Technological procedure risk evaluation method based on FRAM (failure rate assessment machine)

A process specification and risk assessment technology, applied in the field of FRAM-based process specification risk assessment, can solve problems such as logical inconsistency, lack of risk assessment, ambiguity and loopholes, etc., and achieve the effect of avoiding putting into use

Inactive Publication Date: 2017-06-06

BEIHANG UNIV

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

That is to say, when writing the process specification, it is necessary to take into account the many heterogeneous influencing factors in the process and the complex correlation between each heterogeneous factor, which makes it extremely difficult to write the process specification, and it is difficult to accurately describe the complex crafting process

[0006] 2) There are always some ambiguities, ambiguities or loopholes in the process regulations

At present, there is a lack of comprehensive and systematic research and practice on risk assessment for the problem of unreasonable design or inconsistent logic of the content of the regulations

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment

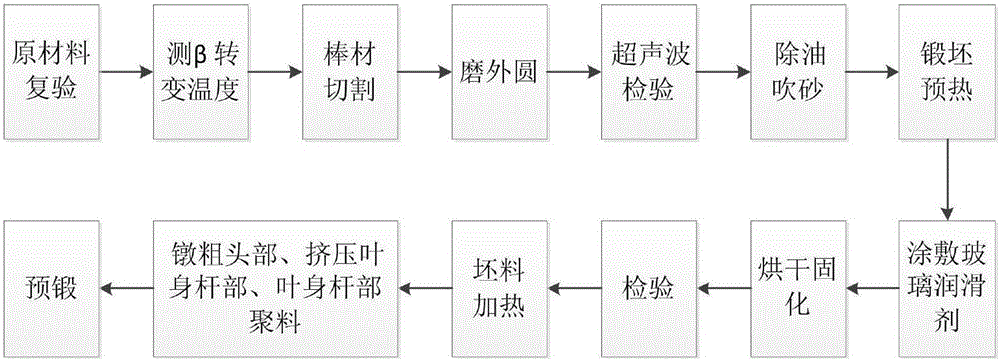

[0057] The partial forging process of a certain type of aero-engine titanium alloy compressor blade is selected as the analysis object, and the relevant process flow chart is shown below figure 2 . Listed in Table 1 are some of the protocol contents related to this analysis.

[0058] Table 1 process and operation requirements

[0059]

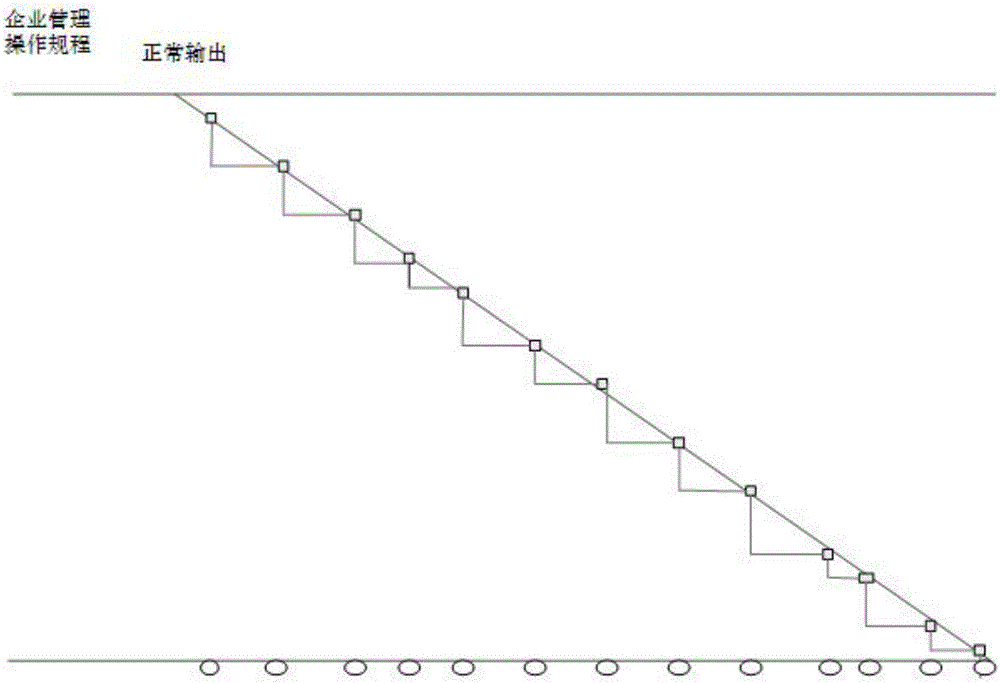

[0060] First, the FRAM-based process specification is modeled

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

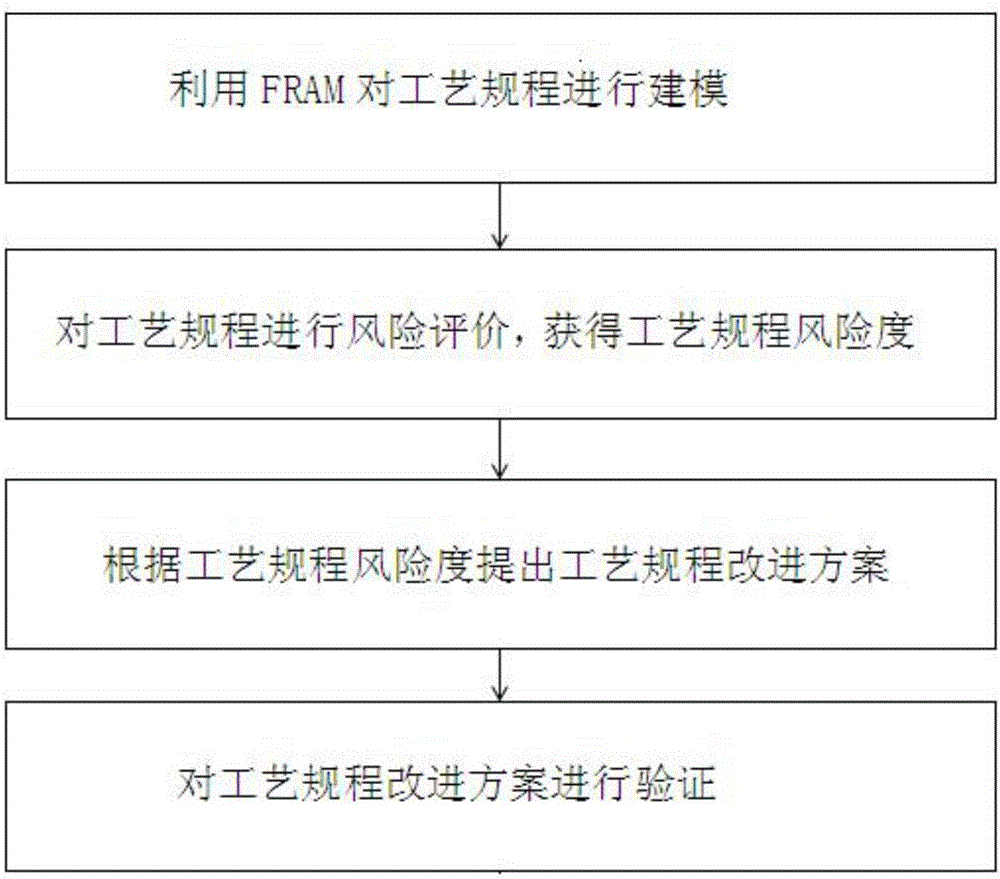

The invention provides a technological procedure risk evaluation method based on a FRAM (failure rate assessment machine). The evaluation method includes the steps: S1 performing modeling for technological procedures by the aid of the FRAM: determining active sub-modules of the technological procedures, performing variation and coupling analysis of variation for the active sub-modules, and performing modeling according to analysis results; S2 building the technological procedure risk evaluation method based on the FRAM: identifying hidden paths (technological activity variation coupling modes) generating unexpected events in the technological process and key activities in the paths, and further identifying related defects of the technological procedures; S3 providing an improved scheme of the technological procedures from restraining or eliminating of variation of the key activities in the paths based on eliminating of generating paths, and performing validation verification. According to the method, modeling of the technological procedures can be achieved, risks are evaluated based on a model, the improved scheme of the technological procedures is acquired according to evaluation results, and the technological procedures are improved.

Description

technical field [0001] The invention belongs to the field of risk assessment, and in particular relates to a FRAM-based process procedure risk assessment method. Background technique [0002] The process specification is a technical document to guide the process. Its purpose is to make the process and method the most reasonable and economical, and to ensure quality and quantity, high quality and high yield. It is the most fundamental and main process document in the workshop. The process specification provides a complete and systematic procedure for the corresponding process. Therefore, it is a guide for the user when working. Correct execution of the process specification is to ensure the rhythmic operation of the workshop, improve product quality, increase labor productivity, and ensure safe production. one of the conditions. [0003] However, there are countless cases of accidents caused by violations of process regulations every year. The reasons are mainly manifested ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G06F17/50G06Q10/06G06Q50/04

CPCG06F30/23G06Q10/0635G06Q50/04Y02P90/30

Inventor 郑紫霞田瑾

Owner BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com