Construction method for steel tube confined concrete composite columns

A technology of concrete filled steel tubes and composite columns, which is applied to columns, pier columns, pillars, etc., can solve the problems of increasing the amount of lining pipes, welding times, increasing costs, and increasing construction periods, achieving good economic benefits, speeding up construction progress, reducing effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

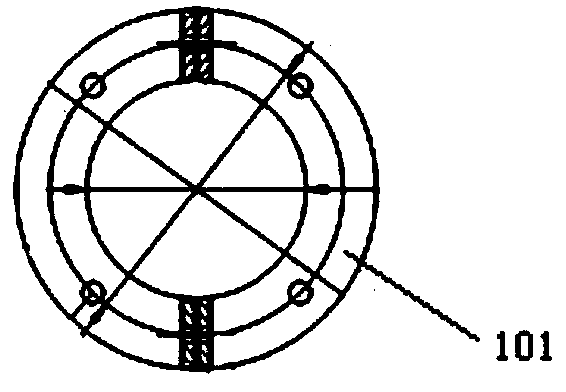

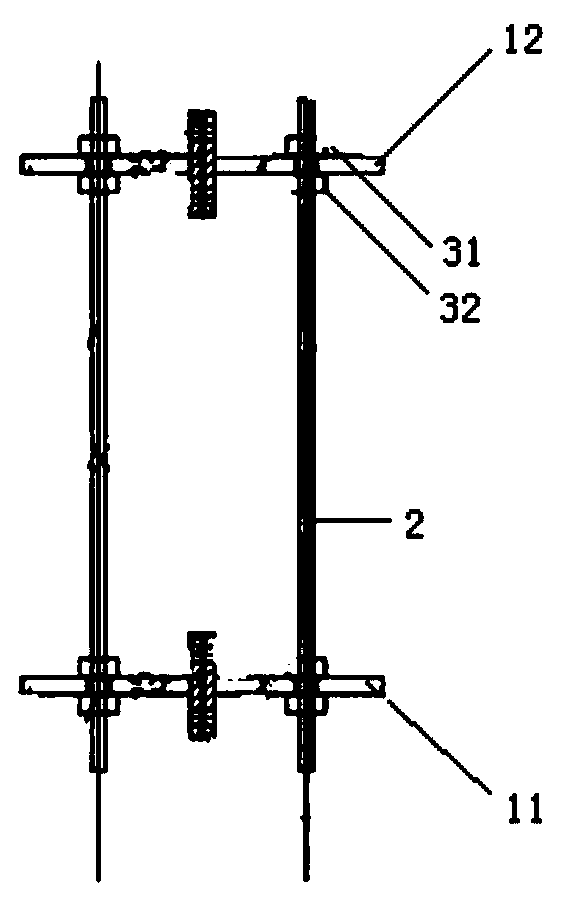

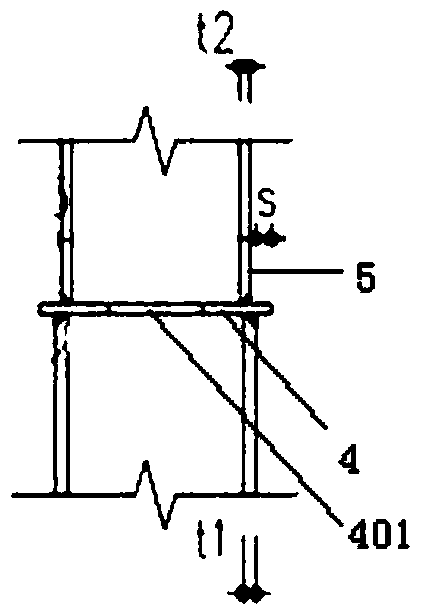

[0033] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0034] The construction method of steel tube concrete composite column includes the following steps:

[0035] Step 1, construction preparation;

[0036] Step 2, temporarily fix the steel pipe column;

[0037] Step 3, connect and fix the steel pipe column;

[0038] Step 4, the outer frame beams are bound with steel bars and the formwork is supported;

[0039] Step five, concrete pouring of the steel pipe concrete composite column.

[0040] Step 1. During construction preparation, according to the design and specification requirements, the height connection position of steel pipes is usually between 0.3-1m above the floor. After each steel pipe enters the site, carry out actual measurement, and make reasonable arrangements to ensure the correct height connection position; each steel pipe is numbered Finally, according to the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com