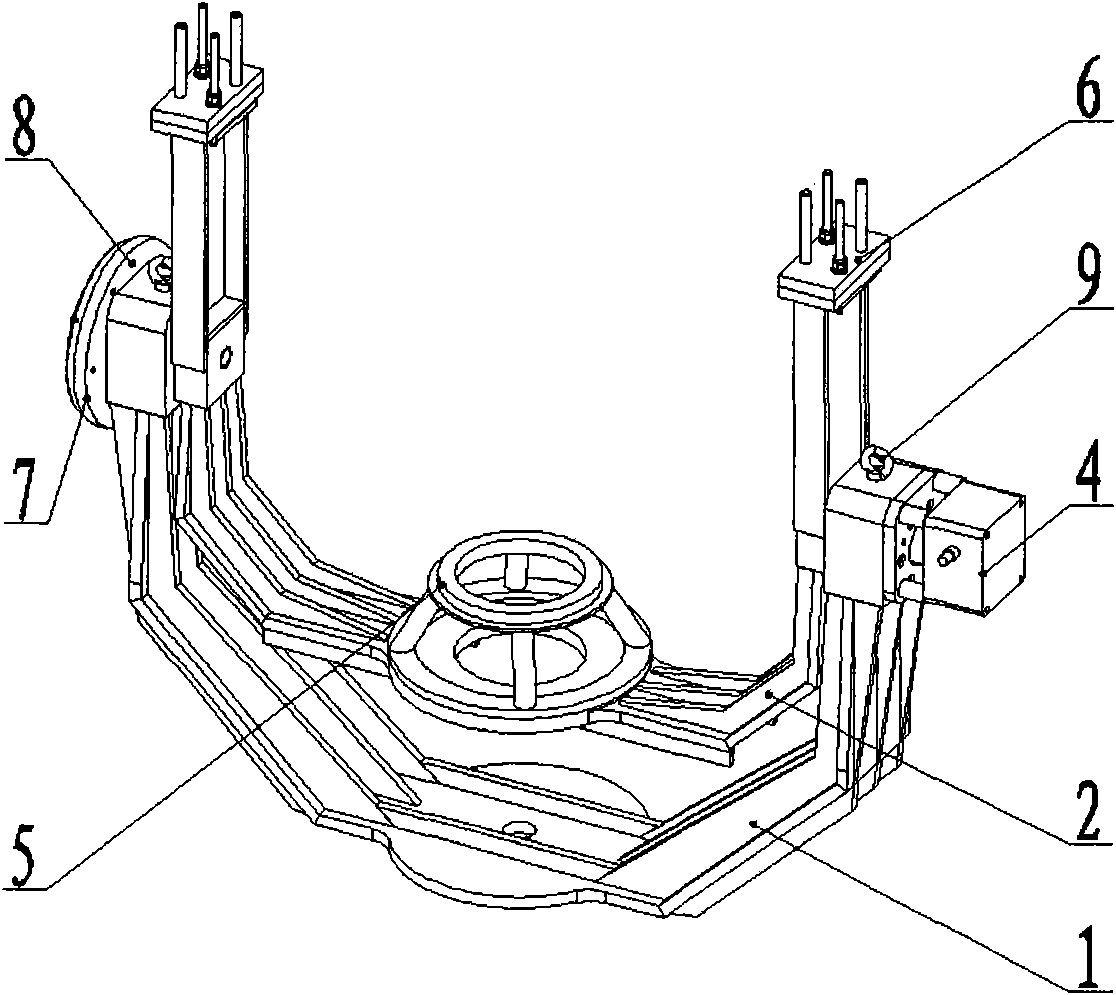

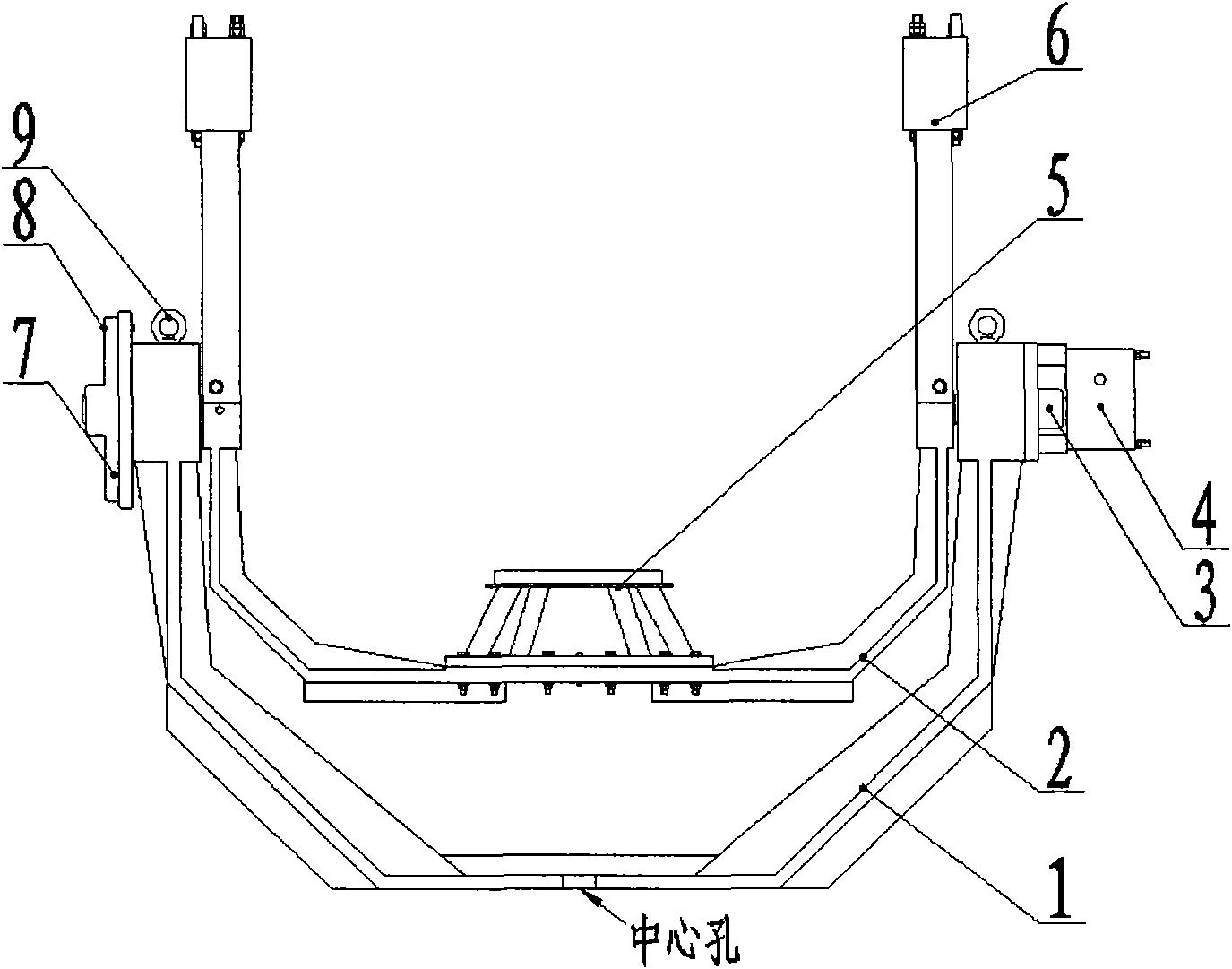

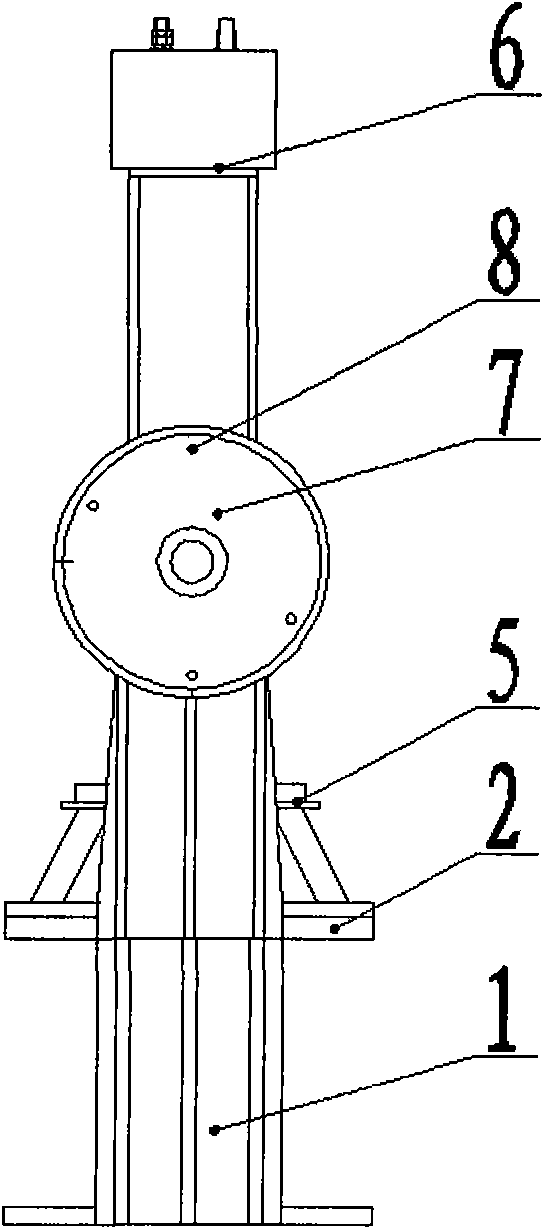

[0035] The structure of the micro-satellite mass characteristic two-way testing equipment of the present invention is as figure 1 , figure 2 , image 3 As shown, a U-shaped symmetrical inner and outer support frame structure is adopted, and the main body of the structure is made of lightweight aluminum, including an outer support frame 1, an inner support frame 2, a deceleration mechanism 4, a docking ring 5, a counterweight section 6, a positioning mechanism 7, and eyebolt screws 9. Both the outer support frame 1 and the inner support frame 2 are U-shaped symmetrical structures, the two sides of the inner support frame 2 and the outer support frame 1 are installed and connected by the positioning mechanism 7 and the reduction mechanism 4 respectively, and the inner support frame 2 can rotate on the outer support frame 1 , the positioning mechanism 7 is used for the positioning of the inner support frame 2, and the reduction mechanism 4 is used for driving and rotating the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com