Defect recognizing and sorting system for straight line welding pipe

A technology of straight seam welded pipe and defect identification, applied in the field of defect identification and sorting system, can solve problems such as personal and property safety threats and hidden dangers, and achieve the effect of eliminating potential safety hazards and preventing them from being put into use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

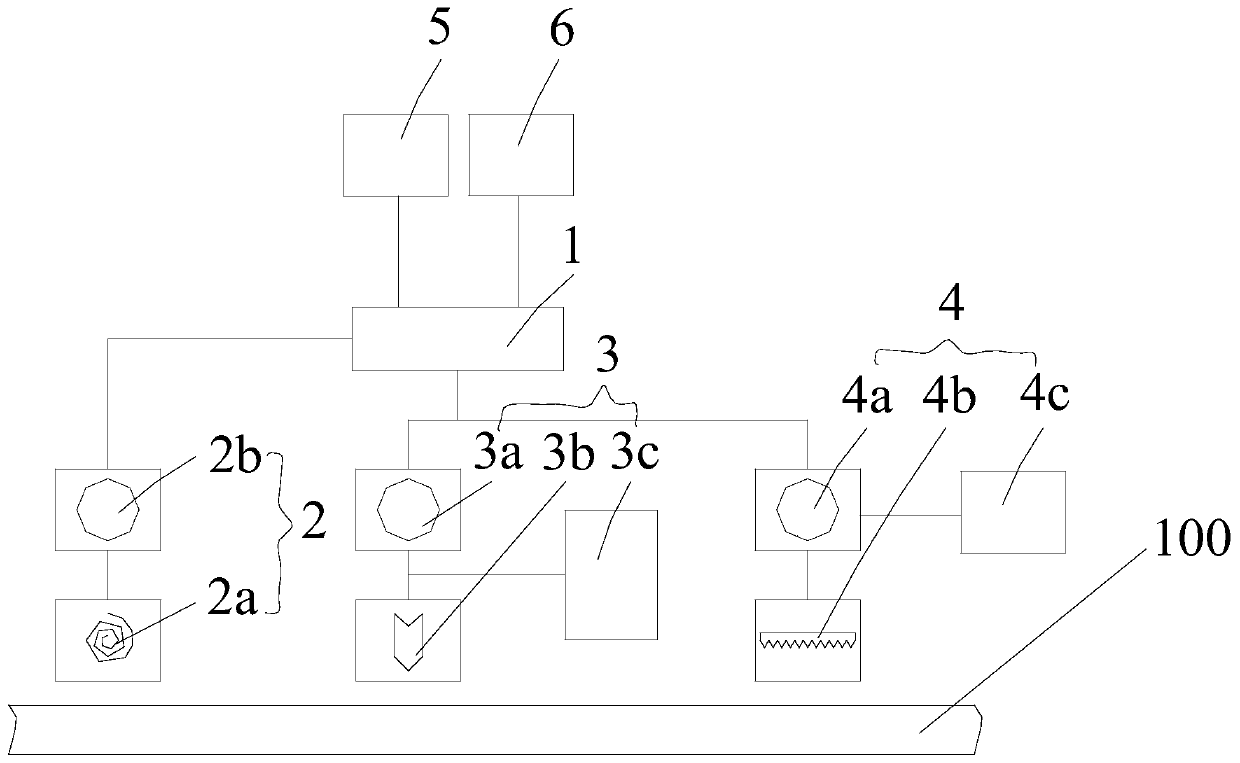

[0030] see figure 1 As shown, a defect identification and sorting system for longitudinal welded pipes is used to identify defects on longitudinal welded pipes 100 and perform resection and sorting thereof. The system includes a control module 1, an identification module 2, an identification module 3 and The execution module 4, through the cooperation of the control module 1, the recognition module 2, the identification module 3 and the execution module 4, can effectively identify the welding defect generated during the welding process, and cut off the pipe body with the defect and divide it into pieces. Sorting out prevents the defective welded pipe 100 from being put into use, and thoroughly eliminates potential safety hazards. Here, the control module 1 is a computer system. By setting the computer system, the control module 1 can calculat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com