Pure manual control hydraulic closed-loop device of speed controller

A technology of manual control and governor, which is applied in the direction of safety devices, machines/engines, engine components, etc., which can solve problems such as complicated construction site implementation, decreased control accuracy, elastic deformation of steel wire ropes, etc., to achieve manual precise control and wide application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

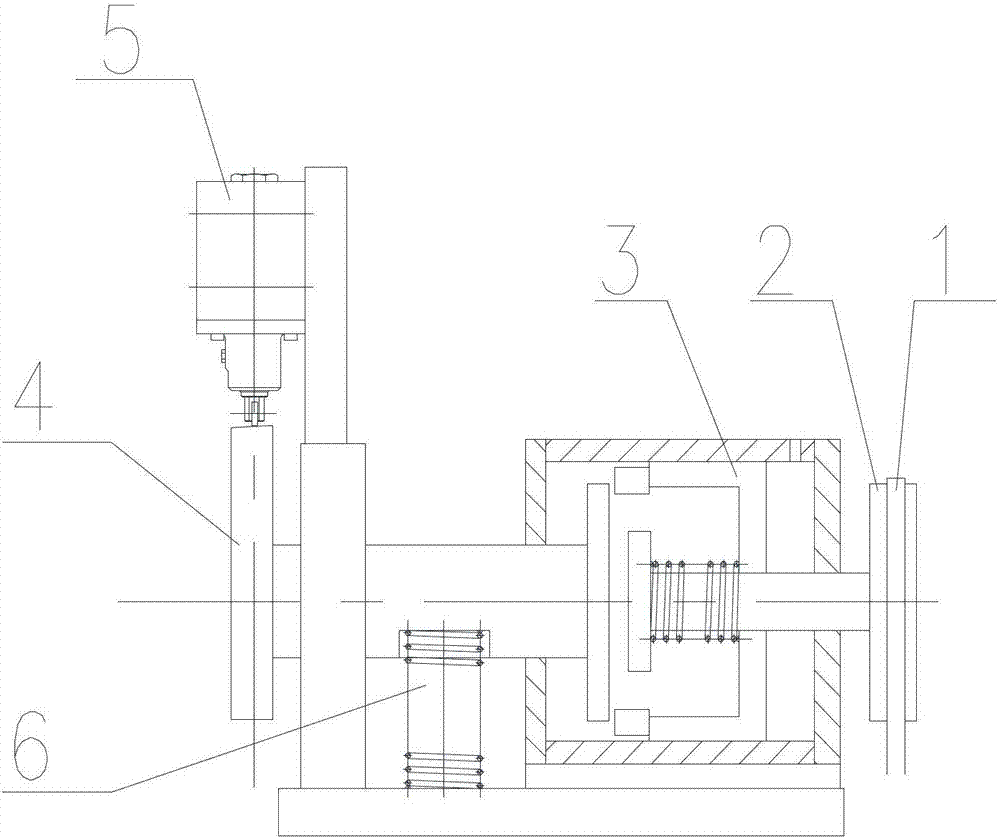

[0011] Such as figure 1 The present invention shown is a pure manual control hydraulic closed-loop device for a governor. The operating mechanism 4 is fixed on the end of the output shaft of the hydraulic clutch 3. The servomotor position balance valve 5 is located above the operating mechanism 4 and fixed on the hydraulic clutch 3. on the housing bracket. The transmission gear 2 is fixed on the input shaft of the hydraulic clutch 3, the positioning spring 6 is located in the slot at the bottom of the output shaft of the hydraulic clutch 3, the transmission chain 1 is meshed with the transmission gear 2, and the operating mechanism 4 is a cam structure.

[0012] The outer edge of the operating mechanism 4 is in contact with the spool guide rod of the servomotor position balance valve 5 .

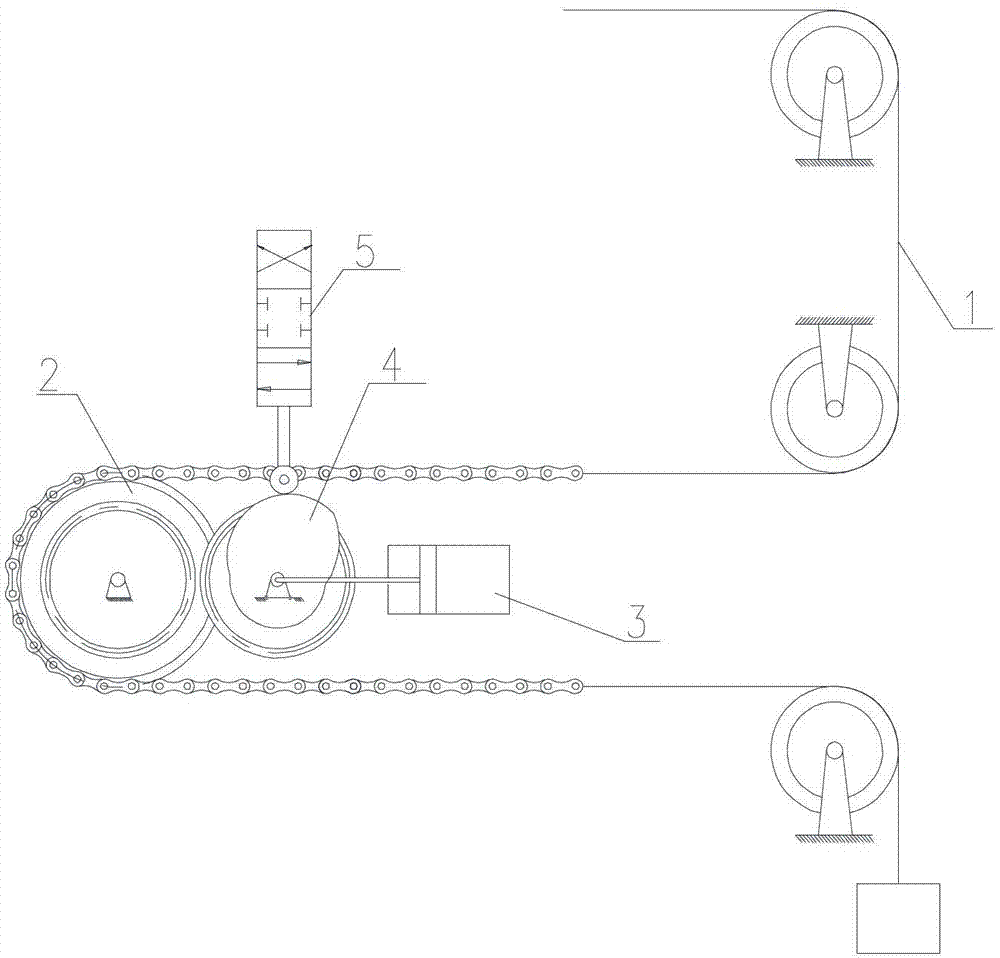

[0013] Such as figure 2 As shown, the transmission chain 1 drives the transmission gear 2 to rotate, and the hydraulic clutch 3 rotates together with the transmission gear 2 by meshing wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com