Ultra fast buffer forked type concrete pouring string pipe and construction method thereof

A concrete and ultra-fast technology, applied in construction, infrastructure engineering and other directions, can solve the problems of difficulty in reaching the designated pouring position, slow concrete conveying speed, inconvenient construction and dismantling, etc., and achieves large pouring coverage, low cost, The effect of enhancing vertical bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

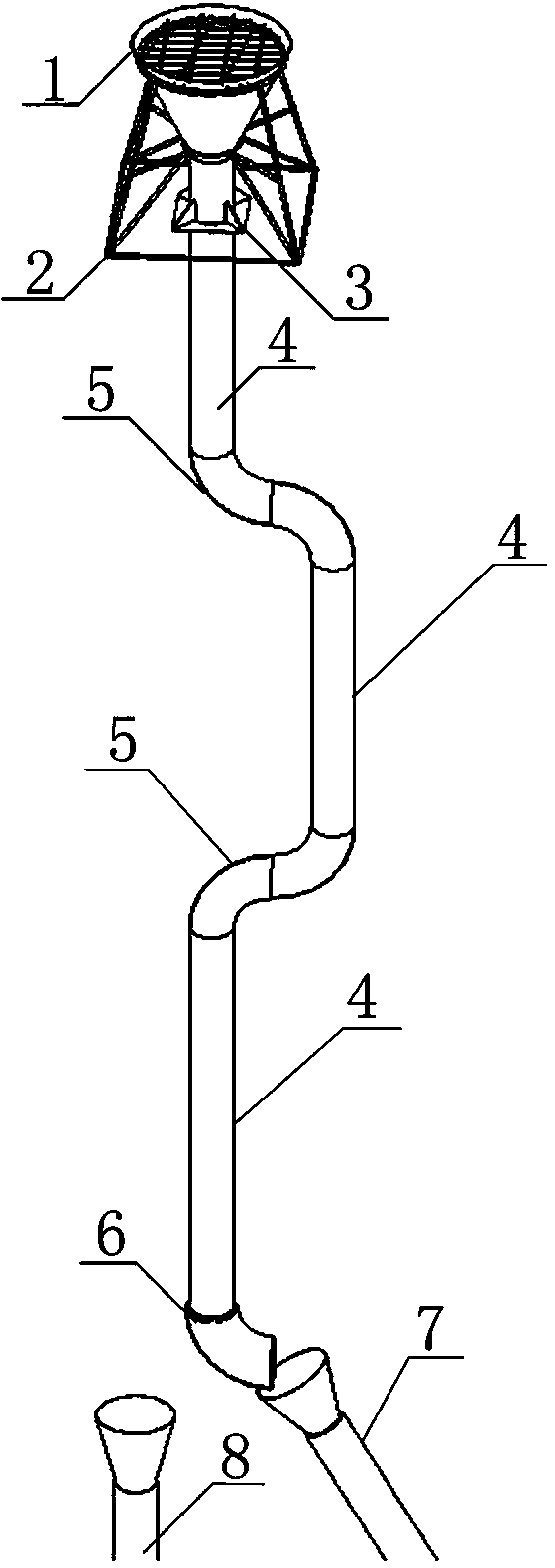

[0048] Examples see figure 1 As shown, this ultra-fast buffer bifurcated concrete pouring string includes a concrete inlet hopper 1, a steel support 2, a straight pipe 4, a buffer bend 5, a rotary bend head 6 and a sub-string.

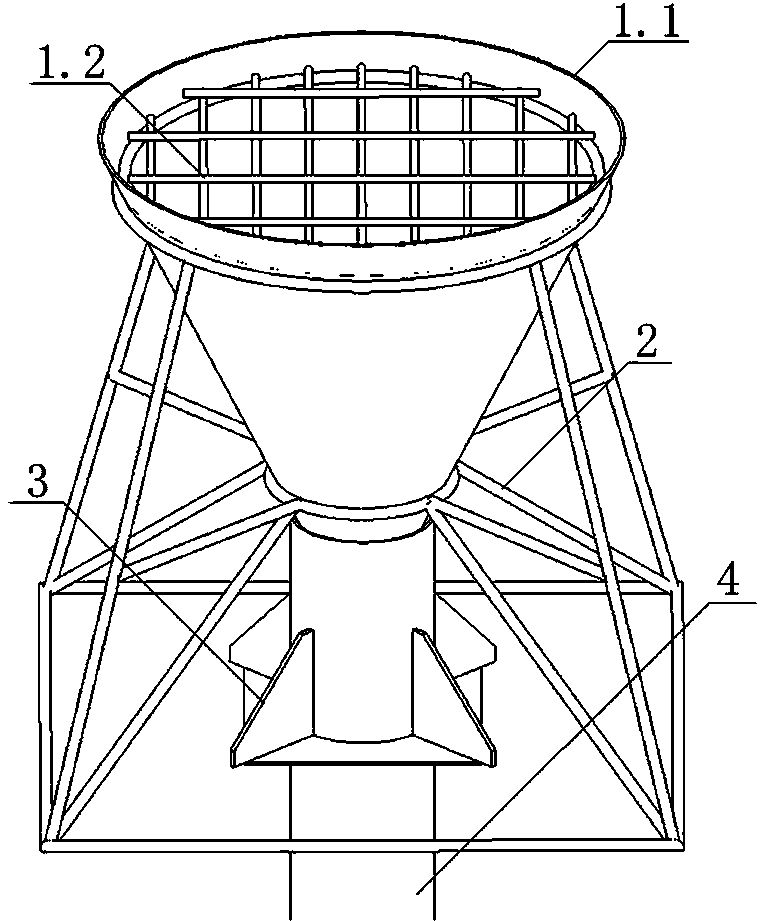

[0049] see figure 2 As shown, the concrete inlet hopper 1 is placed on the steel bracket 2 on the inner support 9 of the first concrete. The concrete inlet hopper 1 is composed of a steel hopper 1.1 and a grate 1.2 welded in the steel hopper 1.1.

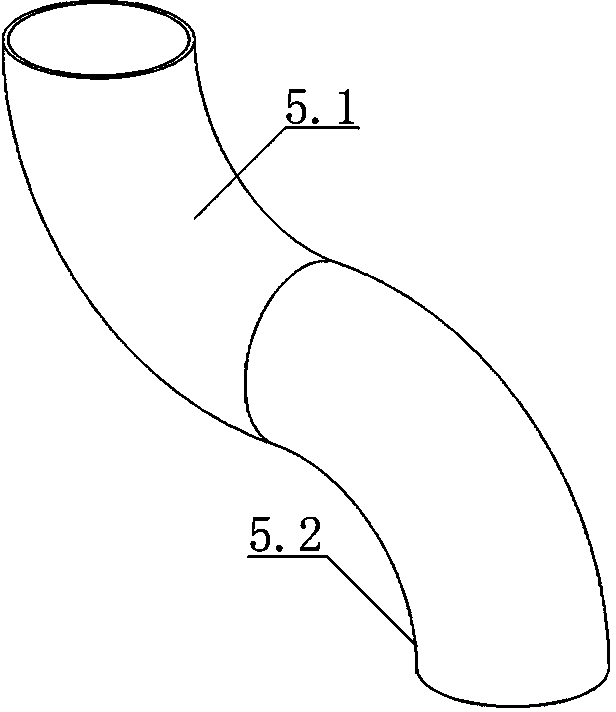

[0050] see figure 1 , Image 6As shown, the straight pipe 4 is passed downwards in segments on the inner support 9 of the first concrete and the holes on the inner support 10 of the concrete below the first pass and fixed. The outer wall of each straight pipe 4 is welded with a reinforcing plate 3, and the straight pipe 4 is fixed at the opening of the plate by the reinforcing plate 3. The positions of the upper and lower straight pipes 4 are staggered and connected by a buffer bend 5; the upper mouth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com