Construction device of high building and concrete pouring construction method

A technology for construction equipment and structures, applied in the field of construction equipment, construction equipment for tall structures, and concrete pouring construction for tall structures, can solve the problems of small thickness of pouring layer, segregation of layers, rough concrete surface, etc., and achieve low lateral pressure. , Improve the construction speed and ensure the effect of life safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

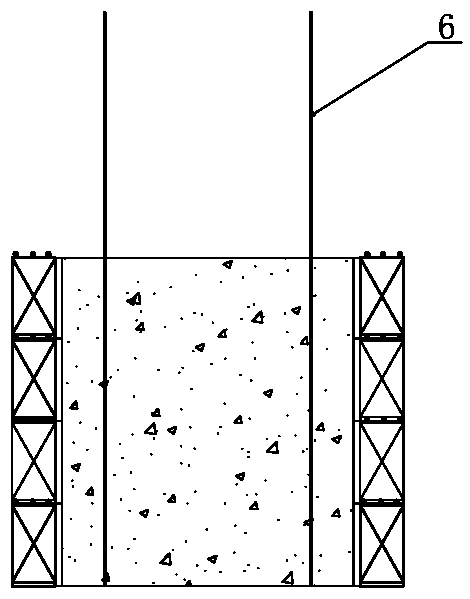

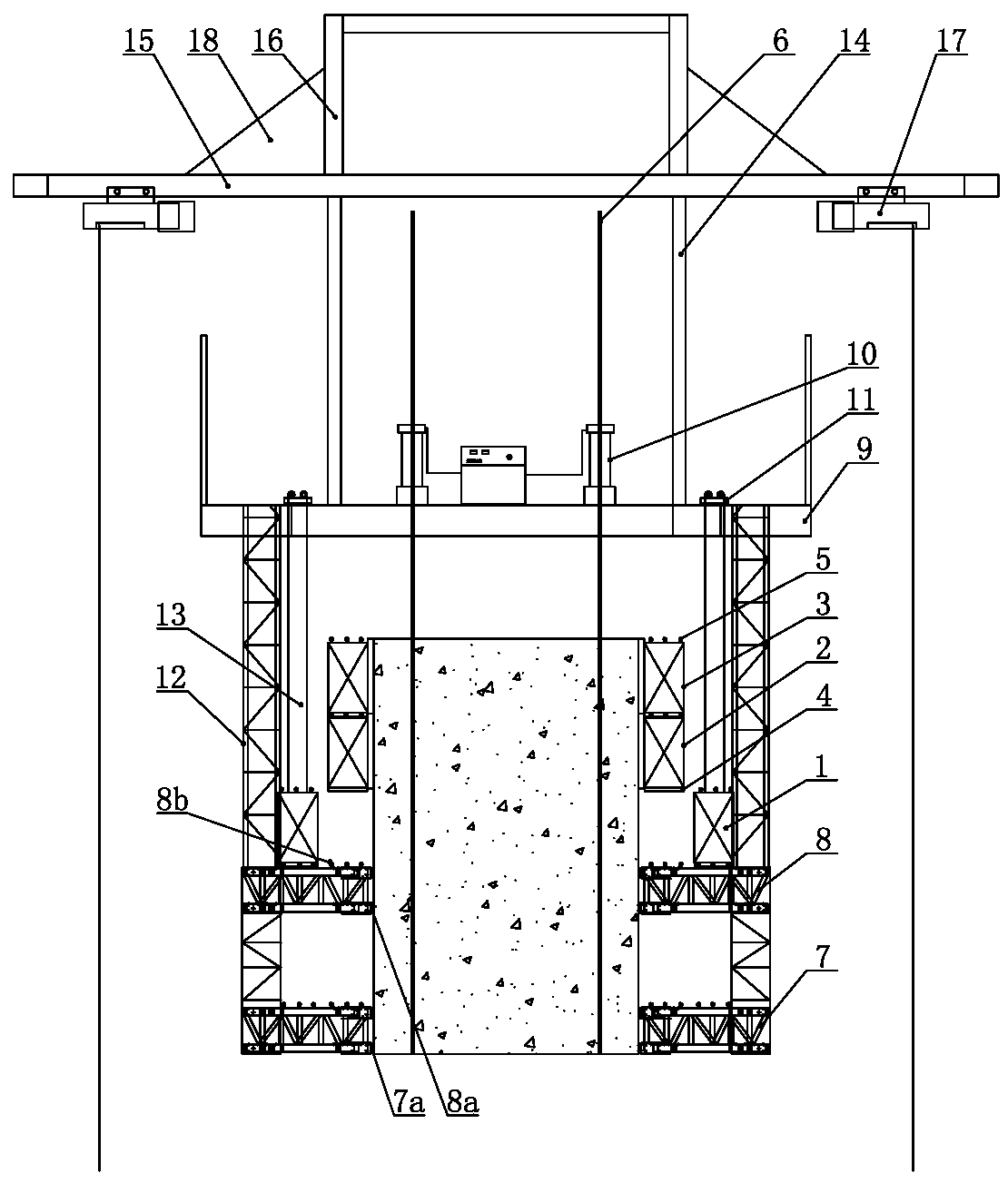

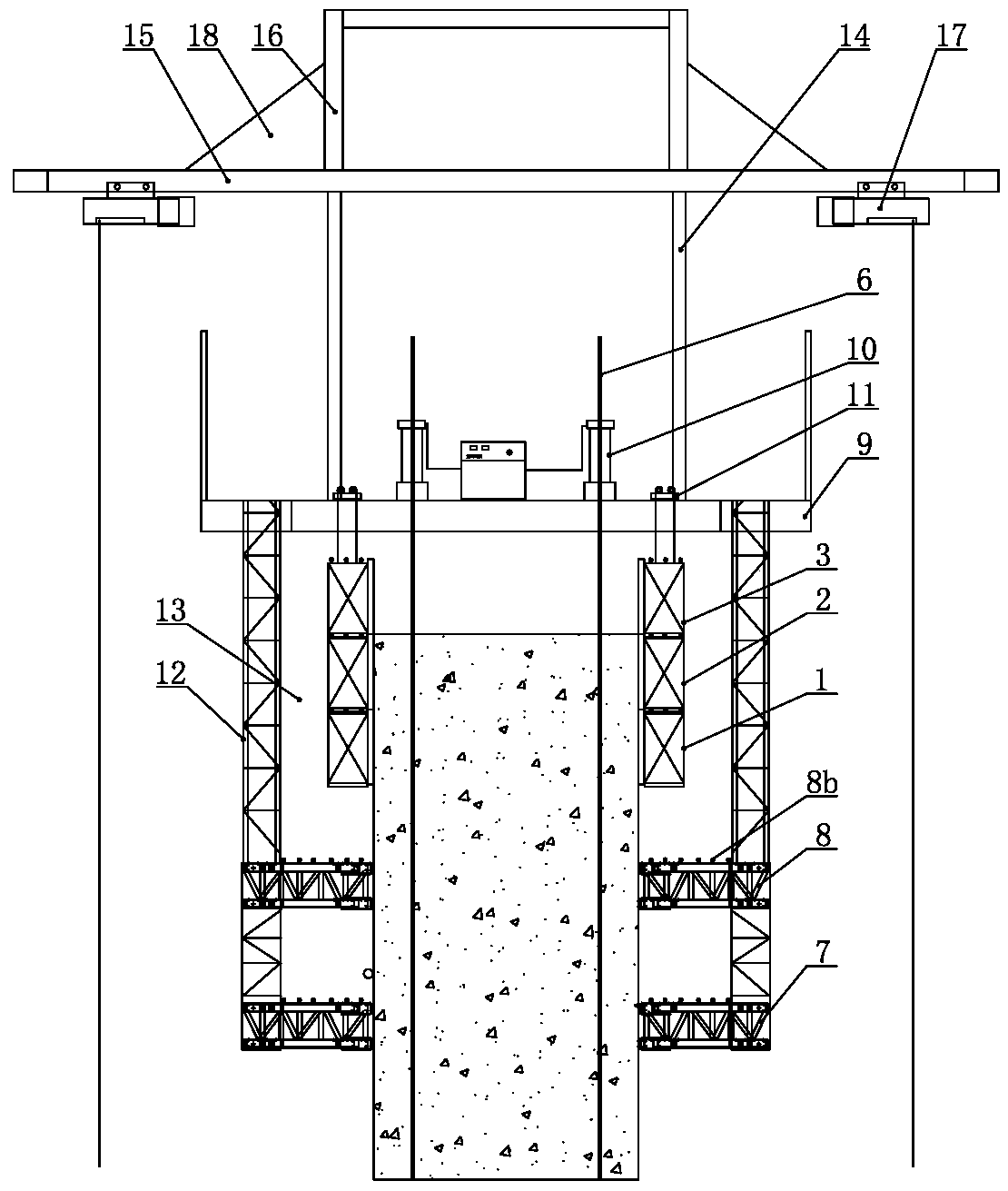

[0031] Such as Figure 1 to Figure 5 As shown, the construction equipment of the towering structure of the present invention includes a formwork standing on the outside of the structure concrete, the formwork is formed by stacking the upper, middle and lower layers in sequence, and the lower formwork 1 is provided with a horizontally extending middle platform 8, and the middle platform 8 The inner ends respectively abut against the concrete wall of the structure through the wall-attached rollers 8a of the middle platform; a bottom platform 7 parallel to the middle platform 8 is provided at a distance below the middle platform 8, and the inner ends of the bottom platform 7 respectively pass through The wall-attached rollers 7a of the bottom platform lean against the concrete wall of the structure, and the outer end of the bottom platform 7 and the outer end of the middle platform 8 are connected to each other through the outer lifting frame 12, and the upper end of the outer lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com