Railway wagon accessory maintenance information system

A maintenance information system and railway wagon technology, which is applied in the field of railway wagon parts maintenance information system, can solve the problems that workshop managers cannot understand the on-site production situation in real time, high replacement rate and scrapping rate, and high cost ratio, so as to eliminate production tasks The effects of accumulation, ensuring balance and order, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

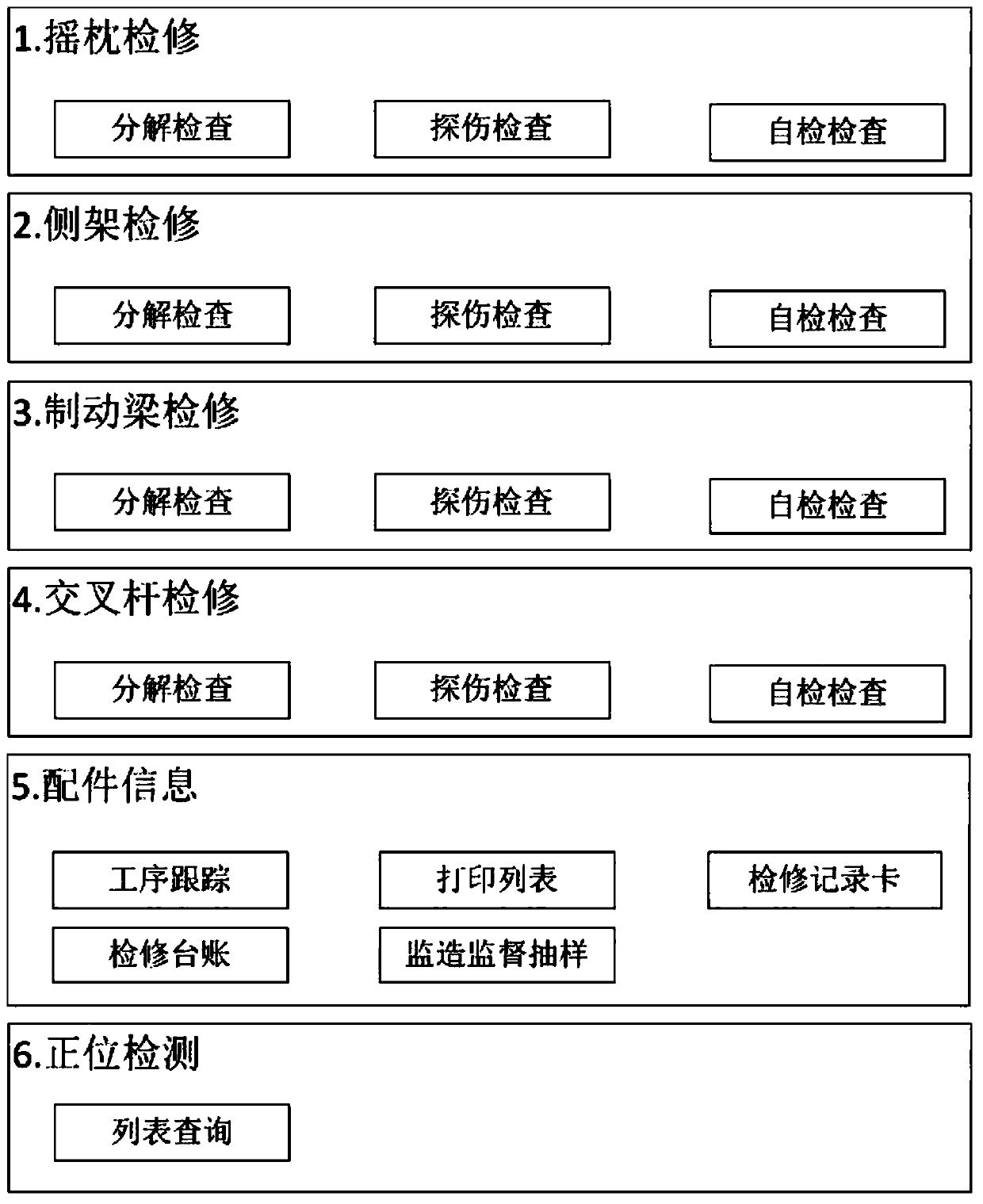

[0031] As mentioned above, an information system for the maintenance of railway wagon accessories (the railway wagon accessories refer to bogie accessories), including bolster maintenance, side frame maintenance, brake beam maintenance, cross bar maintenance, process tracking, print list, maintenance record card , maintenance ledger, manufacturing supervision and sampling, and upright detection, a total of ten modules, of which the four modules of bolster inspection, side frame inspection, brake beam inspection, and cross bar inspection include decomposition inspection, flaw detection inspection, and self-inspection inspection. There are three processes, that is, three modules; the five modules of process tracking, printing list, maintenance record card, maintenance ledger, supervision and sampling of manufacturing supervision include the transfer of K2 bolster, transfer of K5 bolster, transfer of K6 bolster, transfer of 8B (8AB ) Bolster, Zhuan K2 side frame, Zhuan K5 side fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com