Inline capping machine

A capping machine, in-line technology, applied in the direction of conveyors, conveyor objects, bottles/container caps, etc., can solve the problems that the straw cannot be inserted into the bottle accurately, and the capping failure of the in-line capping machine, etc., to achieve structural The effect of simplicity, low cost, and high displacement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

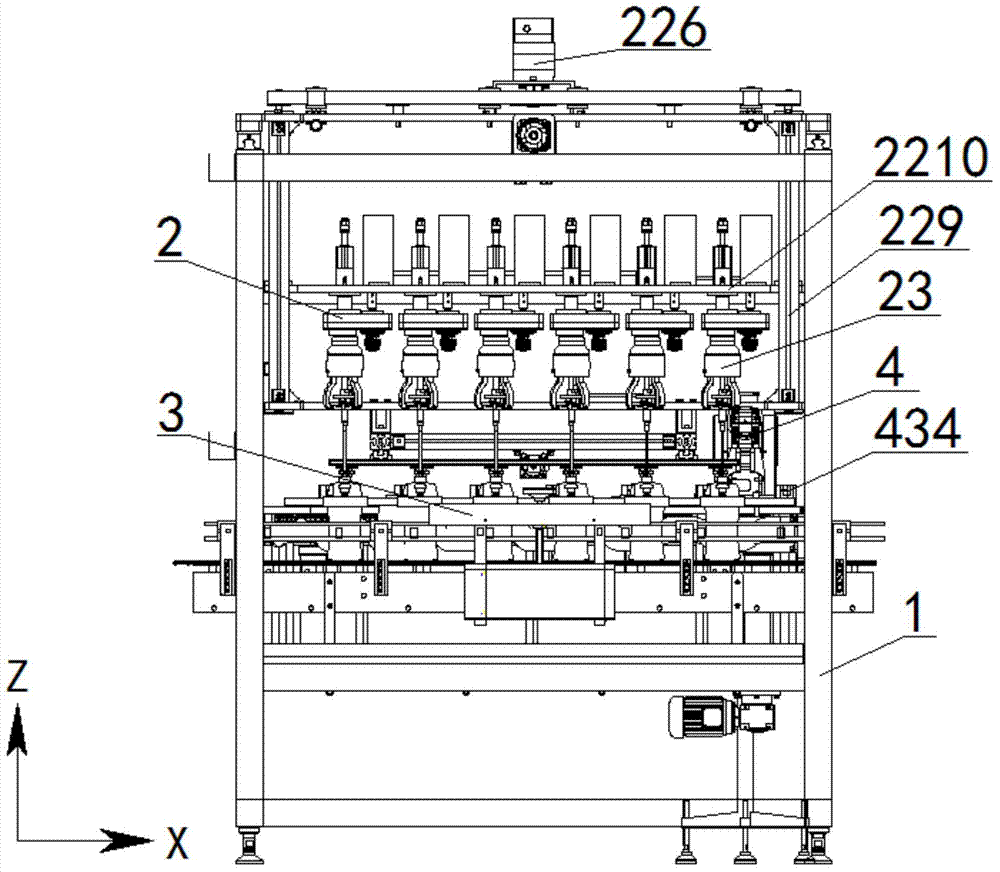

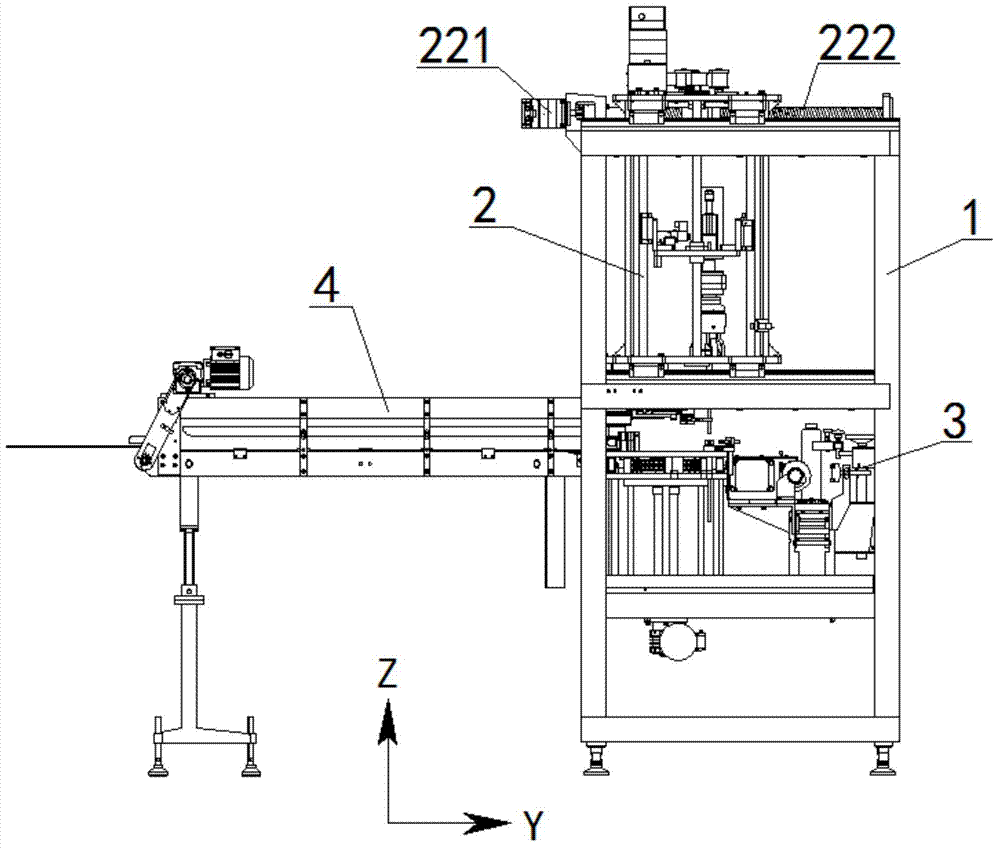

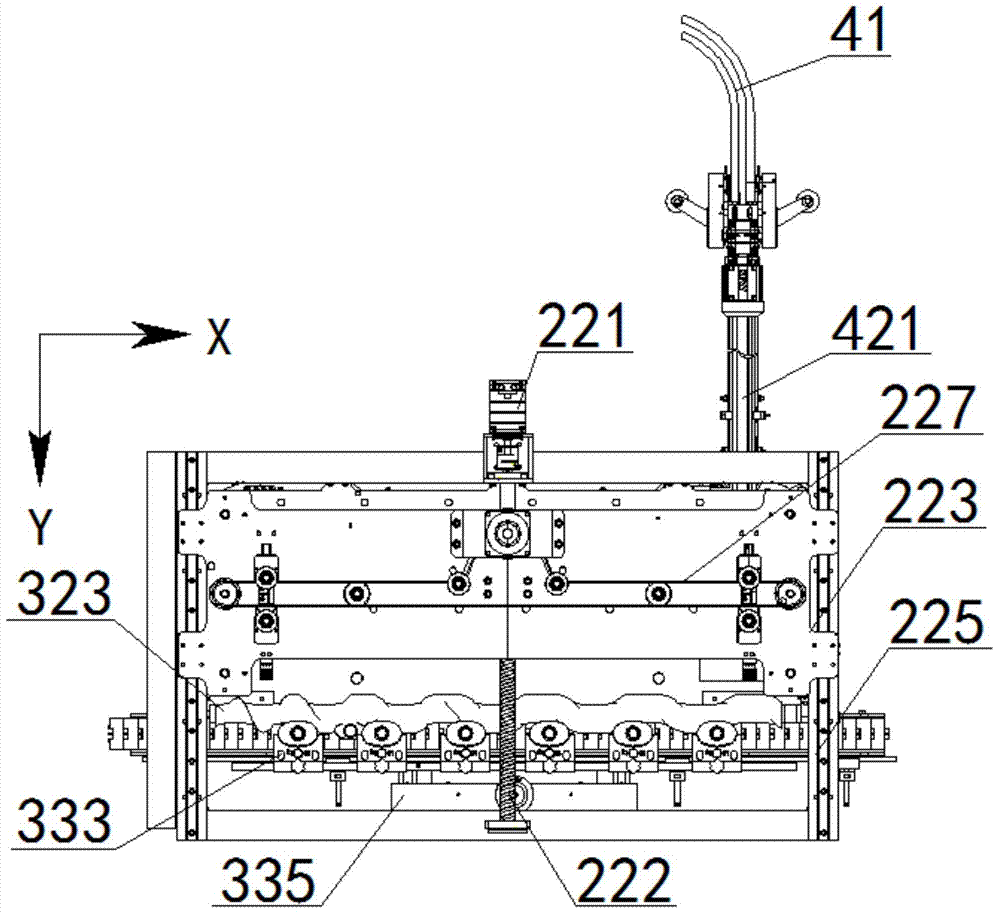

[0041] see Figure 1 to Figure 4 , The in-line capping machine of this embodiment includes a frame 1, and a capping main part 2, a bottle conveying part 3, and a cap feeding part 4 installed on the frame 1. The bottle body conveying part 3 and the cap feeding part 4 are arranged below the capping main part 2, and the bottle body conveying part 3 is arranged in front of the cap feeding part 4.

[0042] see Figure 5 with Image 6 , The capping main component 2 includes a capping head displacement drive assembly 22, a capping head assembly 23 and a clamping jaw assembly 24. The capping head displacement drive assembly 22 is installed on the upper part of the frame 1. The capping head assembly 23 is installed on the capping head displacement driving assembly 22, and there are a plurality of them. The capping head displacement driving assembly 22 drives the capping head assembly 23 to move back and forth and up and down. The jaw assembly 24 is installed at the bottom of the cappin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com