Gravity wharf built on silt foundation and method for constructing gravity wharf

A technology of gravity wharf and construction method, which is applied in the field of wharf engineering, can solve the problems of high cost of retaining structures, and achieve the effect of anti-sliding stability and anti-tilting stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

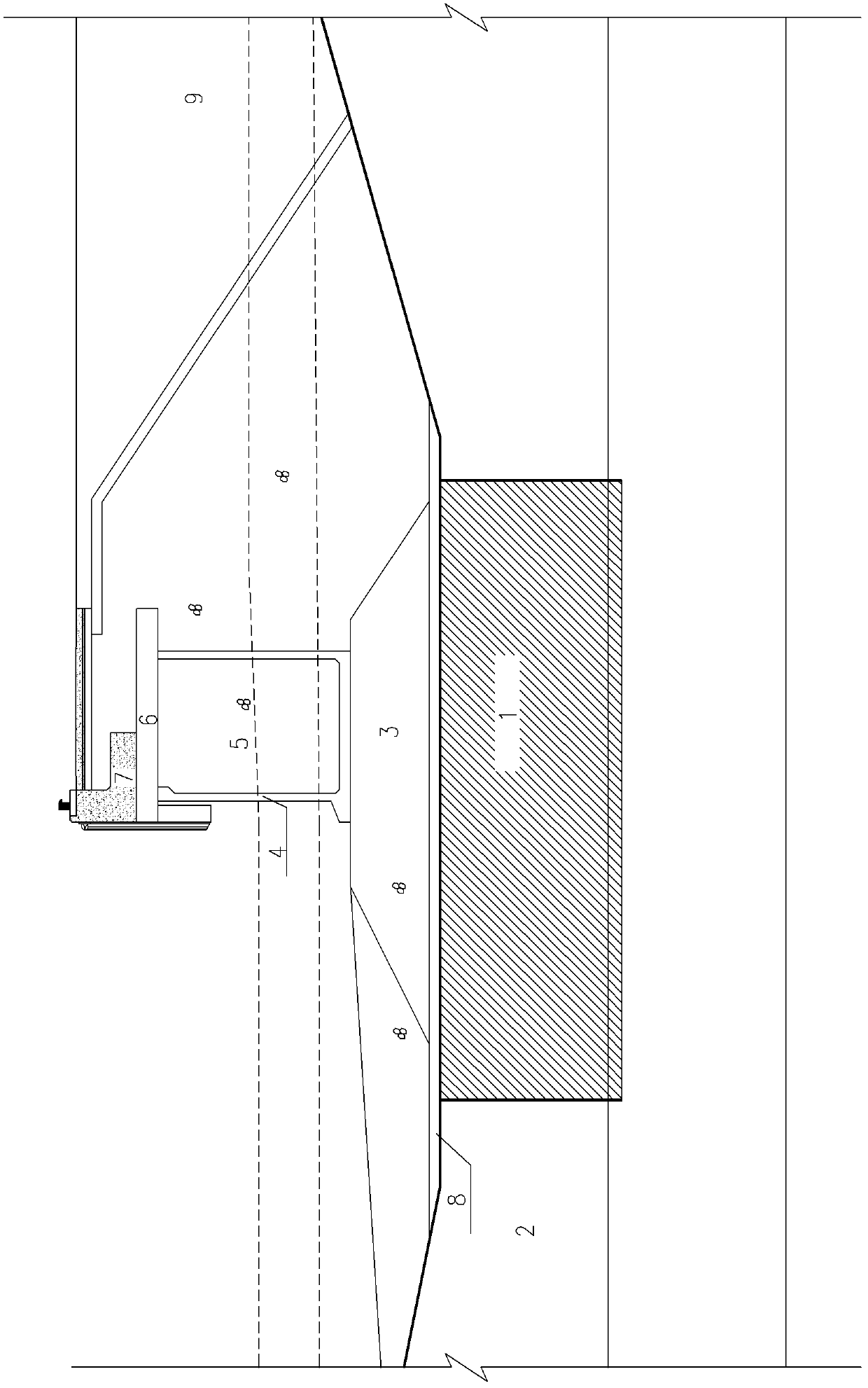

[0024] Referring to Fig. 1, it is a structural sectional view of a gravity wharf built on a silt foundation according to the present invention. According to the construction sequence, it includes a composite foundation 1 from bottom to top, and the composite foundation 1 is formed by a large replacement rate compacted sand pile reinforcing a silt foundation 2; a riprap foundation bed 3, which is built on the composite foundation 1 On the foundation 1; a prefabricated caisson 4, inside the prefabricated caisson 4 is a riprap 5, built on the riprap foundation bed 3, and the top of the caisson is higher than the construction water level; and a superstructure, the superstructure includes a prefabricated The unloading plate 6 and the cast-in-place parapet 7, the prefabricated unloading plate 6 is arranged under the cast-in-place parapet 7.

[0025] Among them, the key to the compacted sand pile composite foundation 1 is to determine the sand pile replacement rate, reinforcement ran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com