Offshore wind power steel pipe pile foundation reinforcement method with anti-scour ability

A technology for offshore wind power and foundation reinforcement, which is applied in the direction of foundation structure engineering, sheet pile walls, soil protection, etc., can solve the problems of increased manufacturing cost and increased construction difficulty of steel pipe piles, and achieves improved physical and mechanical properties and increased horizontal load bearing force, reducing the effect of horizontal deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

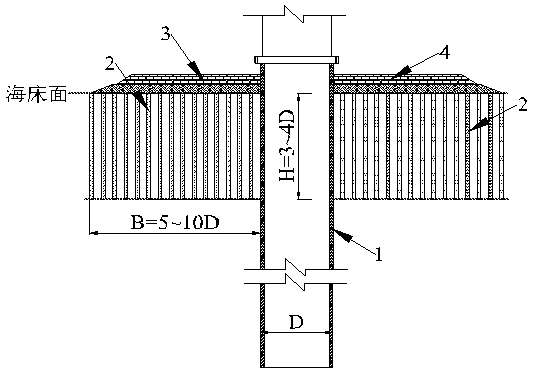

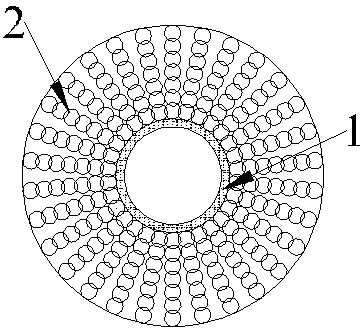

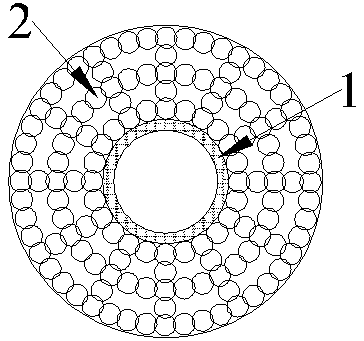

[0025] Such as figure 1 As shown, the present invention designs a foundation reinforcement treatment method for offshore wind power steel pipe piles, which includes three parts: the reinforcement area 2, the cushion layer 3 and the scour protection layer 4; wherein, the reinforcement area is vertically arranged with equal or variable lengths, The reinforcement depth H is 3~4D, the reinforcement width B is 5~10D, and D is the diameter of the steel pipe pile 1;

[0026] Such as figure 1 As shown, the cushion layer 3 adopts pebbles, gravels or concrete fragments of 1-5cm, the anti-scouring layer 4 adopts stones or concrete blocks of 10-50cm, and the thickness of the ant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com