Rear working device for integrated linkage type snow remover

A technology of working device and snow blower, which is applied to snow surface cleaning, cleaning method, construction, etc., can solve the problems of slow snow removal, unclean cleaning, poor cleaning effect, etc., to ensure the continuity of operation and prolong the service life. , to ensure the effect of working height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042]The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

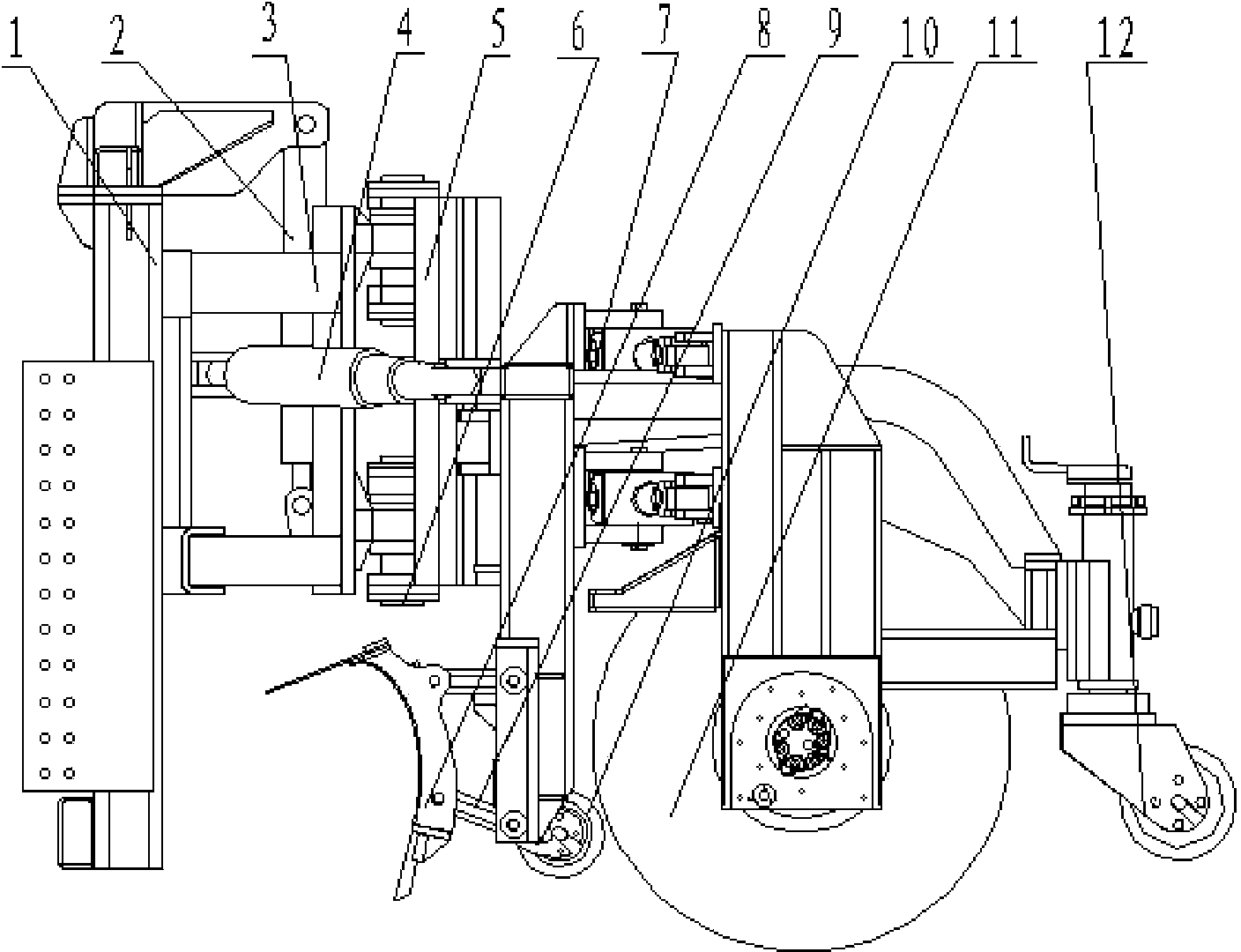

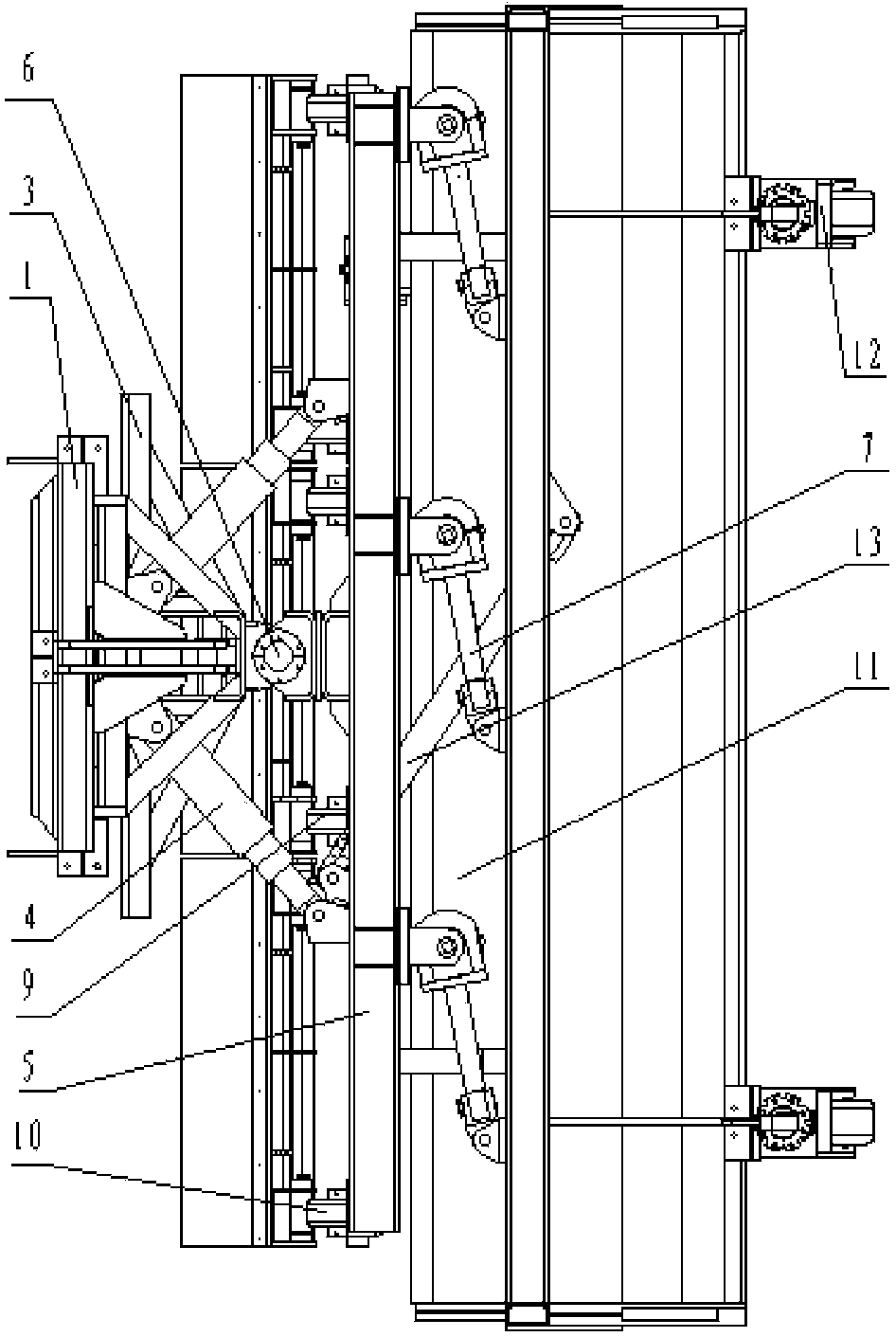

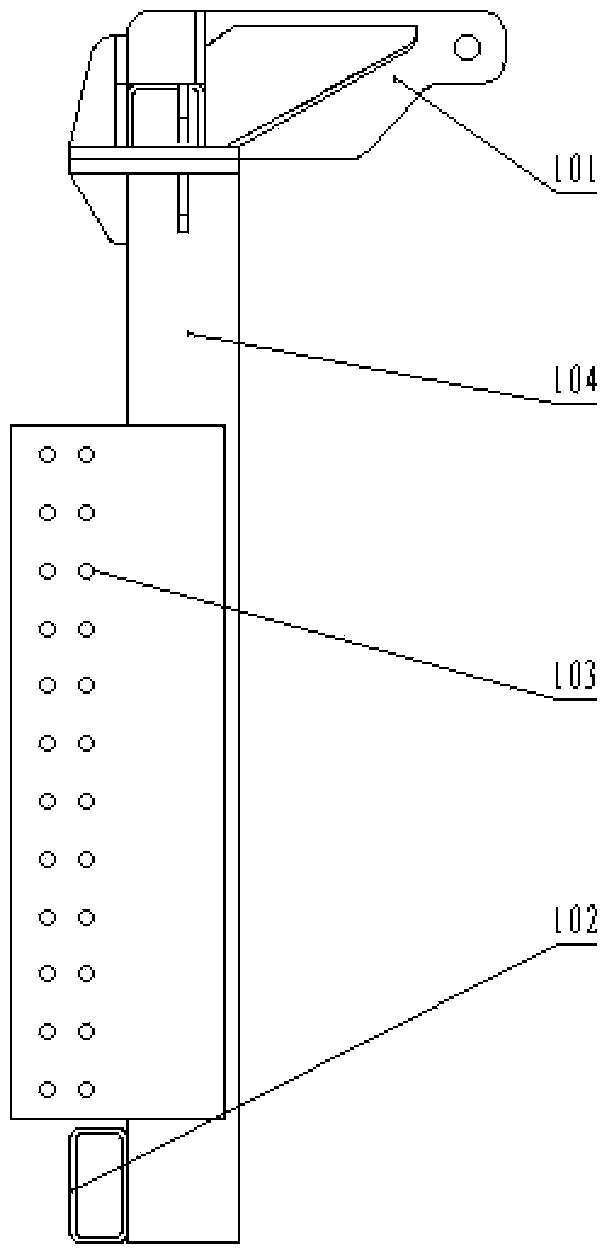

[0043] refer to Figure 1 to Figure 2 It is the overall structure of the rear working device of the integrally linked snow blower. The fixed frame 1 is fixedly connected to the rear of the frame of the snow blower, and the lifting sliding frame 3 is installed on the fixed frame 1 with slideways through pulleys. The two ends are respectively hinged on the fixed frame 1 and the lifting sliding frame 3. The lifting sliding frame 3 can slide up and down on the fixed frame 1 through the control of the lifting cylinder 2. The upper end of the lifting cylinder is twisted to the fixed frame lifting cylinder at the upper end of the fixed frame. On the ear plate 101, the lower end is twisted on the sliding frame lifting cylinder ear plate 304 at the lower end of the lifting sliding frame, and the lifting sliding frame 3 is driven to slide up and down o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com