Underwater riprap foundation bed and side slope erosion resisting structure and construction method thereof

A technology of riprap foundation bed and construction method, which can be used in infrastructure engineering, coastline protection, construction, etc., and can solve the problems of large volume, reducing the depth of harbor basin, and large amount of materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

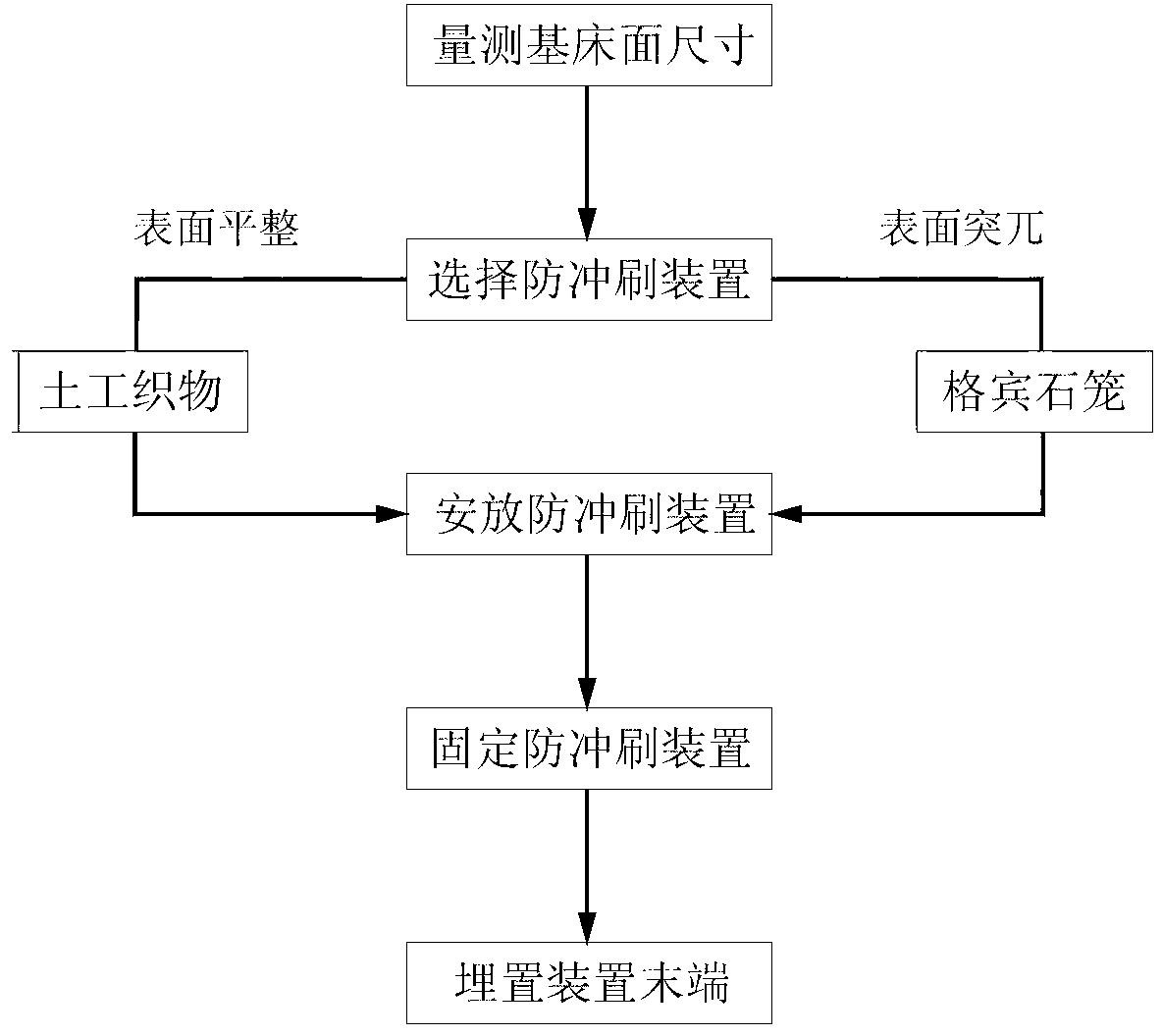

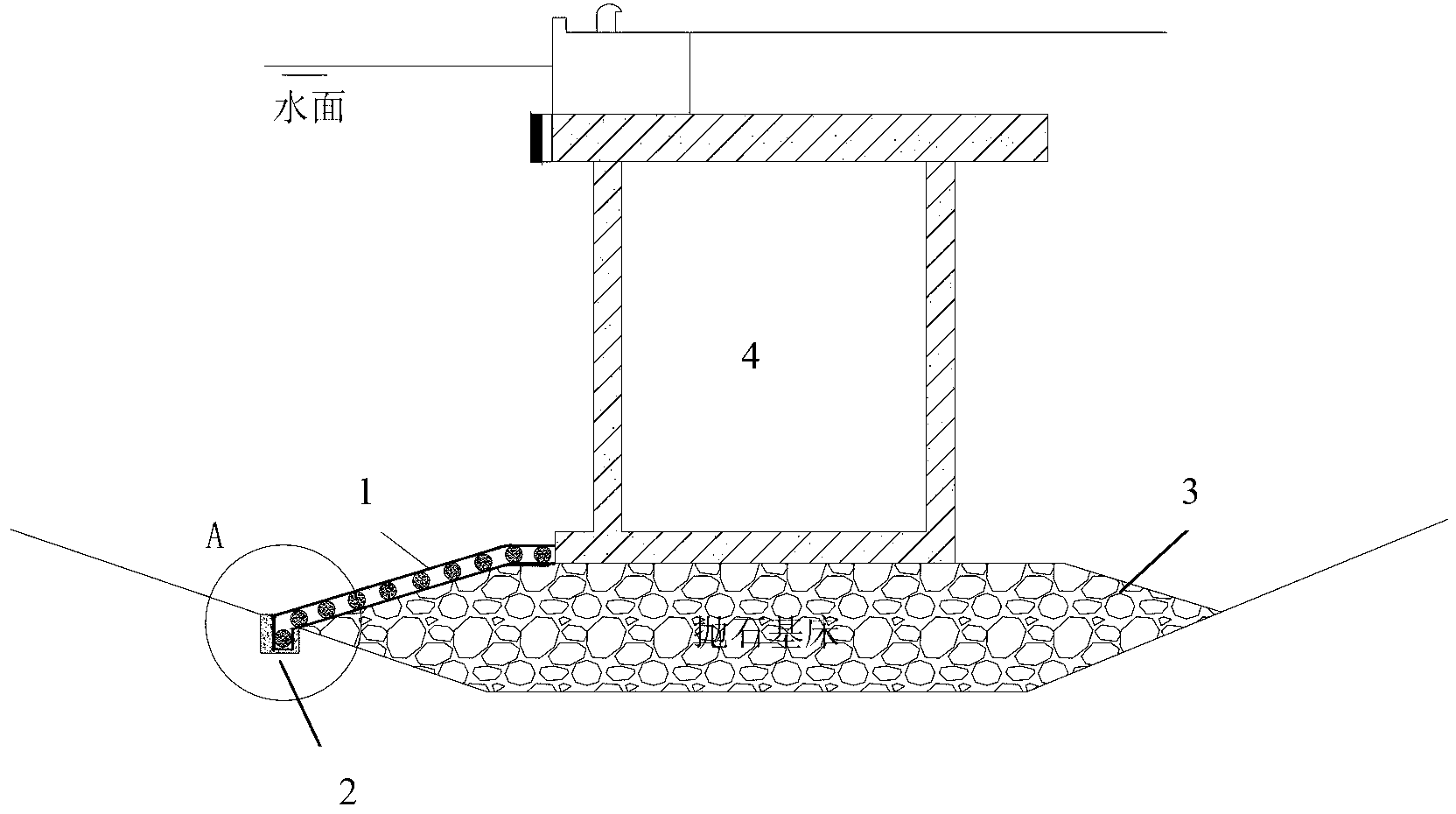

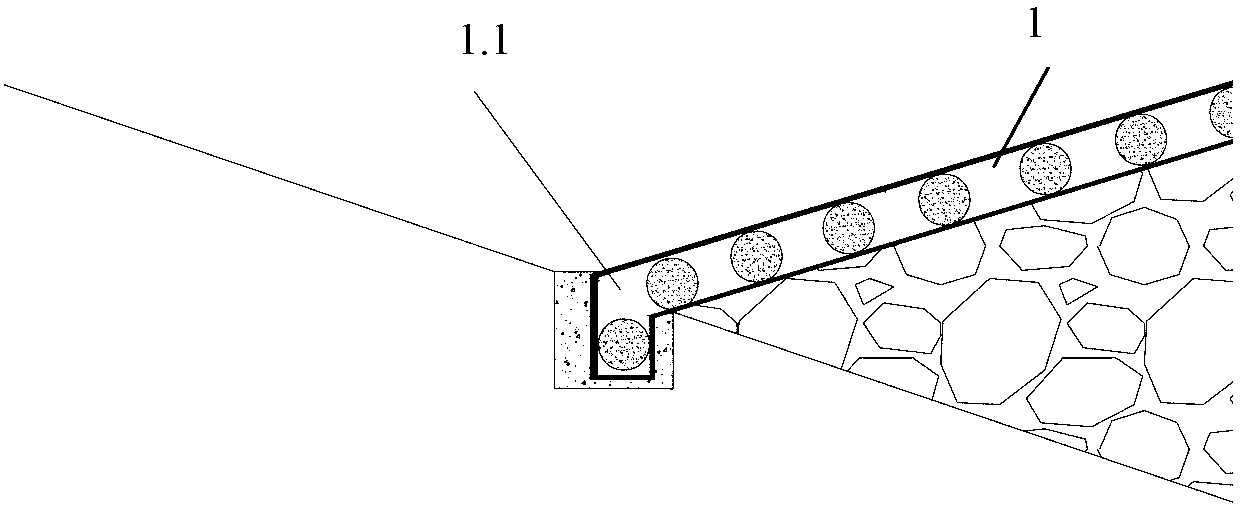

[0032] Measure the size of the foundation bed and make it as Figure 5 As shown in the gabion grid, each grid has a bottom and no top, and the size is 1m×1m×0.5m.

[0033] Place the gabion 1 on the surface of the foundation bed 3, and bind the adjacent grids with iron wires to form an anti-scouring device.

[0034] Make a thin iron sheet cylinder with a diameter of about 20cm, and the length is the distance from the shore to the foundation bed surface. One end of the cylinder is fixed on the shore, and the other end is placed above the gabion net, and the movement is controlled by the diver in the water.

[0035] The staff on the shore threw about 10cm of gravel into the cylinder, and the gravel passed through the cylinder to reach the gabion. When one grid is filled with gravel, the diver moves the cylinder to another grid, and so on.

[0036] When all grids are filled with gravel, cover each grid with a whole piece of wire mesh and tie it tightly with wire.

[0037] Dig ...

Embodiment 2

[0039] Measuring the dimensions of structures such as Figure 4 As shown, the processing surface layer and bottom geotextile 6.1, 6.3 and a layer of grid-shaped geotextile bag 6.2, the middle part of the mold bag 6.2 is provided with a grouting opening, and the periphery of the geotextile and the geotextile bag is provided with zippers.

[0040] Place the underlying geotextile 6.3 on the surface of the foundation bed, and use small wooden piles for temporary fixation.

[0041] Place the grid-shaped geomembrane bag 6.2 and connect it with the underlying geotextile 6.3 using a zipper. Open the grouting port to pour cement mortar into the geotechnical mold bag, and cover the grouting port of the bag every time the bag is filled.

[0042] After the mold bag is fully filled, place the surface layer geotextile 6.1 on the geotechnical mold bag 6.2 and connect it with a zipper to form a complete anti-scouring device.

[0043] Dig a trench 2 along the lower end of the foundation bed,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com