Sand blasting mechanism

A sandblasting and sandblasting gun technology, applied in abrasive jet machine tools, spray guns, used abrasive treatment devices, etc., can solve problems such as low efficiency, and achieve the effect of improving safety, improving work efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

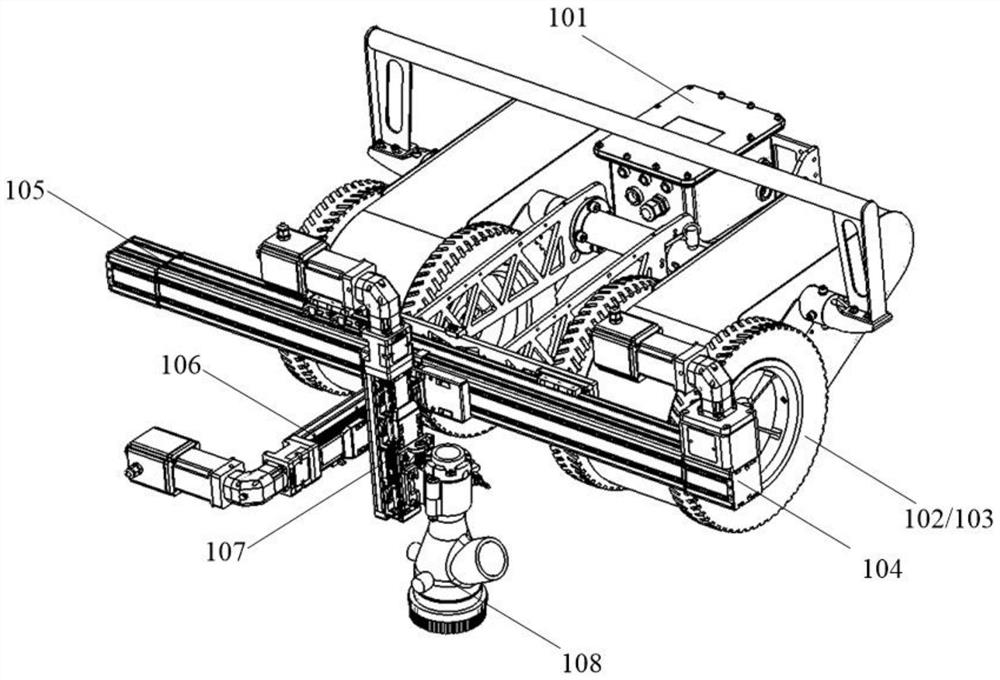

[0057] combined with figure 1 ~ attached Figure 6 , the present embodiment provides a sandblasting mechanism, comprising:

[0058] main body 101,

[0059] The traveling device 102 is arranged on the main body 101; the traveling device 102 includes a traveling wheel 103 and a chassis, and the traveling wheel 103 is installed on the chassis, and the traveling wheel 103 is used to drive the main body 101 to move along the working surface ;

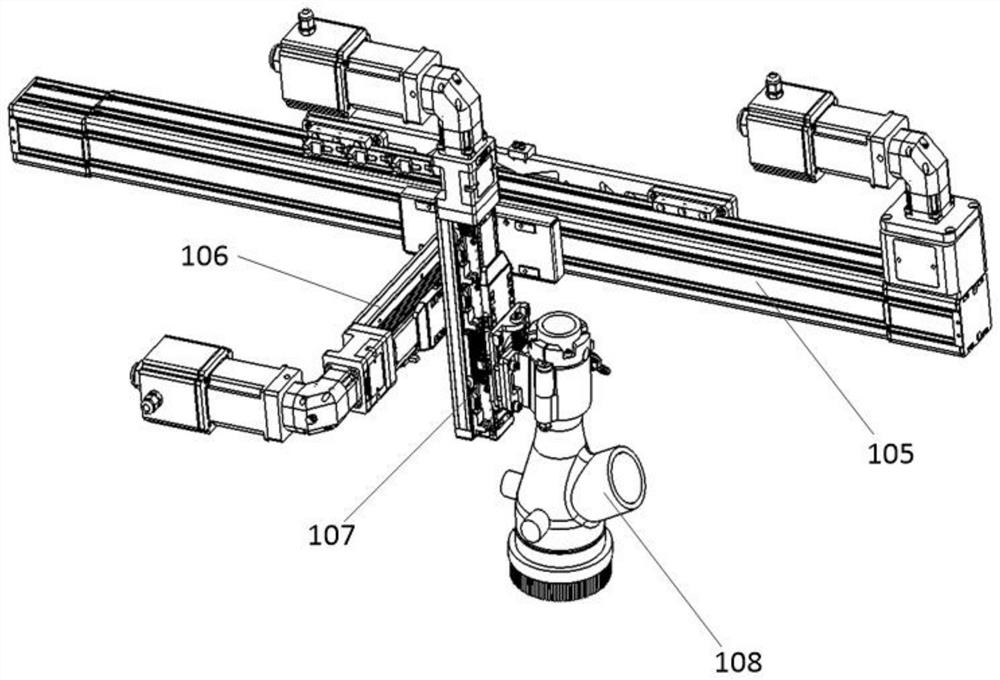

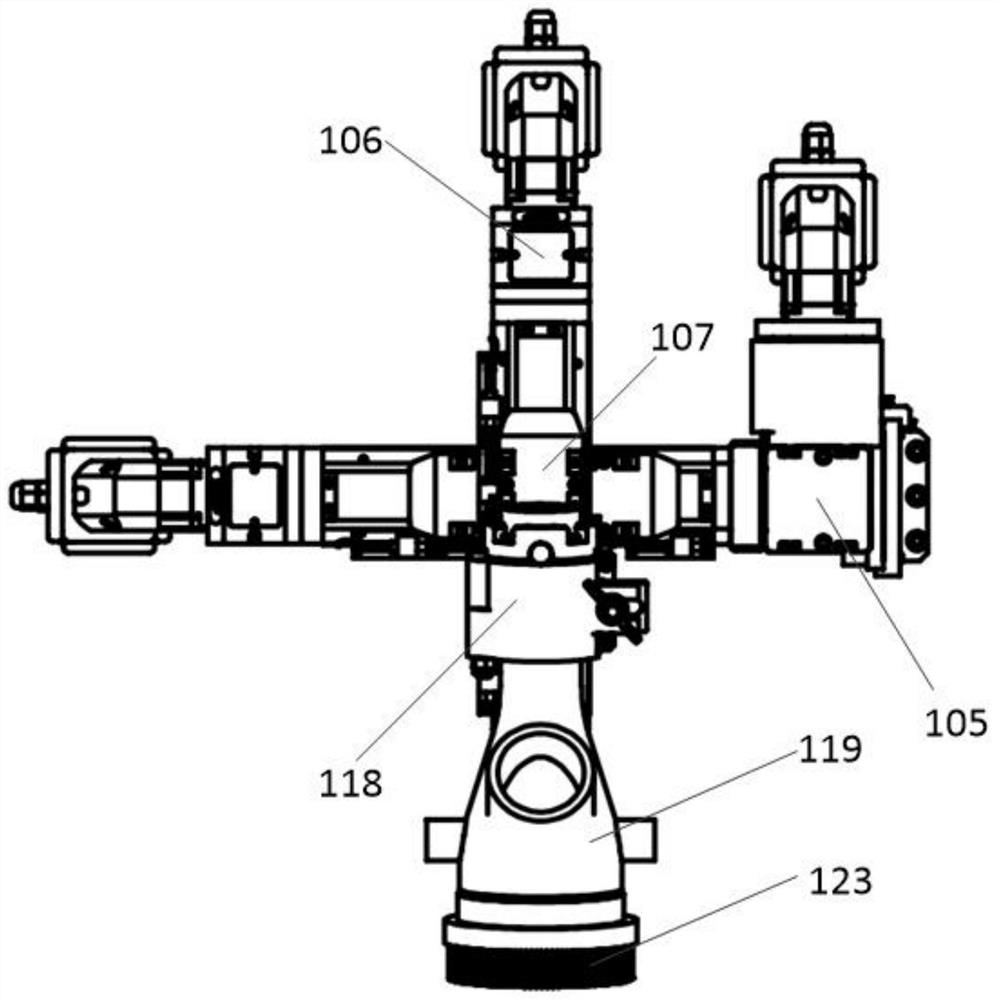

[0060] The sandblasting device moving module 104 includes: a first module 105, a second module 106 and a third module 107, the first module 105 is arranged on the main body 101, and the second module 106 is arranged on the first module 105, and the third module 107 is arranged on the second module 106;

[0061] A sandblasting device 108 is installed on the third module 107 for sandblasting the workpiece; the third module 107 can drive the sandblasting device 108 to move along the first direction; the second mold The group 106 can drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com