Substrate cleaning method

A technology for substrates and cleaning water, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as poor cleaning, slow delivery of substrates 100, large drying capacity, etc., to avoid strips Effects of mura, accelerated cleaning speed, and improved transport speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

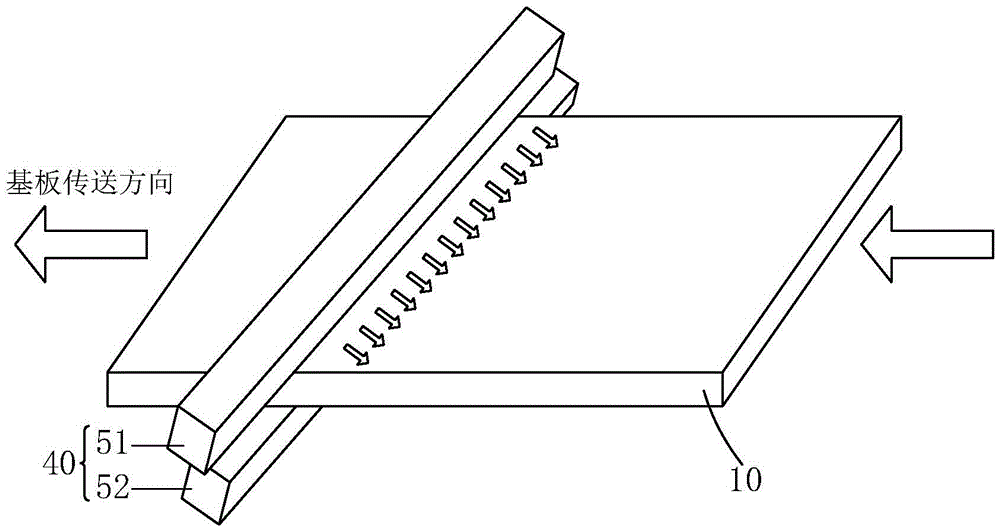

[0042] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

[0043] see Figure 2-4 , the present invention provides a substrate cleaning method, comprising the following steps:

[0044] Step 1. Provide a substrate 10 , and clean the substrate 10 with an aqueous solution to remove pollutants on the substrate 10 .

[0045] Specifically, the substrate 10 may be a TFT substrate, an unfinished TFT substrate, or a plain glass substrate.

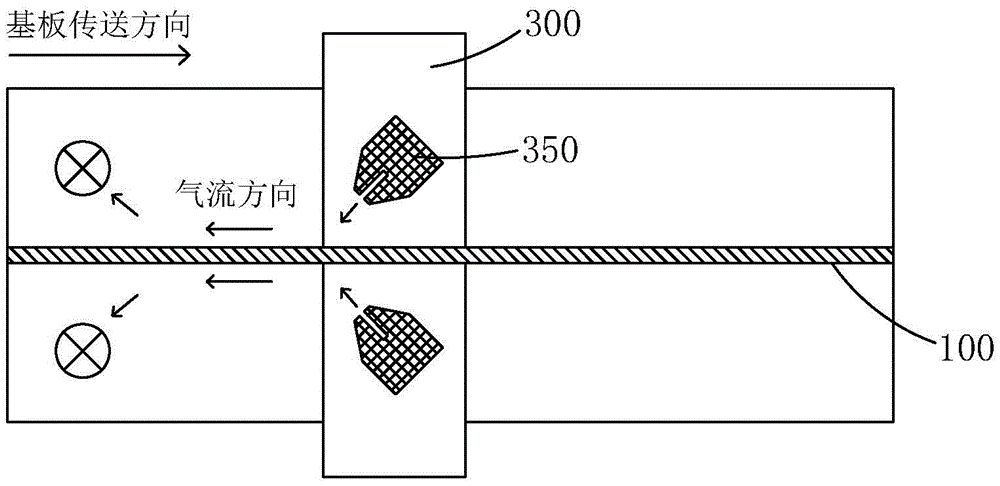

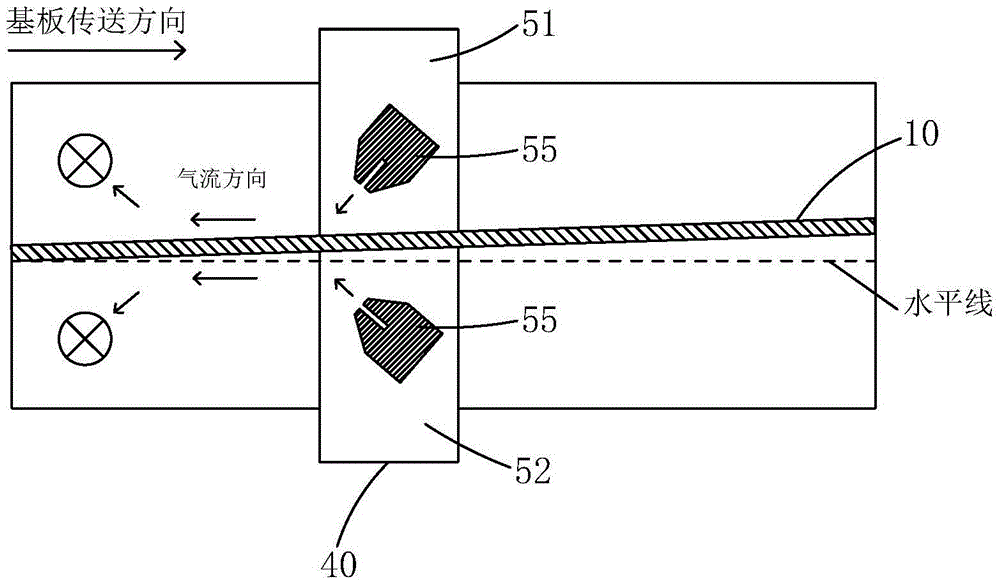

[0046] Step 2, providing a first drying device, the first drying device includes a transfer wheel (not shown) for transferring the substrate 10, and a traditional air knife device 40 for removing residual cleaning water on the substrate 10, the The traditional air knife device 40 includes a first air knife unit 51 corresponding to the top of the substrate 10 and a second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com