Municipal drainage pipeline machining die and method

A technology for municipal drainage and processing methods, which is applied to molds, manufacturing tools, ceramic molding machines, etc., can solve problems such as difficult processing of composite pipes, and achieve the effect of ensuring compactness and smoothness, short construction period, and fast pouring speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

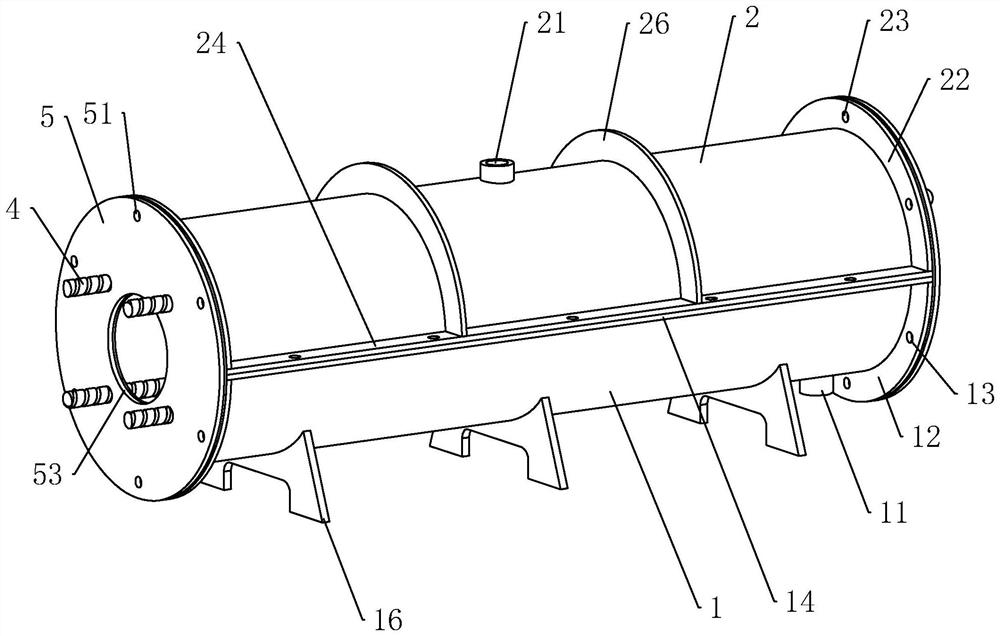

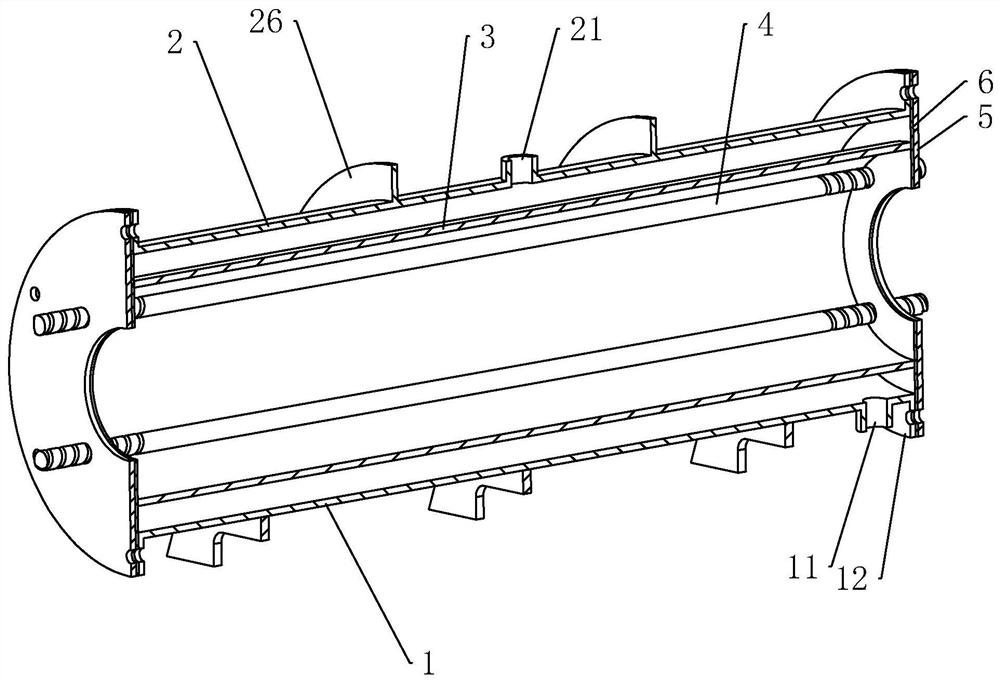

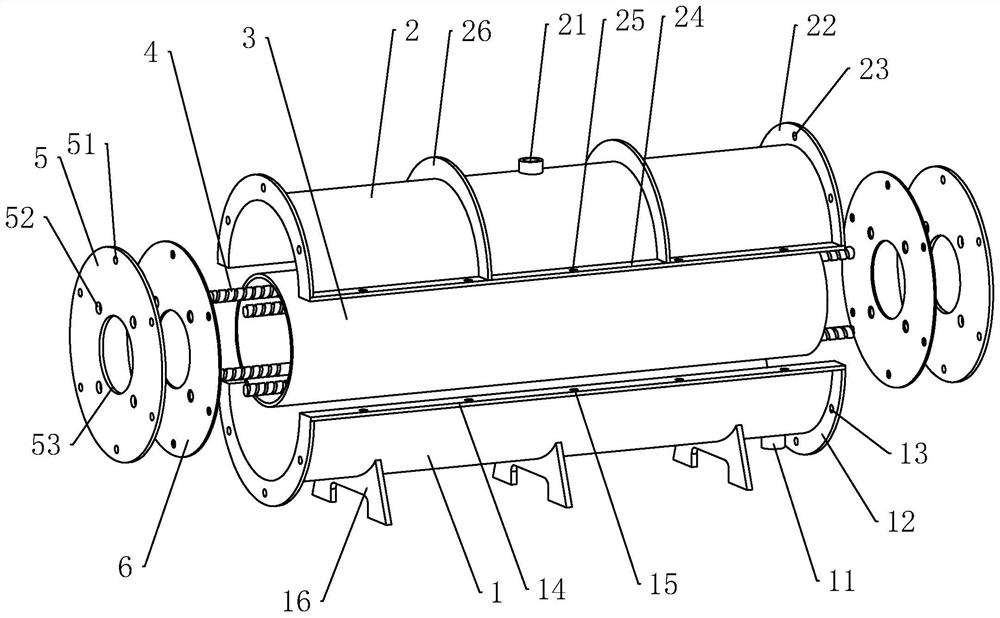

[0051] The following is attached Figure 1-3 The application is described in further detail.

[0052] refer to figure 1 and figure 2, is a mold for processing municipal drainage pipes disclosed in the embodiment of the present application, including a lower mold 1 , an upper mold 2 , a lining pipe 3 , a positioning rod 4 and a sealing plate 5 .

[0053] refer to figure 2 and image 3 , the lower mold 1 is specifically a half pipe with a semicircular cross section, and the upper mold 2 is also a half pipe with a semicircular cross section. When the upper mold 2 and the lower mold 1 are buckled together, a whole pipe is formed. . Both ends of the lower die 1 are respectively fixedly connected with a first flange 12, the first flange 12 is in the form of a half ring, and the first flange 12 is provided with a plurality of first bolt holes 13 along the circumferential direction; the upper die 2 The two ends of the second flange 22 are respectively fixedly connected, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com