Spraying building robot in fully mechanical wall building construction system

A technology of robots and walking systems, applied in buildings, building components, building structures, etc., to reduce environmental pollution, improve construction efficiency, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

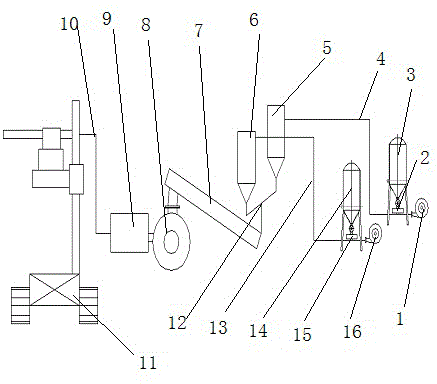

[0018] Now further illustrate the specific embodiment of the present invention in conjunction with accompanying drawing, the transportation of storage tank adopts the back tanker of standard, and back tanker transports dry powder material storage tank 3 and light material storage tank 14 to construction site, places, as figure 1 , choose 18.5kw, 0.6MPa Roots blower as the dry powder fan 1, the diameter of the fan outlet is 75 mm, use a flange to connect the plastic pipe with a diameter of 75 mm to the dry powder fan 1, and the outlet is under the dry powder storage tank 3 At the feed port, install a 160-type quantitative feeding valve, and connect the dry powder material delivery pump 2 at the outlet of the quantitative feeding valve. The pipe connected to the fan 1 is provided with a tee at the dry powder material delivery pump 2, one end is connected to the pipe at the outlet of the dry powder material fan 1, one end is connected to the dry powder material delivery pump 2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com