Pontoon cabin row for stone spreading and levelling continuous work of under water riprap foundation bed construction

A technology of riprap foundation bed and stone paving, which is applied in basic structure engineering, transportation and packaging, special-purpose ships, etc., can solve the problems of high cost, low construction efficiency, and many processes, and achieves low cost and high construction efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

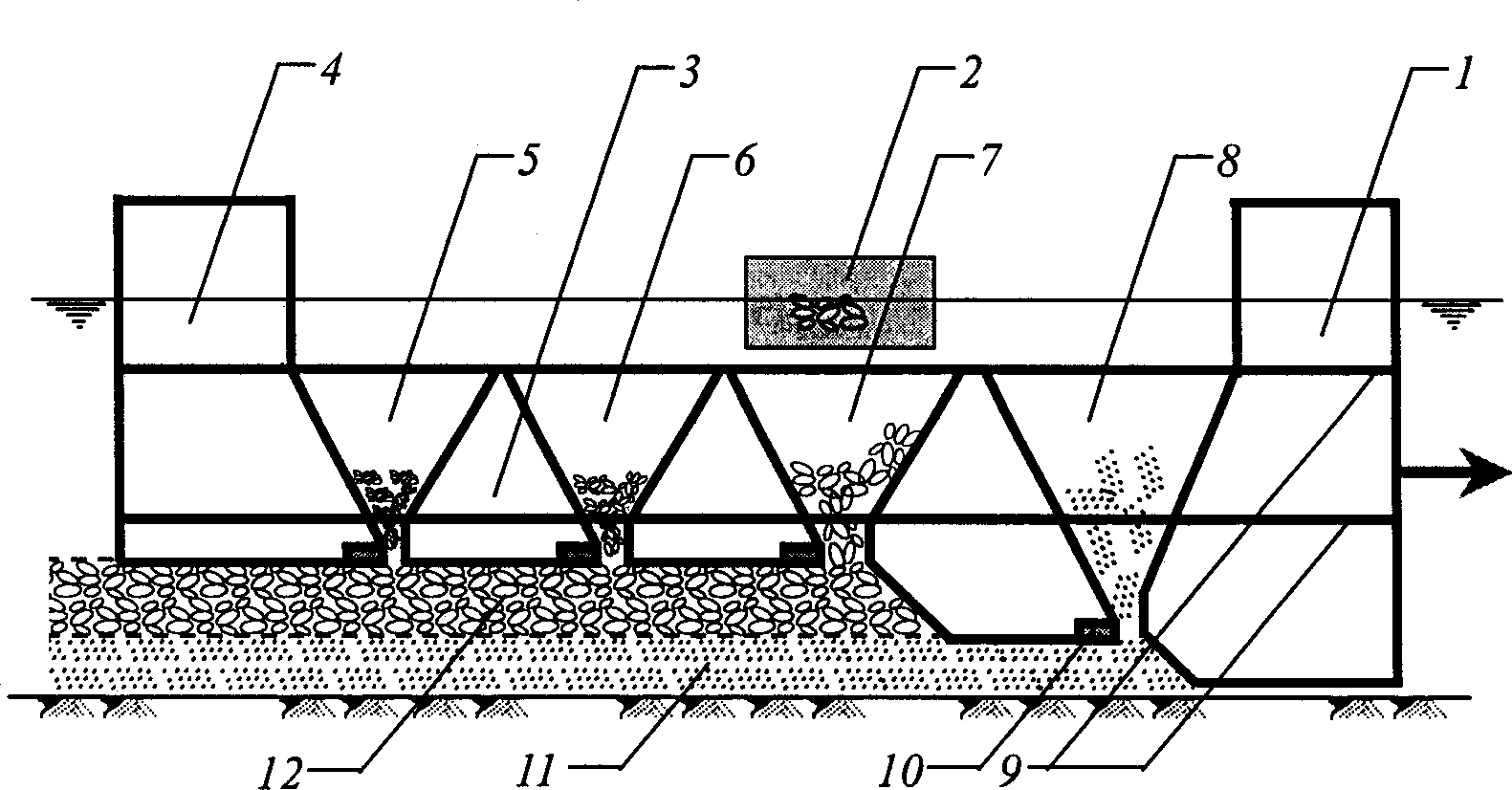

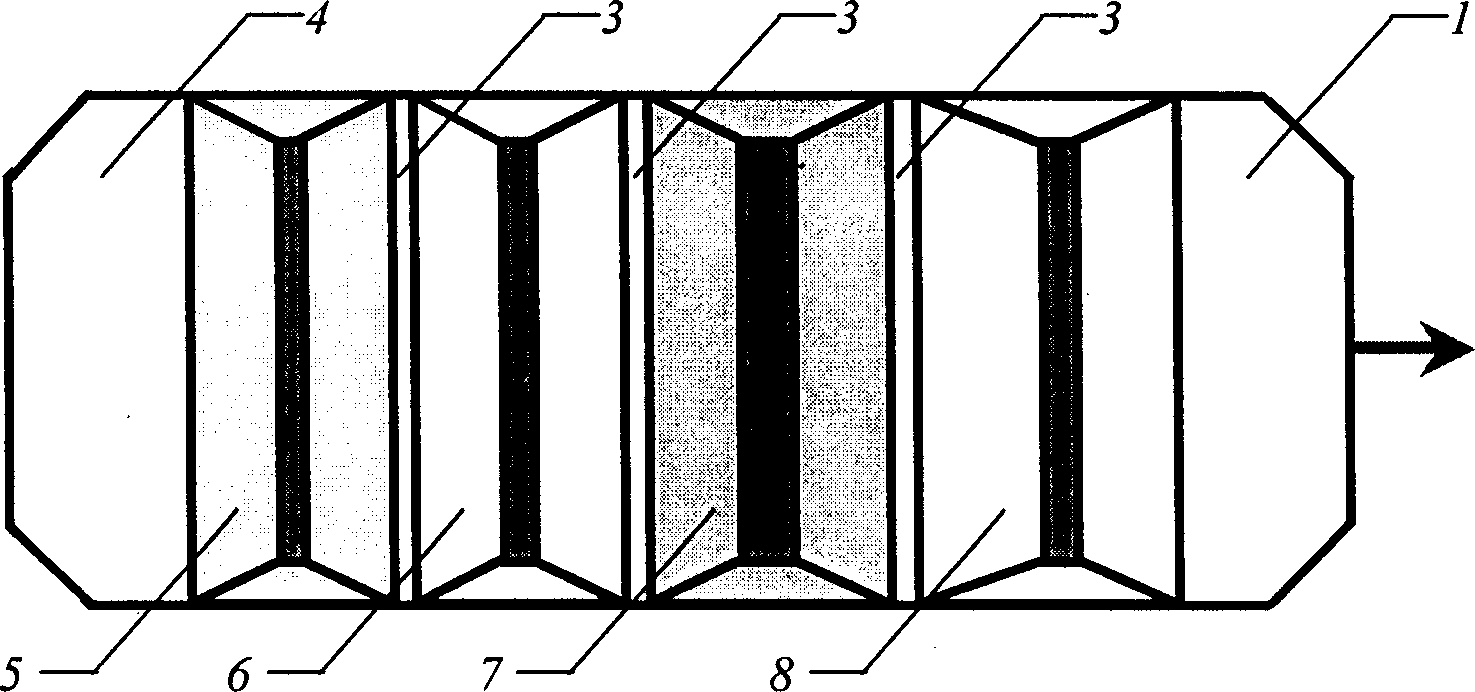

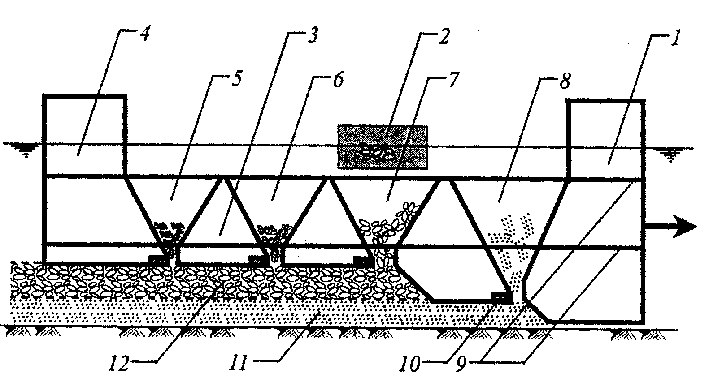

[0011] An example of the present invention is as follows: figure 1 with figure 2 The floating ship cabin row shown in the underwater riprap bed construction that integrates stone paving and leveling and continuous operation is formed by the front floating cabin, the rear floating cabin and the three intermediate floating cabins connected by connecting beams. The three intermediate floating cabins and The front side of the bottom of the rear floating cabin is provided with a rubble bed leveling scraper beam. The outer dimensions of the floating cabin row are 40m long and 20m wide, the front floating cabin is 10m high, the rear floating cabin is 8m high, and the middle floating cabin is 2m-6m high. Made of steel, the total weight of the device is about 350 tons. The volume of the sand and gravel hopper bin is 160~240m 3 , The width of the opening at the bottom of the hopper silo is determined by the width of the rubble bed. The total volume of the floating cabin that can generate b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com