Construction method and equipment for reverse circulation drill to drill hole, hammer to form hole, expand hole and remove slag

A technology of reverse circulation and construction method, applied in drilling equipment and methods, drilling equipment, directional drilling, etc., can solve the problem that the safety factor of workers' hollowing operation is not high, restricting the application and development of bored cast-in-place piles, anti-seismic, anti-pulling Poor corrosion resistance and other problems, to achieve the effect of easy operation of the construction process, ensuring the quality of the pile foundation project, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

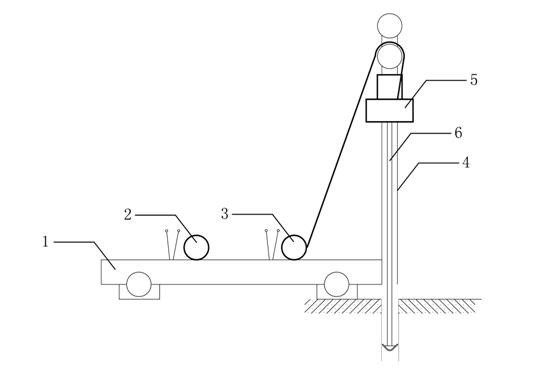

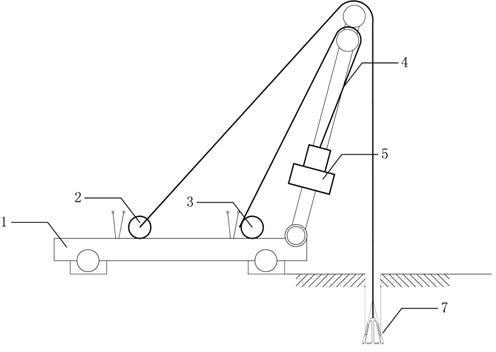

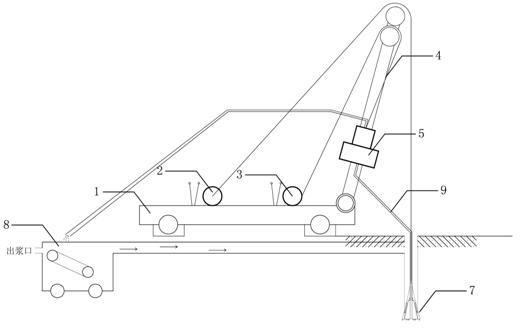

Image

Examples

Embodiment

[0033] The present invention is applied to the construction of Lianyungang Rattan Garden Community. The total construction area of the community is about 120,000 square meters. There are high-rises and some small high-rises. According to the design requirements, the test piles should be driven according to the pile length of 18 meters. According to the design requirements, four cast-in-situ piles should be tested with different constructions.

[0034] 1. In accordance with the requirements of the current drilling specification, try to drive a cast-in-place pile with a diameter of 800mm. According to the requirements of the national standard, the sediment at the bottom of the pile is not greater than 5cm. After the pile is completed, the static load test shows that the ultimate bearing capacity is 2200KN.

[0035]2. According to the requirements of the current drilling specification, try to drill a cast-in-place pile with a diameter of 800. The final slag cleaning pipe 9 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com