Prefabricated concrete tubular block ecological retaining wall

A technology of concrete and retaining walls, applied in artificial islands, underwater structures, sea area engineering, etc., can solve problems that are not suitable for large-scale construction on site, high cost of new structures and materials, and analysis of new structures Problems such as immature theory, to achieve good ecological benefits, good ecological benefits, and controllable costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

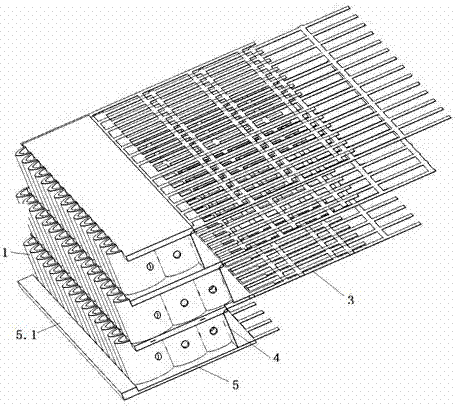

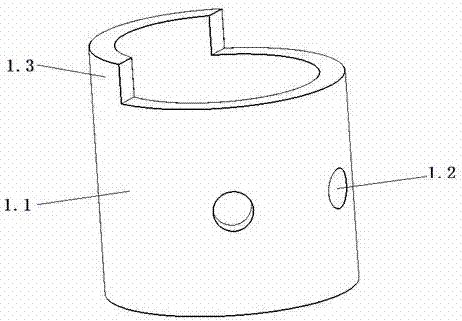

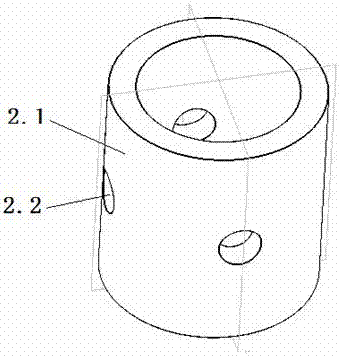

[0030] see Figure 1~Figure 3 , the present invention relates to a prefabricated concrete tubular block ecological retaining wall, which includes a base plate 5, on which a multi-layer concrete tubular block layer is arranged from bottom to top, and the outer layer of the multi-layer concrete tubular block layer The edge surface is indented to the rear layer by layer. The concrete tubular block layer includes a row of first tubular block rows in the front row and at least one second row of tubular block rows in the rear row. The first tubular block row It includes a plurality of first tubular blocks 1 along the length direction of the retaining wall, the second tubular block row includes a plurality of second tubular blocks 2 along the length direction of the retaining wall, and the first tubular blocks 1 It includes a first tubular block body 1.1, first through holes 1.2 are provided at the front, rear, left, and right sides of the middle part of the first tubular block body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com