Independent gas supply pneumatic system capable of providing pneumatic muscles for working

A pneumatic system and pneumatic muscle technology, applied in the field of pneumatic systems, can solve problems such as unfavorable integration in mobile robots, and achieve the effects of compact structure, reduced volume, reduced volume and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

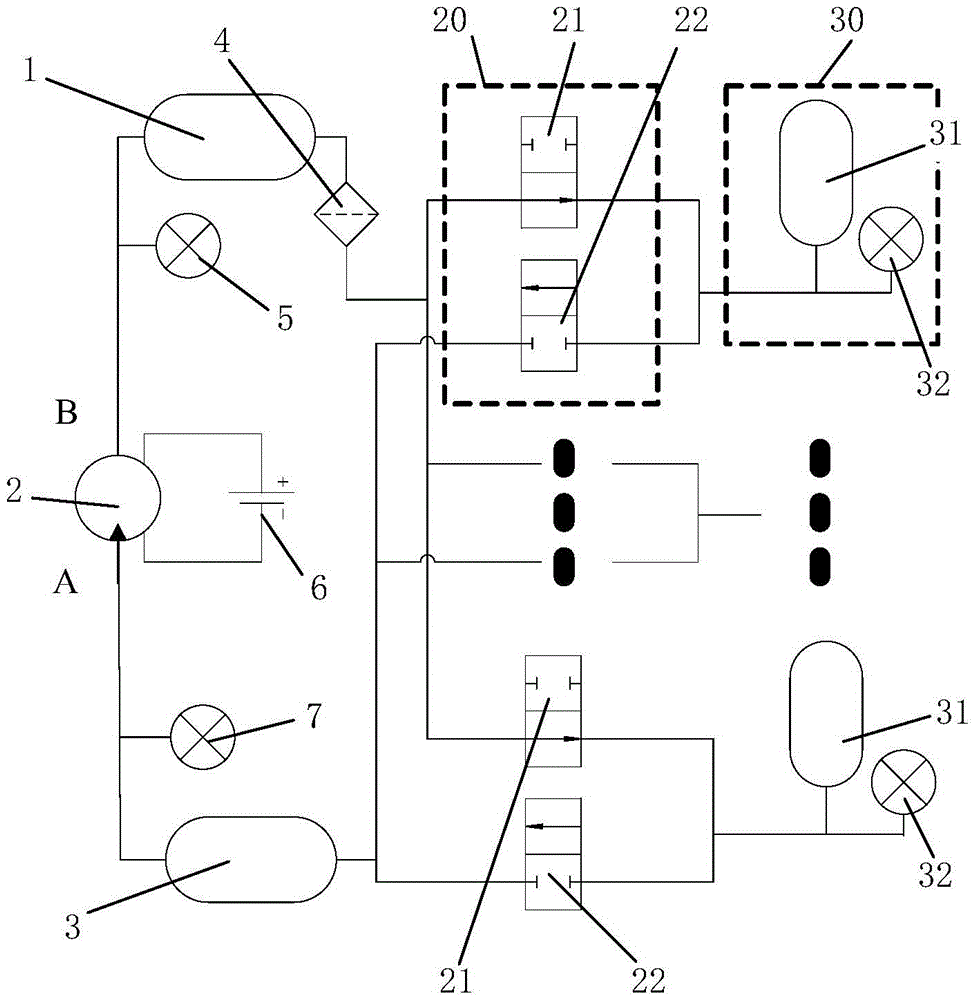

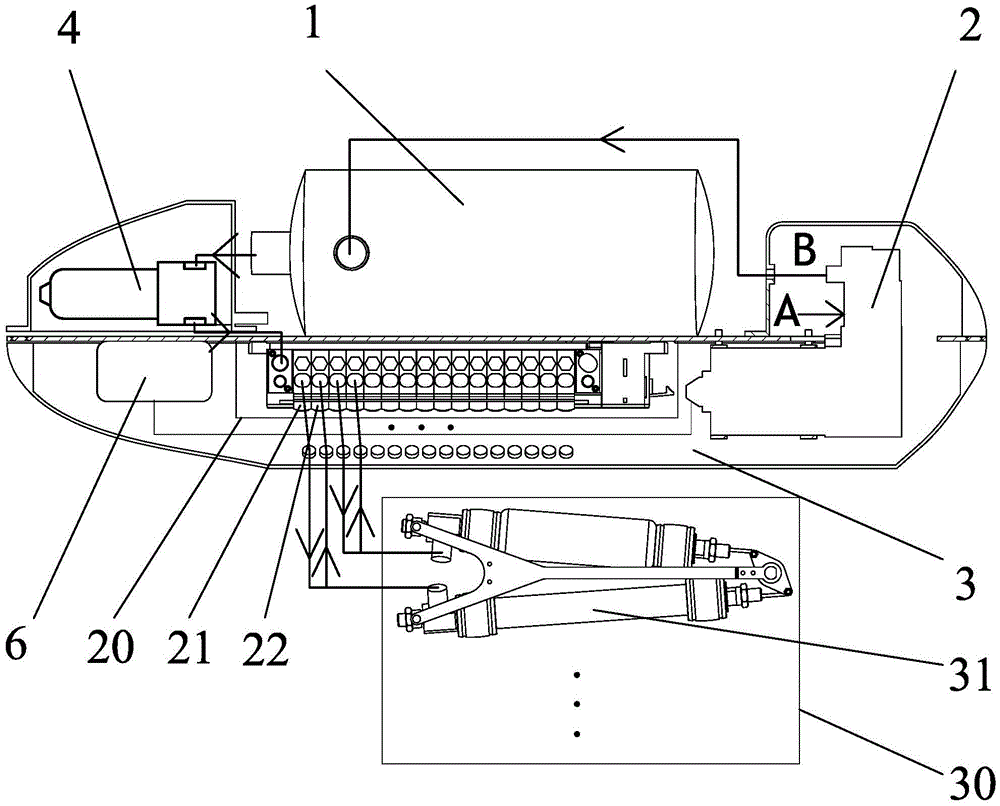

[0014] Specific implementation mode one: combine Figure 1 to Figure 2 Describe this embodiment, this embodiment is an independent air supply pneumatic system that provides pneumatic muscle work, it includes a hyperbaric chamber 1, an air pump 2, a low pressure chamber 3, an air filter valve 4, a hyperbaric chamber pressure sensor 5, a battery 6, and a low pressure chamber The pressure sensor 7, the switch pneumatic system 20 and the pneumatic actuator unit 30, the hyperbaric chamber 1 and the low pressure chamber 3 are arranged oppositely and the hyperbaric chamber 1 and the low pressure chamber 3 are connected through the air pump 2, and the battery 6 is connected to the air pump 2 and supplies power for the air pump 2 , the hyperbaric chamber 1 is connected to the air filter valve 4 and provides an air source for the pneumatic muscle 31 of the pneumatic actuator 30 through the intake high-speed switching valve 21 in the switching pneumatic system 20, and the low-pressure cha...

specific Embodiment approach 2

[0018] Specific implementation mode two: combination Figure 1 to Figure 2 Describe this embodiment, the air inlet A end of the air pump 2 of this embodiment is connected to the low pressure chamber 3 , and the exhaust port B end of the air pump 2 is connected to the hyperbaric chamber 1 . Such setting: it is convenient to realize the pressure difference between the hyperbaric chamber and the low pressure chamber, so that the pneumatic system of the present invention is isolated from the external atmosphere, forming an independent air source that can be integrated. Other compositions and connections are the same as those in the second embodiment.

specific Embodiment approach 3

[0019] Specific implementation mode three: combination Figure 1 to Figure 2 Describe this embodiment, the switching pneumatic system 20 of this embodiment comprises intake high-speed switch valve 21 and exhaust high-speed switch valve 22, and intake high-speed switch valve 21 and exhaust high-speed switch valve 22 are arranged in parallel and with air filter valve 4 or Low pressure chamber 3 connection. The benefit of such setting is that it is convenient to reduce the volume. Other compositions and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com