Patents

Literature

62results about How to "Precise working position" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

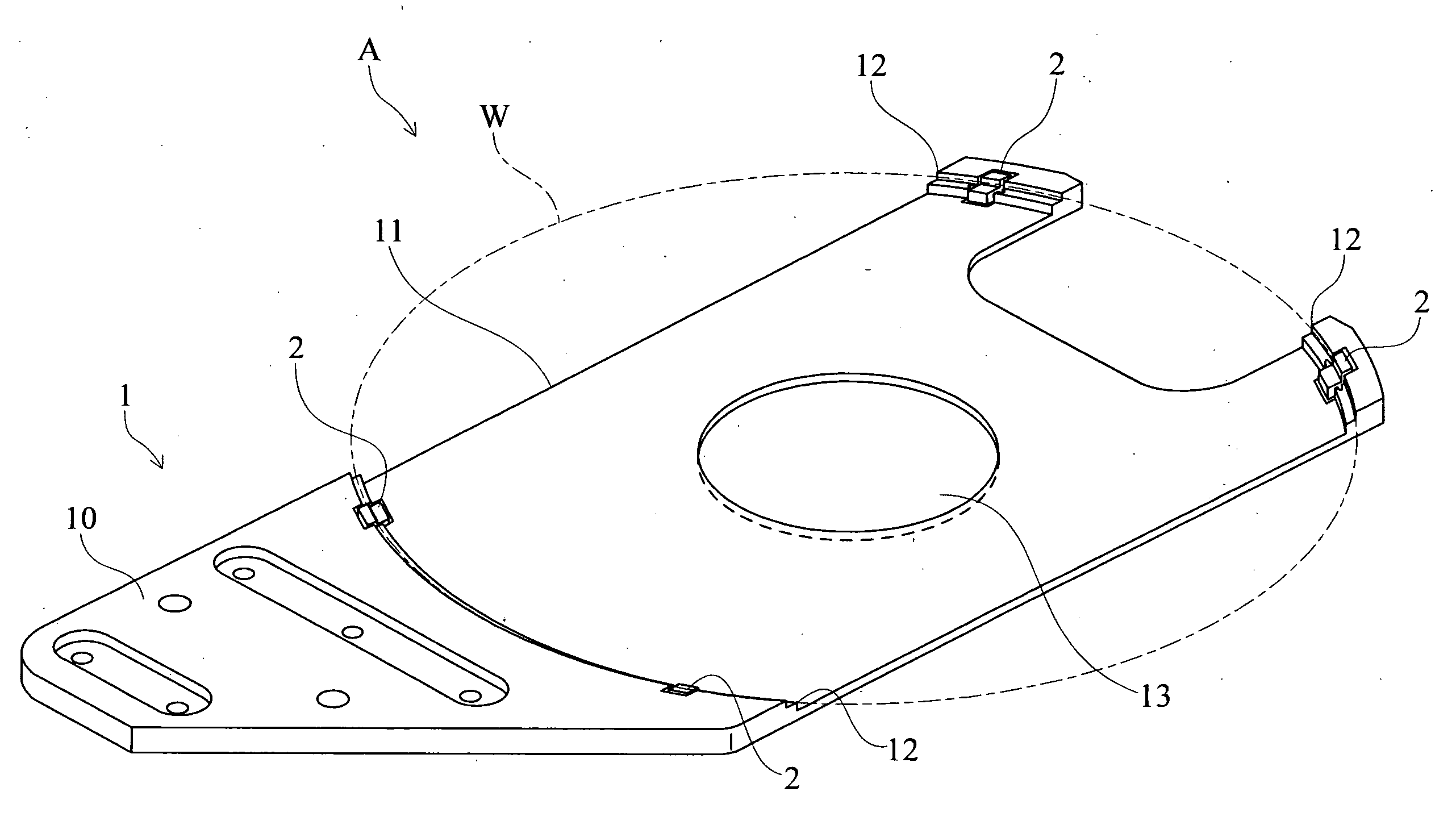

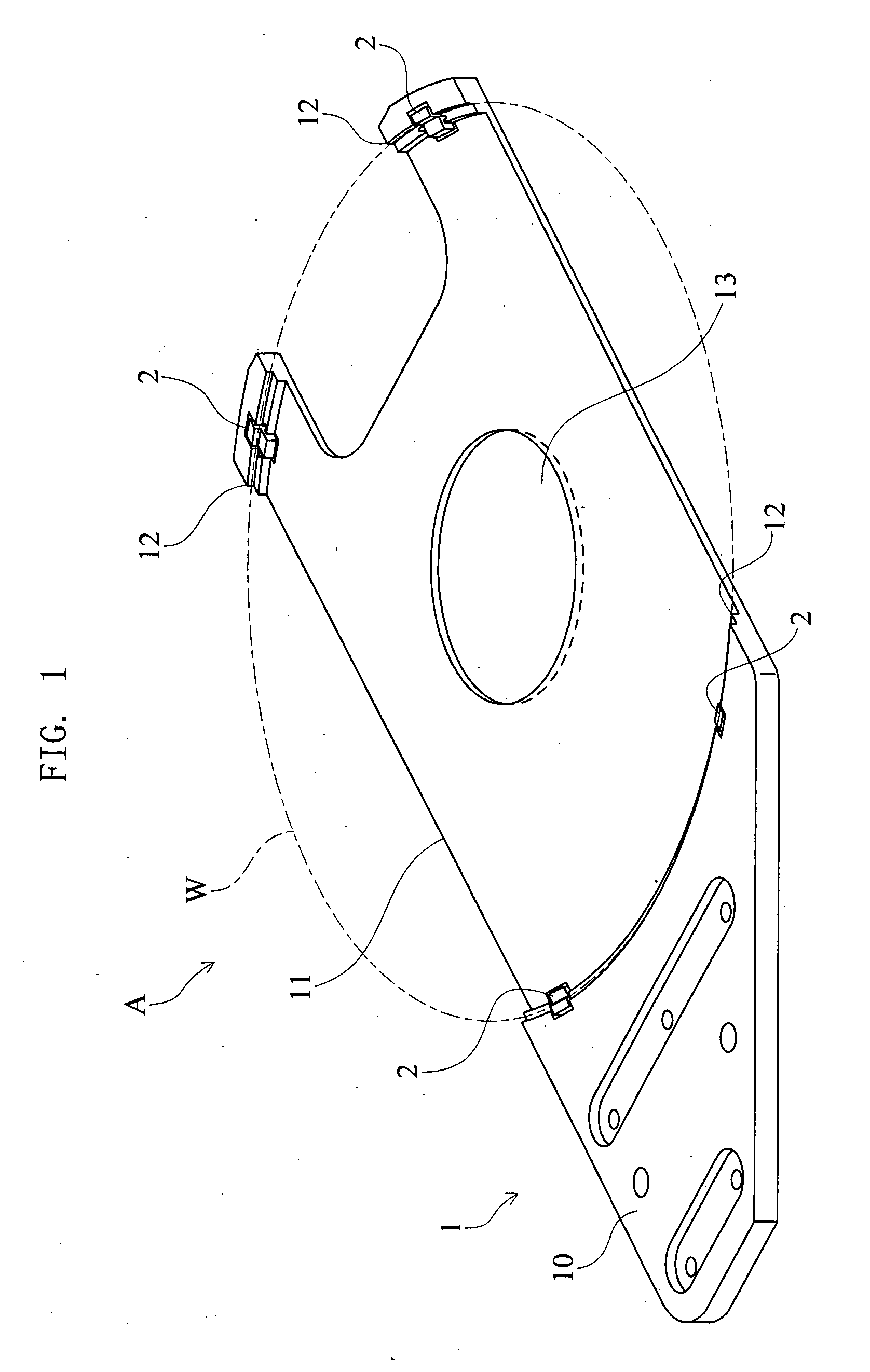

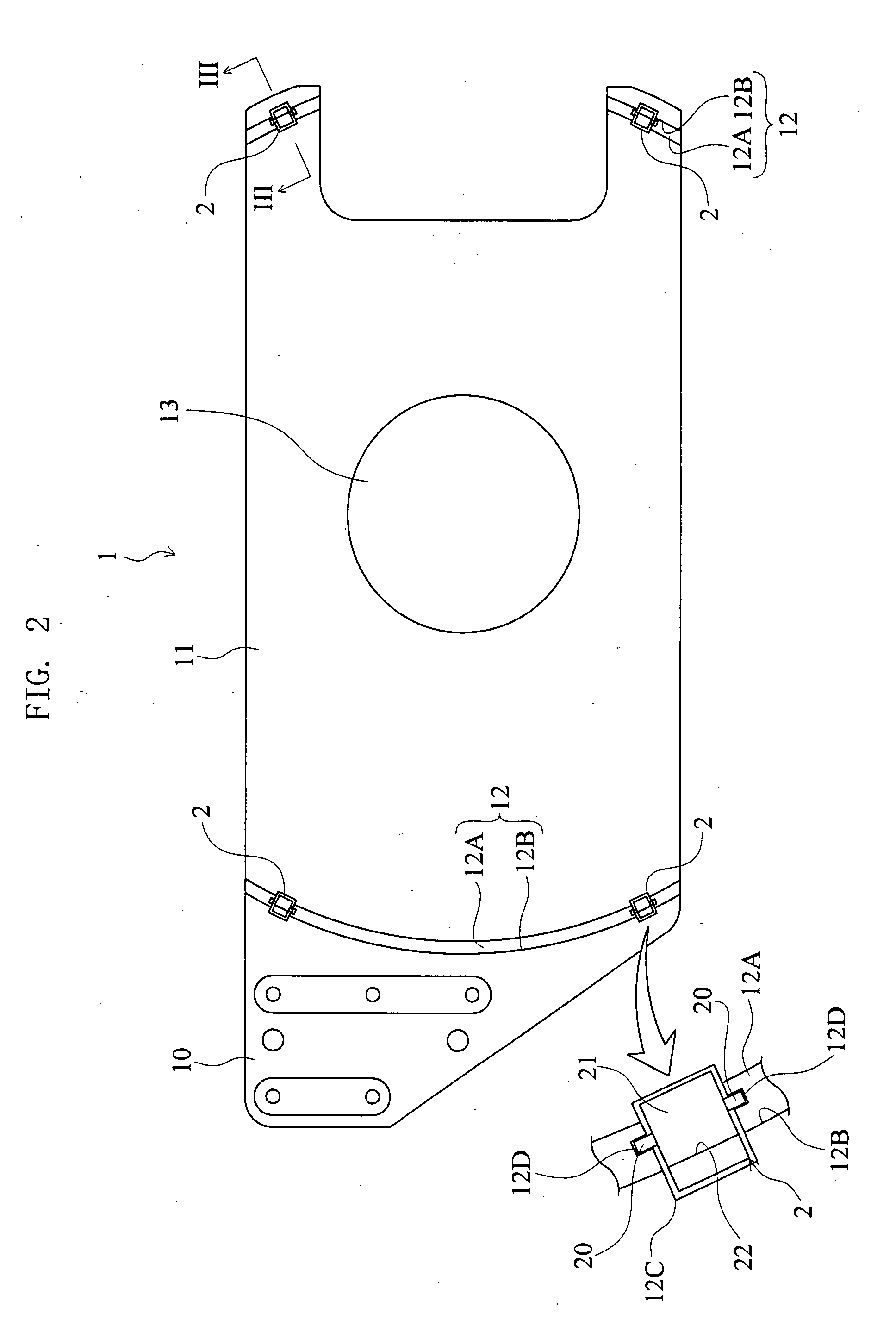

Work holding mechanism

ActiveUS7748760B2Improve shipping speedVacuum operationGripping headsSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

Owner:DAIHEN CORP

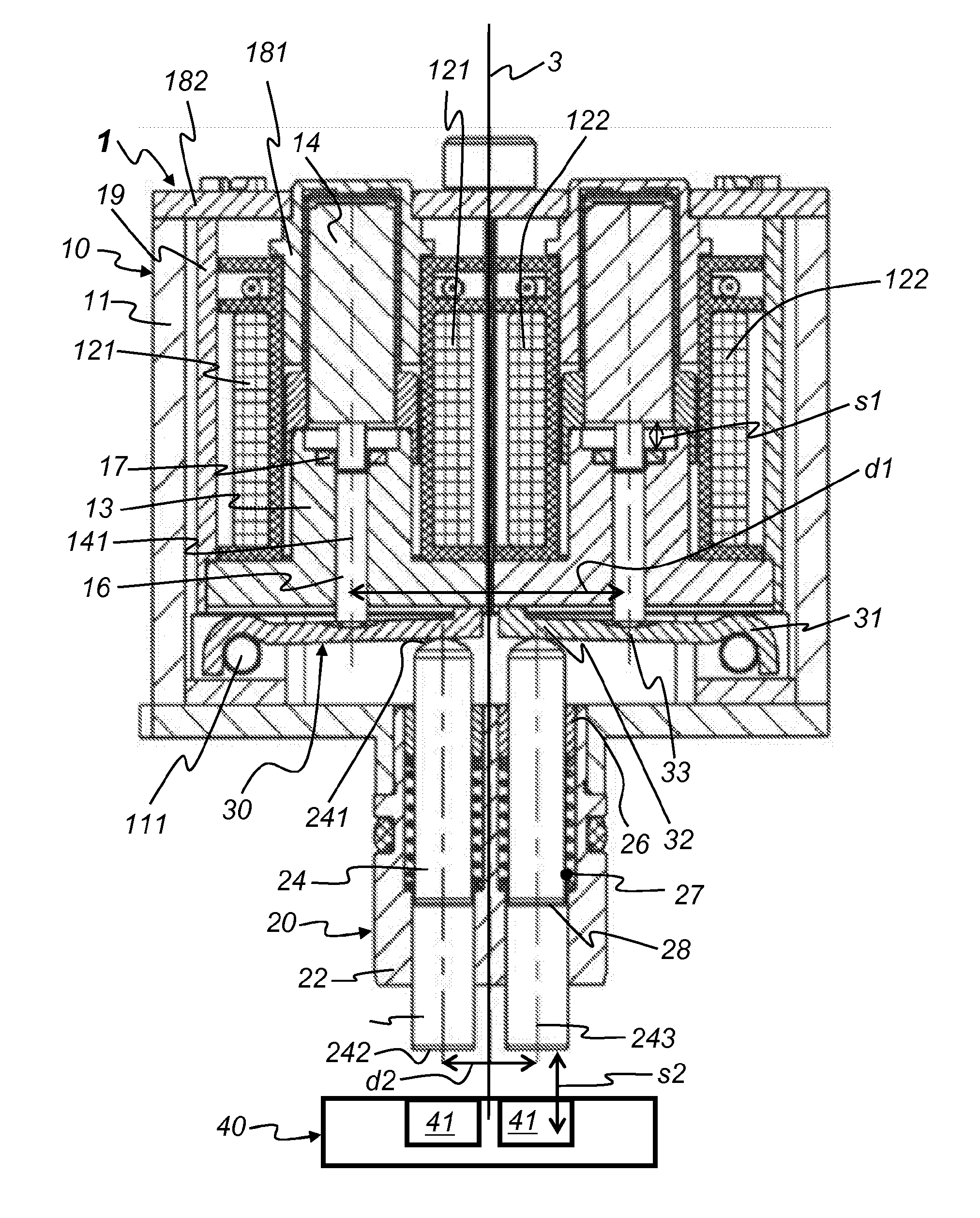

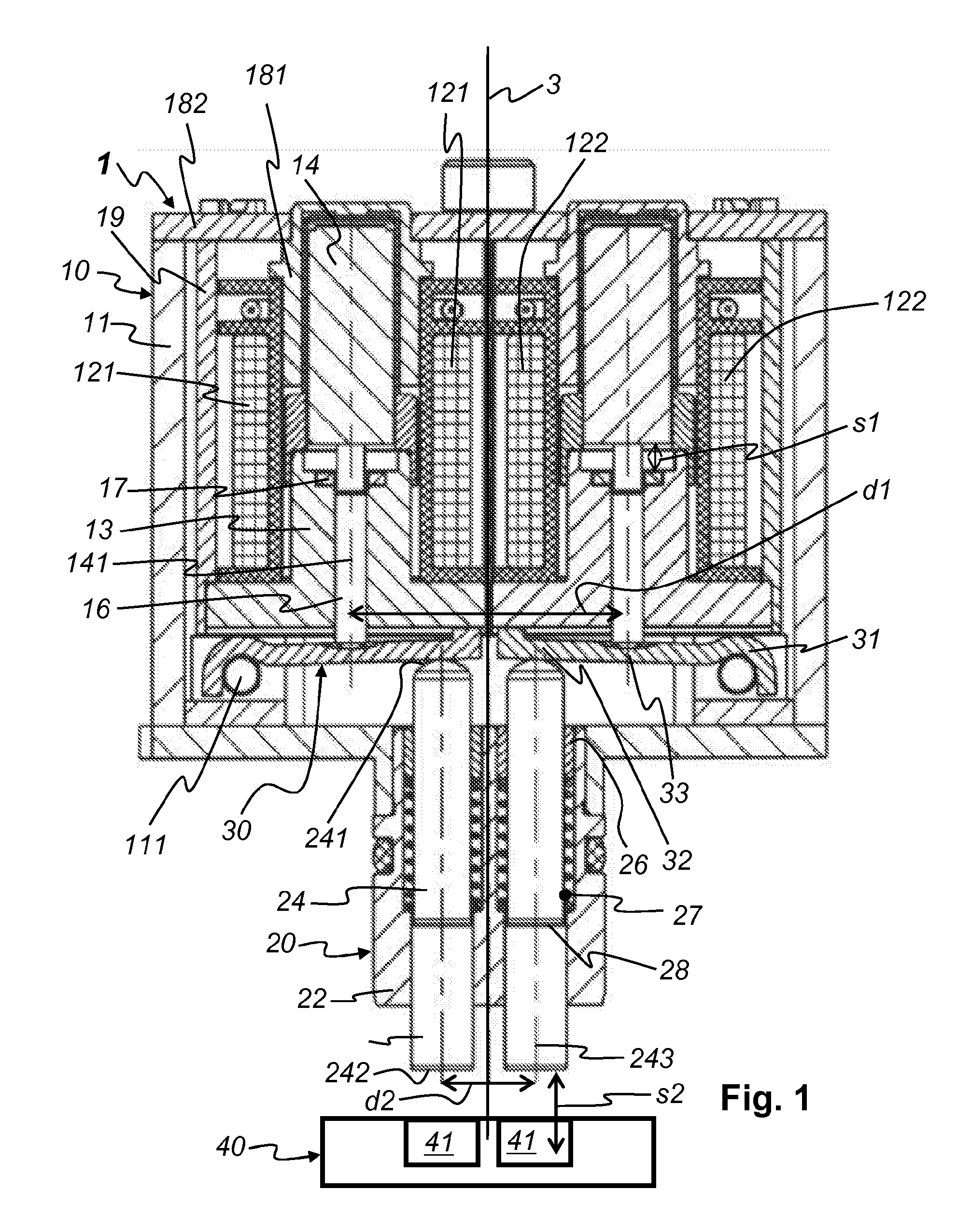

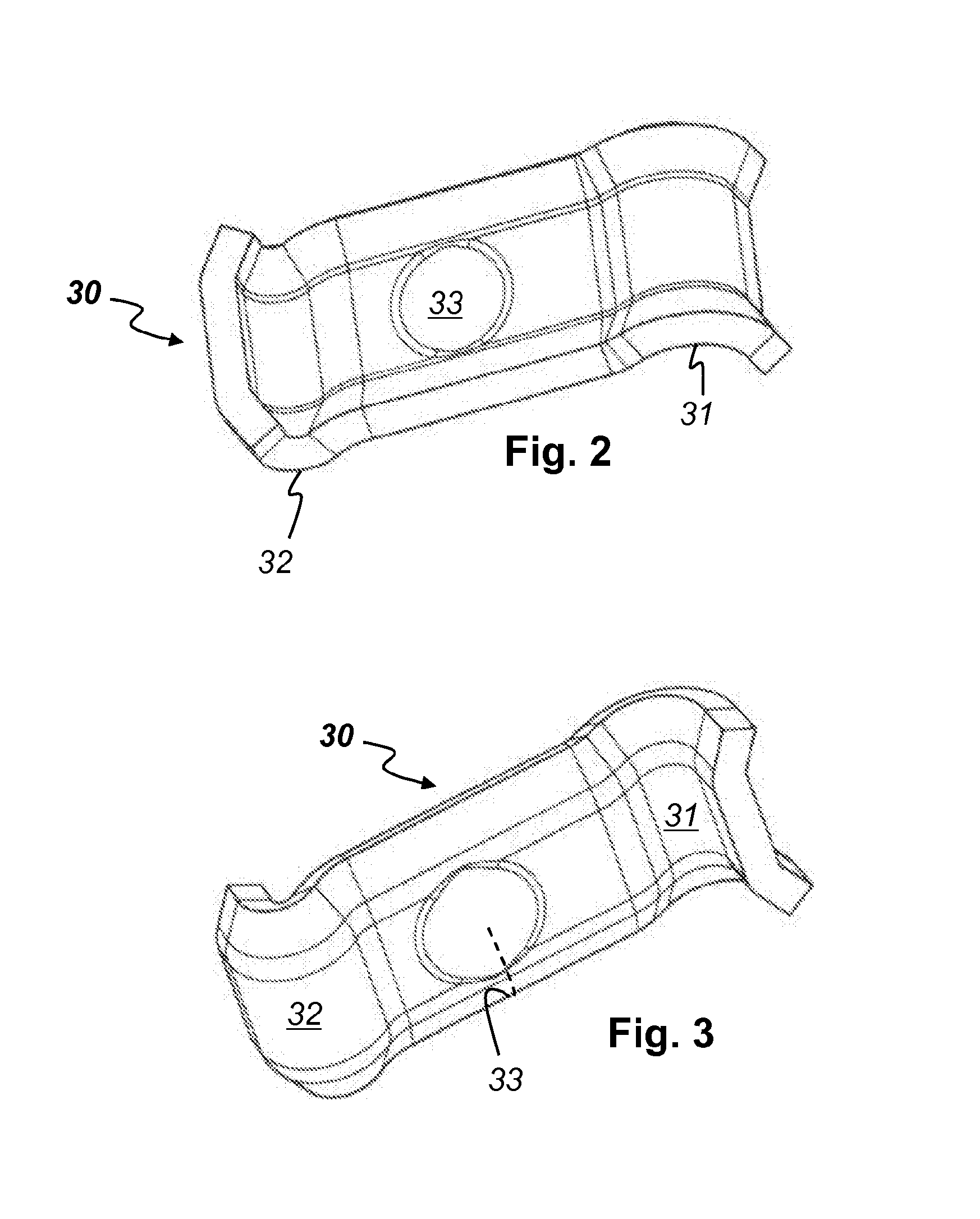

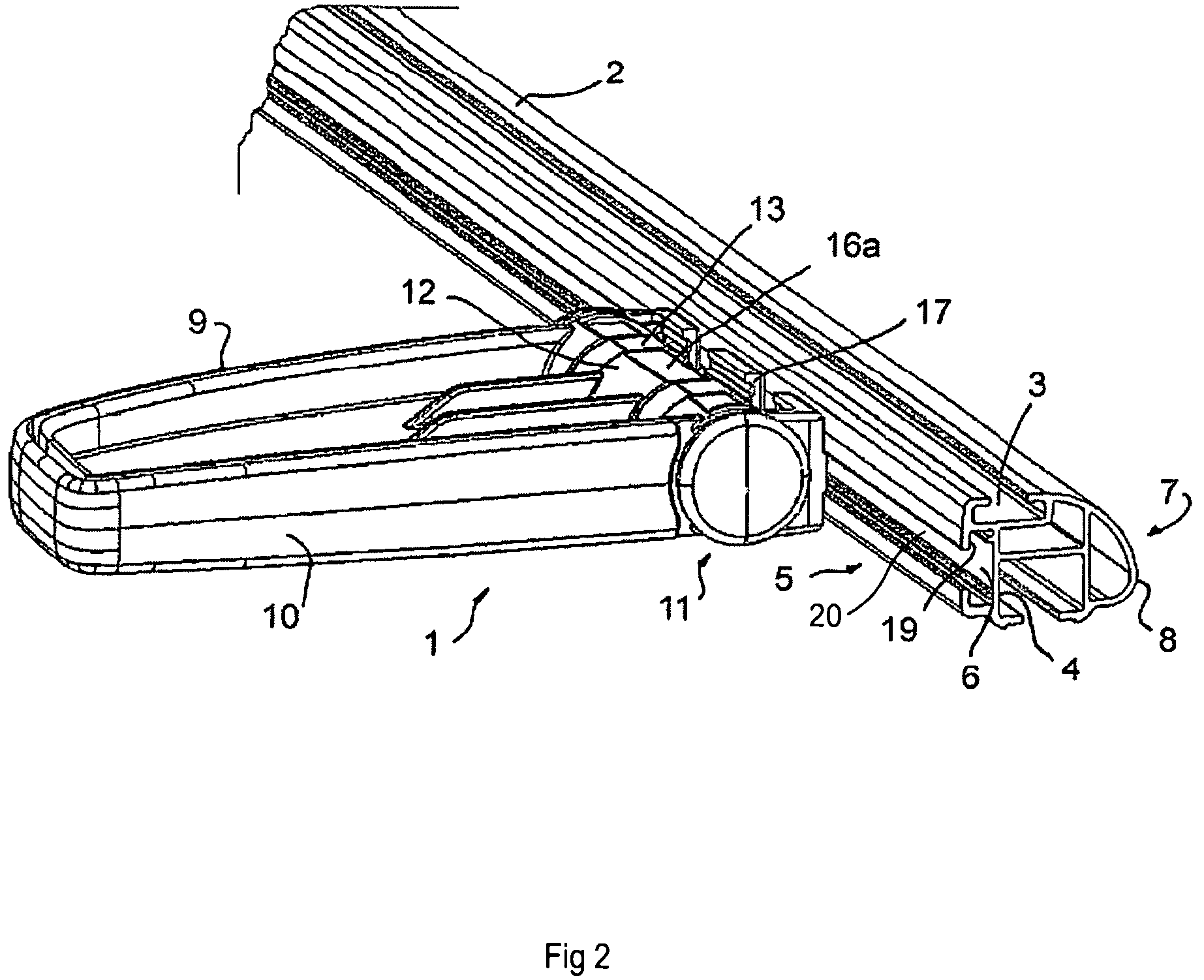

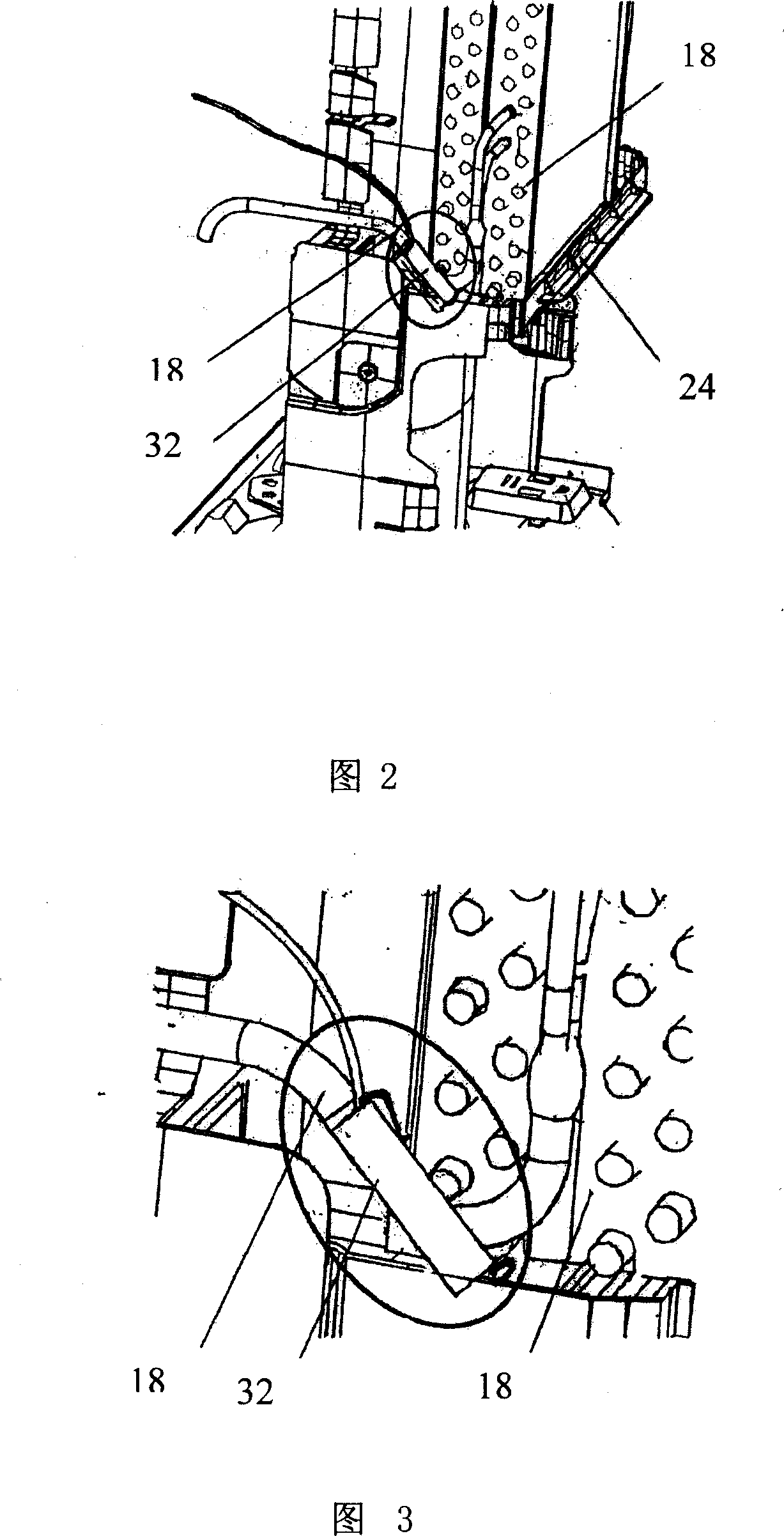

Actuator with transmission element

ActiveUS20160125990A1Cost-effectively assembledCost-effectively manufacturedValve arrangementsMachines/enginesEngineeringActuator

An actuator (1) including at least one electromagnet (121, 122, 13, 14, 16, 17, 181, 182, 19, a magnet housing (11), at least one thrust pin (24) and at least one movable armature (14) with a respective plunger (16) that is movable in an axial direction is provided. When the at least one electromagnet (10) is energized, an axial movement of the at least one armature (14) can be transmitted via the at least one plunger (16) to the at least one thrust pin (24). At least one lever (30) is provided which is pivotably mounted on one side in the magnet housing (11) and with which at least one plunger (16) and the at least one thrust pin (24) are operatively connected such that the axial movement of the at least one plunger (16) can be transmitted to the at least one thrust pin (24).

Owner:SCHAEFFLER TECH AG & CO KG

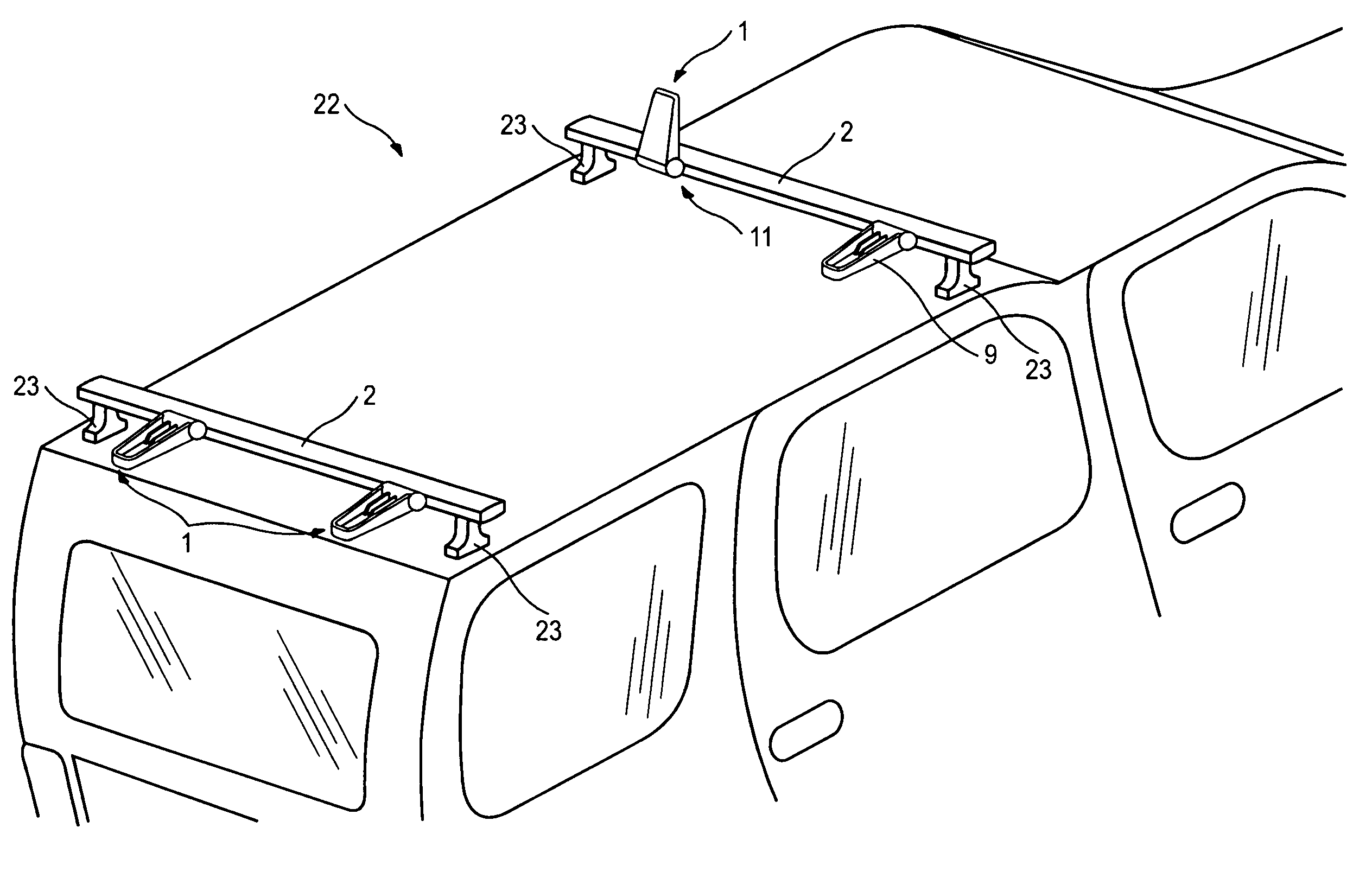

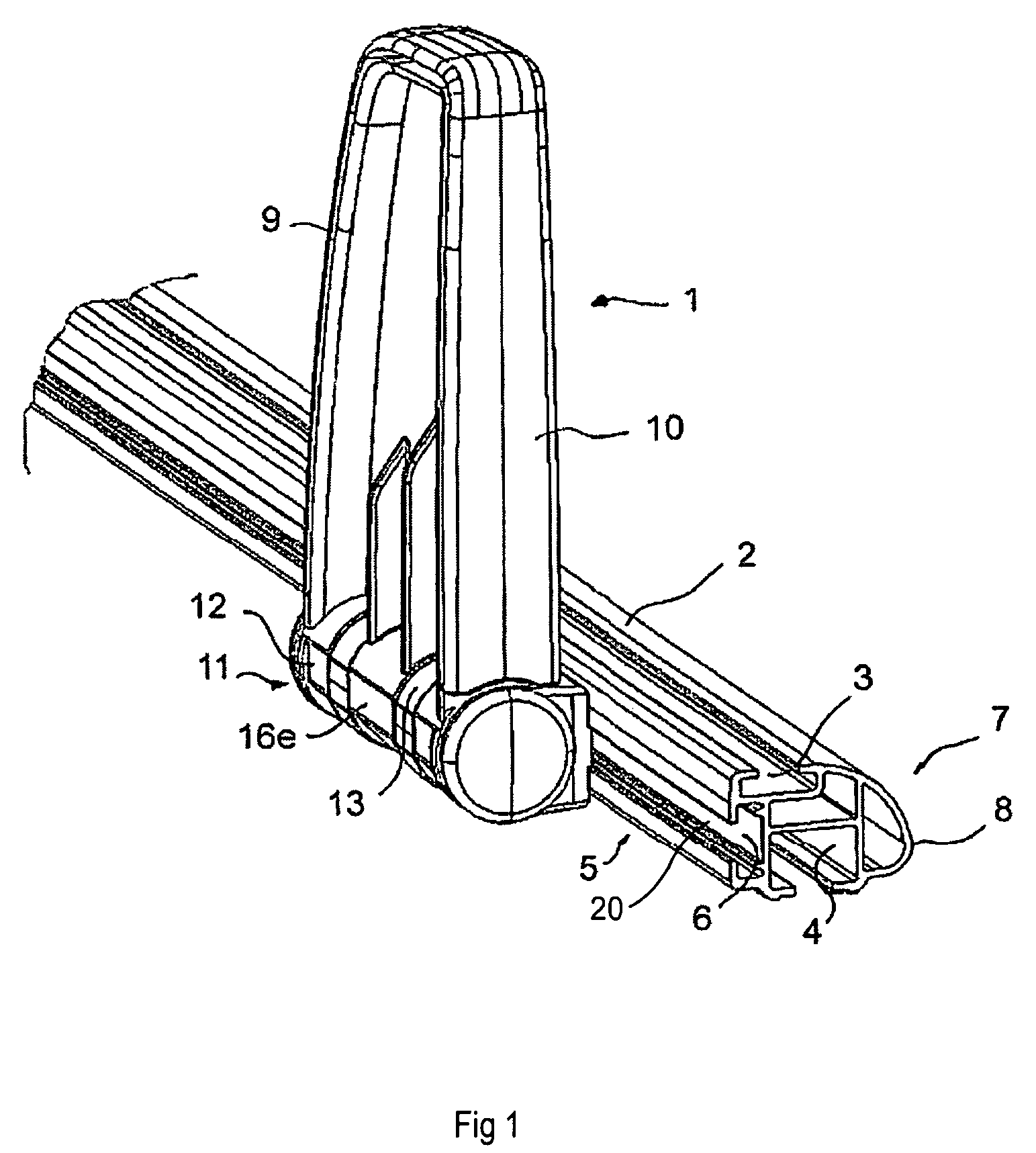

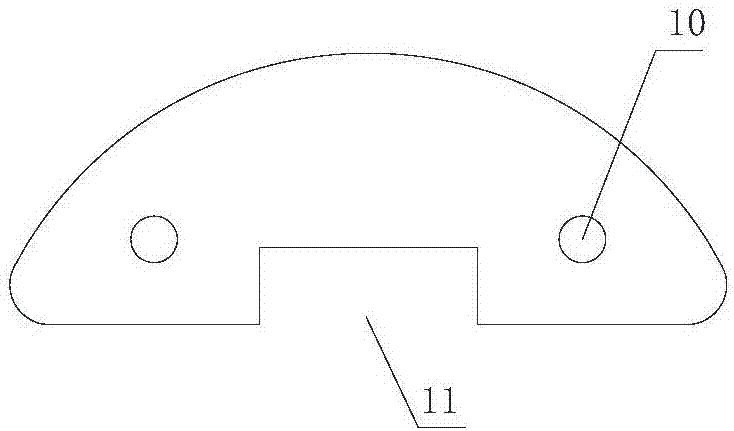

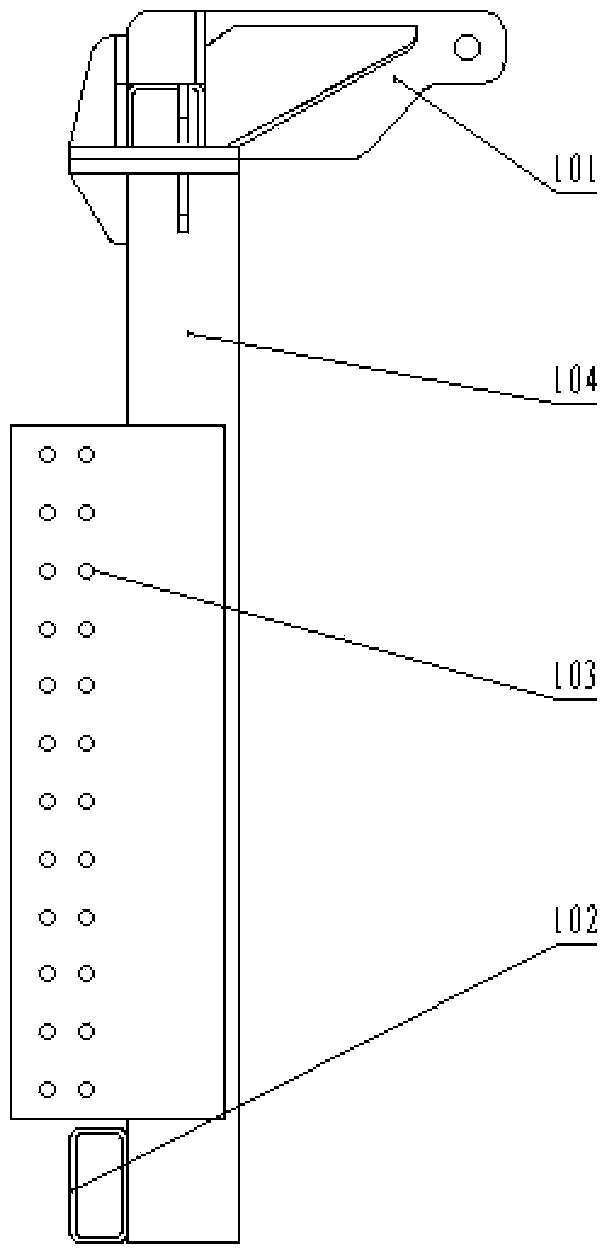

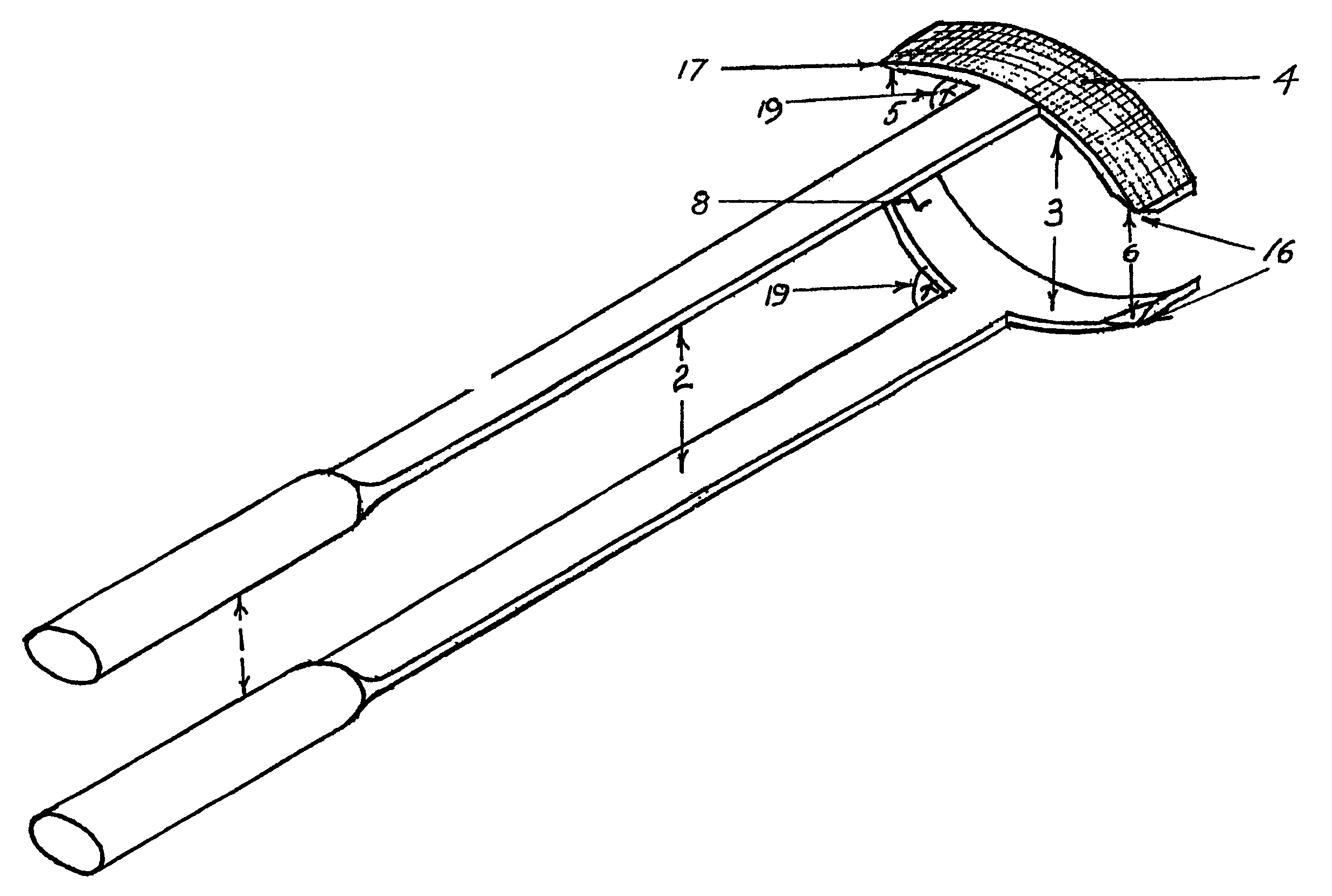

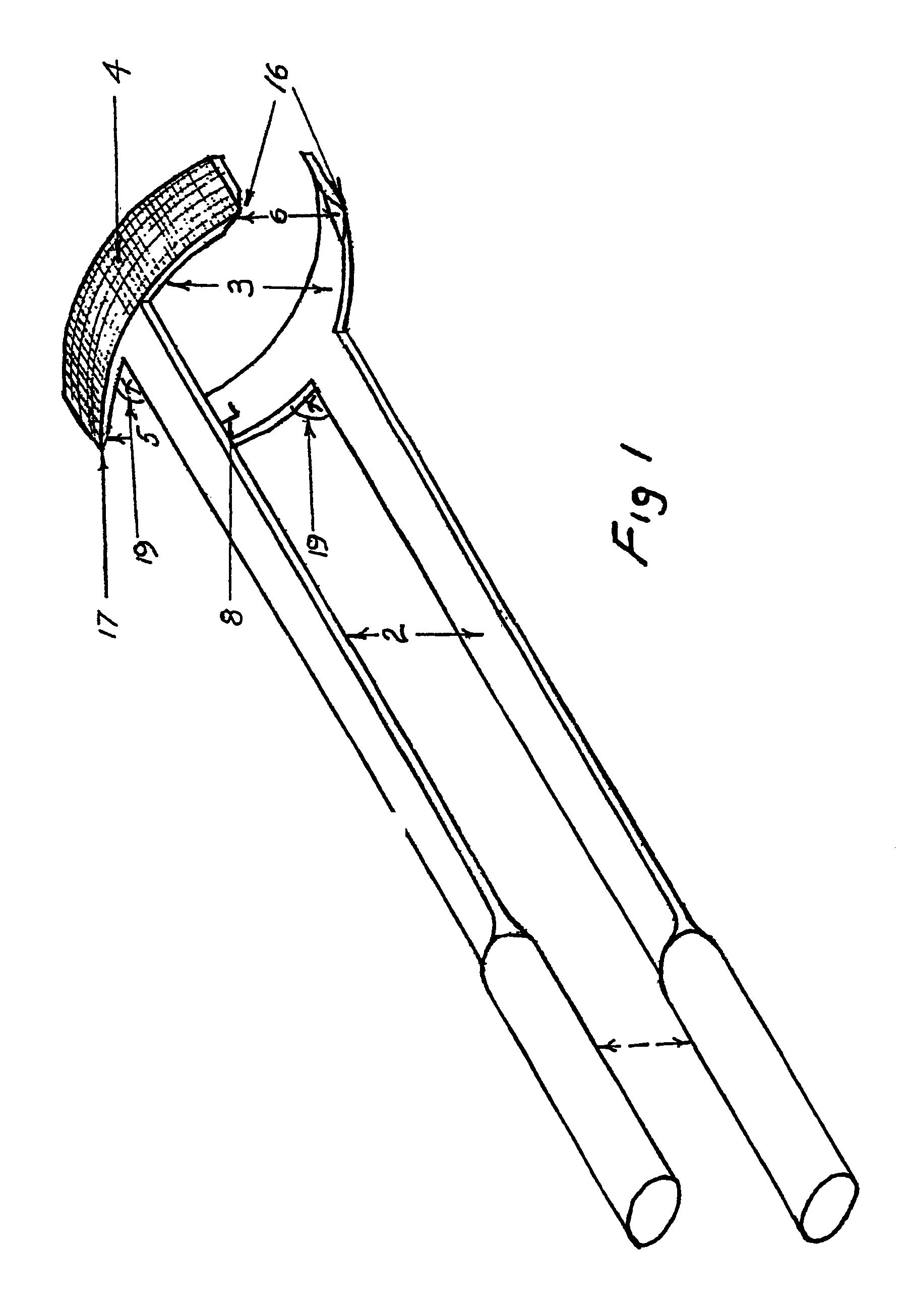

Load stop for supporting a load on a load carrier

ActiveUS8113397B2Precise working positionNutsSupplementary fittingsMechanical engineeringLoad carrying

A load stop (1) for supporting a load being transported on a load carrier arranged on a vehicle. The load carrier includes at least one load carrying tube (2) with at least one groove (6) for fastening the load stop on the load carrying tube. The load stop includes an essentially rigid bracket (9) intended to be supportingly arranged adjacent the load. A fastening portion (11) is also provided for mounting the load stop to the load carrying tube. The bracket (9) is pivoted in at the fastening portion (11), wherein the load stop (1) is foldable between at least a raised working position and a folded transporting position.

Owner:THULE SWEDEN AB

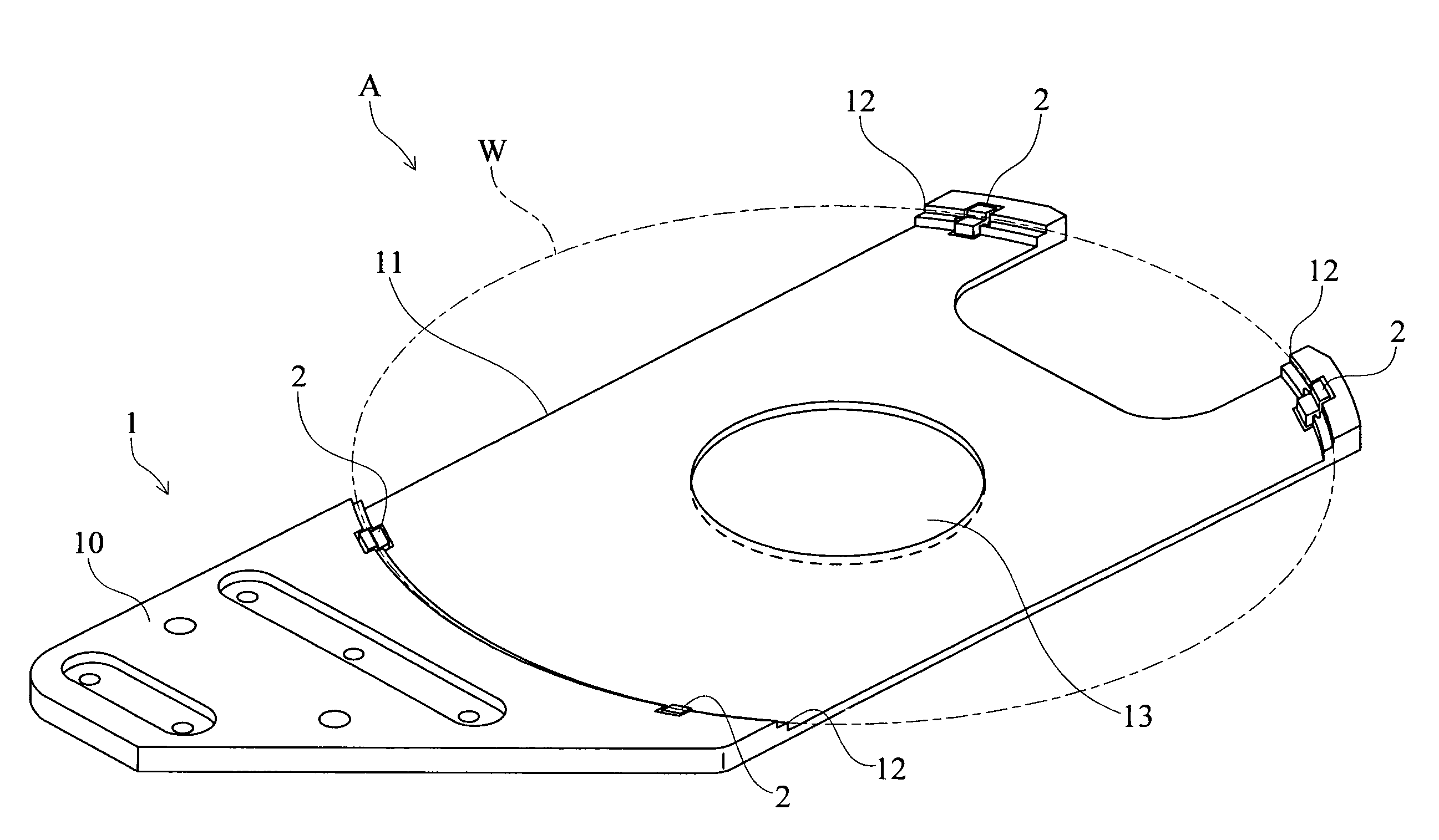

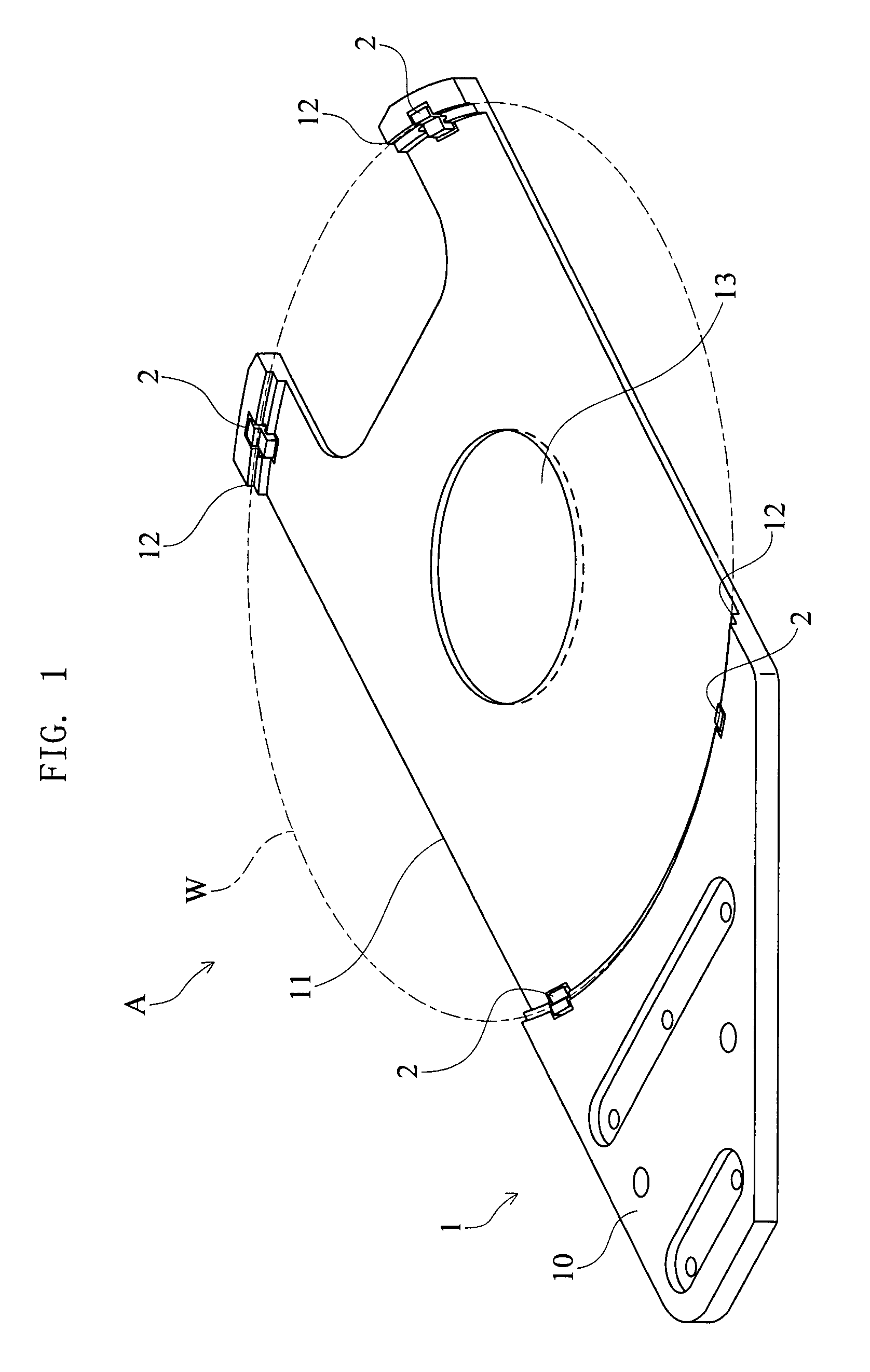

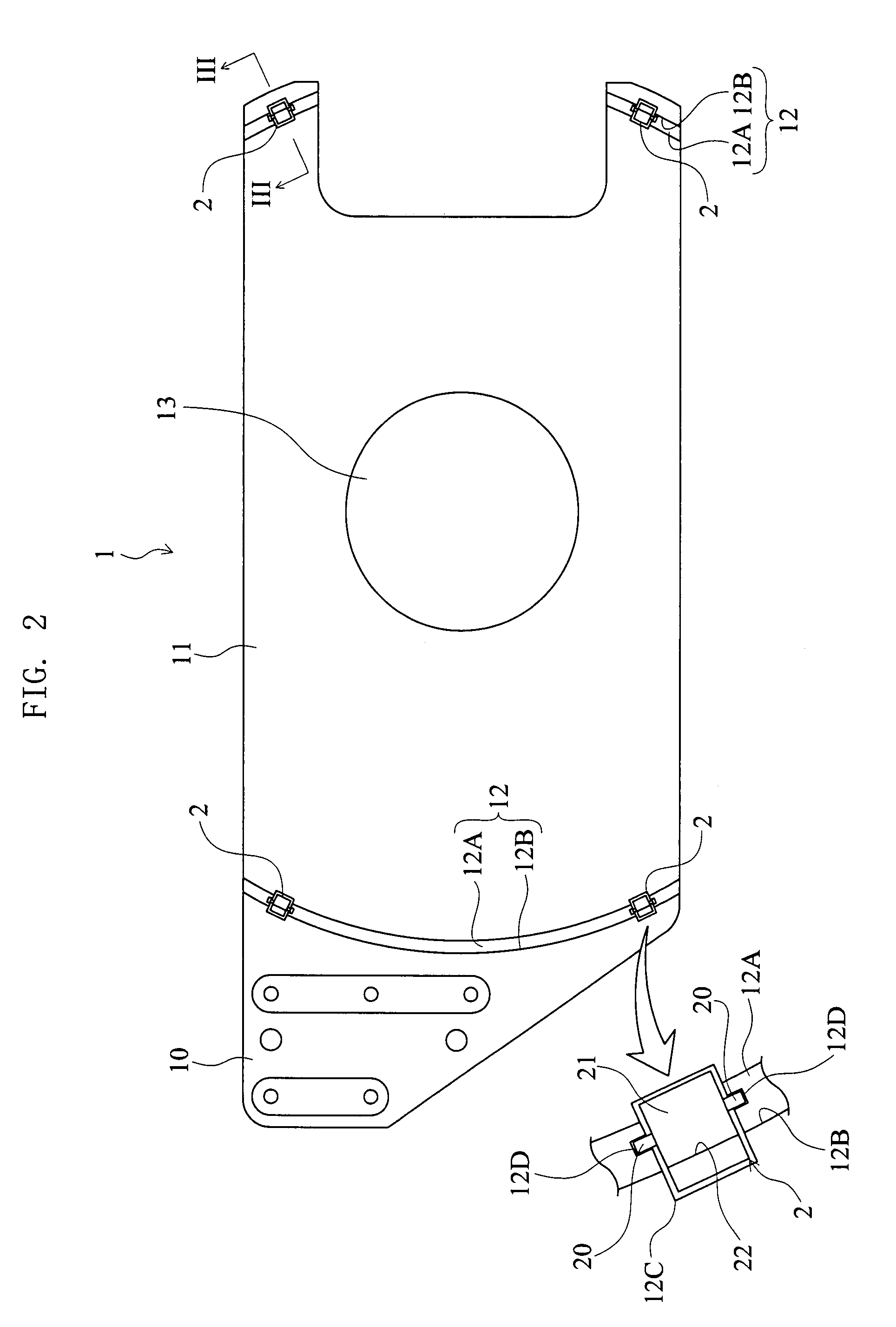

Work holding mechanism

ActiveUS20080099970A1Improve shipping speedVacuum operationSemiconductor/solid-state device manufacturingLifting devicesEngineeringMechanical engineering

Owner:DAIHEN CORP

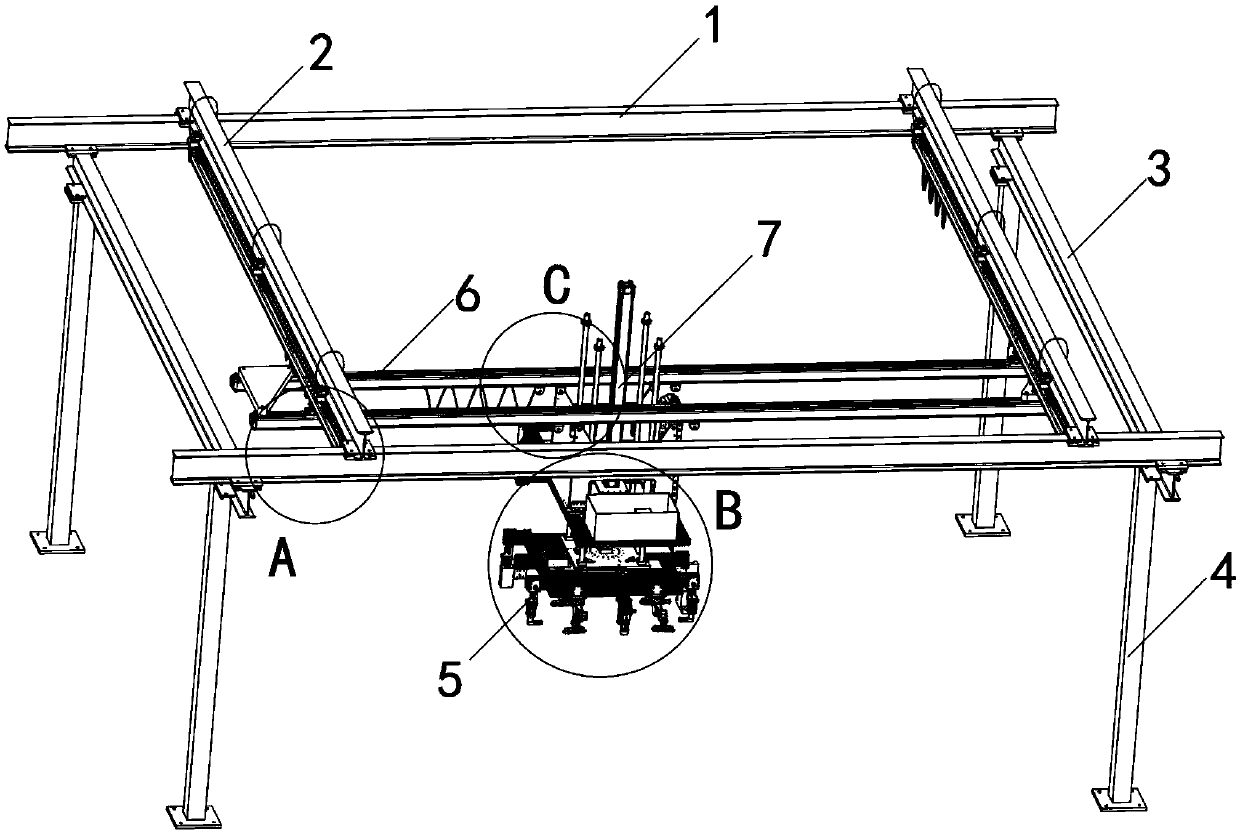

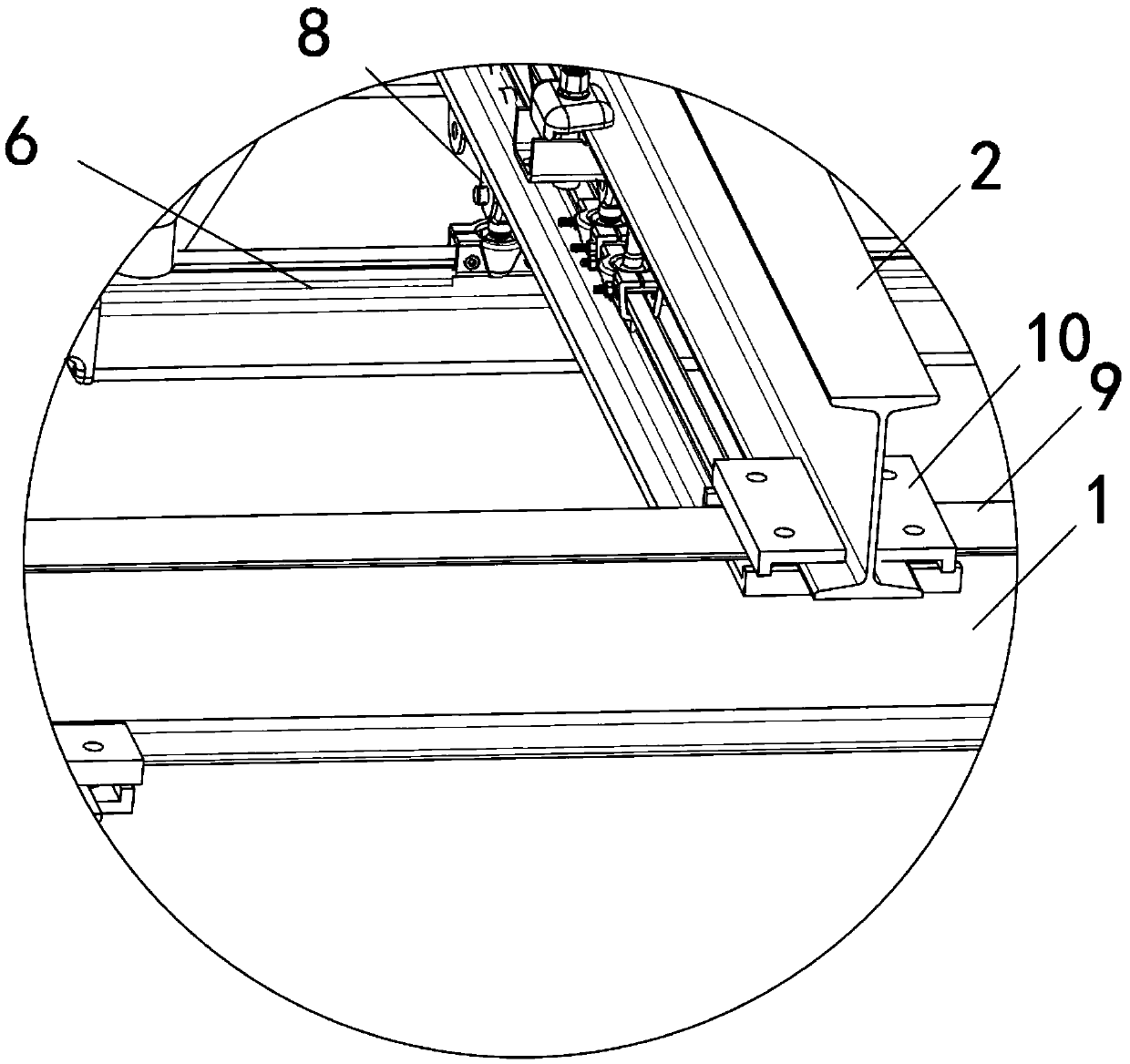

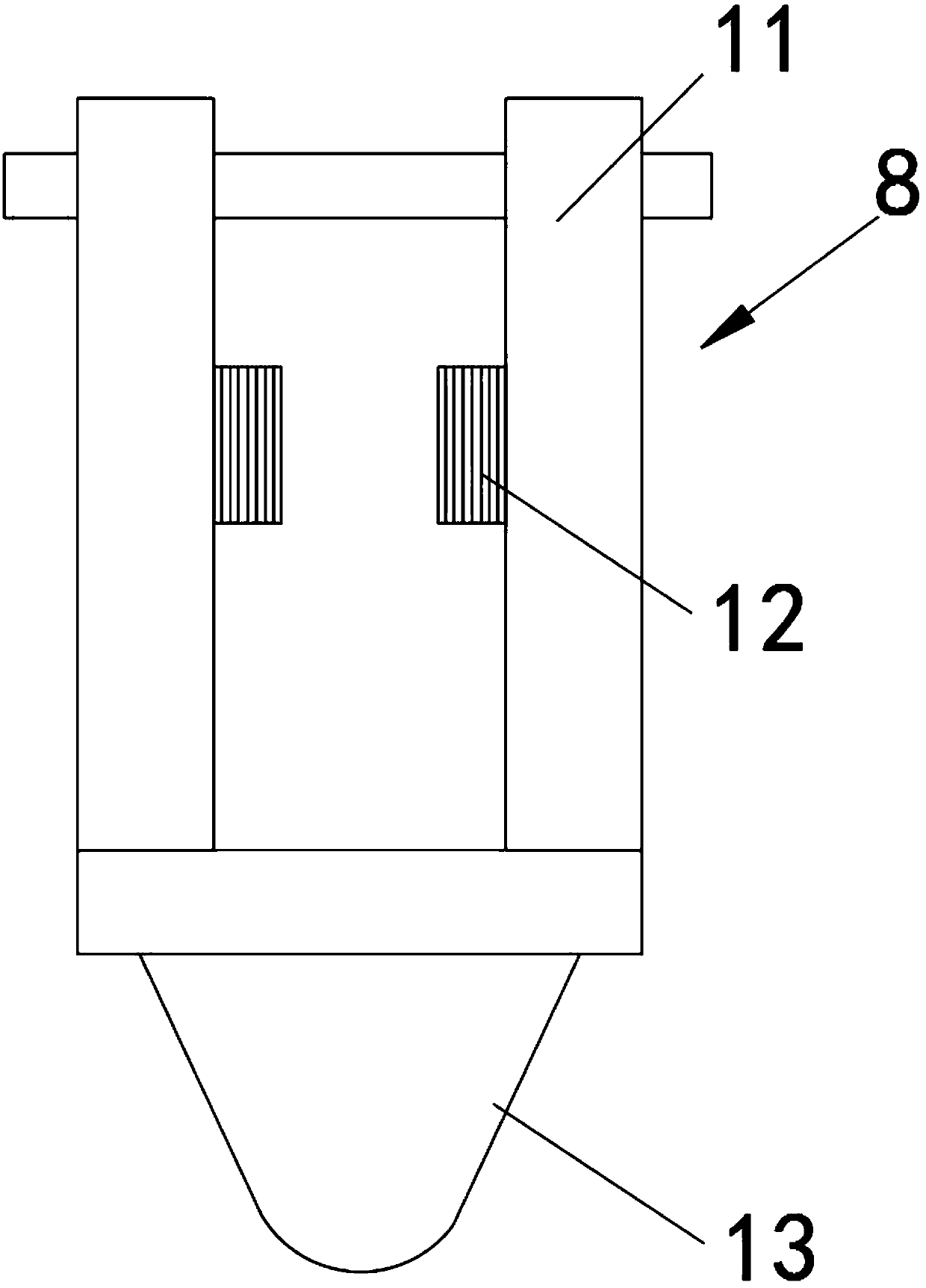

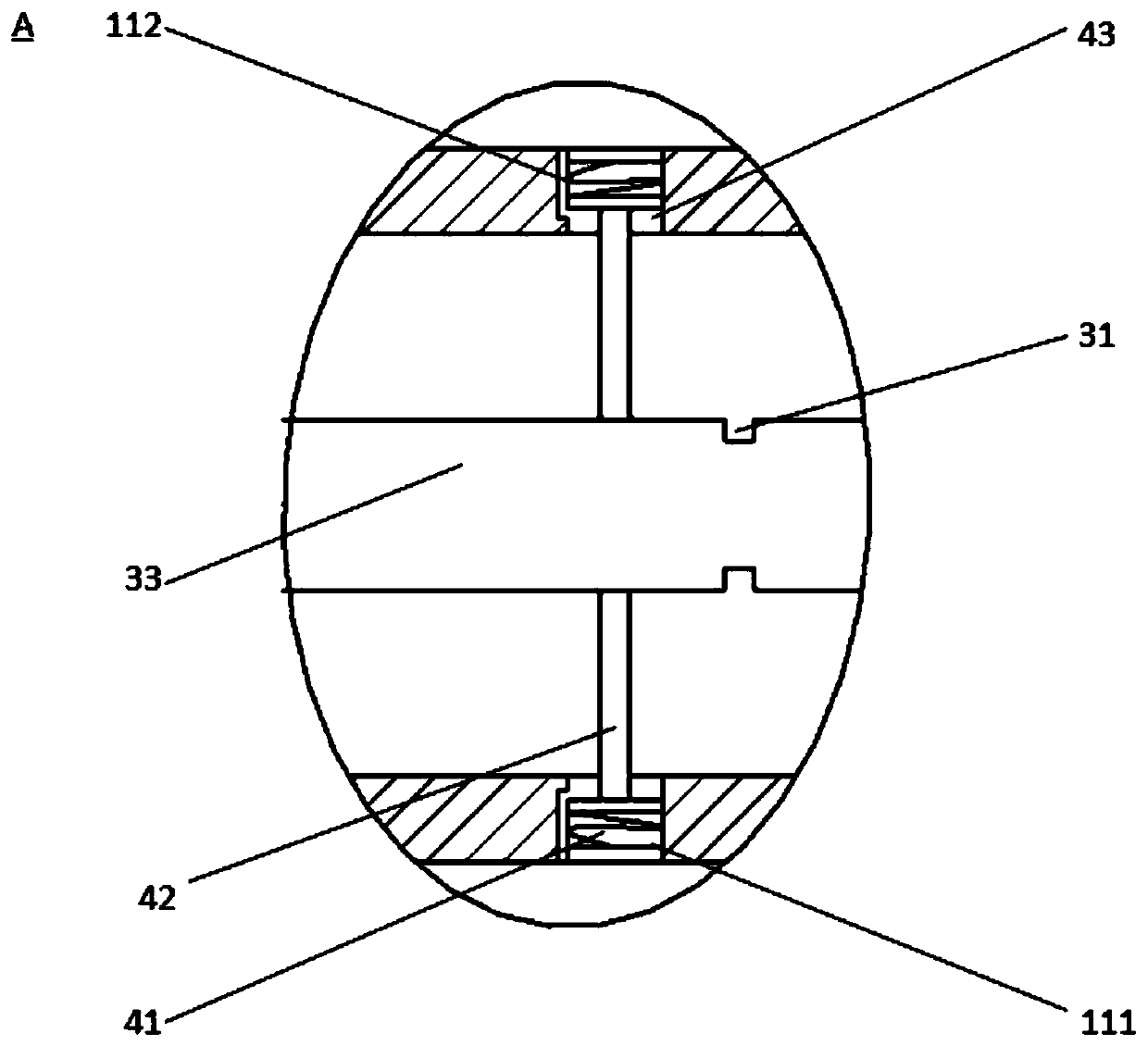

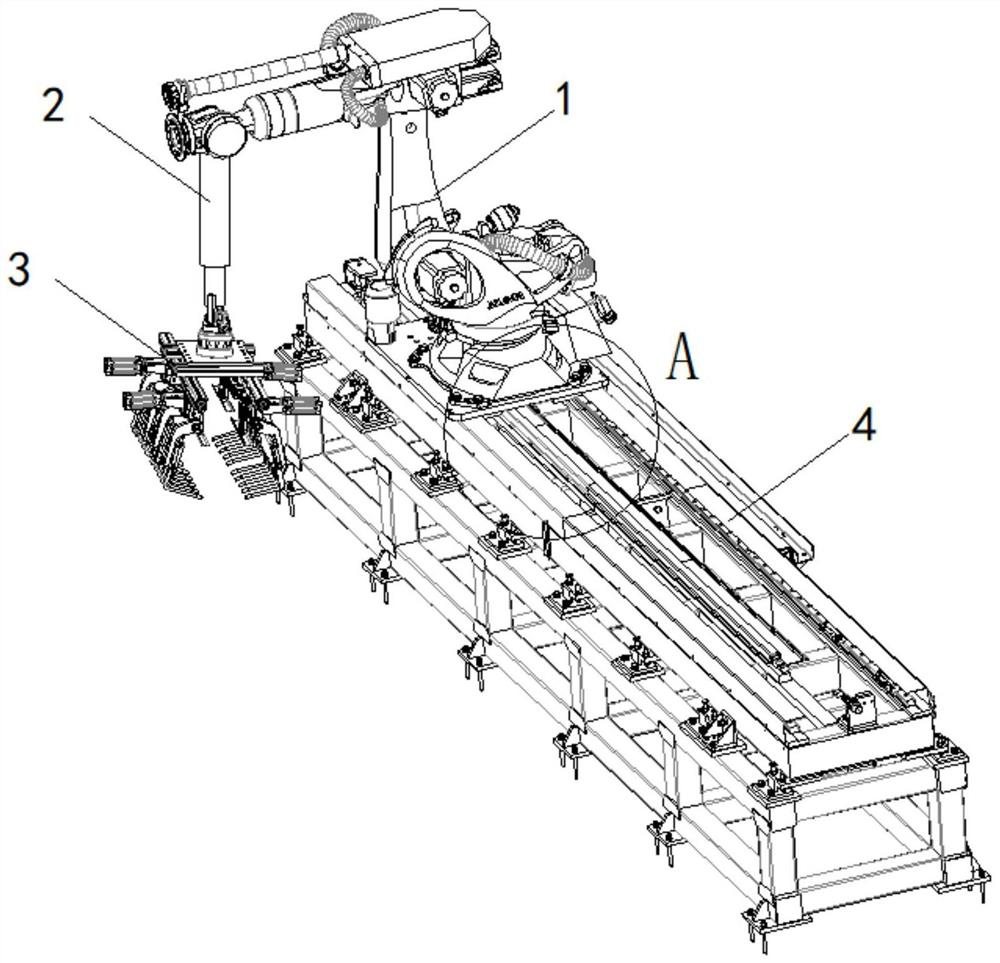

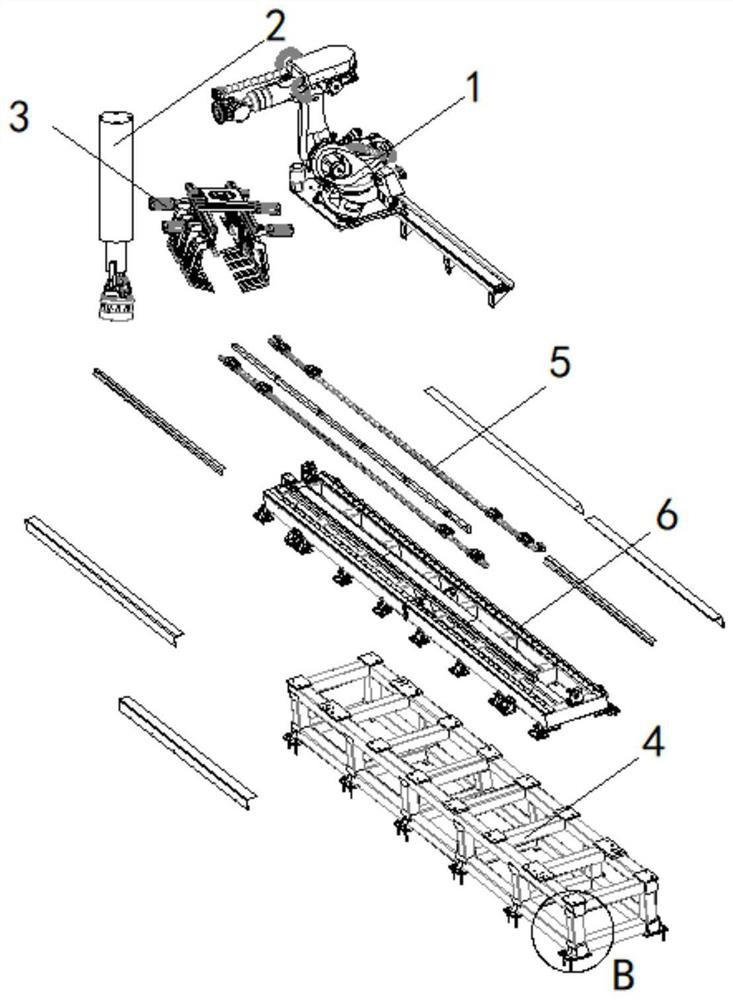

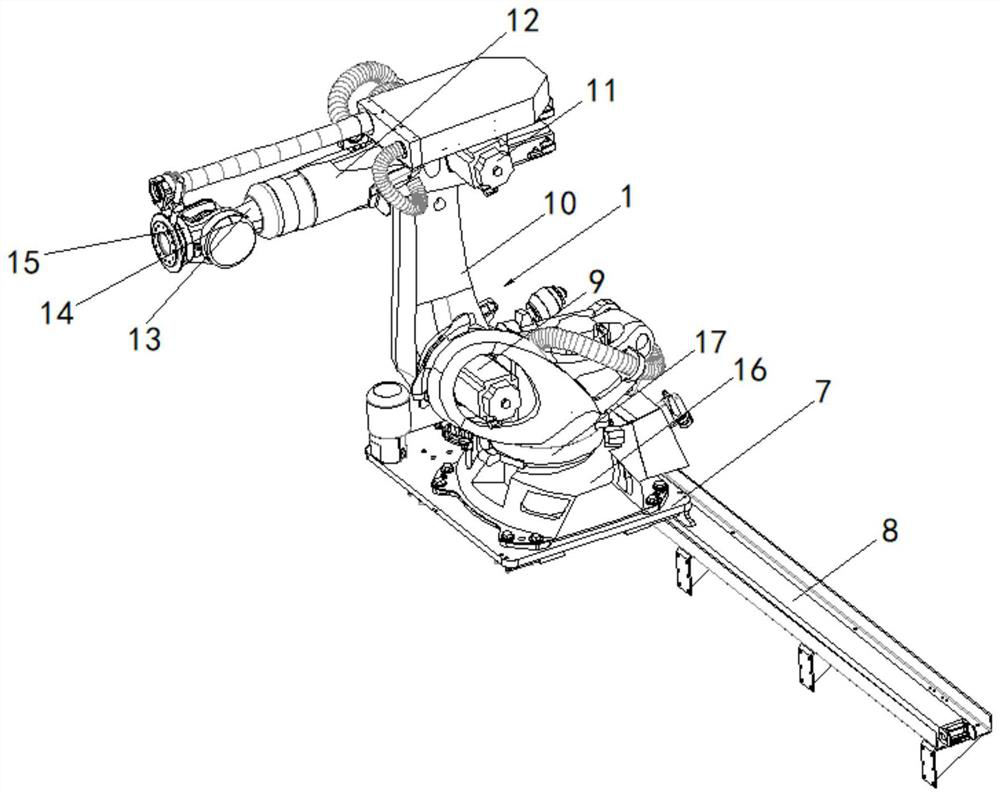

Automatic transferring and placing equipment for building floor slabs and working method thereof

ActiveCN109625939AConvenient pick-and-place transferEasy to operateConveyor partsFloor slabEngineering

Owner:云南天珲建设工程有限公司

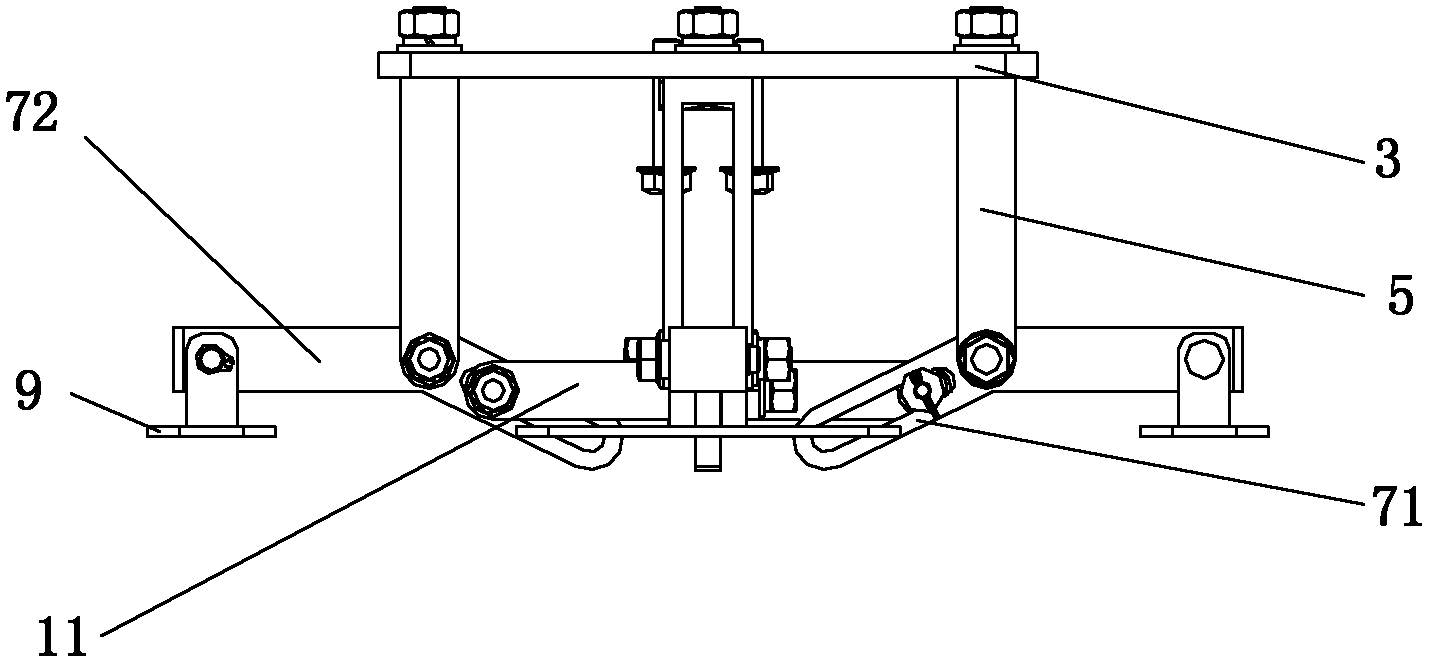

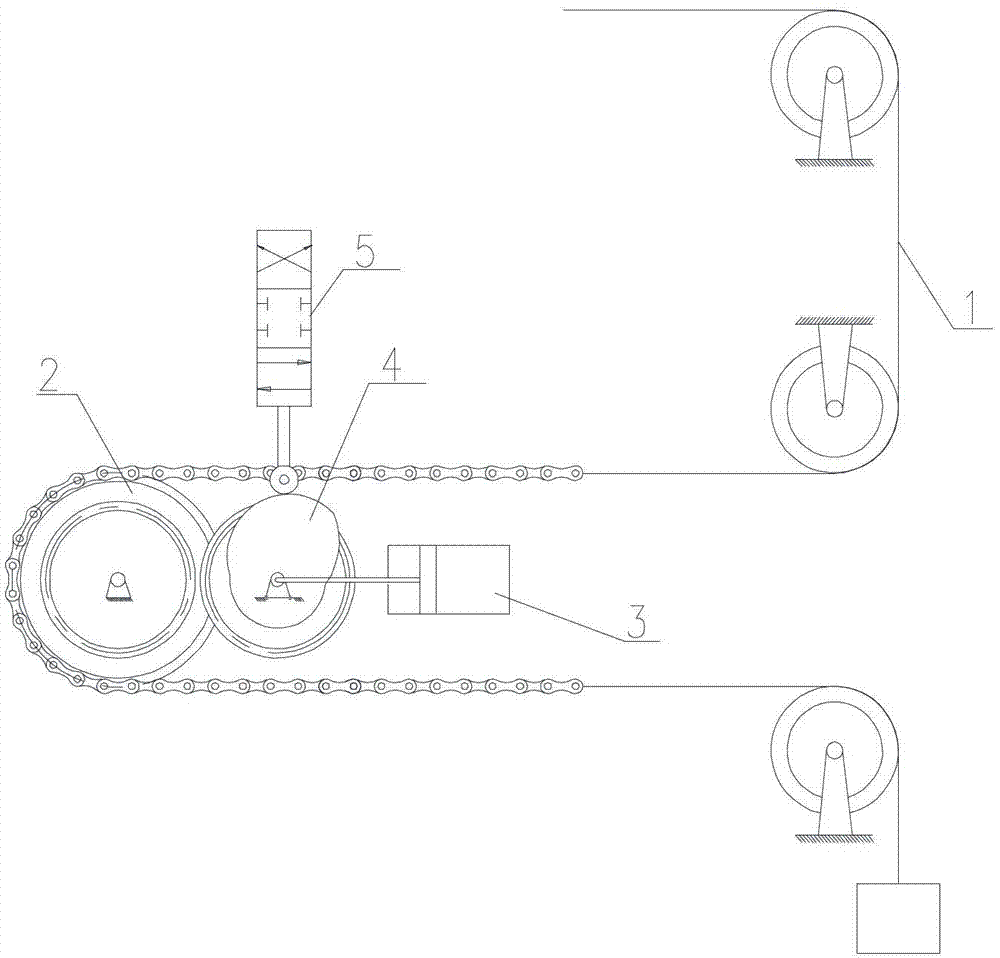

Intermittent self-locking type chain fastening device for scraper machine and chain fastening method

PendingCN108217089APrecise working positionAdapt to the working environmentConveyorsHydraulic cylinderCoupling

The invention provides an intermittent self-locking type chain fastening device for a scraper machine. The intermittent self-locking type chain fastening device comprises a connecting hood barrel andan intermittent hydraulic chain fastening mechanism. The intermittent hydraulic chain fastening mechanism is installed in the connecting hood barrel. The hydraulic chain fastening mechanism comprisesa hydraulic cylinder, a rack, a ratchet-gear wheel, a first pawl, a first ratchet, a coupling, a second ratchet and a second pawl. One end of the rack is fixedly connected with one end of the hydraulic cylinder. The rack and the ratchet-gear wheel are engaged. According to the intermittent self-locking type chain fastening device, the hydraulic cylinder is adopted as a power part, and the intermittent self-locked type chain fastening device can better adapt to a downhole emulsified liquid working environment; the working position of the hydraulic cylinder is accurate, and the tensioning degreeof a chain can be controlled accurately; self-locking of the two sets of ratchets and pawls at any time is achieved , and locking reliability is high; the hydraulic cylinder is arranged to be perpendicular to the transmission direction of the power part, the sizes of the ratchet-gear wheel and the rack are adjusted conveniently, and the size of the chain fastening device can be reduced effectively; the ratchet and pawl structure is achieved, torque is large, and the transmission efficiency is high. The invention further provides a chain fastening method of the intermittent self-locking type chain fastening device for the scraper machine.

Owner:NINGXIA TIANDI BENNIU IND GRP +1

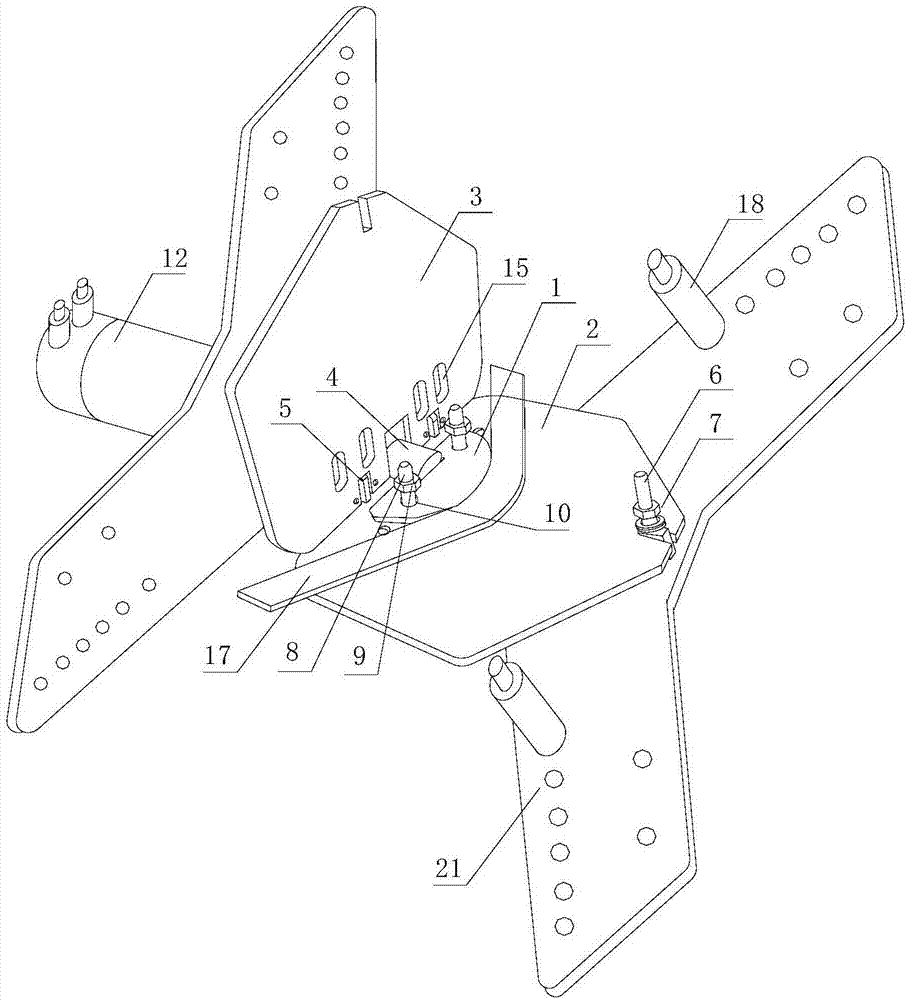

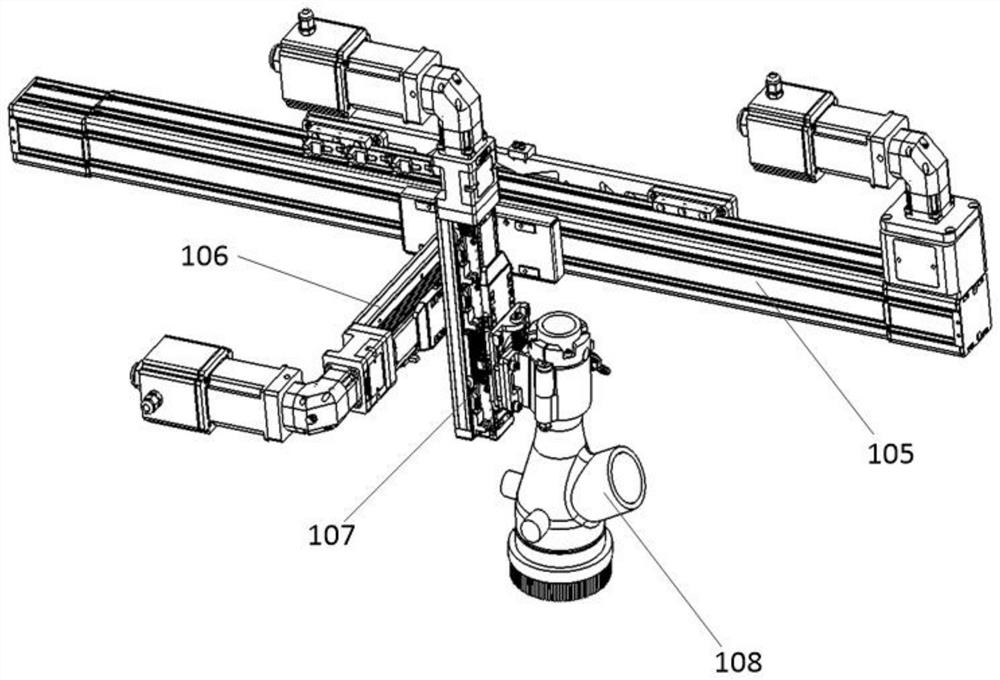

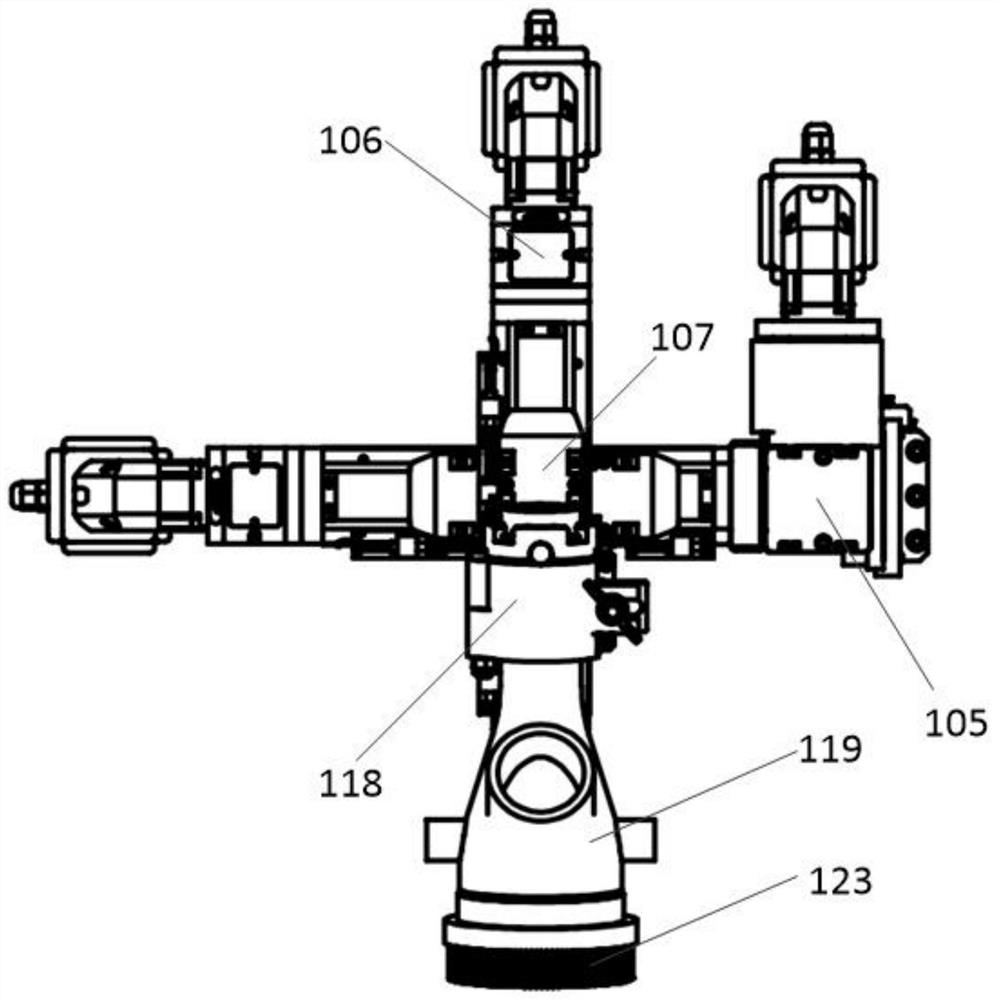

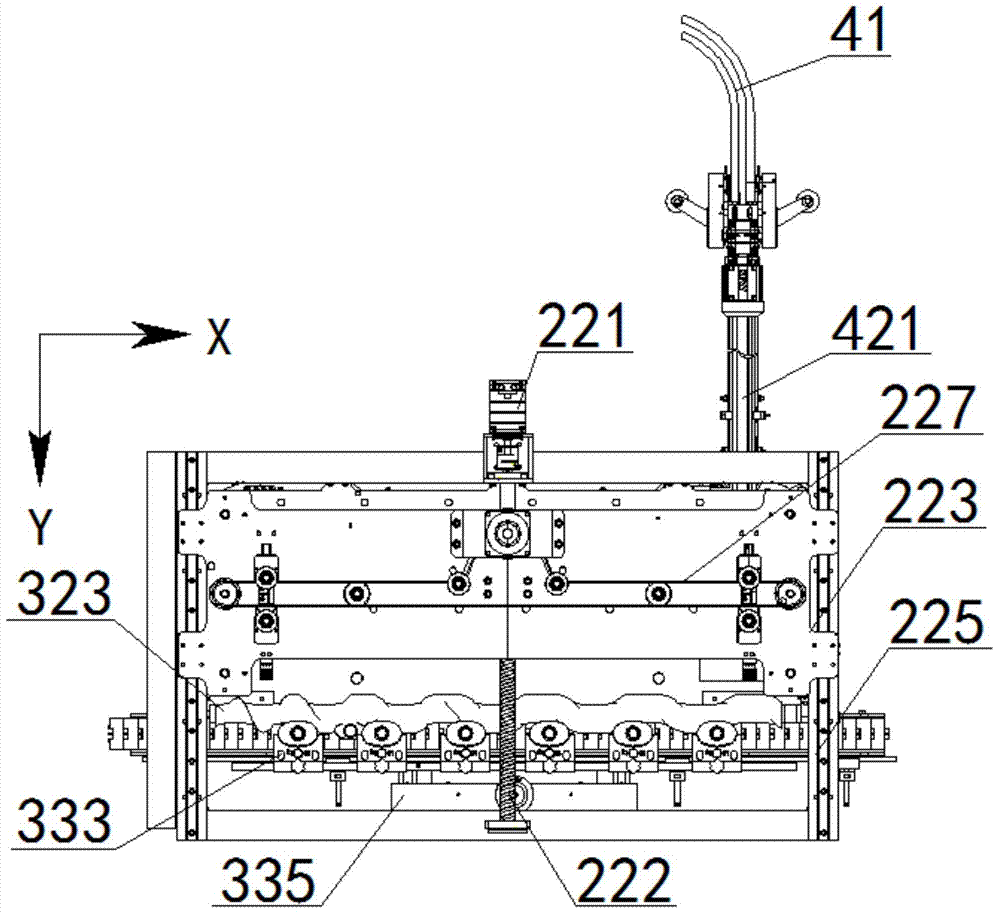

Manipulator unit and production line with same

The invention provides a manipulator unit which comprises a machine frame, a power source and a control device, wherein the power source and the control device are connected, and the power source is controlled via the control device; a clamp plate device is arranged on the machine frame, and comprises a fixing plate on which a supporting rod is arranged; the supporting rod is hinged with a clamp plate arm; the clamp plate arm comprises an upper clamp plate arm and a lower clamp plate arm; an opening groove is arranged at the upper clamp plate arm, and a clamp plate is arranged at the tail end of the lower clamp plate arm; one end of a shifting fork is arranged in the opening groove of the upper clamp plate groove in a manner of slipping, and while the other end of the shifting fork is connected with a first power source and driven by the first power source to move in a vertical direction by a reciprocating way; the fixing plate is connected with a second power source, and the clamp plate drive is driven to upwards move in the level direction by the reciprocating way through the fixing plate; and a working channel is also arranged on the machine frame. A production line is structured as follows: the manipulator units are arranged at intervals in a conveyor belt; and a baffle plate is arranged between the working channels of two adjacent manipulator units. The manipulator unit and the production line have simple structures, can be operated conveniently, and have accurate working positions; the products are shaped during being picked; and with adoption of the manipulator unit and the production line, the continuous production can be achieved along with high production efficiency and high controllability can be ensured.

Owner:TIANJIN TASLY PHARMA CO LTD

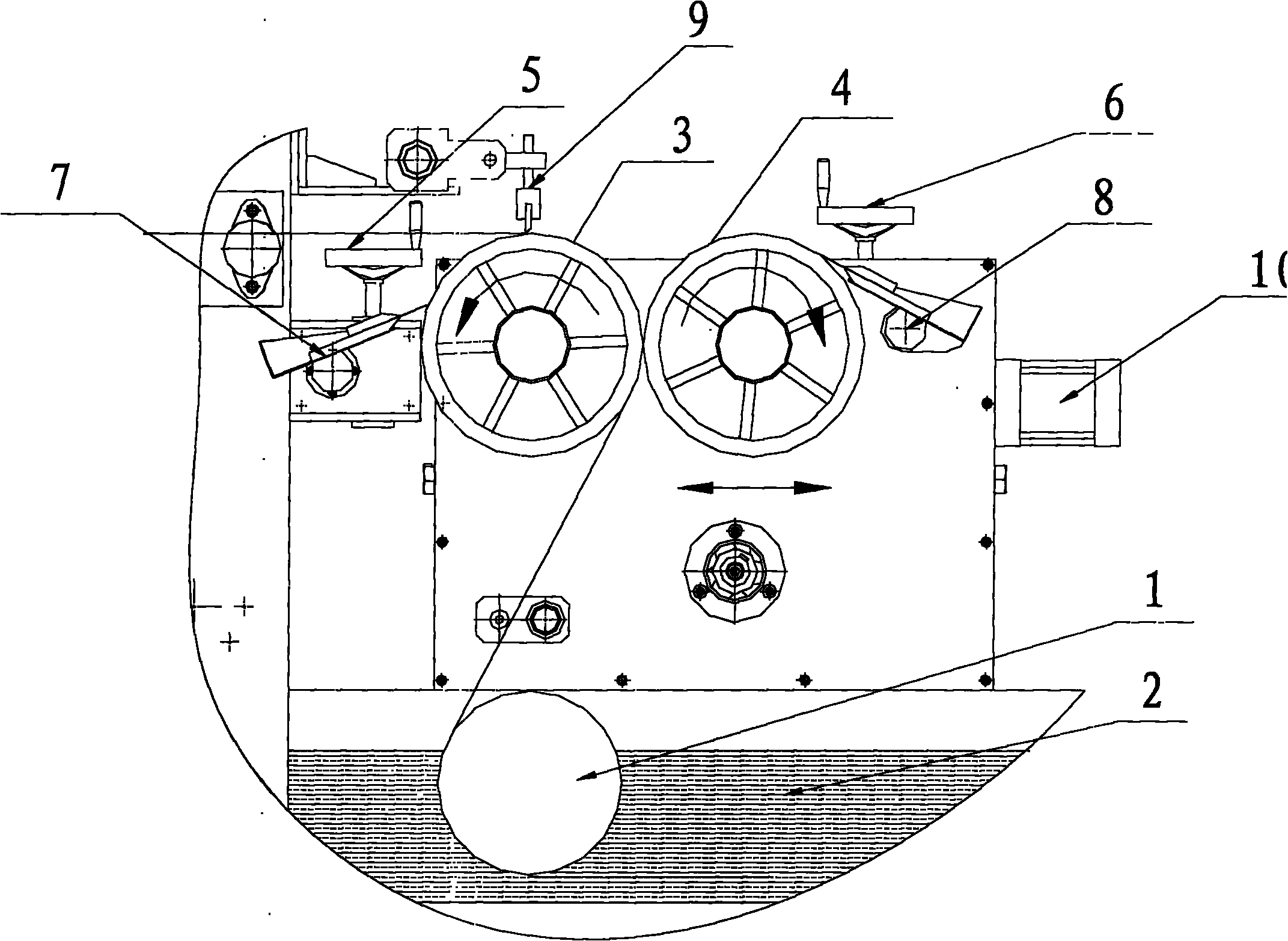

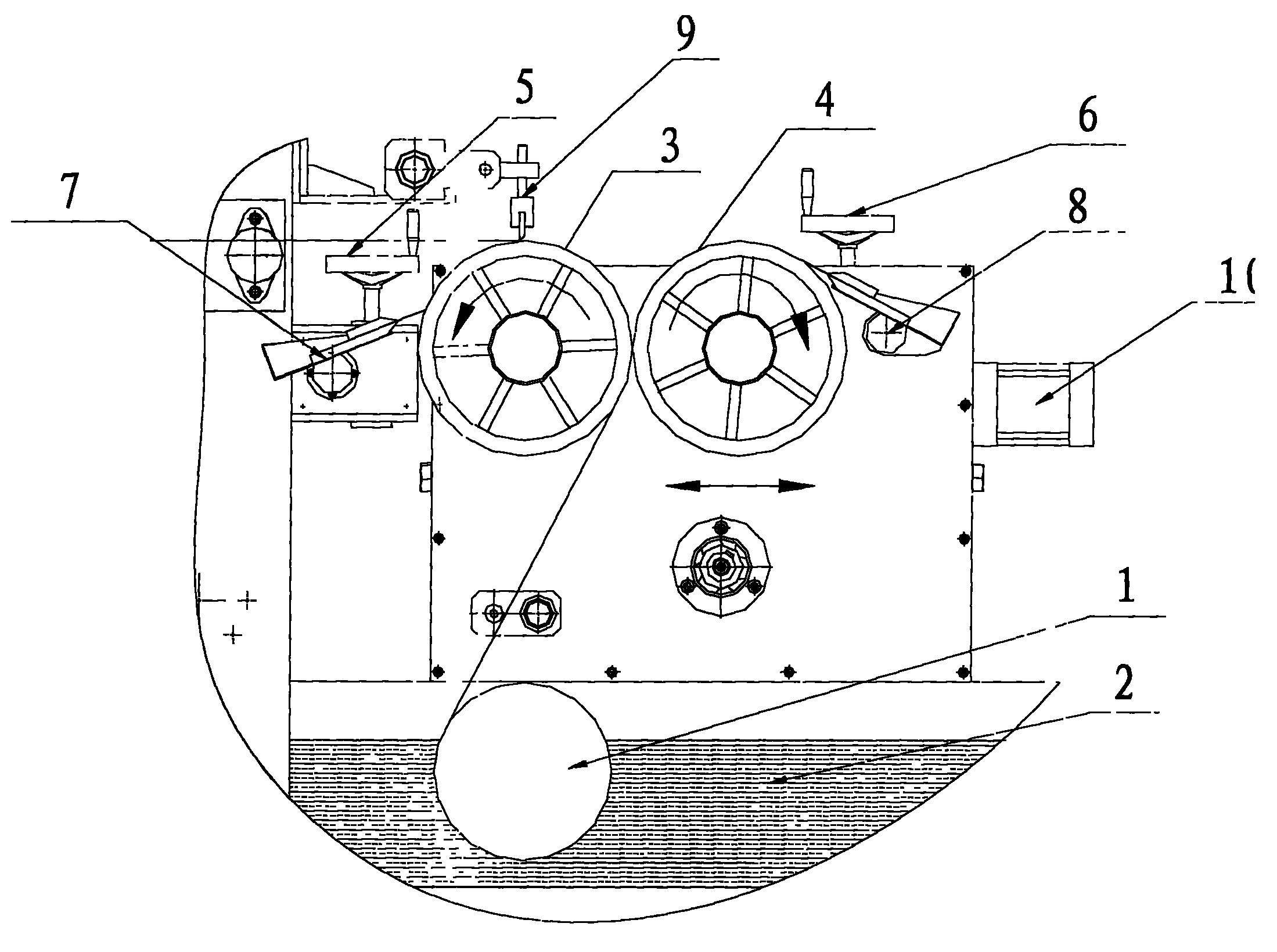

Impregnating and glue squeezing device

InactiveCN102108654AImprove measurement accuracyEasy to open and closePaper/cardboardPulp and paper industry

The invention provides an impregnating and glue squeezing device. The device is characterized by comprising an impregnating roll, a glue squeezing roll 1 and a glue squeezing roll 2, wherein the glue squeezing roll 1 and the glue squeezing roll 2 have the same diameter and rotate synchronously; the impregnating roll is arranged in a glue tank; the glue squeezing roll 1 and the glue squeezing roll 2 are respectively connected with a cylinder and are arranged on a straight guide rail; a certain distance is reserved between the two glue squeezing rolls; and the two glue squeezing rolls are driven by the same motor. The impregnating and glue squeezing device provided by the invention squeezes glue uniformly and accurately, so the paper does not have patterns.

Owner:NANTONG SITONG FORESTRY MACHINE MFG INSTALLATION

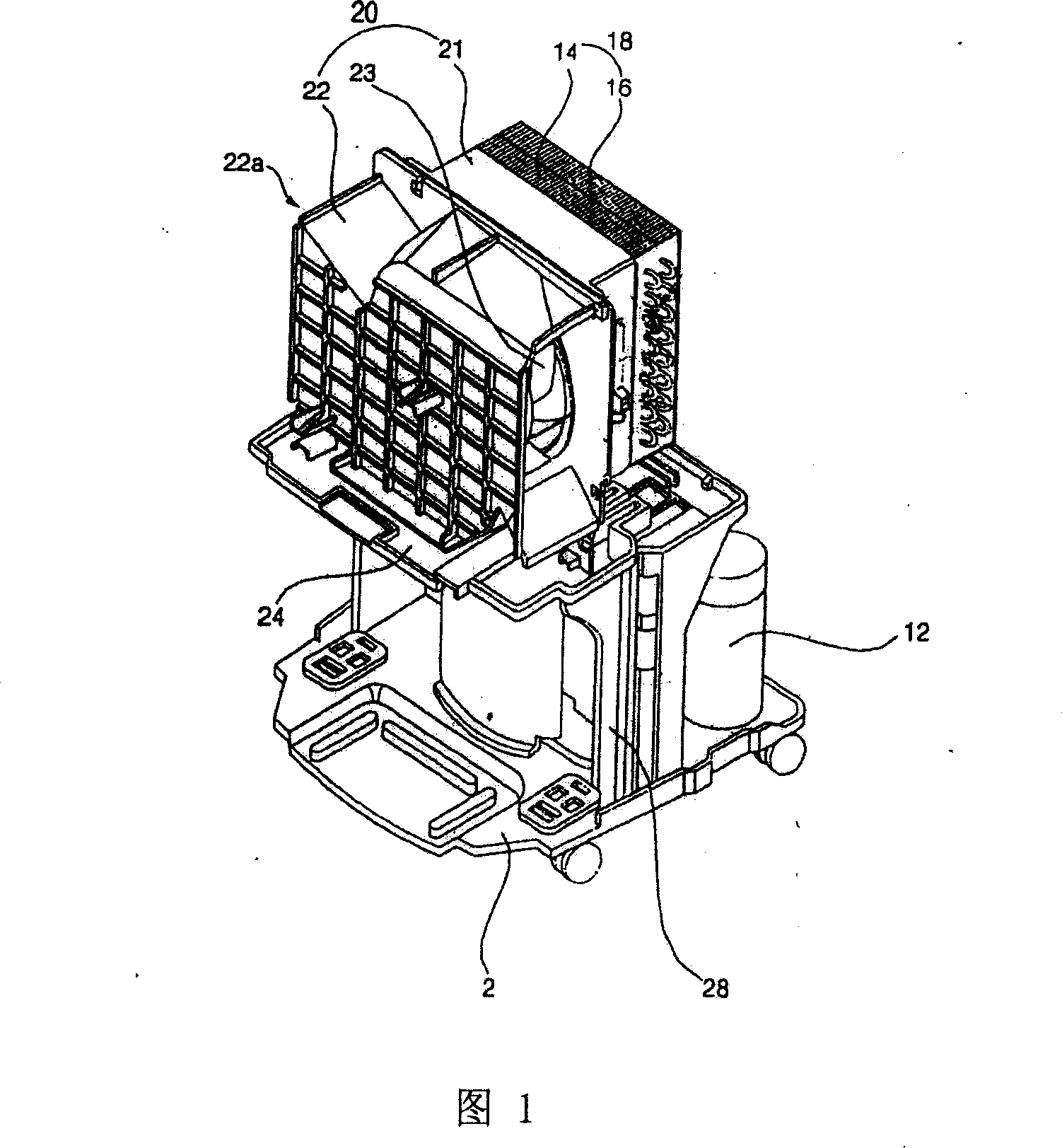

Temperature sensor fixing structure of heat converter

InactiveCN101109555ANo displacementPrecise working positionSpace heating and ventilation safety systemsLighting and heating apparatusControl systemEngineering

The invention pertains to the technical field for the control system of an air conditioner to adjust the temperature, and provides a fixing structure for a temperature sensor of a heat exchanger, which comprises a temperature sensor for sensing the temperature of the heat exchanger; a socket for accommodating the temperature sensor and fixed on the peripheral wall outside the refrigerant conduit of the heat exchanger; a fixing card for supporting the temperature sensor in the socket for the temperature sensor; one end of the fixing card is a limit clip, another end is a limit hook, the middle of the fixing card is an elastic twin supporting lobe for supporting the temperature sensor. Under external force, the invention will not dispose, this guarantees the operation position and the accuracy in measuring temperature of the temperature sensor, hence reduces the wrong reaction of the operation system of the air conditioner, so as to save energy.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

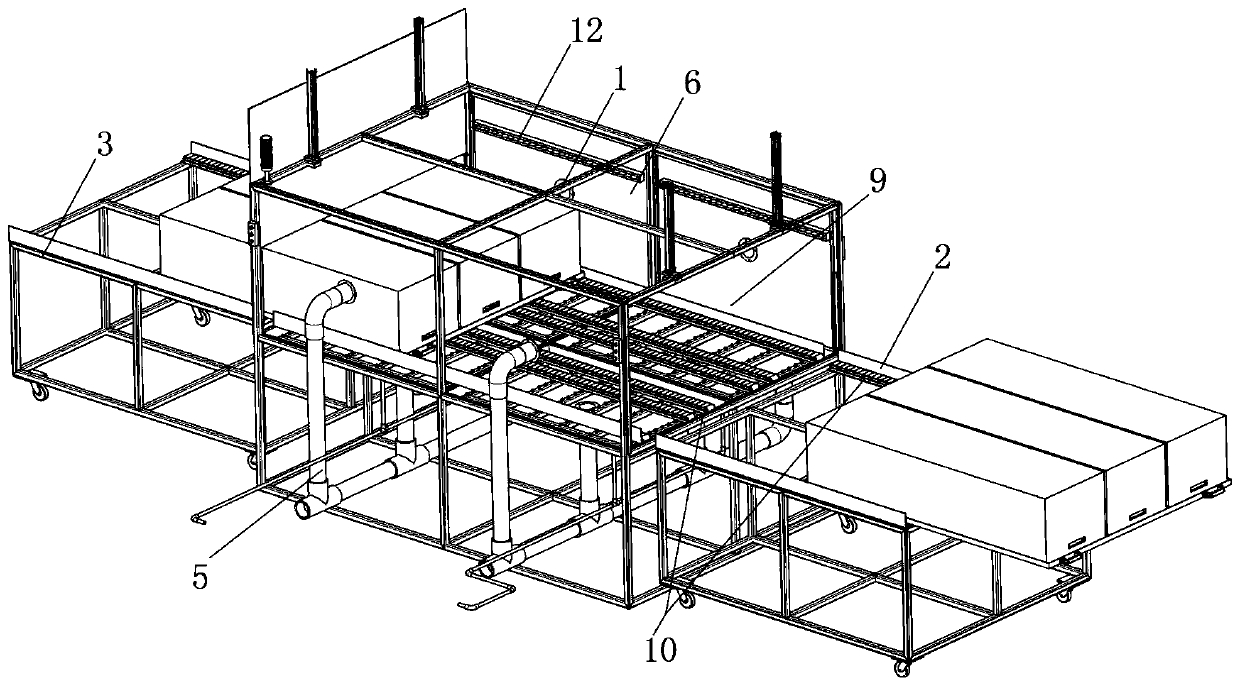

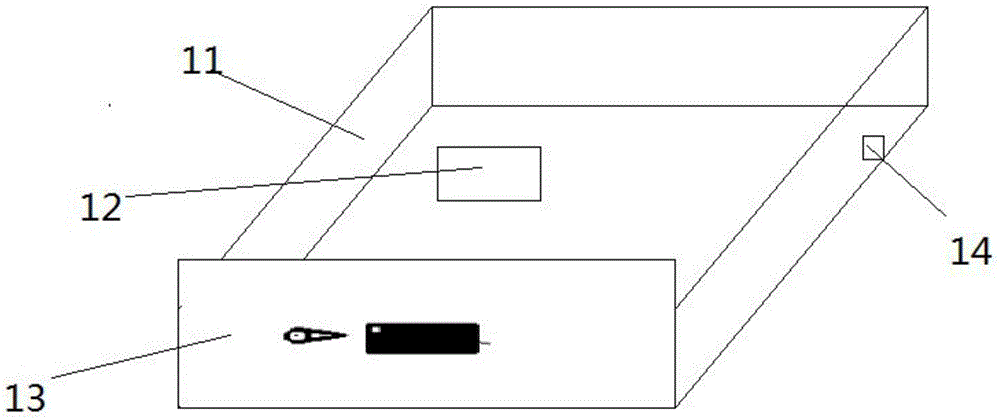

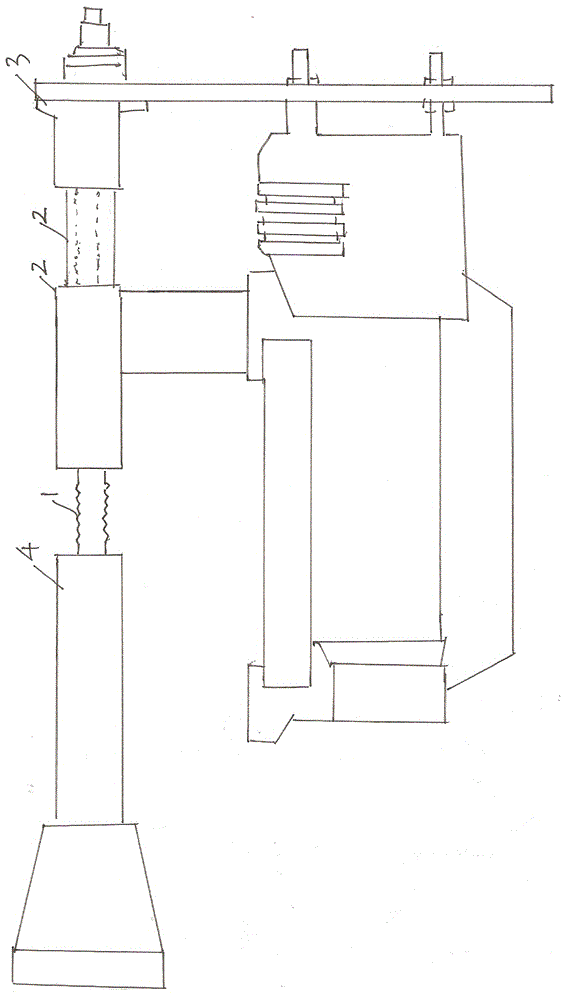

Vacuum paint-dipping device used for transformer production and paint-dipping method thereof

The invention discloses a vacuum paint-dipping device used for transformer production and a paint-dipping method thereof. The vacuum paint-dipping device comprises a sealing frame, a paint dipping bin, a front conveying table, a rear conveying table, a vacuum pump and a gas exhaust tube, wherein the paint dipping bin surrounds the sealing frame; one side of the sealing frame is equipped with the front conveying table, and the other side of the sealing frame is equipped with the rear conveying table; and one side of the middle part of the sealing frame is equipped with the vacuum pump. According to the vacuum paint-dipping device disclosed by the invention, a transformer is placed on the front conveying table, and a conveying disc drives the transformer to move and convey into the paint dipping bin to subject to paint dipping processing, so that paint dipping work of putting the transformer into the paint dipping bin is easier and is more convenient; a first motor drives an end sealing plate to perform up-down regulating motion through a hobbing gear, so that the end sealing plate can be quickly switched to seal or open and close the paint dipping bin, and therefore, the device is accessed into the transformer more conveniently for performing paint dipping or taking out the paint-dipped transformer, and integral sealing performance for the paint dipping bin by the sealing frame is greatly improved in a mode that a rubber strip is connected to a blocking slot in the lower portion of the end part of the sealing frame.

Owner:ANHUI HEHAN OPTOELECTRONICS TECH

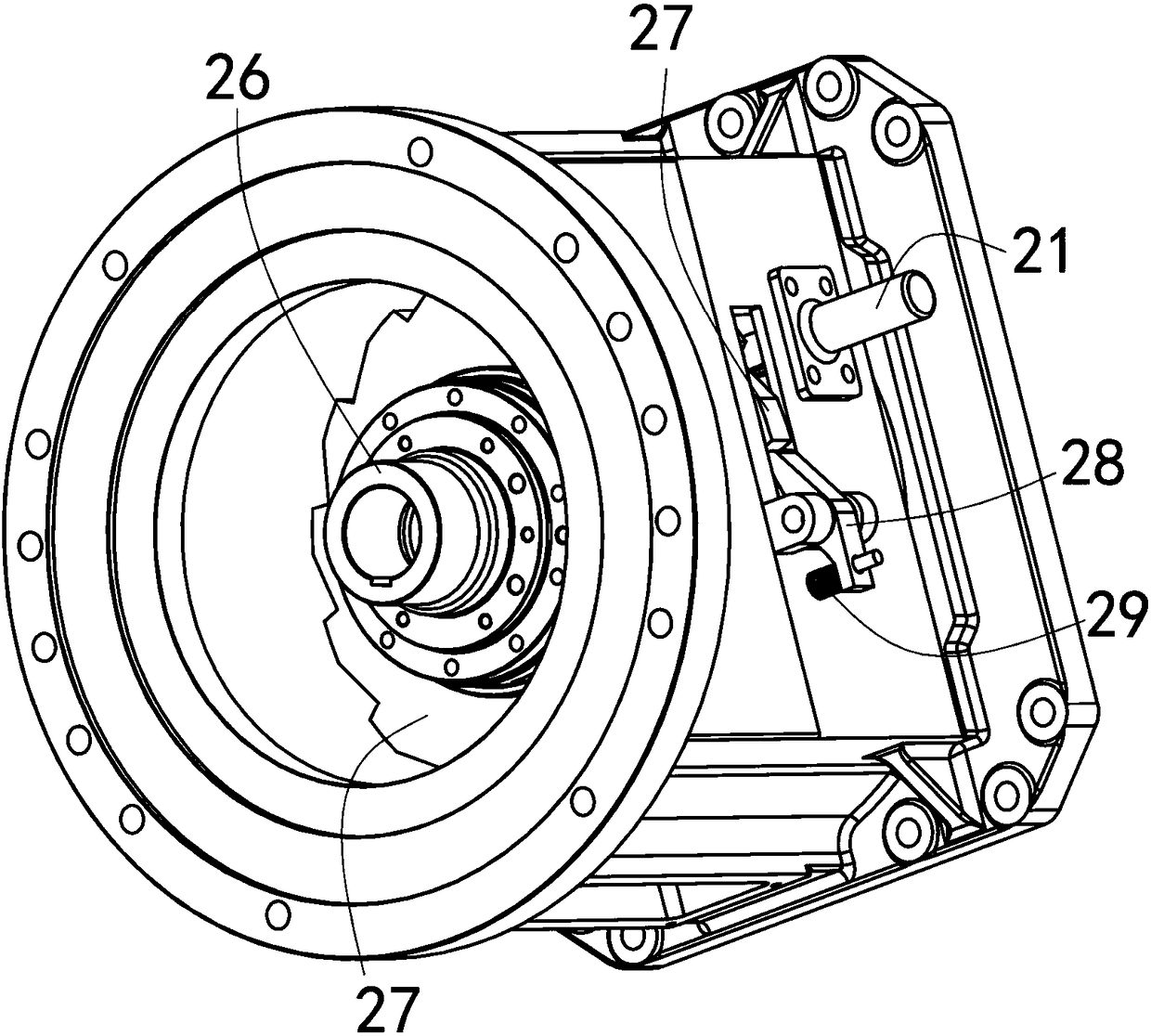

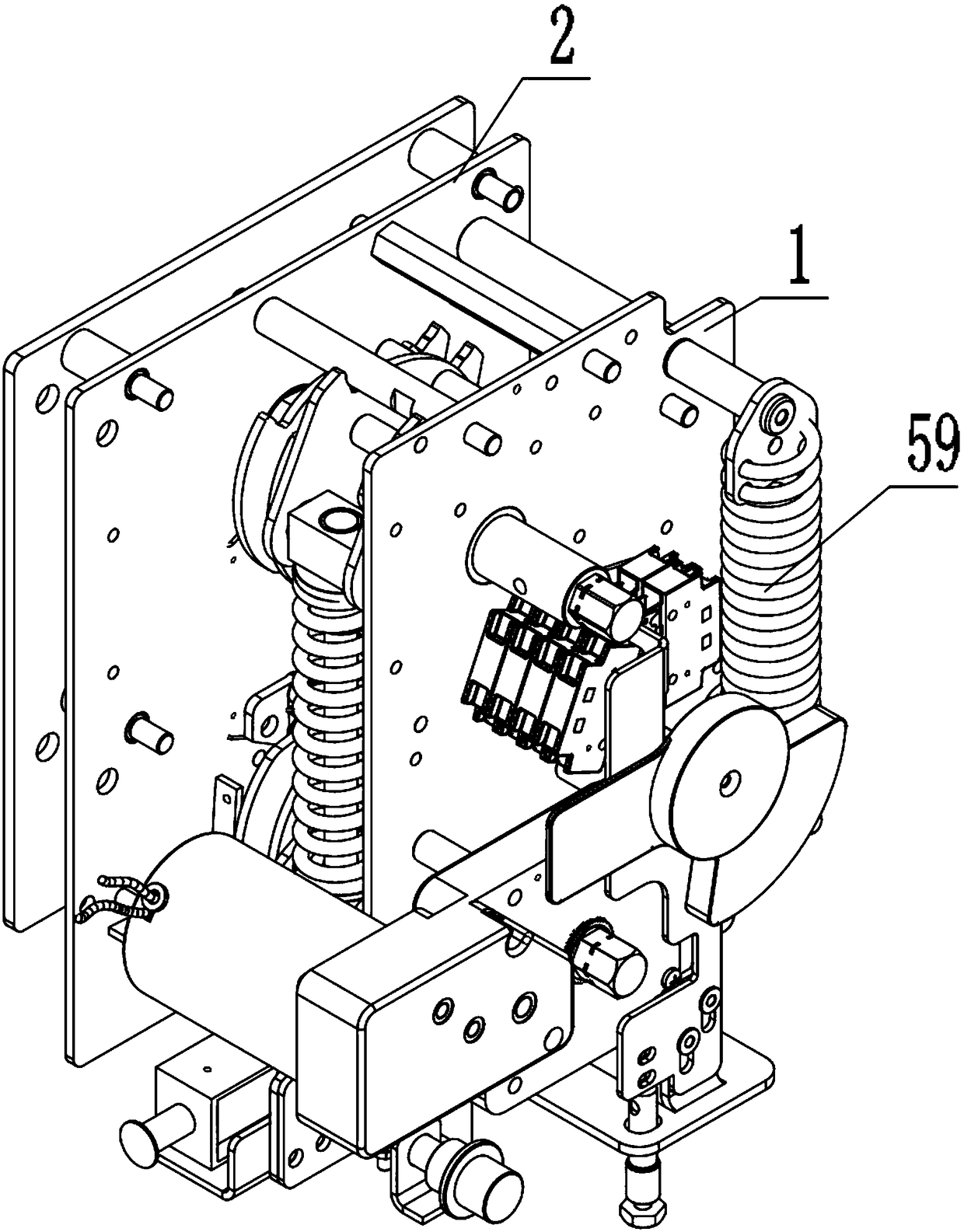

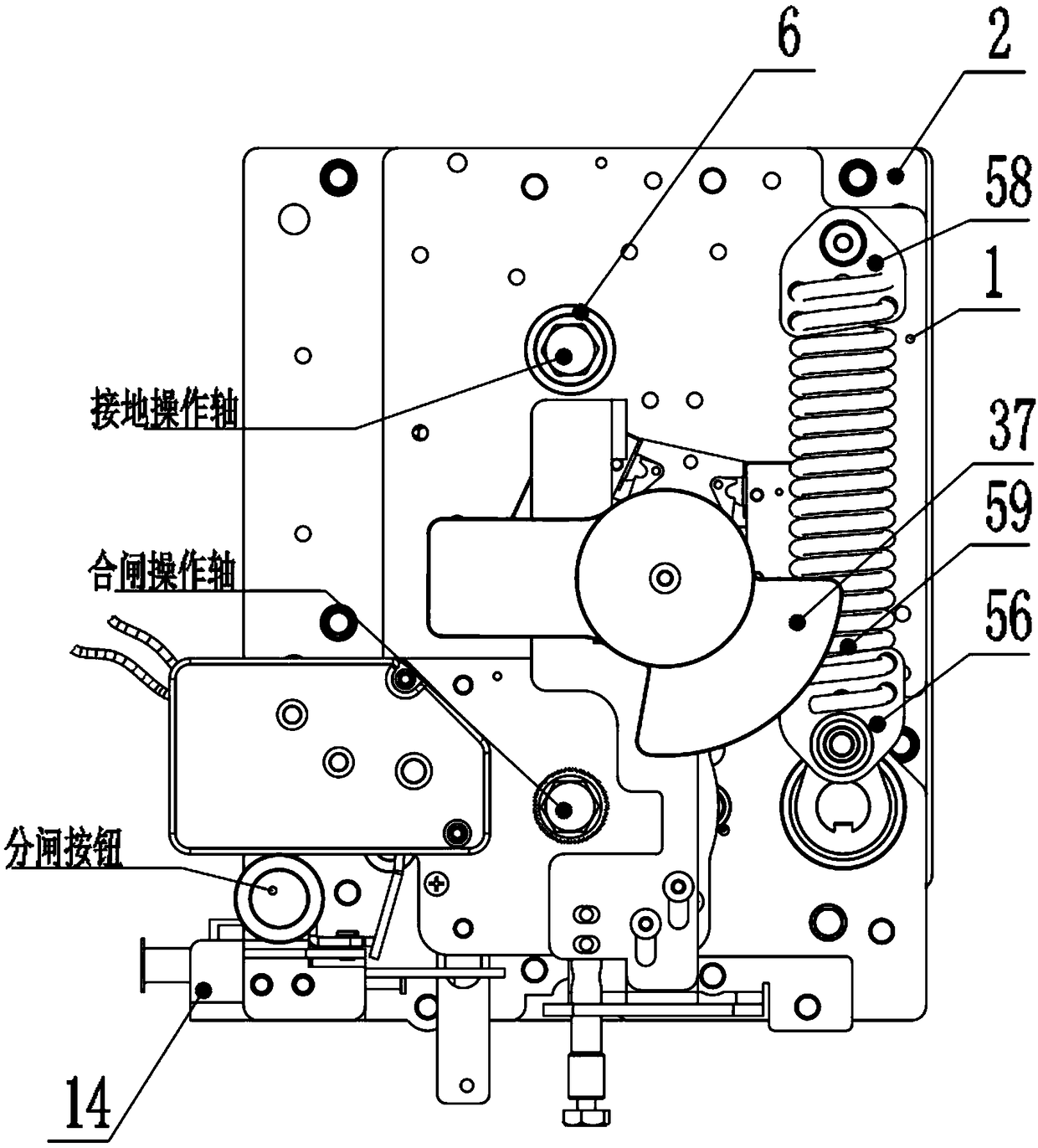

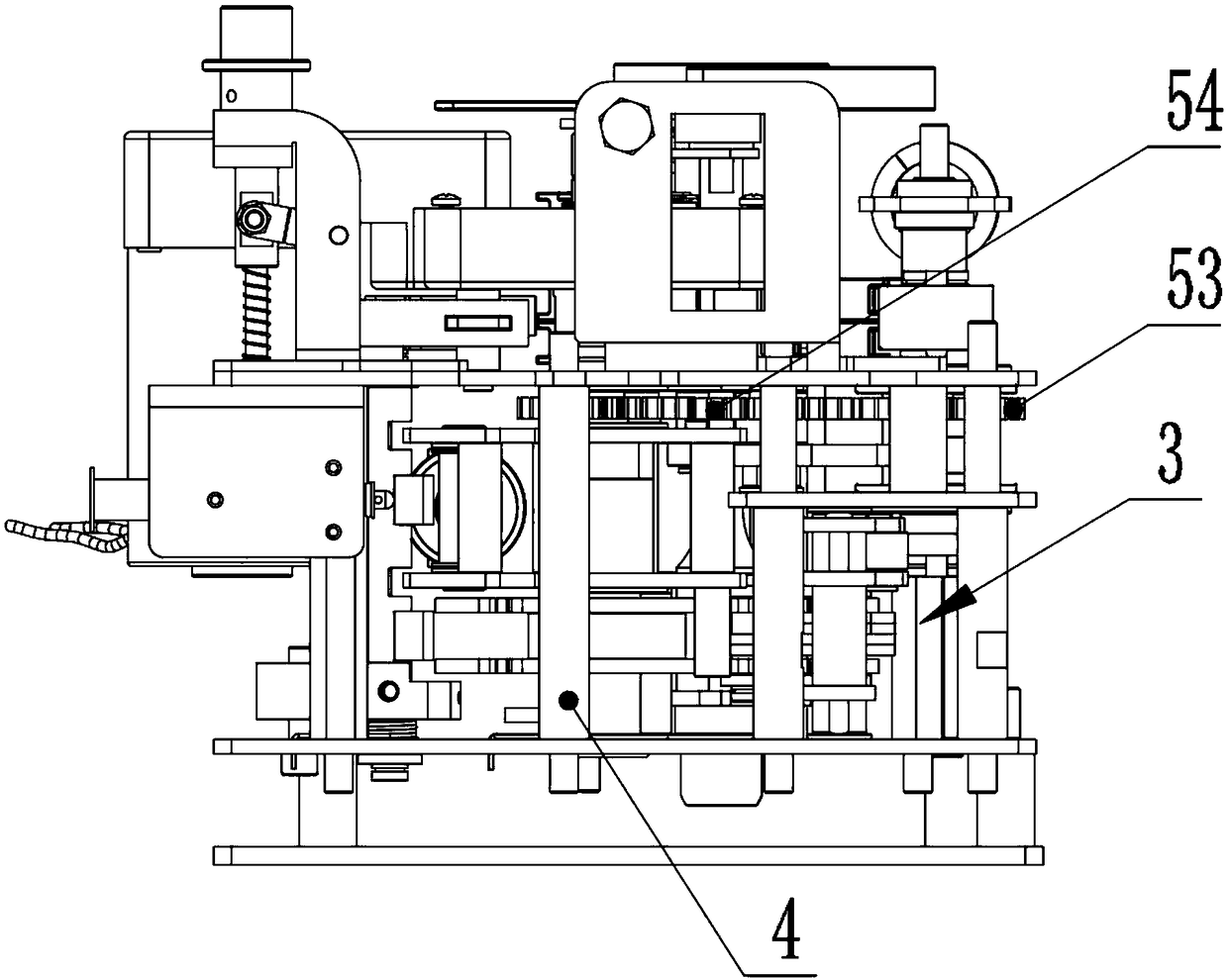

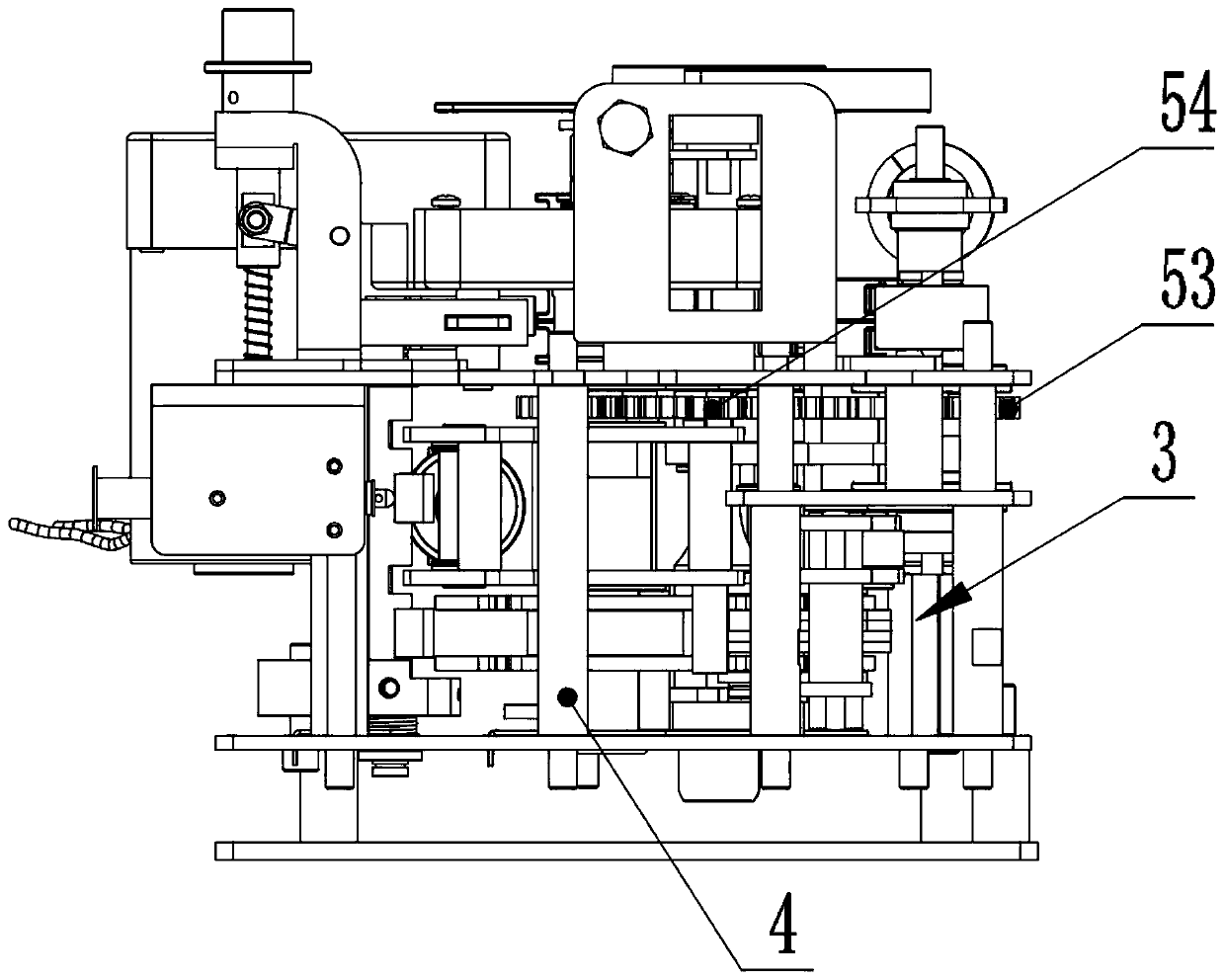

Gas filled tank load switch fuse-combination unit mechanism

The invention discloses a gas filled tank load switch fuse-combination unit mechanism. The gas filled tank load switch fuse-combination unit mechanism comprises a front plate, a rear plate, a closingspring, a motor and a switch-on and switch-off cam welding wire outlet mechanism. The front plate and the rear plate are separately arranged at the two ends of the mechanism, and the front plate and the rear plate are arranged in parallel. The gas filled tank load switch fuse-combination unit mechanism has the beneficial effects that a mechanism transmission mode is changed by the gas filled tankload switch fuse-combination unit mechanism, the mechanism transmission structure is optimized, good transmission property of the mechanism is ensured, and transmission operation is accurate and stable; a hexagonal shaft, a positioning shaft, a shaft III, a shaft IV and a shaft V are arranged between the front plate and the rear plate and perpendicularly penetrate through the front plate and the rear plate, and the strength and firmness of the integral mechanism during working are improved; shaft bodies are protectively isolated by shaft sleeves, friction and collision of the shaft bodies arerelieved, and the service lives of the shaft bodies are prolonged; and the electrical mechanism is high in sensitivity during working, is firm and durable, has good social benefit, and is suitable forbeing popularized and used.

Owner:浙江联格电气科技有限公司

Plane bending forming clamping device and die with clamping device

PendingCN107363136ASolve the problem of low precisionMeet the needs of different anglesShaping toolsMetal-working feeding devicesEngineeringMechanical engineering

The invention discloses a plane bending forming clamping device and a die with the clamping device. The plane bending forming clamping device comprises a first clamping plate, a second clamping plate and an angle forming die piece arranged between the first clamping plate and the second clamping plate. The first clamping plate and the second clamping plate are hinged through a connecting piece. The angle forming die piece arranged between the first clamping plate and the second clamping plate is locked through a locking device via the first clamping plate and the second clamping plate. The angle forming die piece is arranged on the side, close to the connecting piece, of the first clamping plate. The angle forming die piece is arranged on the side, close to the connecting piece, of the first clamping plate. The side, away from the connecting piece, of the angle forming die piece is an arc making contact with a formed piece. The plane bending forming clamping device and the die with the clamping device solve a series of problems that an existing copper (aluminum) row bending tool difficultly bends and forms a copper (aluminum) row plane, the forming angle precision is low, an obtained formed piece is poor in quality stability, scratches exist on the surface of the formed piece, the forming quality is hard to guarantee, applicable occasions are single, and mounting and dismounting procedures are complex.

Owner:大唐国信滨海海上风力发电有限公司

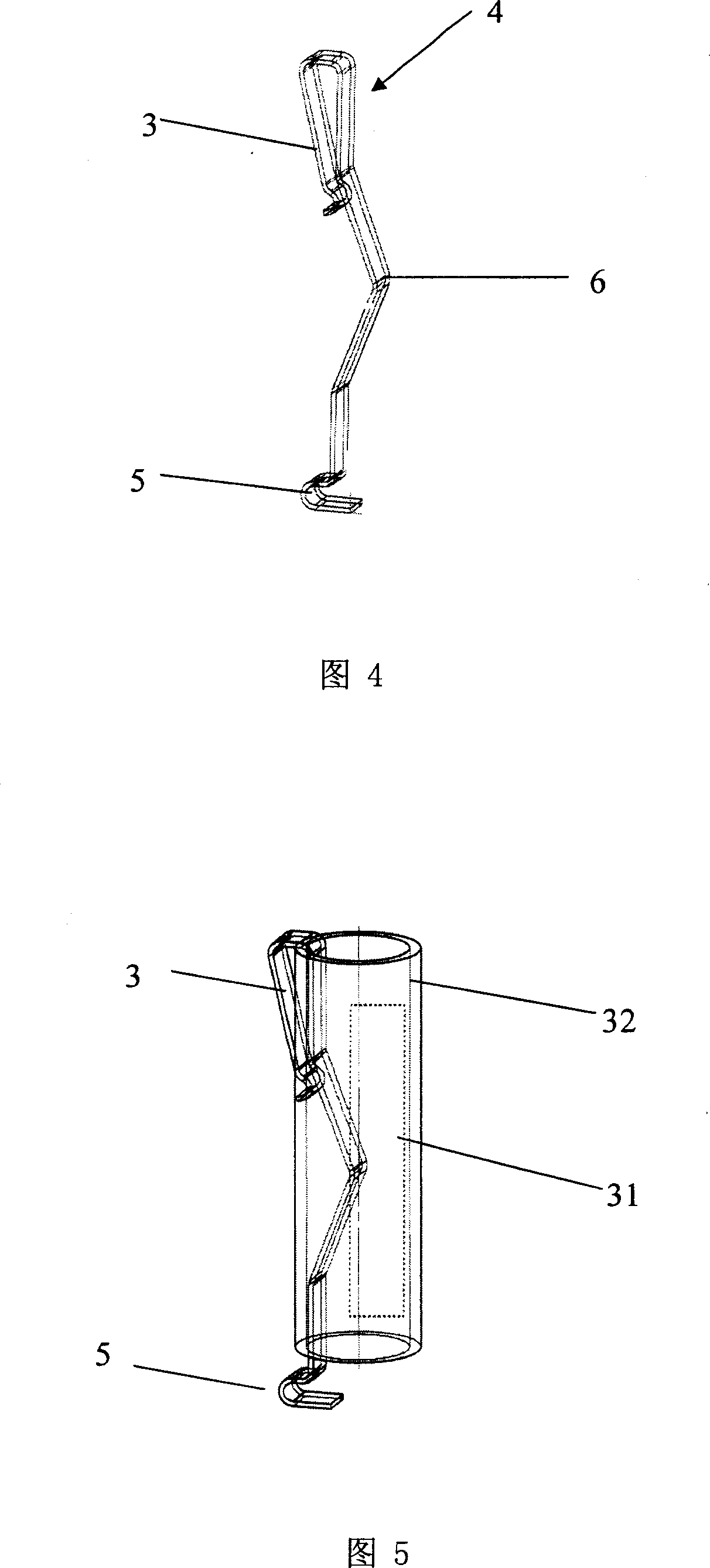

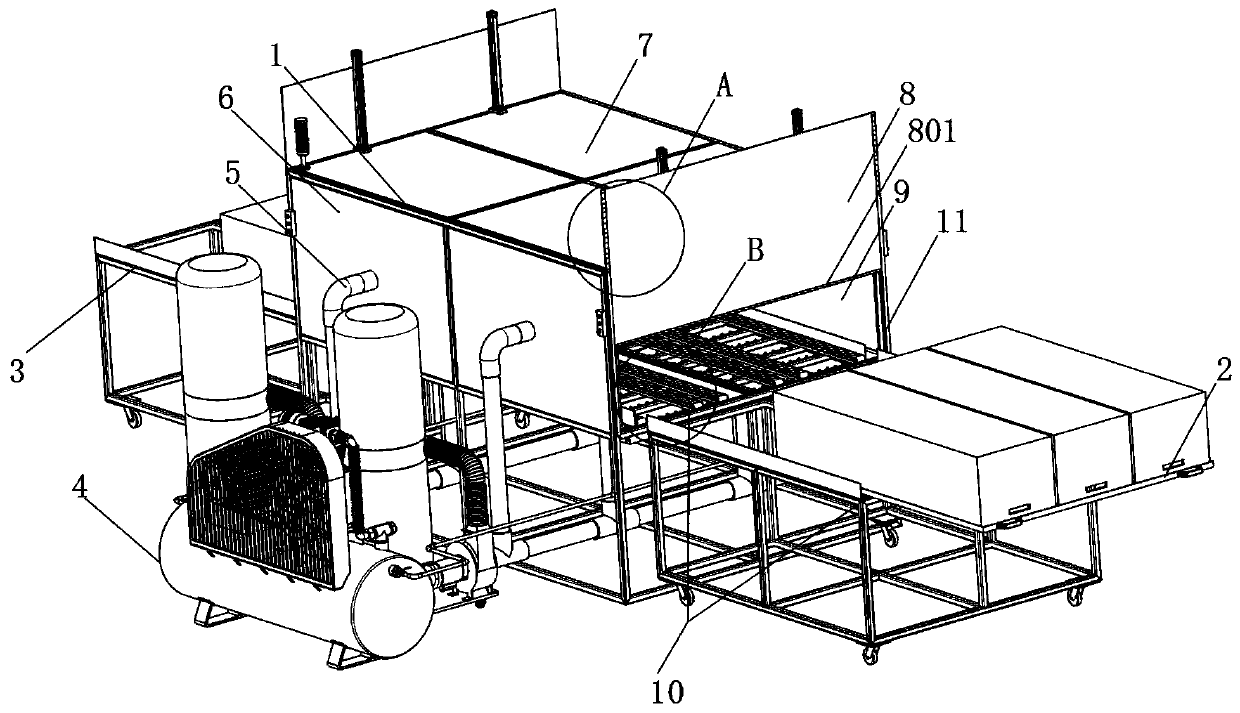

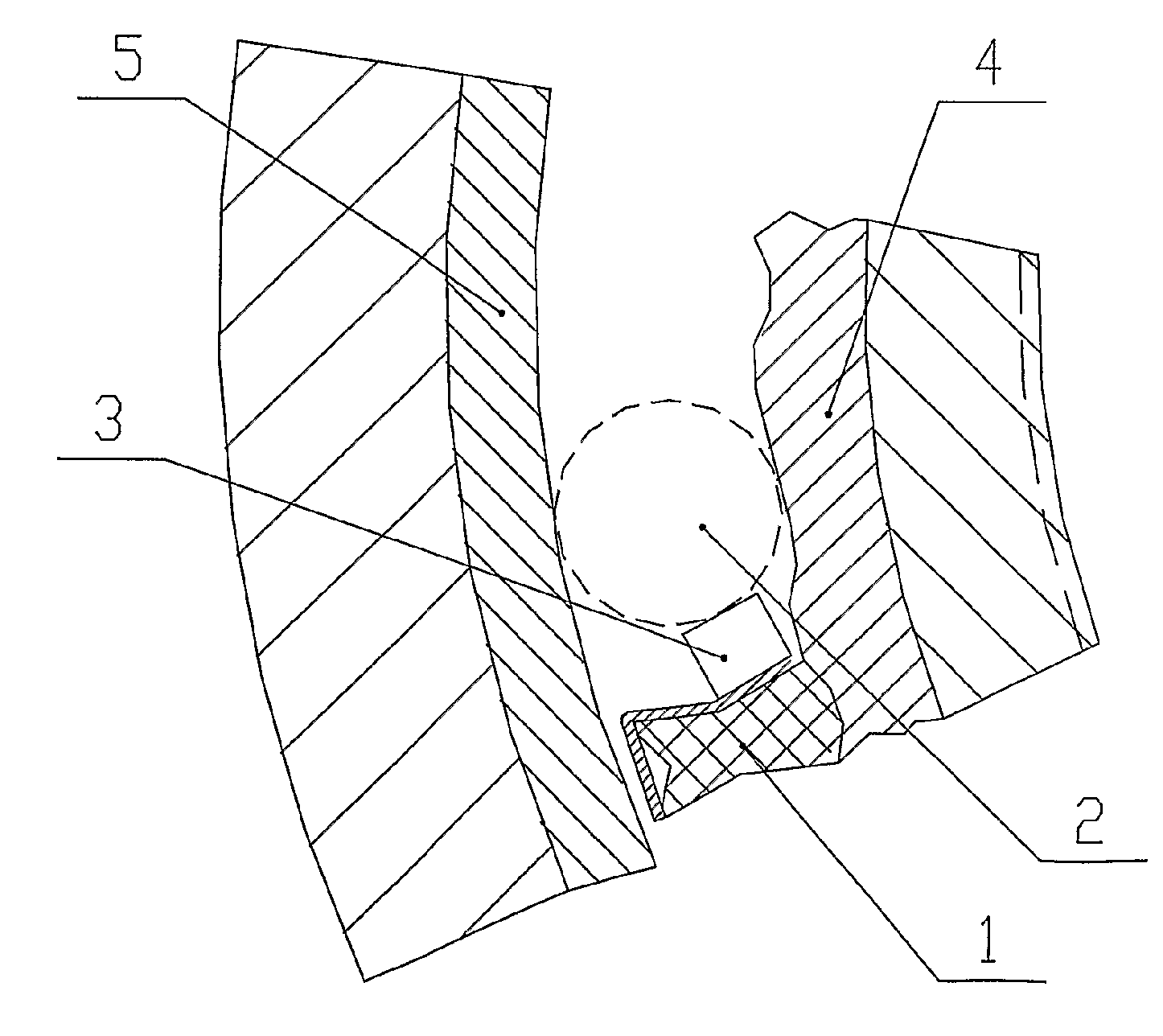

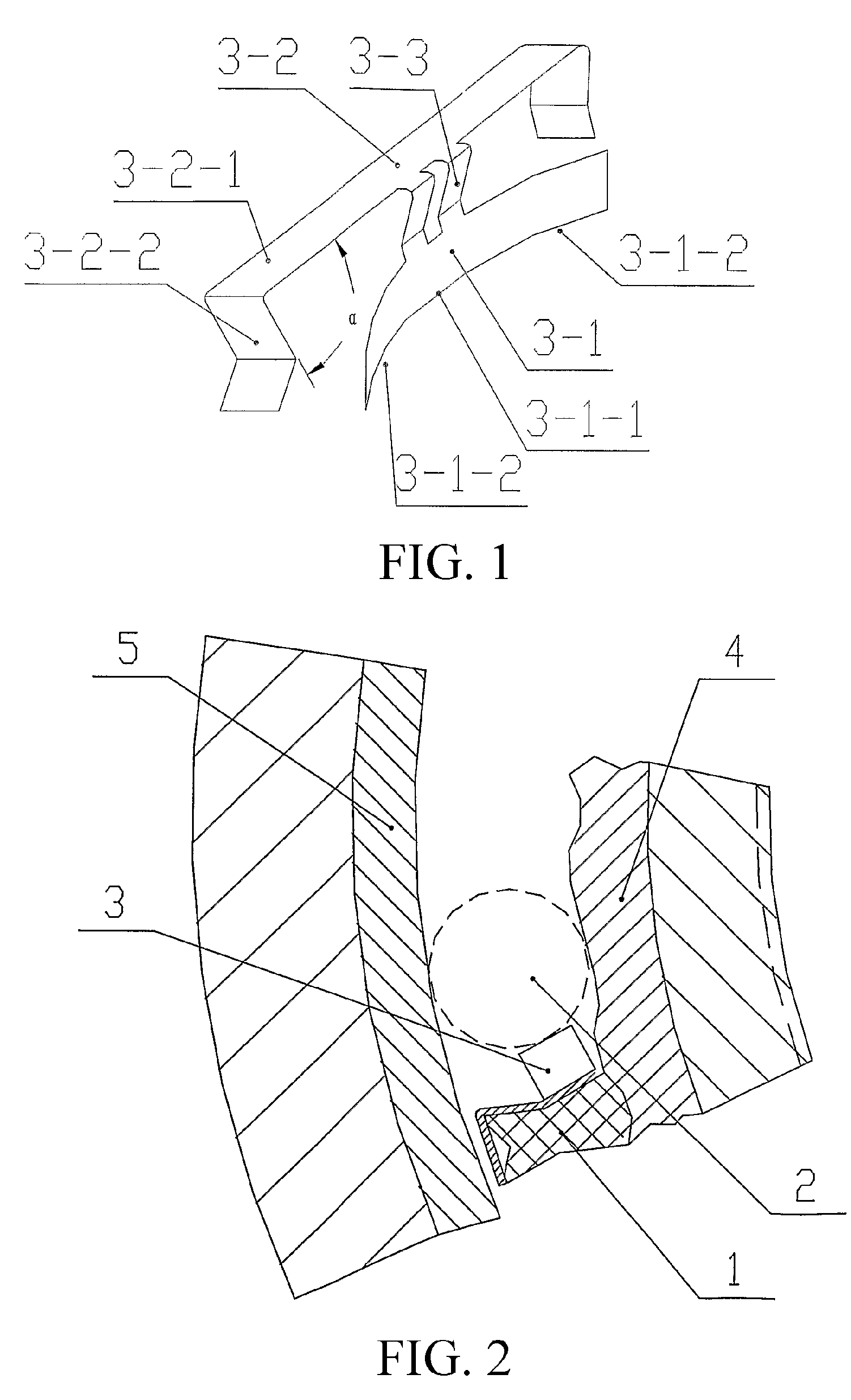

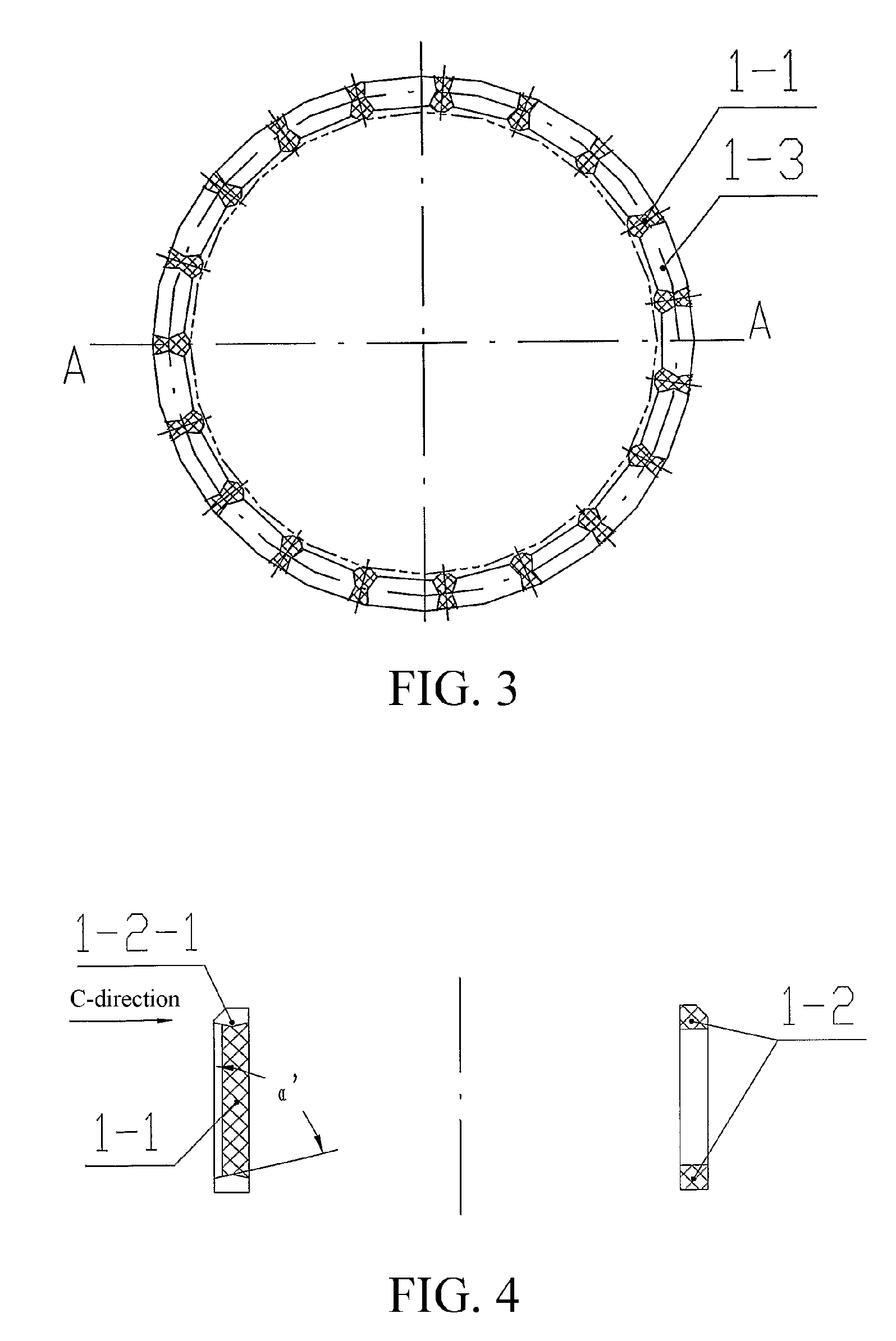

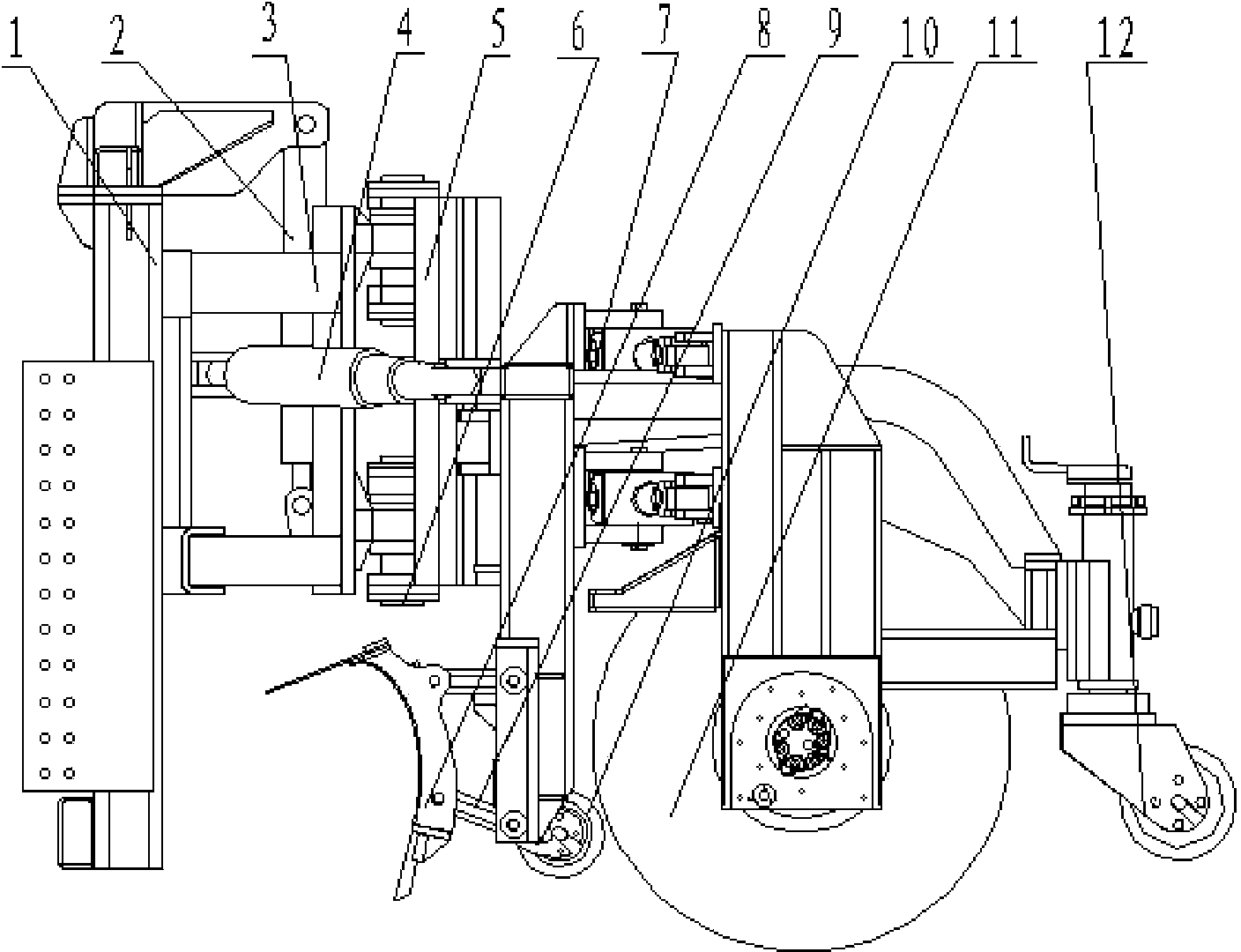

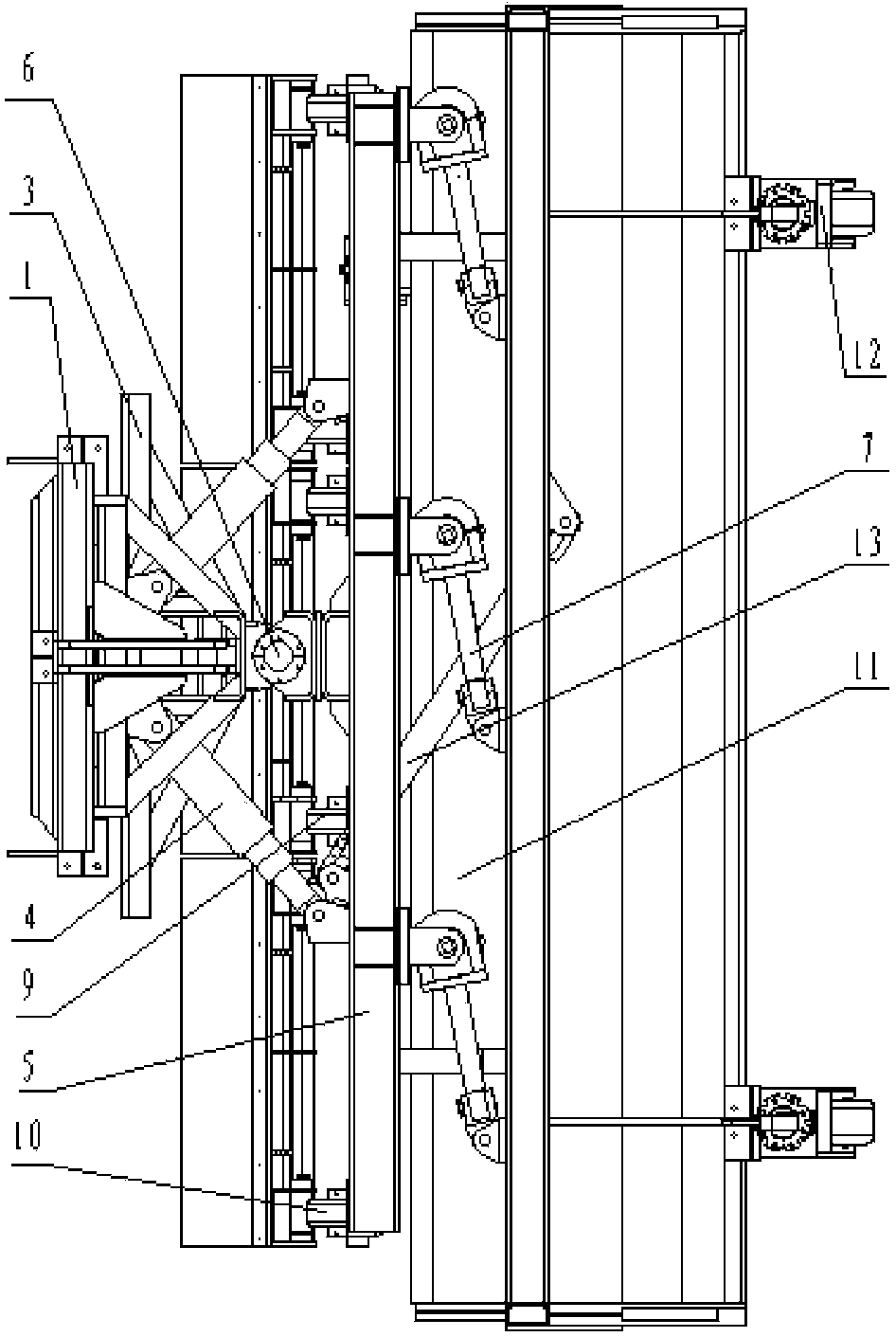

Spring leaf and overrunning clutch provided with the same

ActiveUS20120279817A1Simple structureConvenient to fabricateMechanical actuated clutchesAutomatic clutchesClutchHigh frequency

A spring leaf and an overrunning clutch provided with the same are provided. The spring leaf is made up of a support strip (3-1), a clamping strip (3-2), and a connection beam (3-3). The support strip (3-1) supports a needle roller in suspension. The connection beam (3-3) connects the support strip (3-1) with the clamping strip (3-2). The main body of the clamping strip (3-2) is a straight strip (3-2-1), either end of which is provided with a V-shaped bended part (3-2-2). The overrunning clutch is provided with a retainer, multiple needle rollers, and multiple spring leaves. Mounting grooves for the spring leaves are respectively disposed at positions, corresponding to each crossbeam, on outer end surfaces of a first and a second annular end edge at both ends of a window hole of the retainer. The bottom of the mounting groove for the spring leaf is V-shaped when cut along an axial direction of the retainer. An inner surface of the straight strip (3-2-1) of the clamping strip (3-2) of the spring leaf is matched with an outer surface of the crossbeam. An inner surface of the V-shaped bended part (3-2-2) of the clamping strip (3-2) is matched with a bottom surface of the mounting groove for the spring leaf. The technical problem of the potential displacement and detachment of the spring leaf during the reciprocation of the existing overrunning clutch at a high rotational speed and high frequency is solved by the invention.

Owner:JIANG SU NAN FANG BEARING CO LTD

Rear working device for integrated linkage type snow remover

ActiveCN104032700AExtended service lifeGuaranteed working heightSnow cleaningVehicle frameFixed frame

The invention discloses a rear working device for an integrated linkage type snow remover. The device comprises a fixing frame, a rolling brush assembly, a lifting cylinder, a lifting slide frame, a swing angle cylinder, an operating device supporting frame, single-head universal connecting rods, a rear snow removing mechanism, an obstacle crossing connecting rod, and a return cylinder of the rolling brush assembly, wherein the fixing frame is fixedly connected behind a vehicle frame of the snow remover, the lifting slide frame is mounted on the fixing frame by a pulley, both ends of the lifting cylinder are respectively hinged and connected to the fixing frame and the lifting slide frame, the operating device supporting frame is mounted on the lifting slide frame, both ends of the swing angle cylinder are respectively hinged to the operating device supporting frame and the lifting slide frame, the rear snow removing mechanism is mounted on the operating device supporting frame by the obstacle crossing connecting rod, the rolling brush assembly is mounted on the operating device supporting frame by the single-head universal connecting rods, and both ends of the return cylinder of the rolling brush assembly are respectively hinged to the operating device supporting frame and the rolling brush assembly. The structure of the device is simplified, and simultaneously, rolled ice blocks and snow blocks can be expelled to roadsides, and the snow is cleaned.

Owner:JILIN NORDIC HEAVY MACHINERY CO LTD

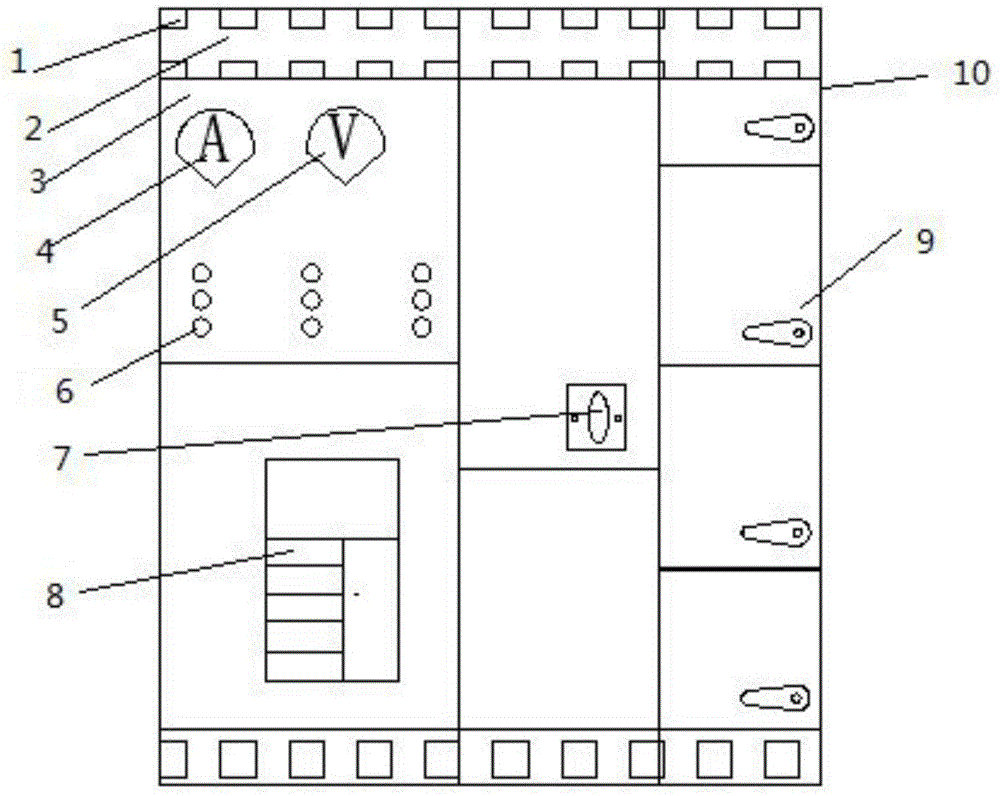

HGCS-type low-voltage draw-out switch cabinet

InactiveCN105680360AGood interchangeabilityImprove work efficiencySwitchgear with withdrawable carriageCurrent meterAmpere-meter

The invention discloses an HGCS-type low-voltage draw-out switch cabinet, and aims at solving the problems that an existing switch cabinet is relatively low in protection grade and inconvenient to operate. The HGCS-type low-voltage draw-out switch cabinet comprises a power distribution cabinet, control cabinets, a power receiving cabinet and radiating grooves, wherein the power distribution cabinet, the control cabinets and the power receiving cabinet form a cabinet body; the radiating grooves are arranged at the upper end and the lower end of the cabinet body for radiating and cooling; reminder lights are arranged below an ampere meter and a voltage meter; the ampere meter is used for monitoring the current change condition; an instrument panel is arranged on the surface of the cabinet body; and each control cabinet comprises a drawer unit and a drawer door.

Owner:TIANJIN HUANHANG PEOPLE ELECTRICAL APPLIANCE CO LTD

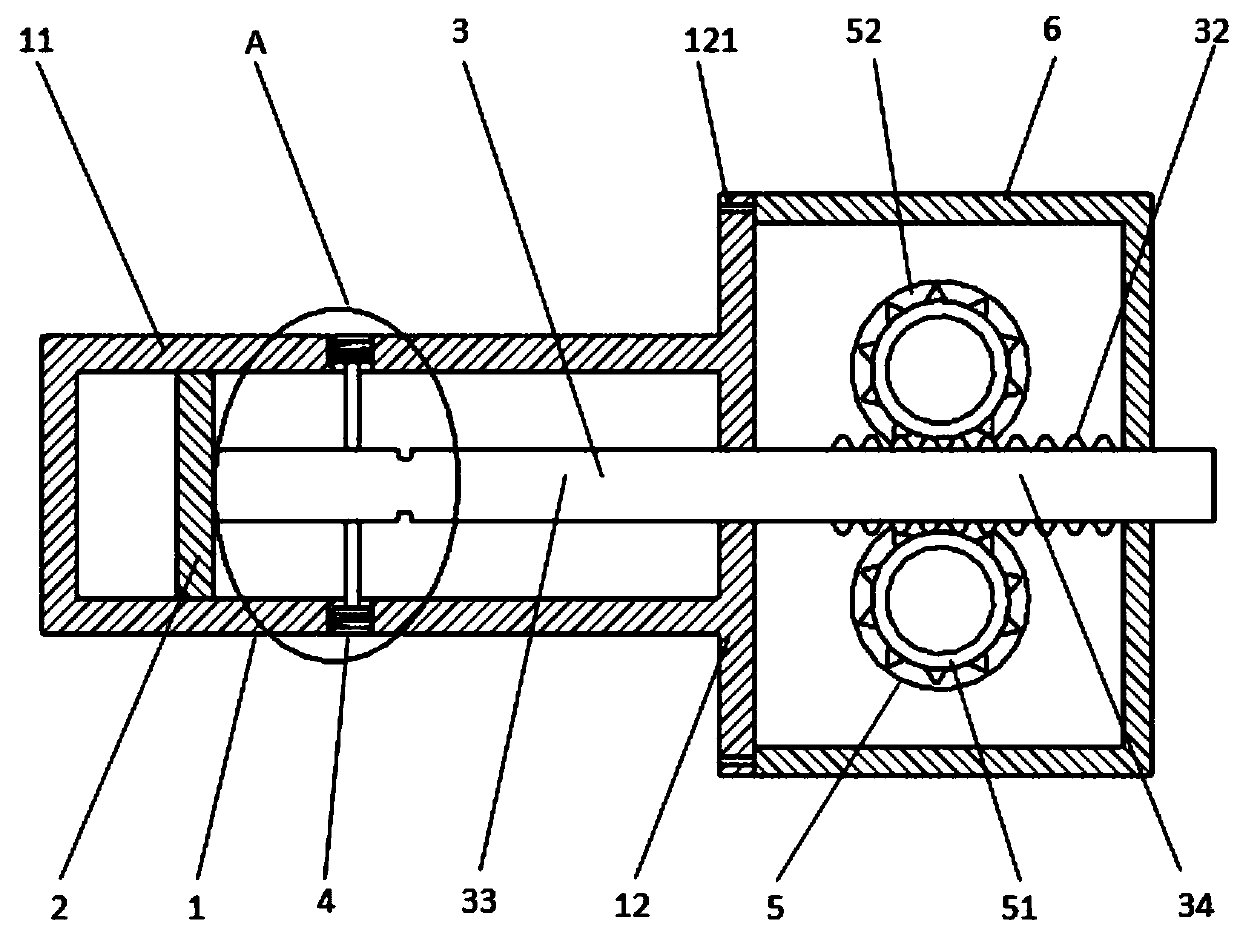

Internal and external combined mechanical self-locking hydraulic cylinder

The invention relates to an internal and external combined mechanical self-locking hydraulic cylinder which comprises a cylinder block, a piston slidably connected in the cylinder block, a piston rodfixedly connected to the piston, an internal self-locking assembly arranged in the cylinder block, an external self-locking assembly arranged outside the cylinder block and a housing arranged on the external self-locking assembly in a sleeving manner. The housing is connected to the cylinder block and the external self-locking assembly separately, the piston rod is provided with a tooth part arranged on the surface of the piston rod, the external self-locking assembly comprises a gear and a gear brake connected to the gear, the gear is engaged to the tooth part, and the gear brake is connectedto the housing. By arranging the internal self-locking assembly and the external self-locking assembly inside and outside the hydraulic cylinder, separately, the hydraulic cylinder is locked internally and externally in a combined manner, so that high precision and high reliability of a long-time working position of the hydraulic cylinder are guaranteed.

Owner:苏州鑫旭合智能科技有限公司

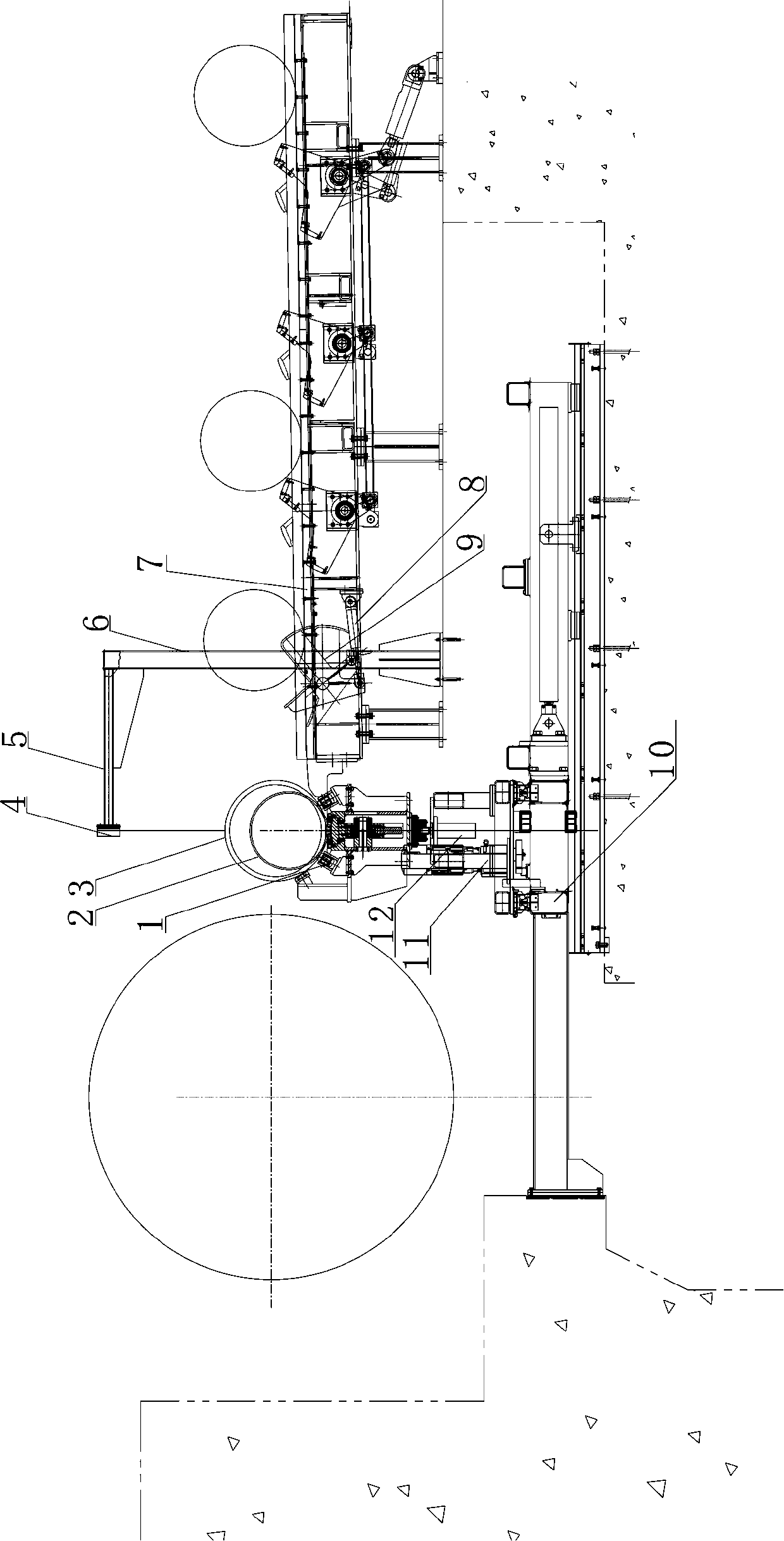

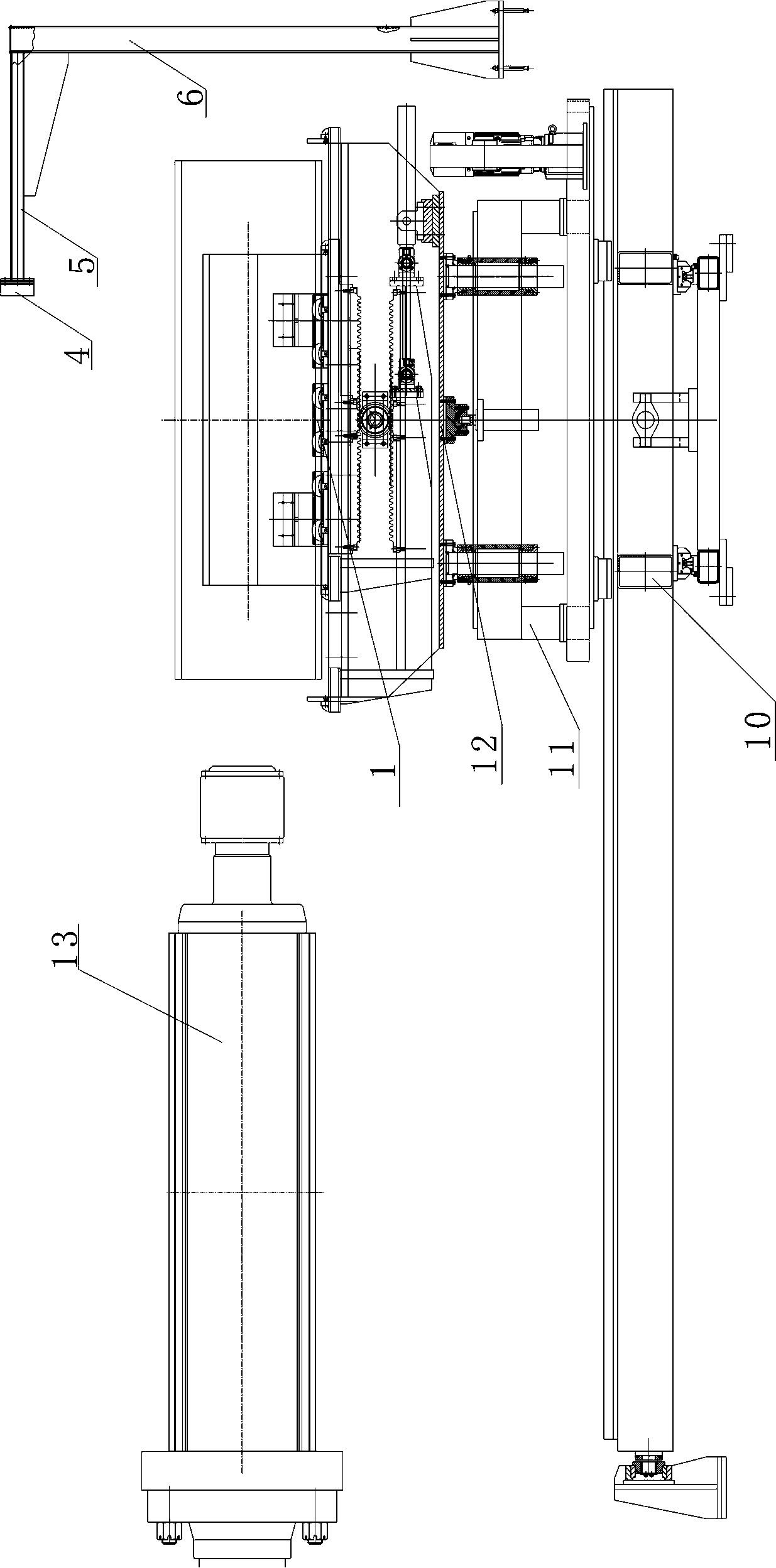

Coiling machine coiling shaft sleeve feeding device suitable for different specifications of sleeves

The invention discloses a coiling machine coiling shaft sleeve feeding device suitable for different specifications of sleeves. The coiling machine coiling shaft sleeve feeding device comprises a sleeve storage rack, a centering device, a bracket device, a longitudinal moving device and a transverse moving device. The sleeve storage rack is inclined at the inclined angle of 1 degree-5 degrees in the horizontal direction. The head end of the sleeve storage rack is lower than the tail end of the sleeve storage rack. The sleeve storage rack is provided with a plurality of shifting fork devices atintervals in the length direction of the sleeve storage rack. The longitudinal moving device is mounted on the transverse moving device. The bracket device is slidably mounted on the longitudinal moving device. The centering device is mounted on a bracket of the bracket device. The head end of the sleeve storage rack is arranged close to the centering device. The coiling machine coiling shaft sleeve feeding device can achieve the sleeve feeding effect on two or more kinds of sleeves and is accurate in place and high in automation degree.

Owner:CHINA ALUMINUM INT ENG CORP +1

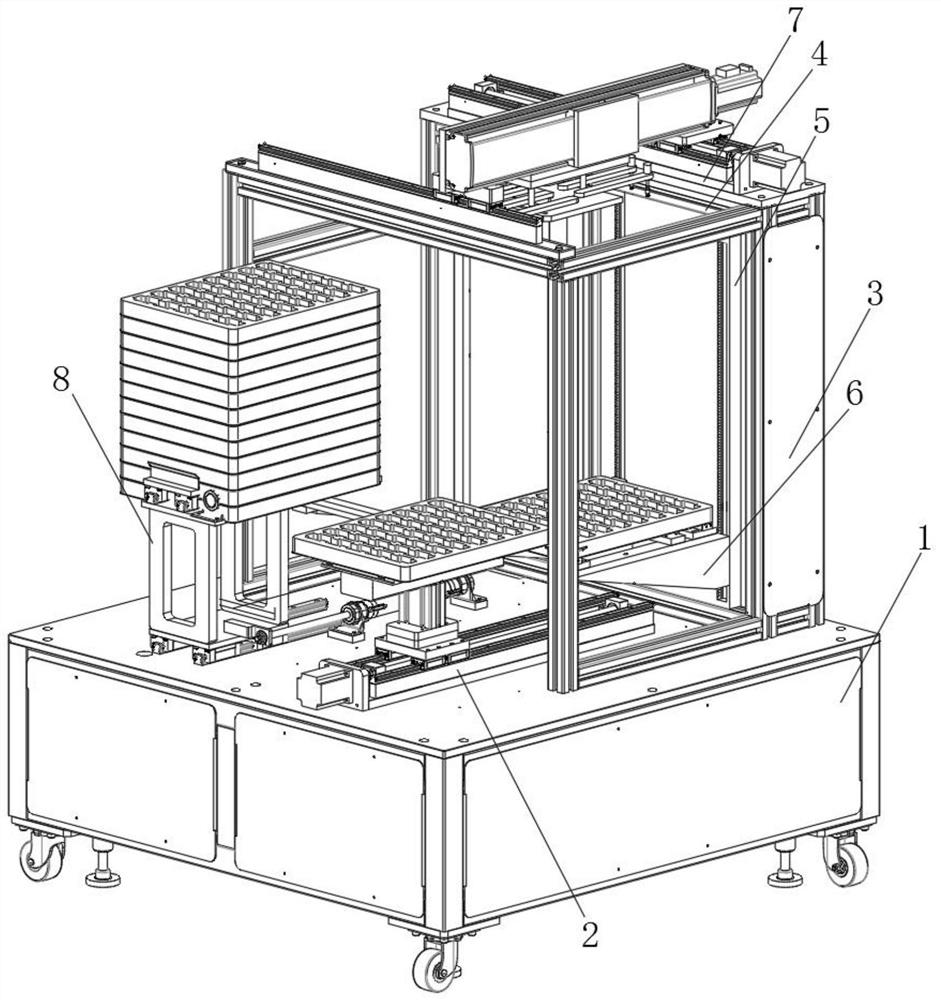

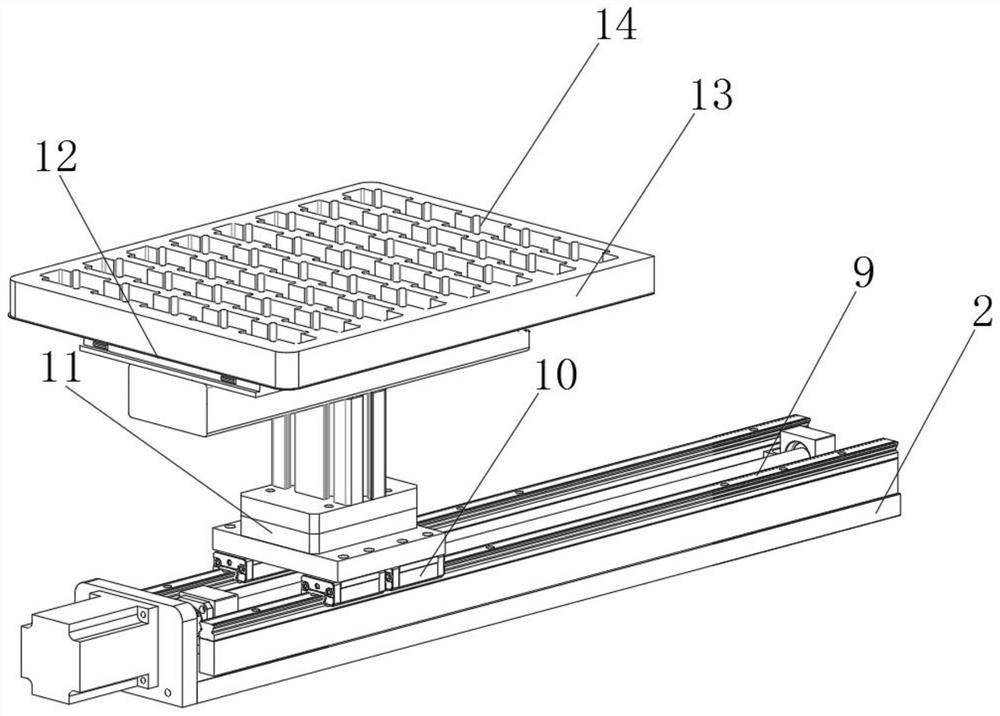

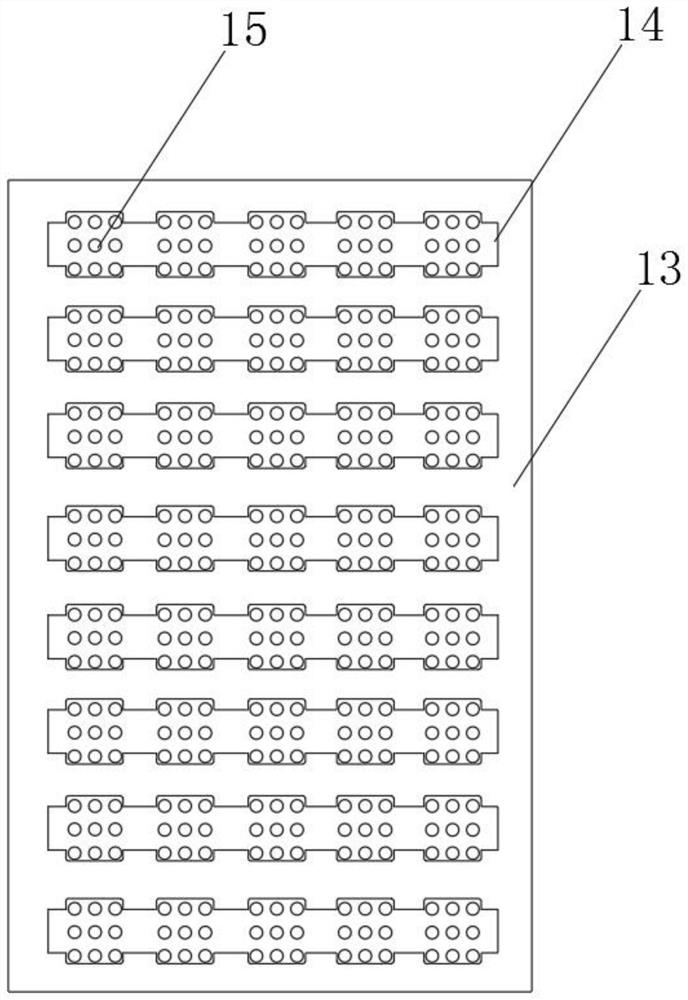

Hole cleaning and threading device used during machining of titanium alloy connector for aeronautic equipment

ActiveCN110497268AEasy to fixHigh degree of automationEdge grinding machinesGrinding carriagesHydraulic pumpEngineering

The invention discloses a hole cleaning and threading device used during machining of a titanium alloy connector for aeronautic equipment. The hole cleaning and threading device comprises a workbench,a connector hopper, a carrying disc, front cleaning tables, a rear cleaning table, a cable bearing disc and a loading disc. The workbench is of a cuboid-shaped structure, and the connector hopper isobliquely arranged at one end of the upper end face of the workbench. The carrying disc is arranged on one side of the connector hopper, and the multiple front cleaning tables are arranged on one sideof the carrying disc at equal intervals. The hole cleaning and threading device has the beneficial effects that first motors drive rotary polishing barrels to rotate to conduct polishing and removalburrs or projections in preformed holes in the connector, the effect that the inner walls of the preformed holes of the connector are smoother and rounder is ensured, and scraping damage between a metal cable and the hole walls of the connector is prevented during threading of the titanium alloy connector in the preformed holes; and in addition, the first motors are arranged in an equal-height mode, first hydraulic pumps correspondingly drive different-height first motors and the rotary polishing barrels to conduct hole cleaning treatment on the preformed holes in different-height positions onthe titanium alloy connector, and working adaptive universality of the hole cleaning and threading device is ensured.

Owner:SUZHOU XIANGYI NETWORK TECH

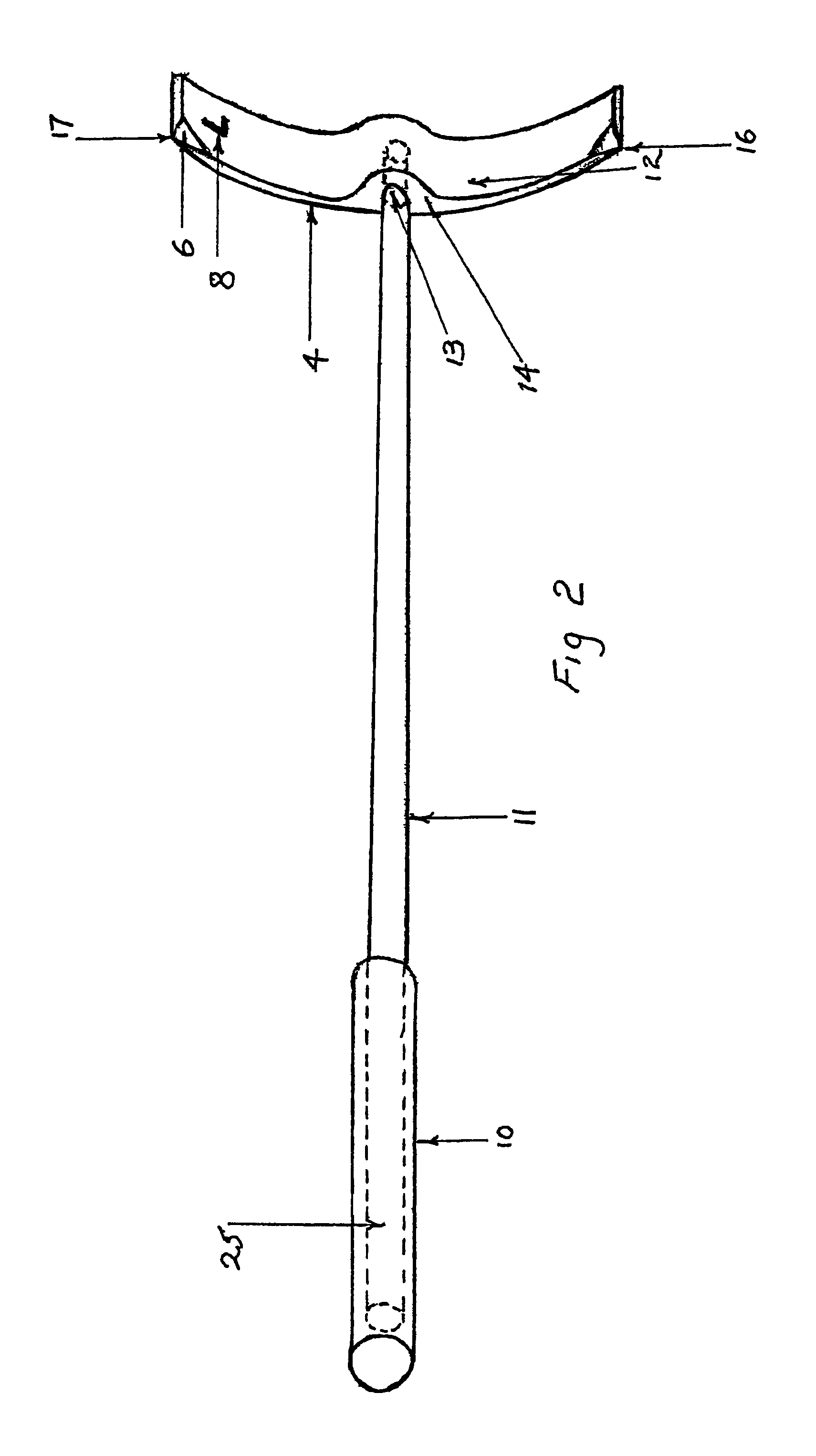

Device to assist in putting on and taking off clothing

ActiveUS9186010B2Easy to carryReduced flexibilityApparel holdersPhysical medicine and rehabilitationKnee height

Owner:CARBRAY WILLIAM

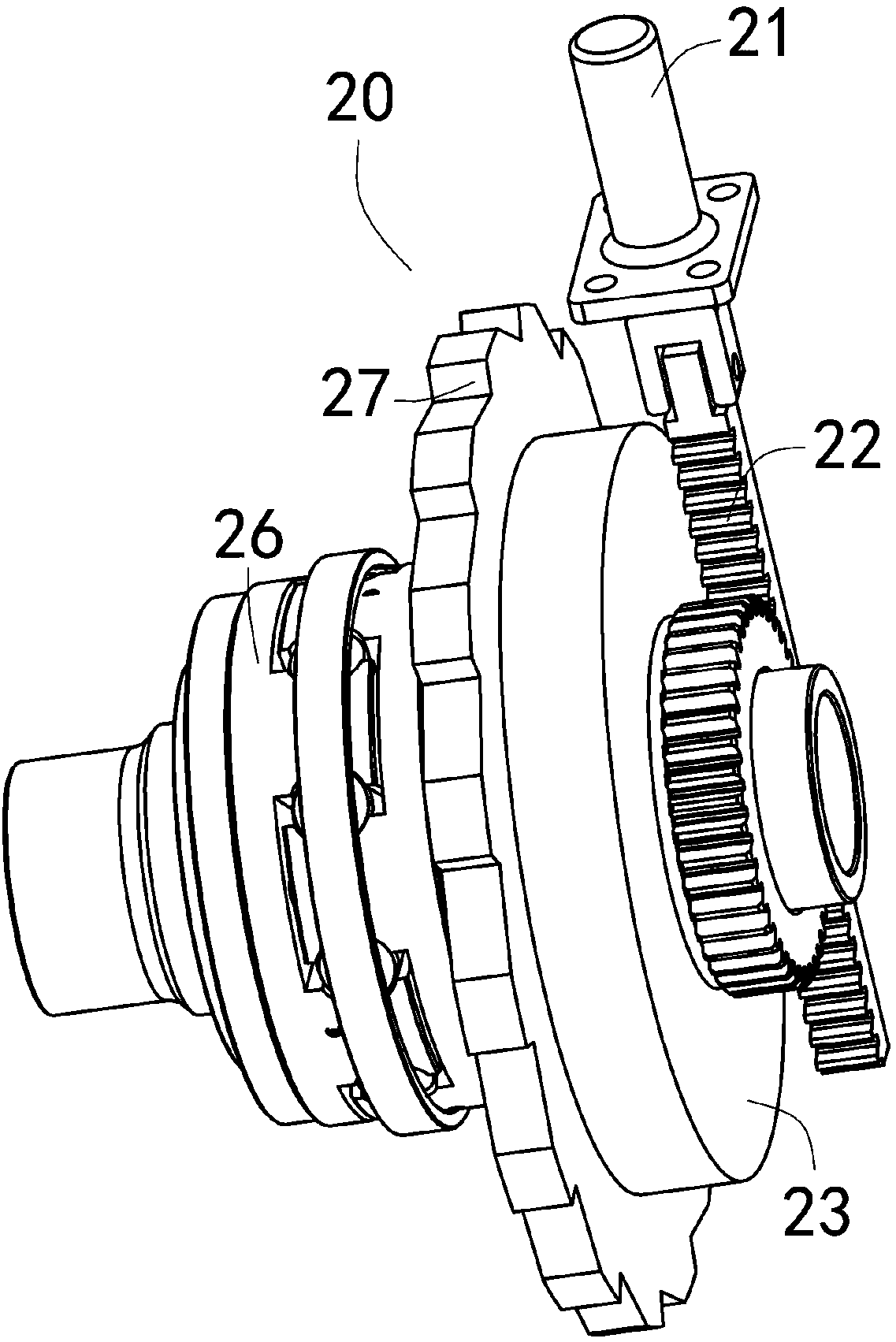

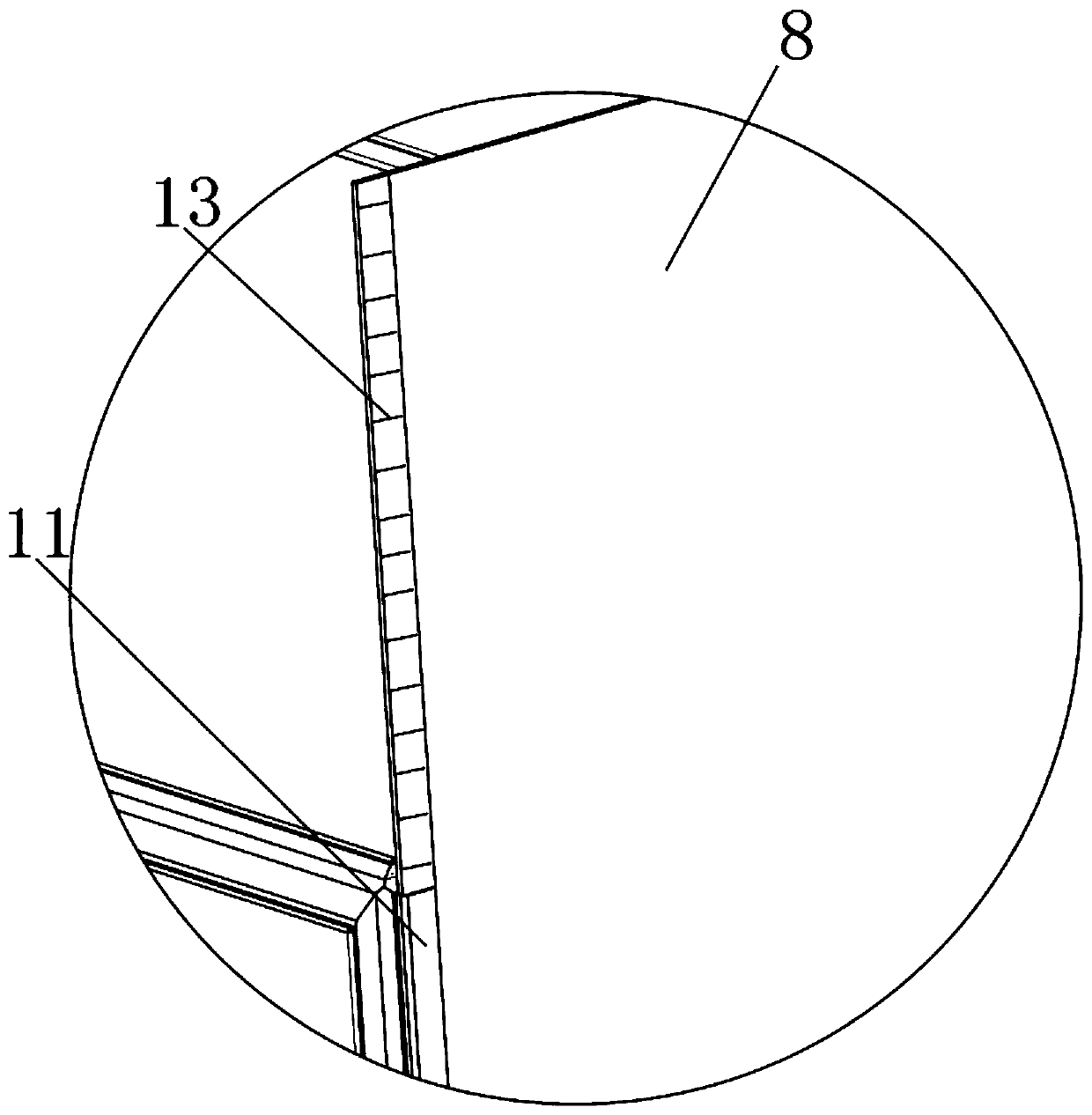

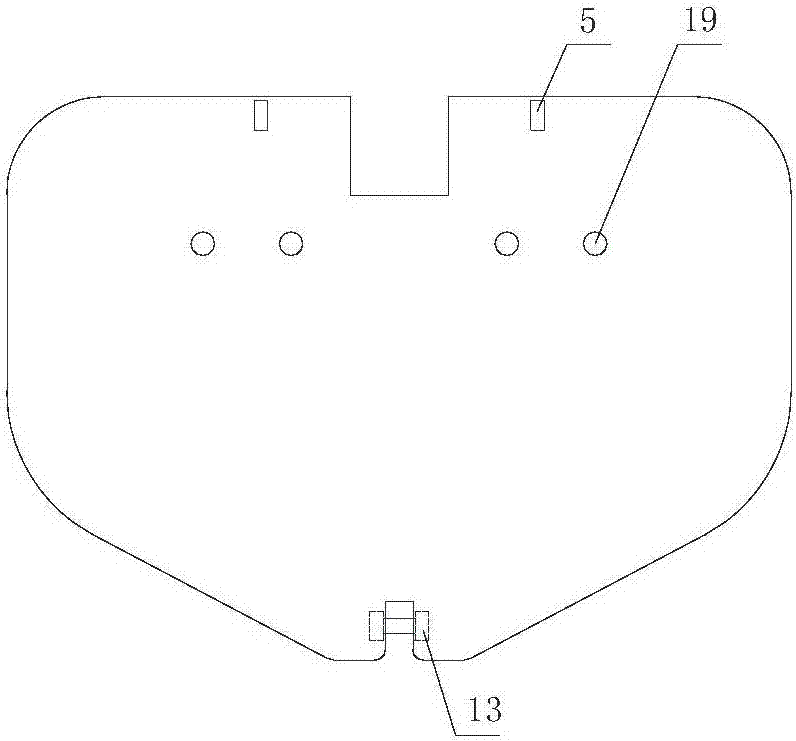

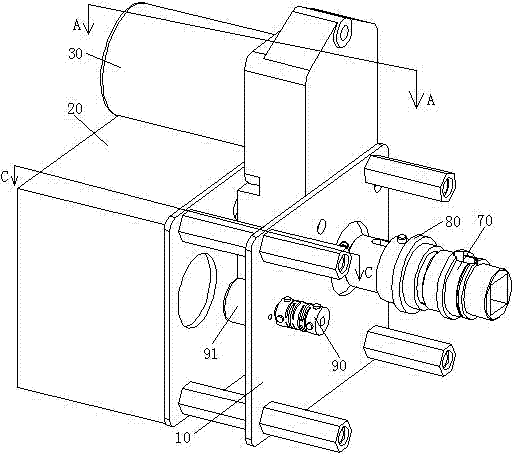

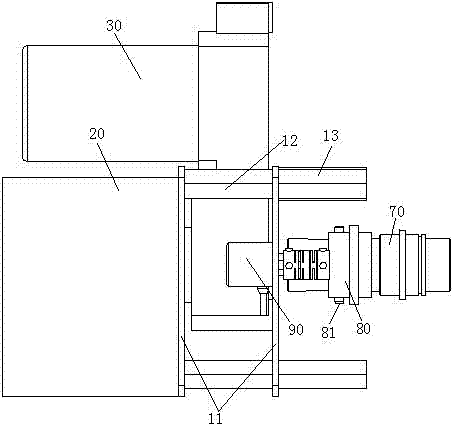

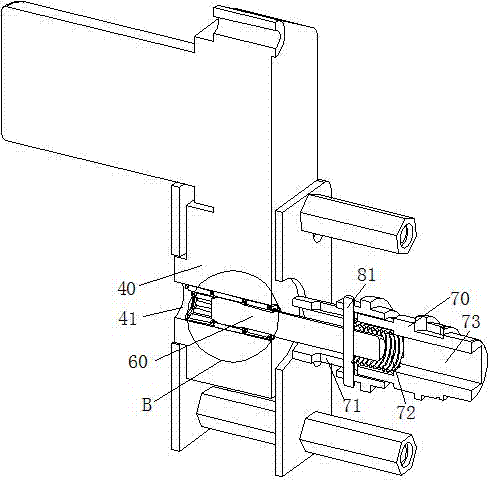

An electric operation module of a direct-acting three-position isolating switch and its application method

ActiveCN105895400BPrecise working positionContact driving mechanismsSwitch power arrangementsDrive shaftElectric machine

The present invention relates to an electric operation module of a direct-acting three-position disconnector and an application method thereof. The electric operation module of the direct-acting three-position disconnector comprises a mounting rack; one side of the mounting rack is provided with a controller and a driving motor located on an upper side of the controller; a motor output shaft of the driving motor is provided with an axial through-hole; a pair of one-way bearings in opposite mounting directions are meshed in the axial through-hole; a transmission shaft with an output end extending out of the other side of the mounting rack runs through the one-way bearings; an output shaft used for connecting a gear transmission assembly is arranged on the output end of the transmission shaft; a switching handle for driving transmission shaft to move transversely is arranged on the output shaft; and the mounting rack is further provided with a rotary encoder that is connected to another synchronous output shaft though a coupler. The operating mechanism is not only compact in structure, but also helpful in solving the isolation position "drift" problem.

Owner:福州许继电气有限公司

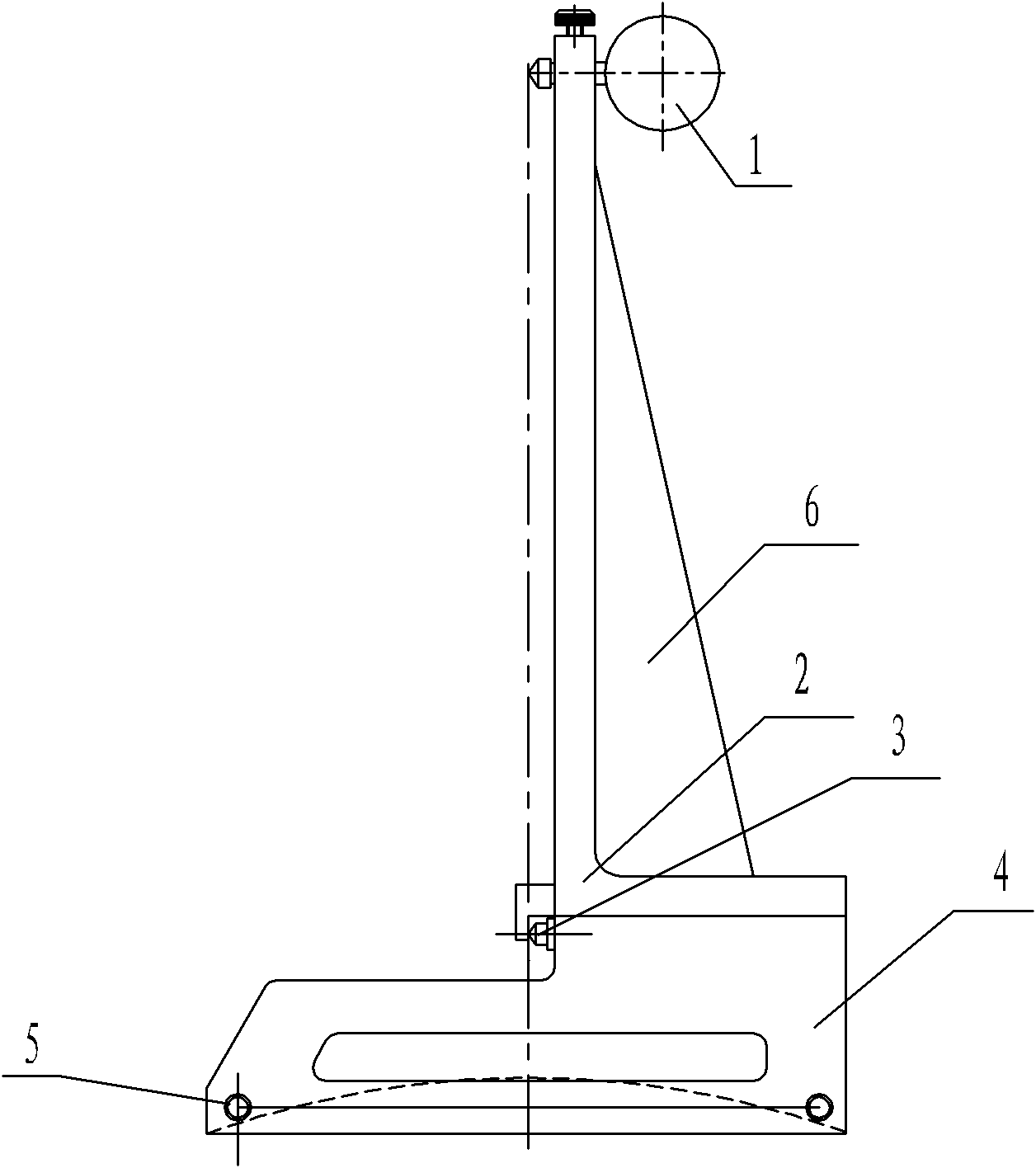

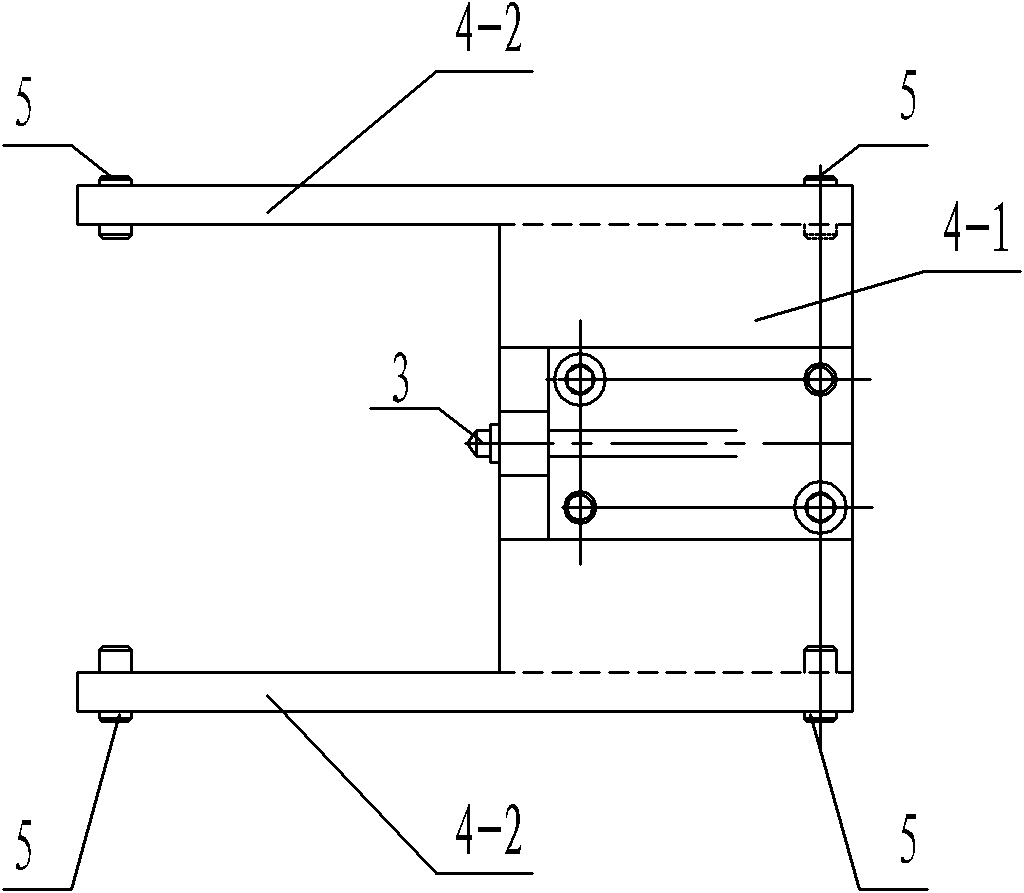

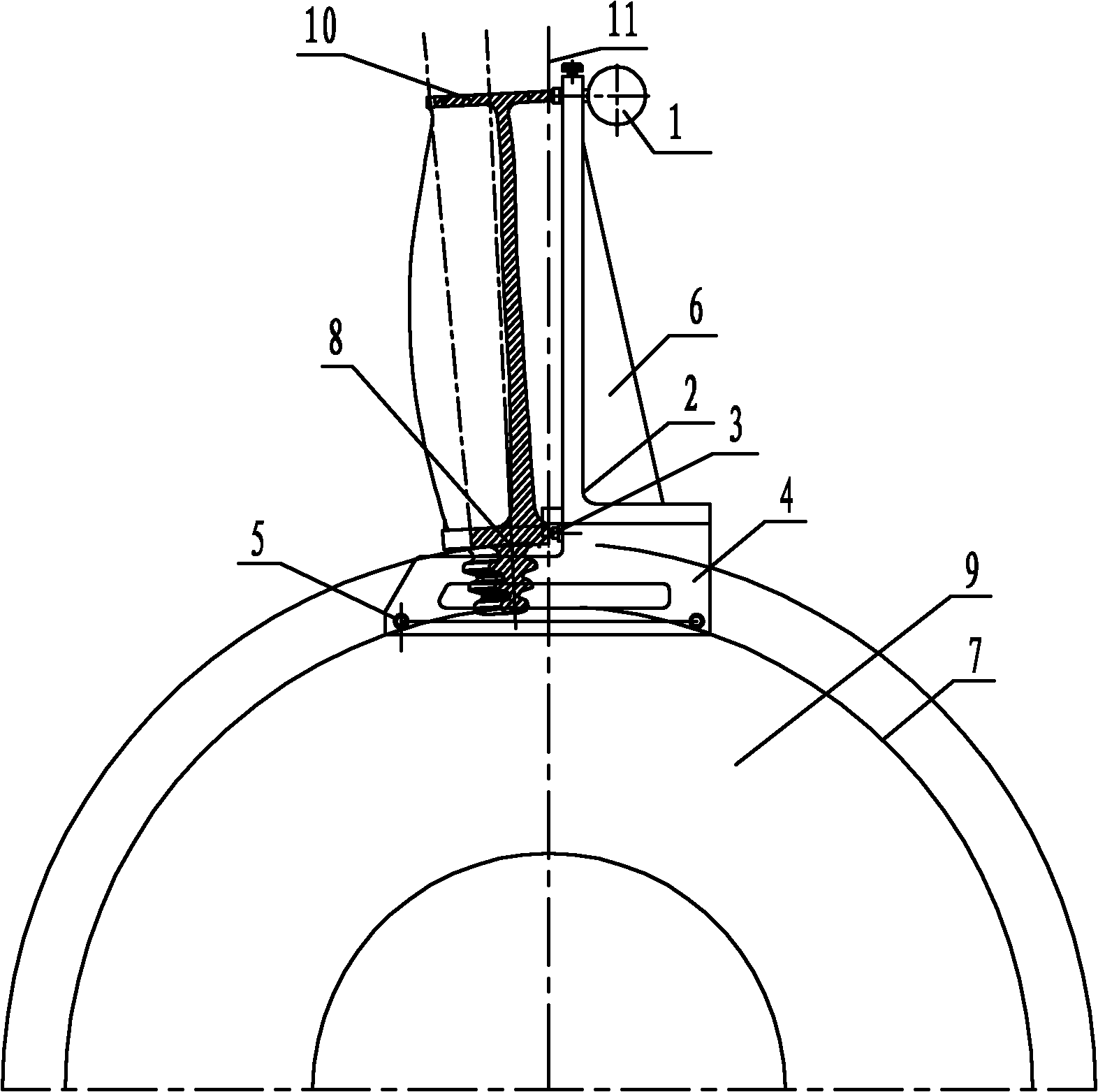

Locking sheet groove type blade assembled radial line deviation measuring apparatus of steam turbine rotor

InactiveCN102401621AShorten the lengthHigh precisionMechanical measuring arrangementsSteam turbine rotorMotherboard

A locking sheet groove type blade assembled radial line deviation measuring apparatus of steam turbine rotor relates to a deviation measuring apparatus of blade assembled radial line, which solves the problem in the radial line deviation measuring tool that cannot guarantee the measuring precision, is inconvenient to measure and cannot realize the deviation measurement of the large low pressure rotor last-stage blade radial line. A base includes a main board and two side boards, wherein the front side and the rear side of the main board are respectively provided with a side board; the bottom surface of each side board is provided with two cylinder pins; an L-shaped rack is installed on the upper end face of the main board; a locating pin is installed on the left side face of the main board; a dialgage is installed on the vertical plate of the L-shaped rack; the top point on the head of the dialgage and the top point of the locating pin are on the same vertical line. The invention is used for the deviation measurement of locking sheet groove type blade assembled radial line of steam turbine rotor.

Owner:HARBIN TURBINE

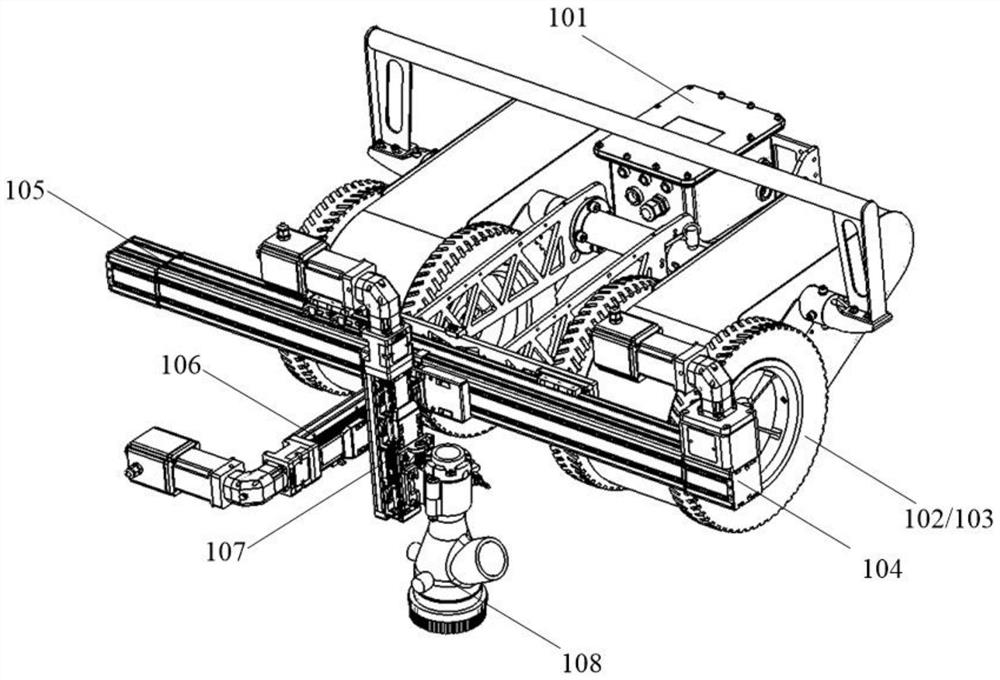

Intelligent robot and method for automatic inspection and maintenance of wind turbines

ActiveCN110978006BExtended service lifeThe connection is tight and firmOther manufacturing equipments/toolsManipulatorElectricity systemControl engineering

The present disclosure provides an intelligent robot and method for automatic inspection and maintenance of wind turbines. When the infrared scanner on the maintenance sub-seat scans that there is a welding gap between the components on the wind turbine or the components are broken, the gap or the component is broken through the welding torch. Welding is carried out at the fracture to ensure that the components of the wind turbine are more securely connected, and when the infrared scanner scans that there is a gap in the bolt connection of the component on the wind turbine, it means that the bolt connection is loose, and the bolt is re-tightened clockwise through the screw barrel to fix it. Ensure that the connection and use of each component of the wind turbine is more stable and reliable, improve the service life of the wind turbine, and reduce the probability of failure of the wind turbine power system. The invention has a high degree of automation and saves time and effort.

Owner:SHANDONG UNIV

Sand blasting mechanism

PendingCN111843846AImprove securityAccurately reachBlast gunsAbrasive machine appurtenancesSand blastingGeotechnical engineering

The invention discloses a sand blasting mechanism. The sand blasting mechanism comprises a body portion, a walking device, a sand blasting device moving module and a sand blasting device. The walkingdevice comprises walking wheels and a bottom disc. The sand blasting device moving module comprises a first module, a second module and a third module, the first module is arranged on the body portion, the second module is arranged on the first module, and the third module is arranged on the second module. The sand blasting device is mounted on the third module and used for carrying out sand blasting on workpieces. The third module can drive the sand blasting device to move in the first direction. The second module can drive the third module to move in the second direction. The first module can drive the second module to move in the third direction. Set angles are formed between the first direction, the second direction and the third direction. According to the sand blasting mechanism, though the drive function of the walking device, the first module, the second module and the third module, the sand blasting device can accurately arrive at the work position, the work efficiency and quality are improved, personnel do not need to do aerial work, and safety of rust removal work is improved.

Owner:BEIJING SHIHE TECH CO LTD

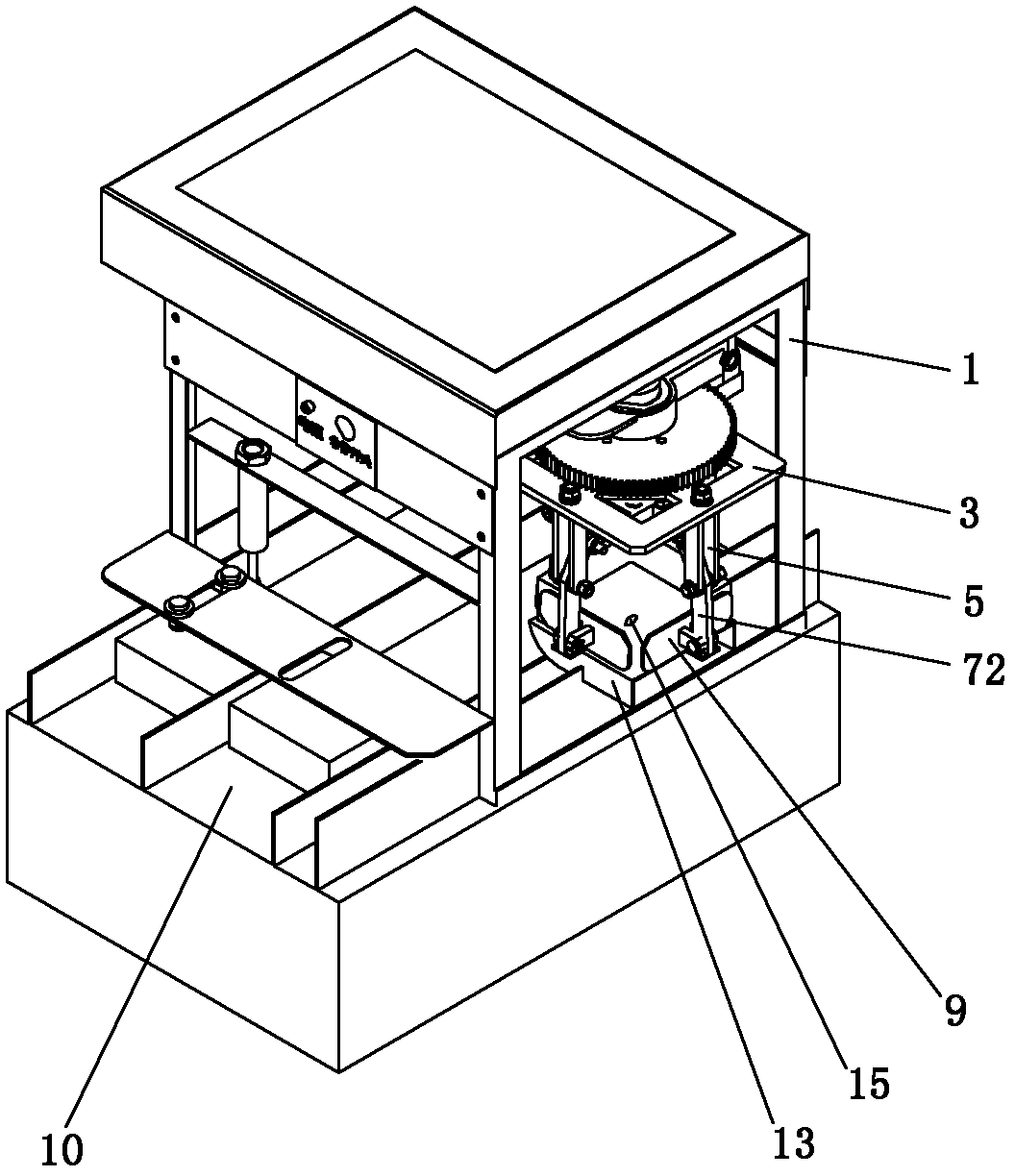

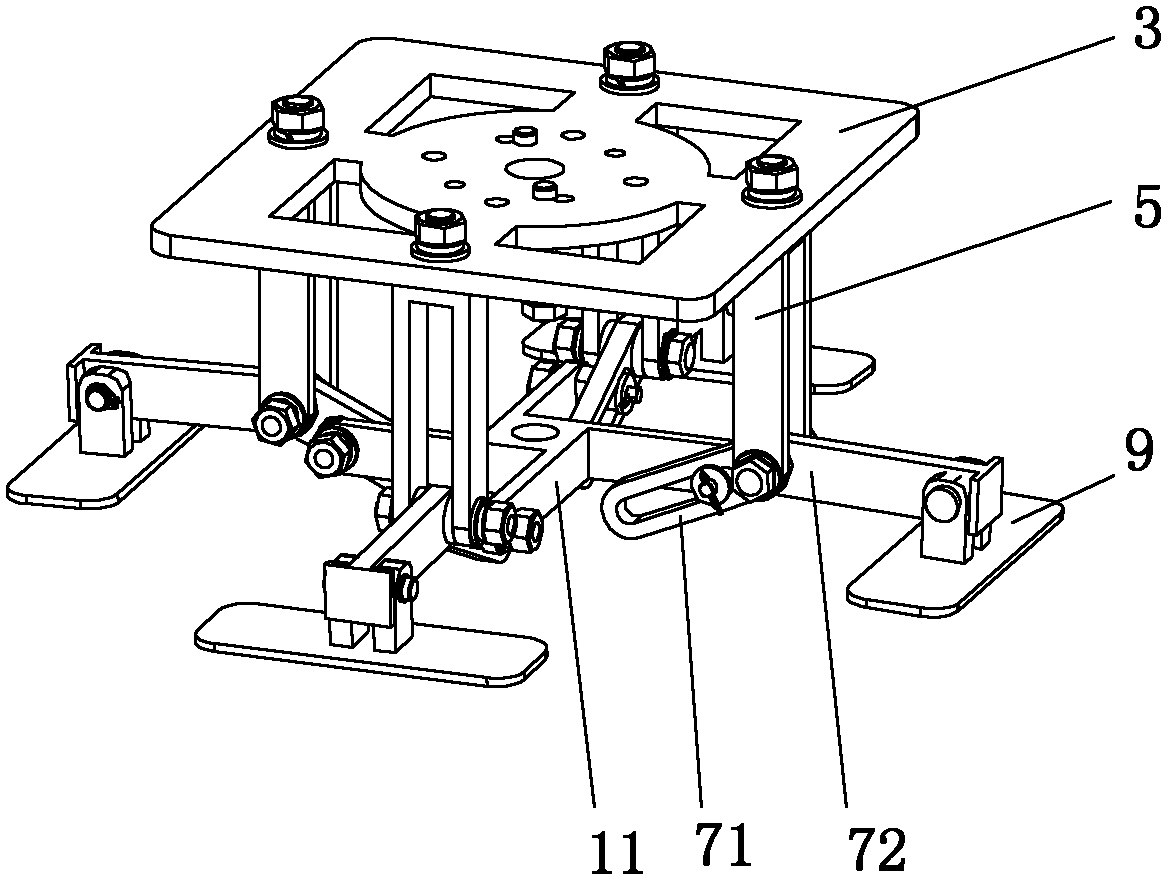

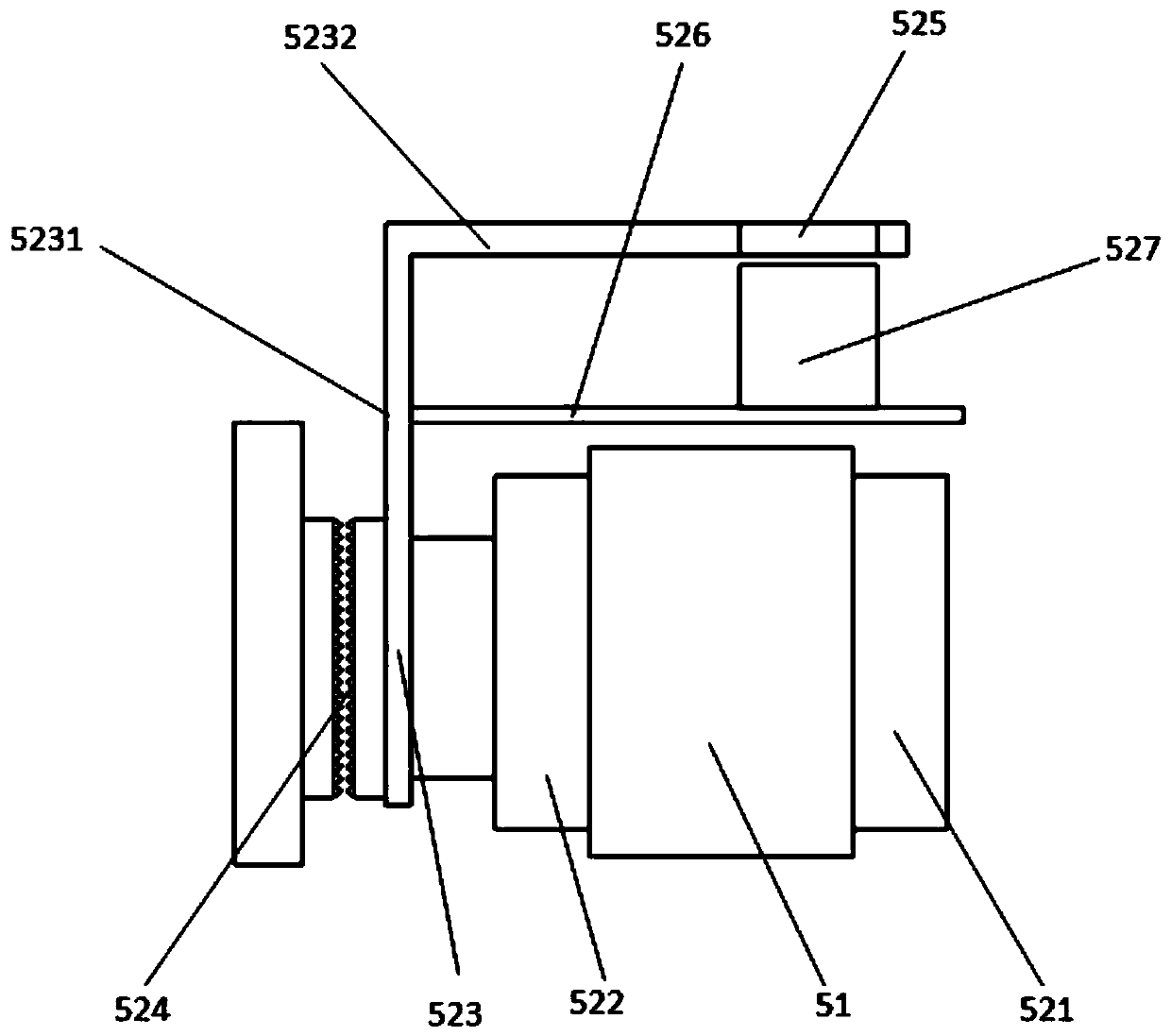

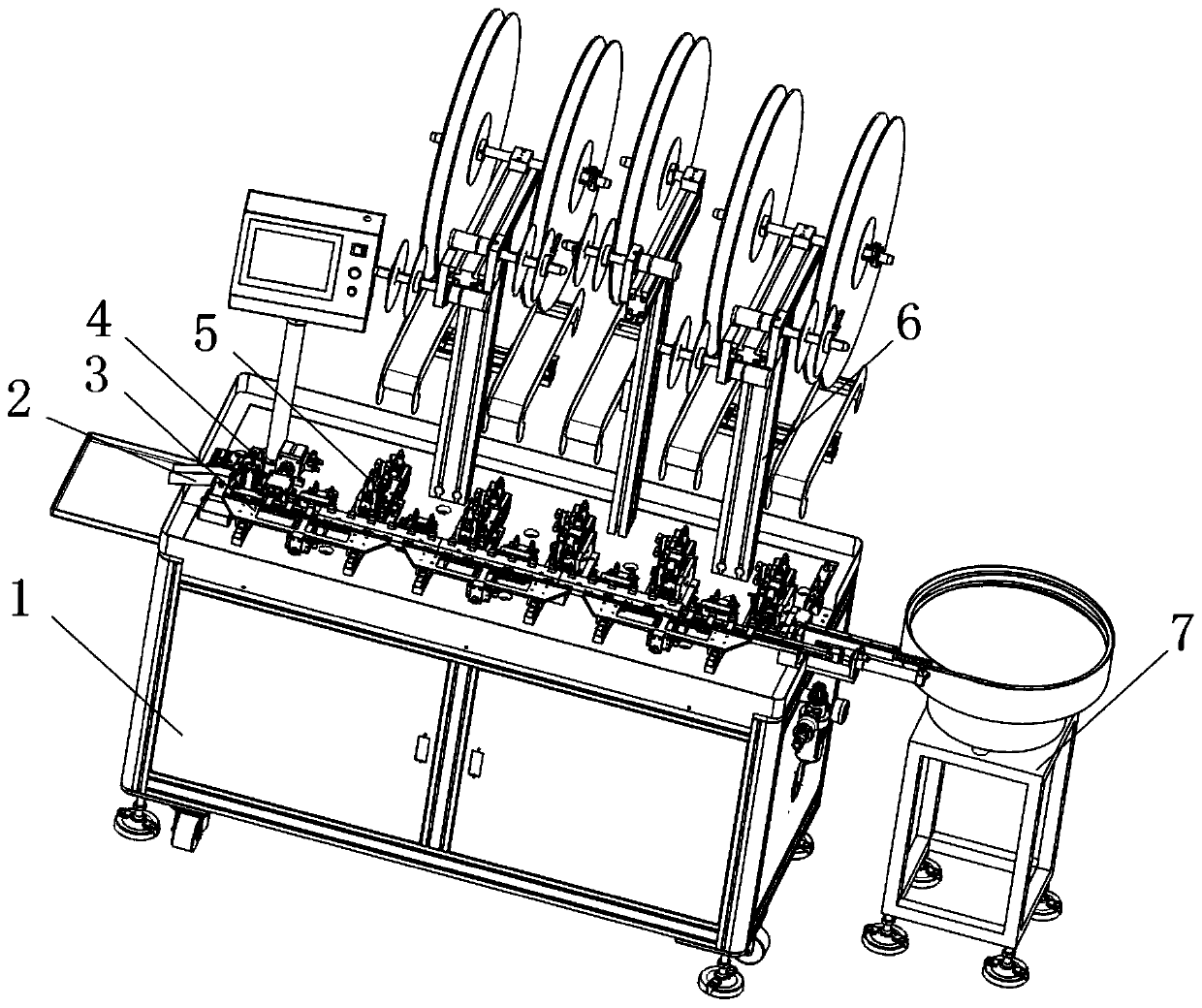

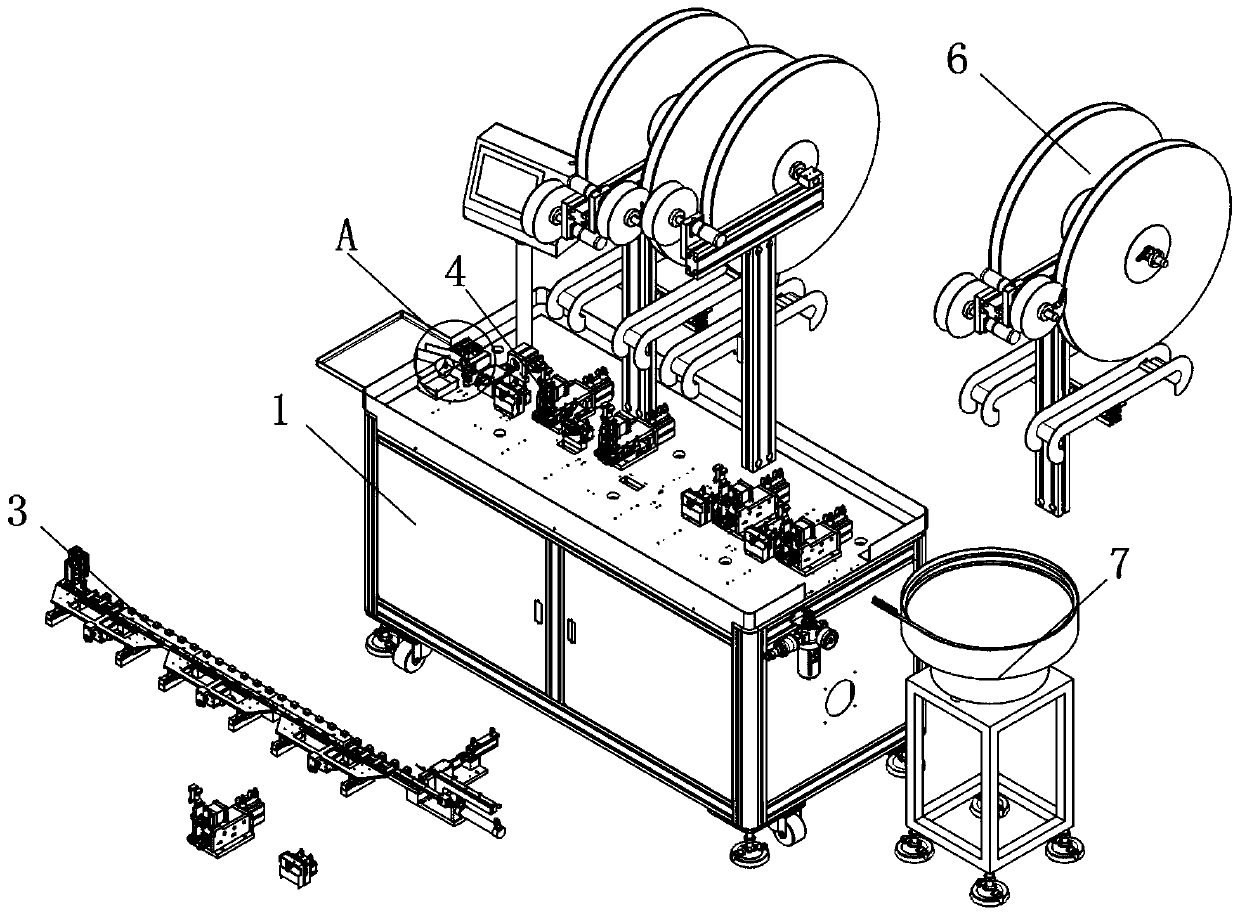

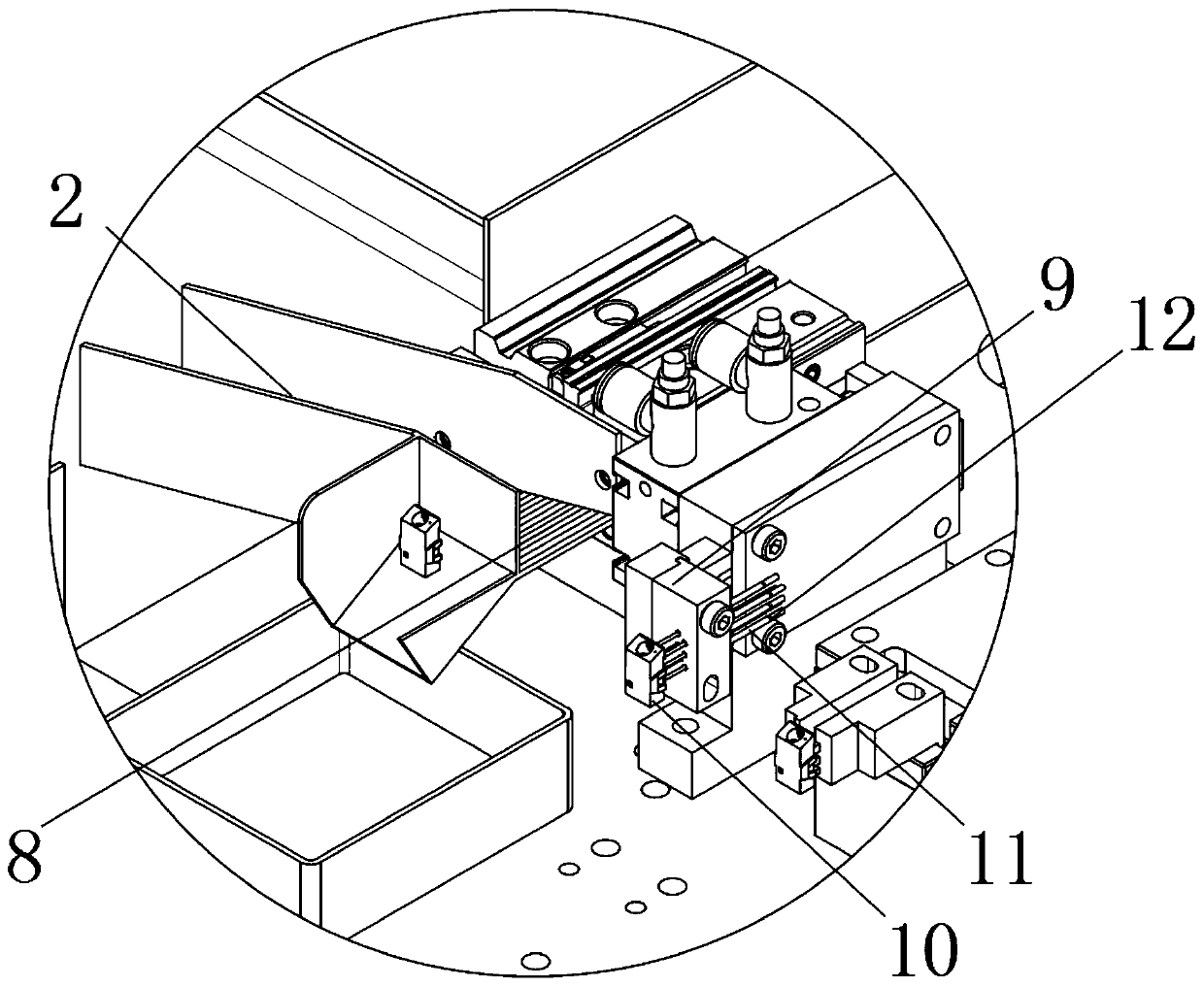

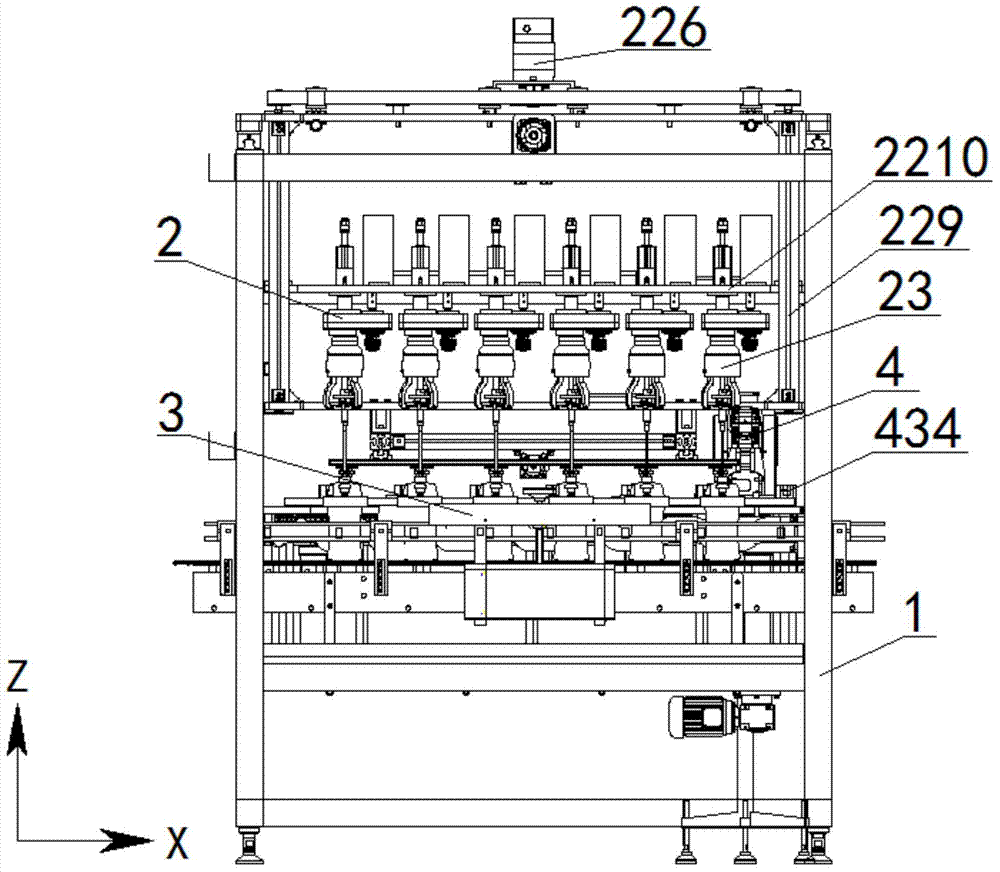

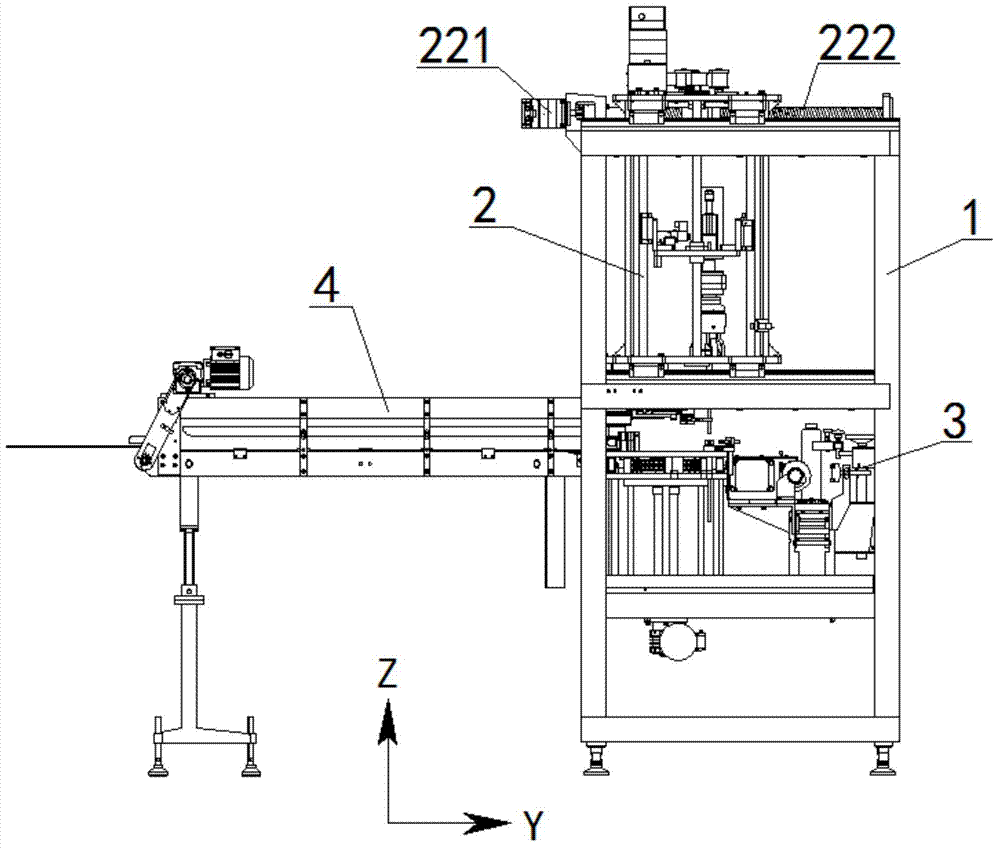

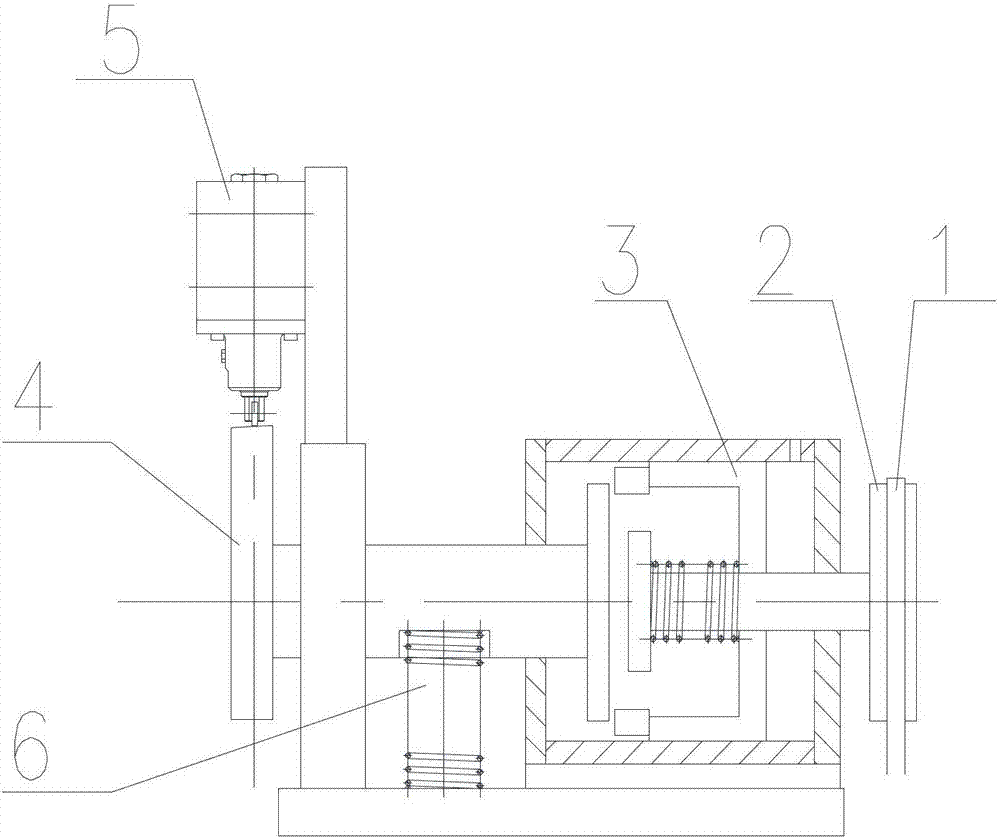

Inline capping machine

ActiveCN103754806BMake up for the defect of bendingAccurate insertionCapsConveyorsEngineeringBottle cap

The invention discloses an in-line arrangement cap screwing machine. The in-line arrangement cap screwing machine comprises a machine frame, a main cap screwing part, a bottle body conveying part and a cap conveying part, wherein the main cap screwing part, the bottle body conveying part and the cap conveying part are arranged on the machine frame. The main cap screwing part comprises a cap screwing head displacement driving assembly, a plurality of cap screwing head assemblies and a clamping jaw assembly. The cap screwing head displacement driving assembly is arranged at the upper portion of the machine frame, the cap screwing head assemblies are arranged on the cap screwing head displacement driving assembly, and the clamping jaw assembly is arranged at the bottom of the cap screwing head displacement driving assembly. For the main cap screwing part, the clamping jaw assembly is arranged at the bottom of the cap screwing displacement driving assembly, and straws of bottle caps are clamped through pneumatic clamping jaws, so that the bottle caps always keep a vertical state in the lifting process, the shortcoming that the bottle caps themselves possibly curve is overcome, it is ensured that the straw of each bottle cap can be accurately inserted into a bottle body, and cap screwing can be smoothly conducted.

Owner:江苏汤姆森智能装备有限公司

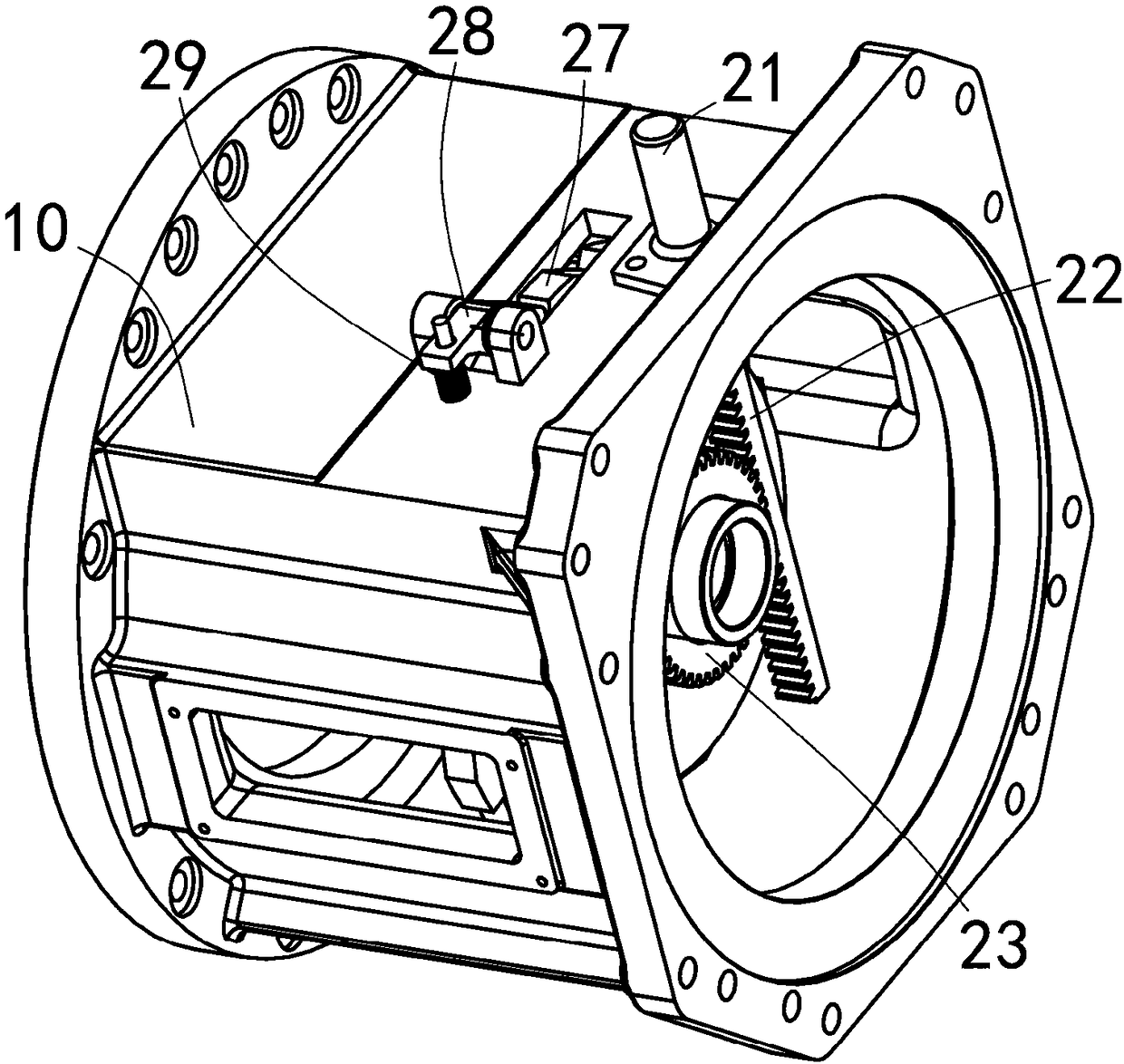

Three-position switch of gas-insulated switchgear using numerical control technology

ActiveCN103311006BReasonable structureEasy to operateContact driving mechanismsSwitch power arrangementsNumerical controlElectric machinery

The invention discloses a three-position switch of gas-insulated switchgear using the numerical control technology. The three-position switch comprises a moving contact driven by a screw. The left and right sides of the moving contact are provided with a ground end and an isolated closed end respectively. When the moving contact is driven by the rotating screw to be located on the left, the moving contact is jointed with the ground end, and the switch is grounded; when the moving contact is driven by the rotating screw to be located on the right, the moving contact is jointed with the isolated closed end, and the switch is isolated and not jointed; when the moving contact is driven by the rotating screw to be located in the middle, the moving contact is not jointed with the ground end or the isolated closed end, and the switch is isolated and open; the screw is driven by a motor, a sensor for sensing the rotation conditions of the screw is disposed on the screw, the sensor is connected with a numerical control device which controls the motor to rotate, the numerical control device controls the motor to positively or reversely rotate and stop, and accordingly rotation conditions of the screw are controlled. The three-position switch is reasonable in structure, convenient to operate, precise in operating position and fine in operating performance.

Owner:JIANGSU DONGYUAN ELECTRIC APPLIANCEGROUP

Pure manual control hydraulic closed-loop device of speed controller

InactiveCN102777315AAvoid putting into usePrecise working positionHydro energy generationMachines/enginesWater turbineClosed loop

The invention relates to a pure manual control hydraulic closed-loop device of a speed controller. The pure manual control hydraulic closed-loop device is applied to a water-turbine generator set to realize closed-loop control of pure manual control. A realization method is characterized in that displacement output of a guide vane servomotor is converted to hydraulic output by an operation mechanism so as to serve as a feedback signal to control a control head so that the pure manual control of the speed controller can realize the closed-loop control.

Owner:HARBIN ELECTRIC MASCH CO LTD

Multi-angle lubricating device for injection molding machine and working method thereof

The invention discloses a multi-angle lubricating device for an injection molding machine and a working method thereof. Motor 1 is vertically sleeved inside the moving frame, and the upper part of the motor 1 is connected to the lower rotating frame through the rotation of the rotating shaft 1, and the motor 2 is horizontally sleeved above the lower rotating frame, and one end of the motor 2 is rotated through the rotating shaft 2. Attached to the side swing frame. The beneficial effects of the present invention are: motor eight drives the lubricating table to adjust back and forth, and cooperates with motor three to drive the top swing frame and the swing mechanism to swing upwards through the rotating shaft three, and the oil guide tube is placed above the injection molding machine. On the one hand, the oil guide tube is guaranteed to be The position of the injection molding machine that needs to be lubricated for lubricating work is more precise. On the other hand, it is ensured that the device can perform lubrication work on injection molding machines of different heights, which improves the adaptability of the device.

Owner:重庆安丰塑胶科技有限公司

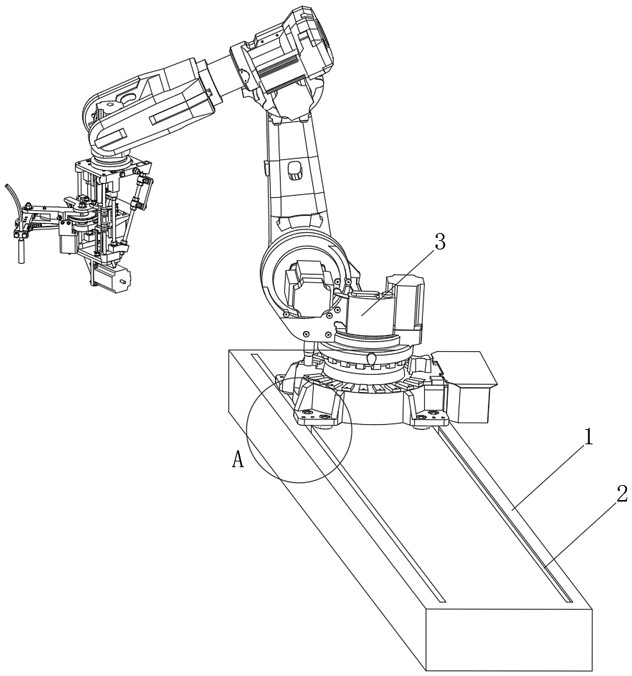

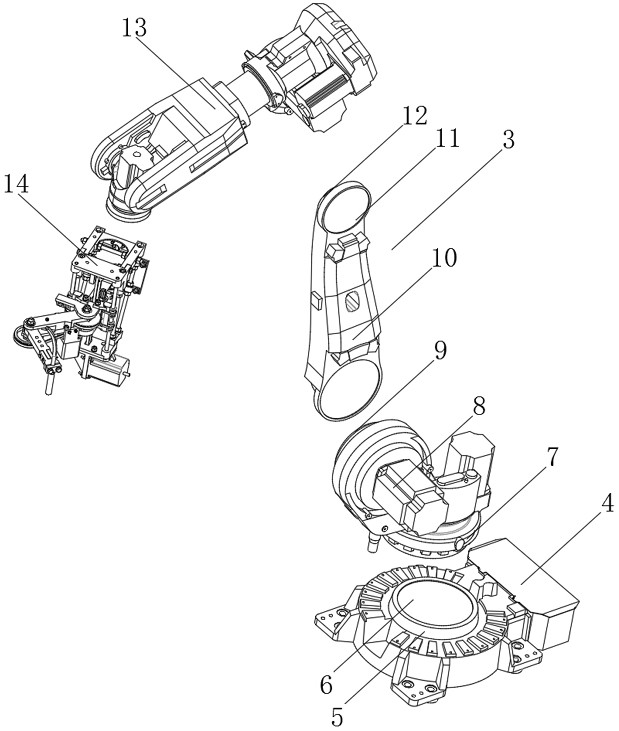

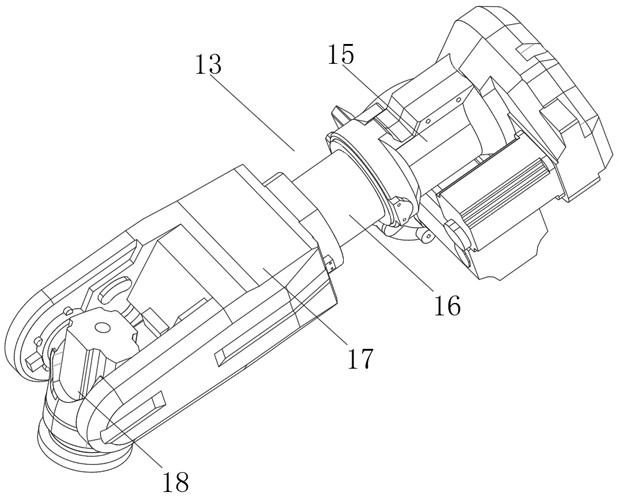

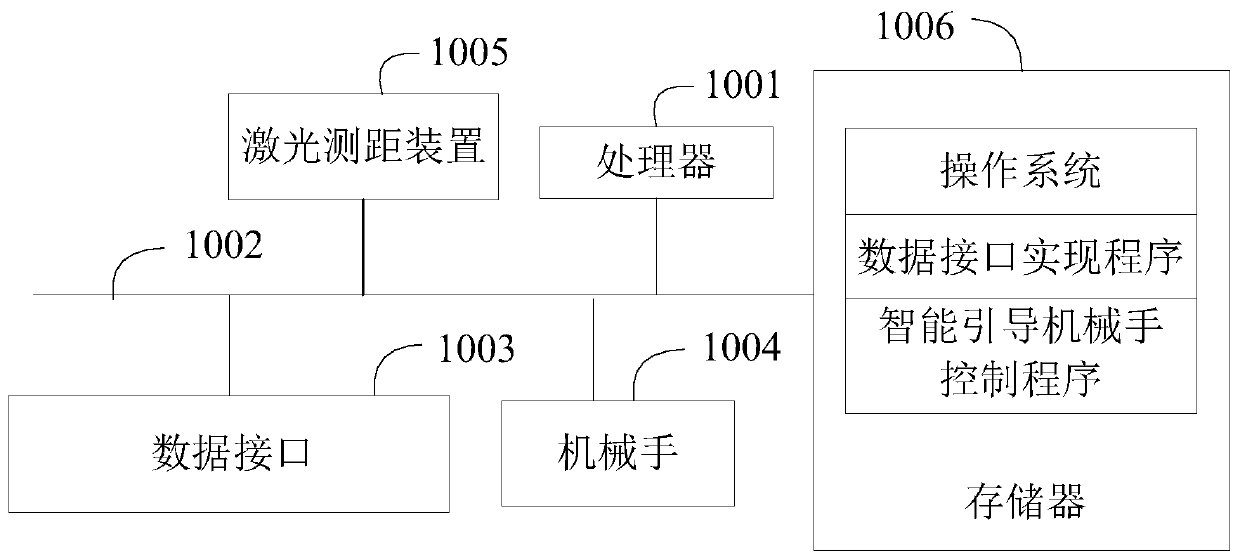

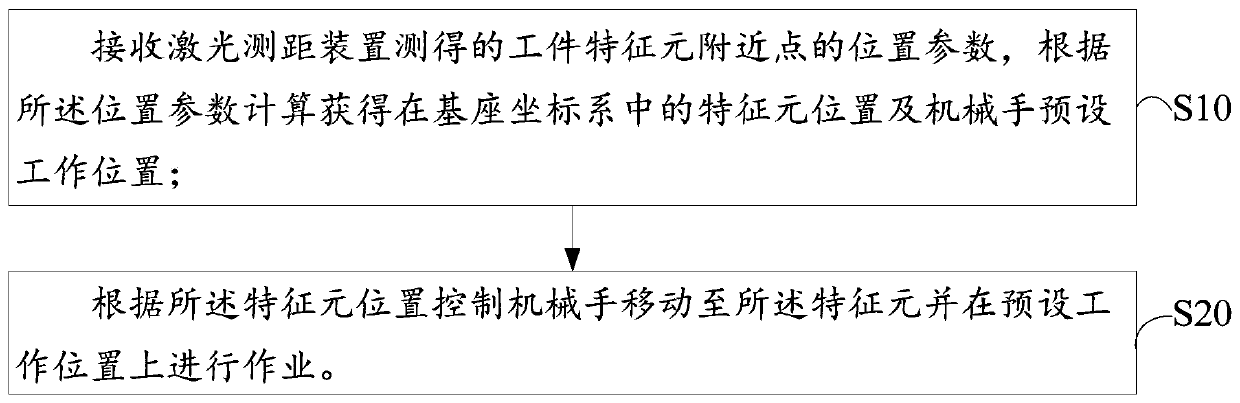

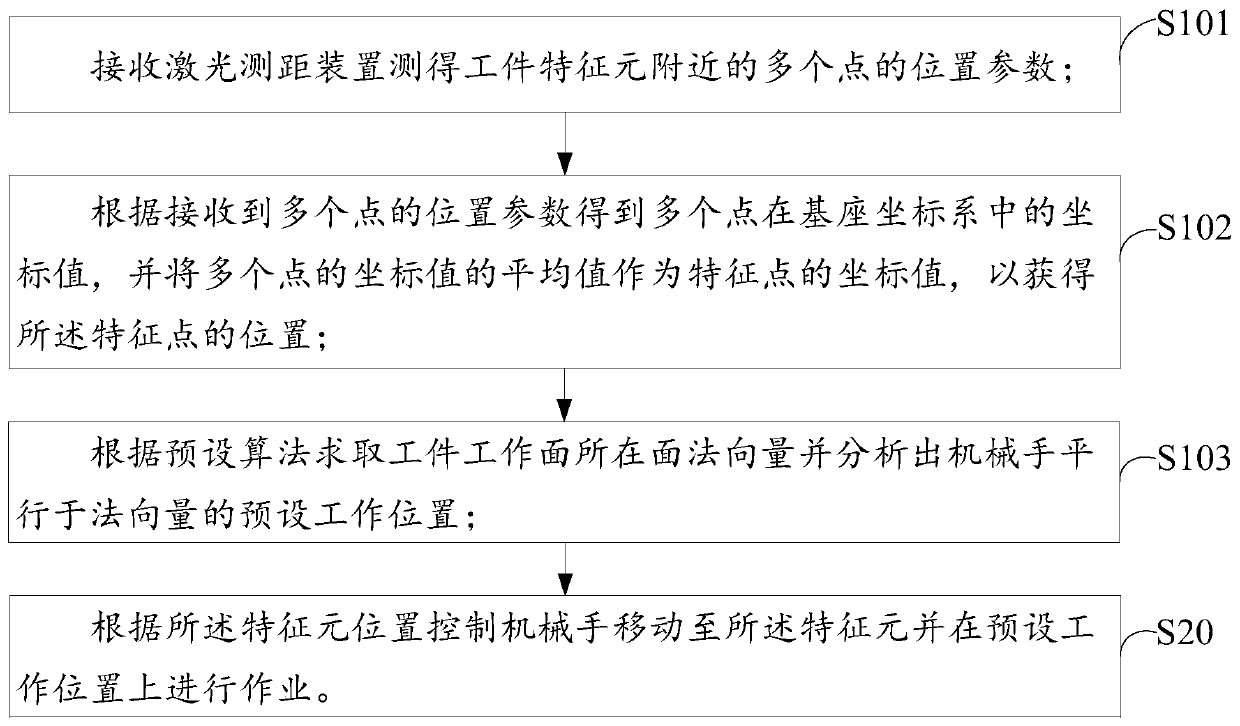

Manipulator control method and device, readable storage medium and automation equipment

ActiveCN107511829BPrecise working positionAvoid damageProgramme-controlled manipulatorLaser rangingControl engineering

The invention discloses a control method and device for a mechanical hand, a readable storage medium as well as automatic equipment. The control method for the mechanical hand comprises the following steps of: receiving a position parameter, measured by a laser distance measuring device, of a workpiece characteristic element nearby point, and calculating to obtain a characteristic element position in a pedestal coordinate system and a mechanical hand preset working position according to the position parameter; and controlling the mechanical hand to move to a characteristic element according to the characteristic element position and operating on the preset working position. According to the technical scheme adopted by the invention, a working position of a workpiece and a working gesture of the mechanical hand are quickly found through the mechanical hand, so that errors caused by line of sight of staff or visual-angle naked-eye judgment are avoided, adverse factors caused by insufficient debugging experience of staff are reduced, and damages due to the fact the mechanical hand collides with the workpiece when the line of sight is blocked are avoided; and meanwhile, through the technical scheme, the mechanical hand can quickly and precisely search the working position, on the workpiece, of the mechanical hand, so that production efficiency is improved.

Owner:SQUAREDOG AI SERVICES LTD

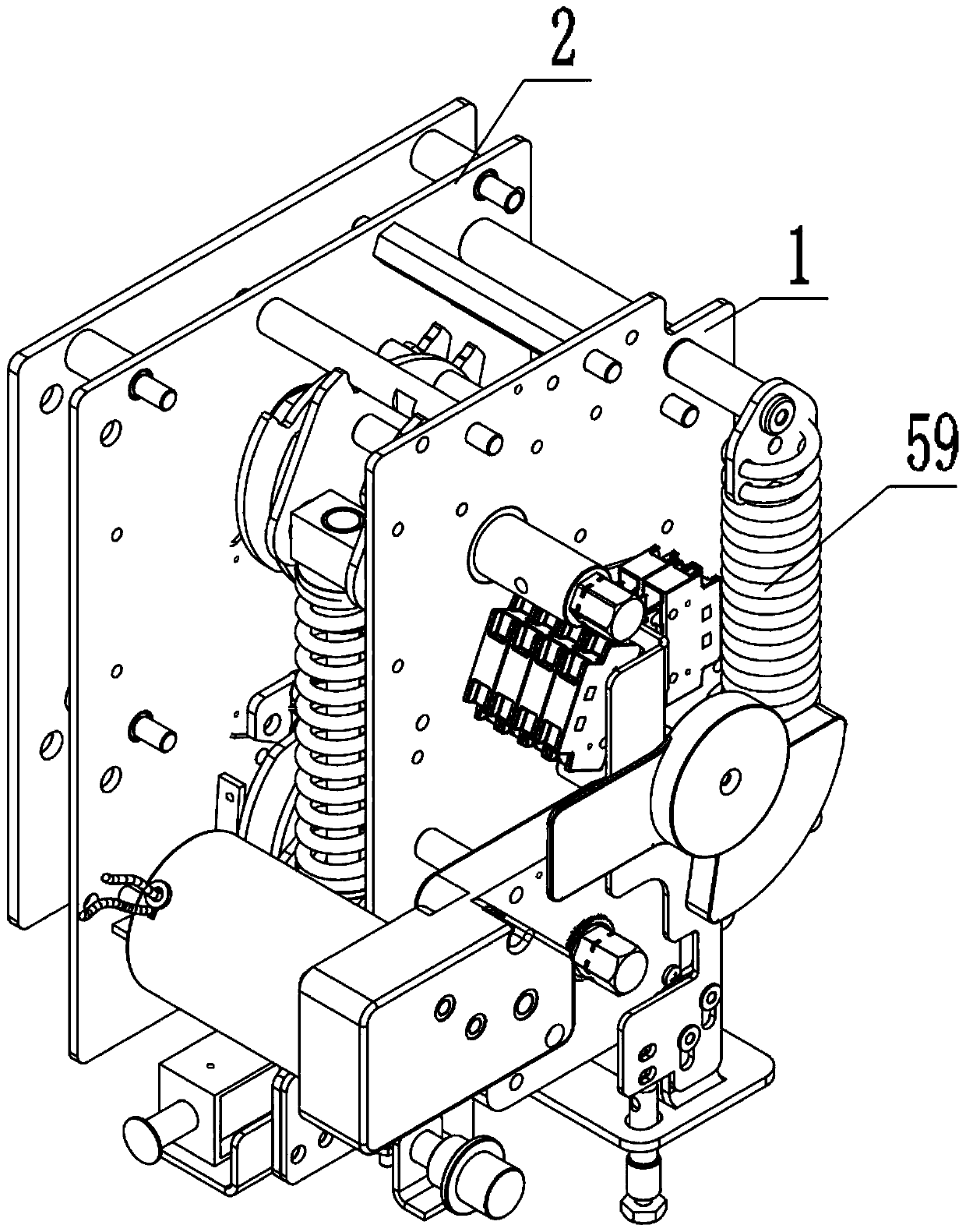

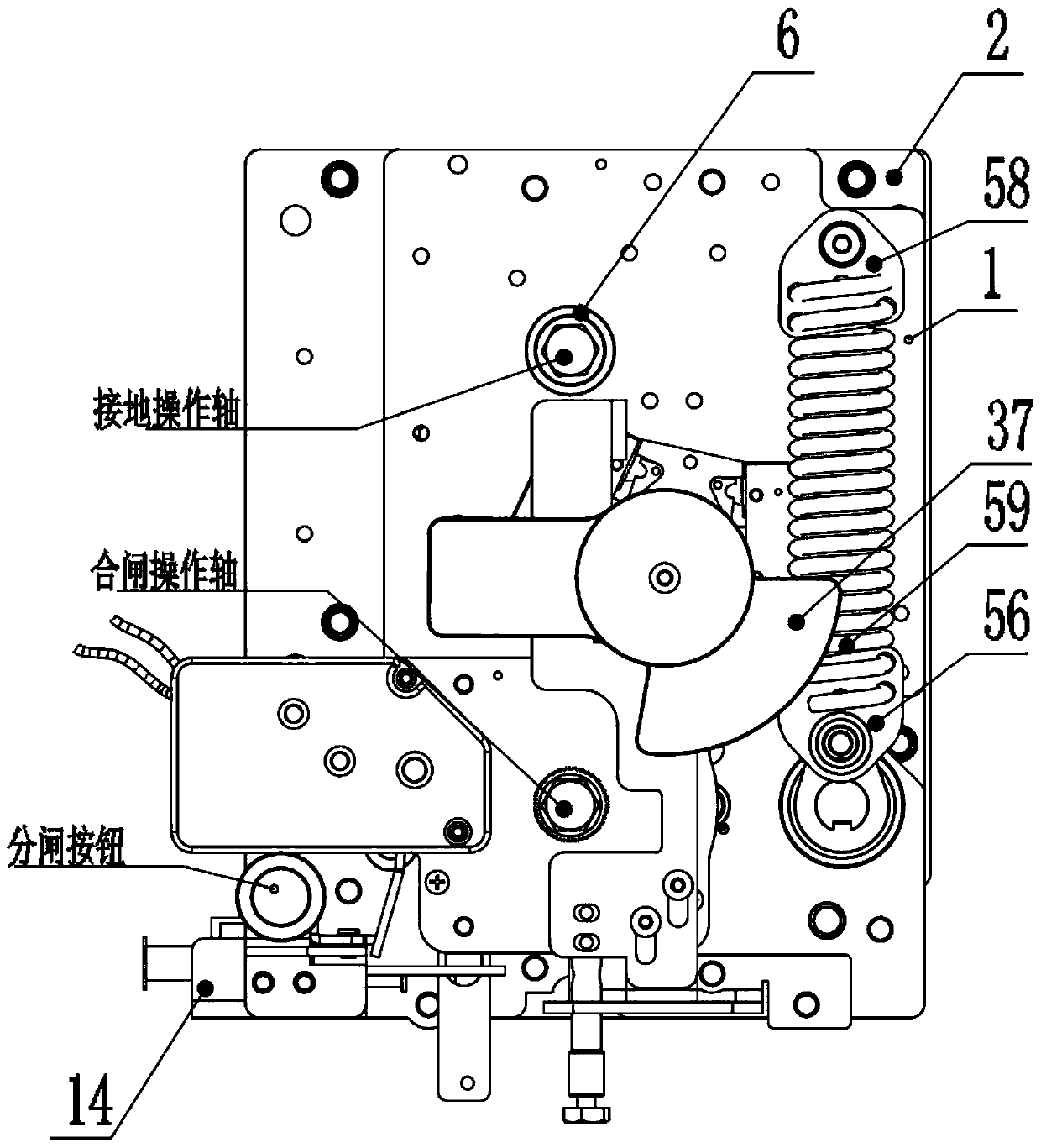

Inflatable cabinet load switch fuse combination electrical mechanism

ActiveCN109326985BHigh sensitivityHigh precisionSwitchgear arrangementsElectric machineStructural engineering

The invention discloses a gas filled tank load switch fuse-combination unit mechanism. The gas filled tank load switch fuse-combination unit mechanism comprises a front plate, a rear plate, a closingspring, a motor and a switch-on and switch-off cam welding wire outlet mechanism. The front plate and the rear plate are separately arranged at the two ends of the mechanism, and the front plate and the rear plate are arranged in parallel. The gas filled tank load switch fuse-combination unit mechanism has the beneficial effects that a mechanism transmission mode is changed by the gas filled tankload switch fuse-combination unit mechanism, the mechanism transmission structure is optimized, good transmission property of the mechanism is ensured, and transmission operation is accurate and stable; a hexagonal shaft, a positioning shaft, a shaft III, a shaft IV and a shaft V are arranged between the front plate and the rear plate and perpendicularly penetrate through the front plate and the rear plate, and the strength and firmness of the integral mechanism during working are improved; shaft bodies are protectively isolated by shaft sleeves, friction and collision of the shaft bodies arerelieved, and the service lives of the shaft bodies are prolonged; and the electrical mechanism is high in sensitivity during working, is firm and durable, has good social benefit, and is suitable forbeing popularized and used.

Owner:浙江联格电气科技有限公司

A battery cover extrusion molding device and use method in the battery production process

ActiveCN112317587BIncrease capacityHigh degree of automationMetal-working feeding devicesFinal product manufactureCompression moldingHydraulic cylinder

The invention discloses a battery cover extrusion molding device in the battery production process and a use method thereof, which comprises a rectangular parallelepiped-shaped cabinet body, a frame delivery platform, a support seat, an end sleeve plate and a transfer frame. The platform is arranged above the cabinet body, and a support seat is vertically provided on one side of the frame delivery platform, and end sleeve plates are horizontally provided at both upper and lower ends of the support seat. The beneficial effects of the present invention are: the motor six drives the turntable to rotate, and the extruding assembly is moved to the top of the battery cover, and the hydraulic cylinder on the extruding assembly drives the stamping pad to align with the battery cover and pushes downward through the hydraulic column, squeezing the battery cover. Compression molding processing, several loading slots are arranged side by side at equal intervals on the swinging frame, and several sub-packing slots are arranged in each of the several loading slots, which greatly improves the capacity of the device for the battery cover, and the device does not affect the battery. The automation degree of the extrusion molding process of the cover is high, and the use saves time and labor.

Owner:安徽浩瀚星宇新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com