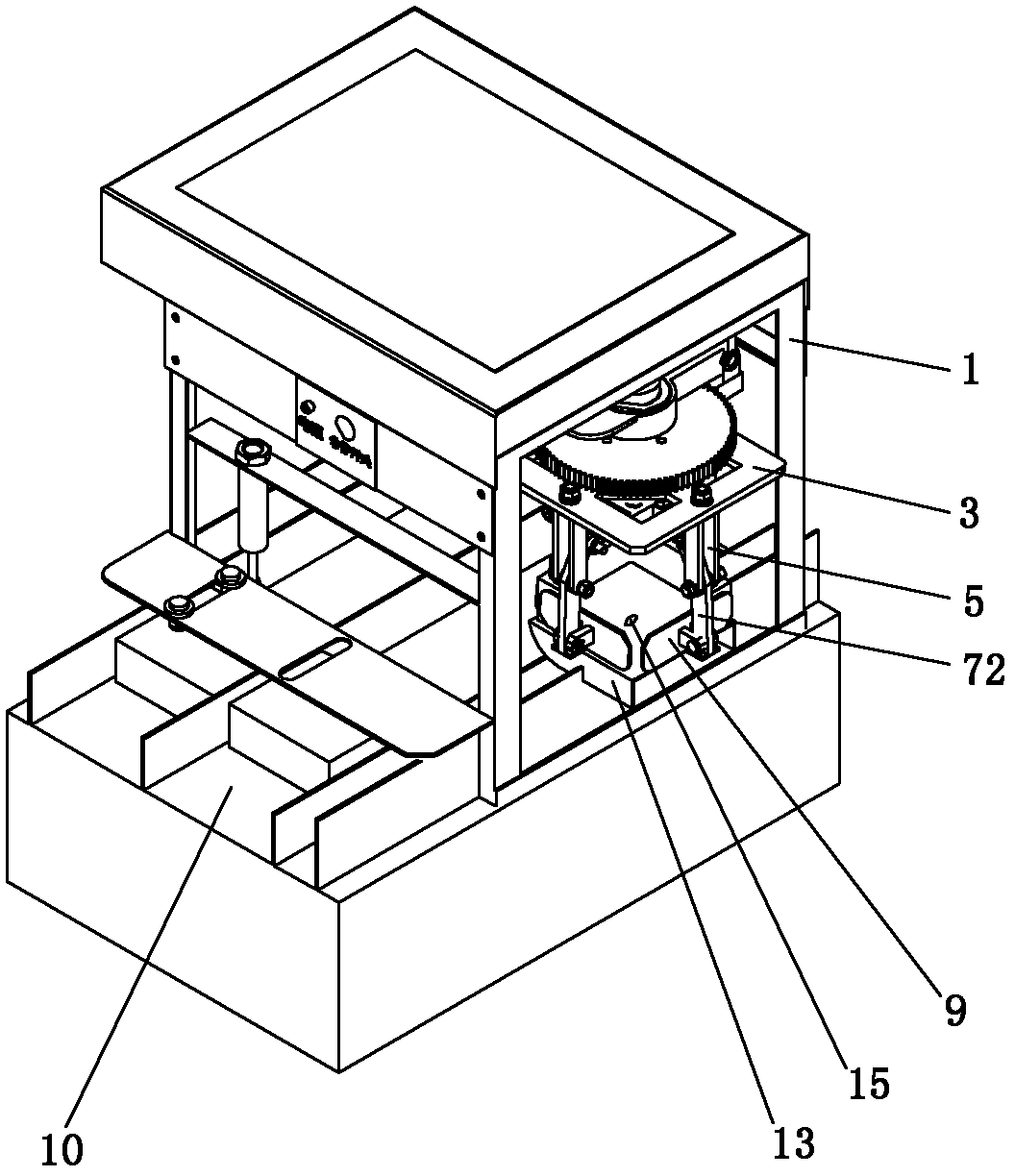

Manipulator unit and production line with same

A technology of manipulators and racks, applied in the field of manipulator units and production lines with the manipulator units, can solve the problems of inability to adapt to large-scale industrial production, low work efficiency, poor working environment, etc., to ensure smooth operation, convenient operation, and easy operation The effect of accurate position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

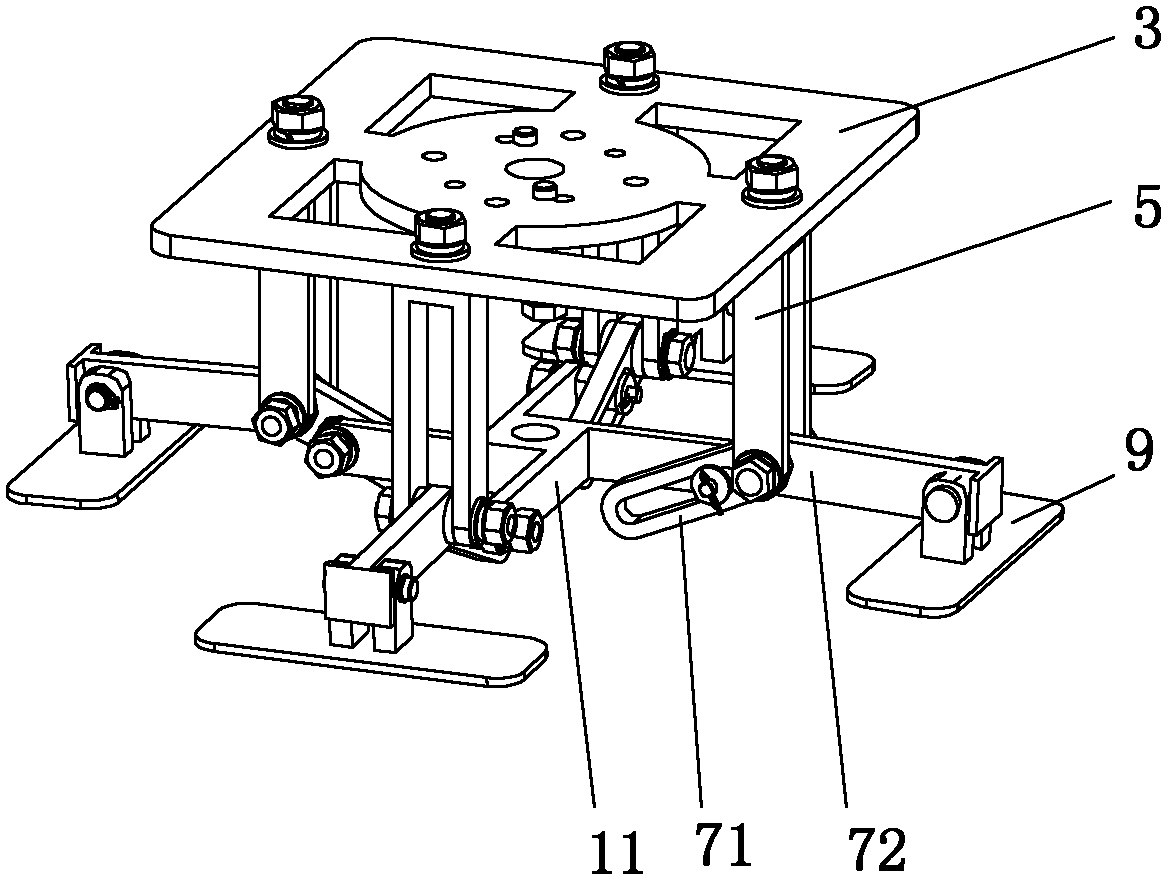

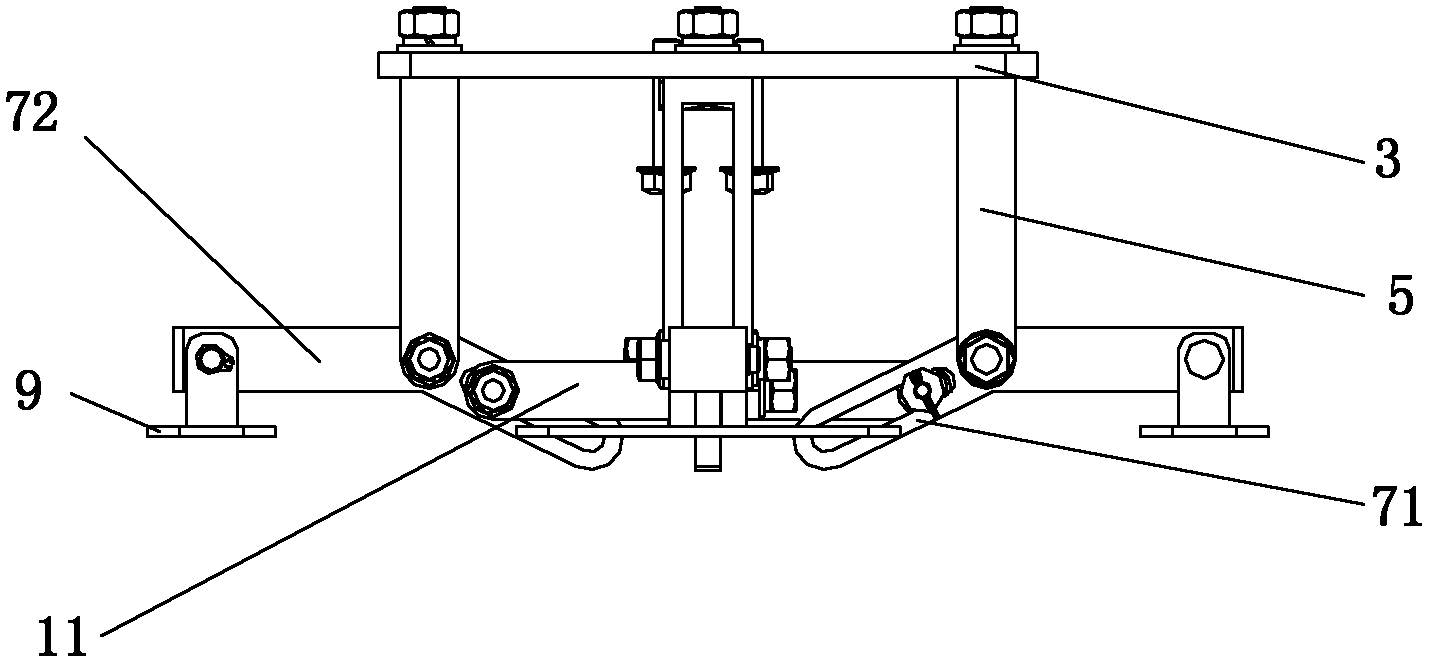

Method used

Image

Examples

Embodiment 1

[0056] Power source embodiment one, servo motor + cylinder type

[0057] Figure 13 It is a schematic diagram of the overall structure of an embodiment of the power source of the present invention. Such as Figure 13As shown, in the present embodiment, the horizontal motion is controlled by the servo motor 50, the rotary motion becomes linear motion easily and simply, the operation is stable and reliable, there is no impact, the noise is low, and the most important thing is strong controllability. The cylinder is used for vertical movement, the linear movement is directly realized, the structure is simple, time-saving and there is no impact source here, so the noise and vibration are not large. The cylinder 55 realizes the connection with the splint mechanism through the bearing seat and the bearing seat pillar, and the guide rod ensures the reliability of the horizontal movement. The cylinder 55 is fixed on the fixed plate 3 and is connected with the fork of the splint mec...

Embodiment 2

[0058] Power source embodiment two, double servo motor type

[0059] Figure 14 It is a schematic diagram of the overall structure of Embodiment 2 of the power source of the present invention. Such as Figure 14 As shown, in this embodiment, dual servo motors 50 are adopted, the controllability is the best, the structure is the simplest and the operation is reliable.

Embodiment 3

[0060] Power source embodiment three, single servo motor + rack and pinion type

[0061] Figure 15 and Figure 16 They are the overall structure schematic diagram and partial structure schematic diagram of the third embodiment of the power source of the present invention, respectively. Such as Figure 15 and combine Figure 16 As shown, the present embodiment adopts a single servo motor 50, which saves one power source, and the rotational motion is separated into horizontal motion and vertical motion through the clutch and the brake. Turning rotary motion into linear motion, the cost is relatively low; there is no noise and impact phenomenon, and the operation is reliable.

[0062] The specific action process of this embodiment is as follows:

[0063] First of all, the manipulator is in a static standby state above the middle bag pallet 13 . Now the horizontal movement clutch 61 loses power and disengages, the vertical movement clutch 63 is energized and sucked in, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com