Furnace-front mechanical hand

A technology of manipulators and manipulators, applied in manipulators, program-controlled manipulators, control of molten metal pouring from ladles, etc., can solve problems such as splashing of molten iron, dangerous working environment, and slow pouring speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

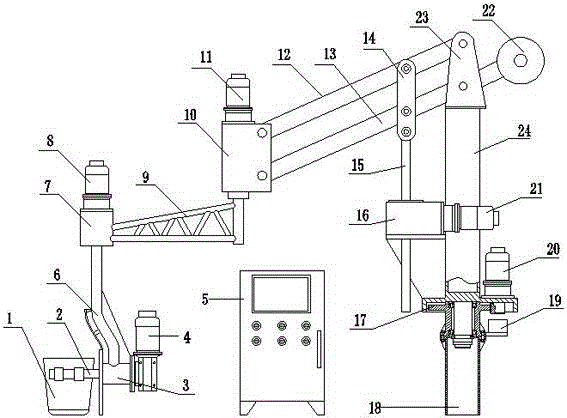

[0020] Example 1, such as figure 1 The manipulator in front of the furnace shown, iron kettle (1), manipulator (2), manipulator tilt support (3), manipulator tilt servo motor (4), manipulator arm (6), manipulator arm rotation support (7), mechanical arm Arm rotation servo motor (8), rotation arm (9), rotation arm support (10), rotation arm servo motor (11), swing arm (12), balance arm (13), balance arm support (23), Support plate (14), vertical lift screw (15), vertical lift (16), vertical lift servo motor (21), complete machine rotary support seat (17), complete machine rotary sensor (19), complete machine rotary servo Motor (20), support bar (24), counterweight (22), base (18), PLC computer control cabinet (5).

[0021] The iron kettle (1) is connected to the manipulator tilt servo motor (4) through the manipulator (2), the manipulator tilt support (3) is connected to the manipulator tilt servo motor (4), and the manipulator tilt support (3) controls the iron kettle (1) an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com