Portal crane and GPS positioning technology combined concrete pouring method

A technology of GPS positioning and concrete, which is applied in the direction of construction, building structure, and building material processing, etc., can solve the problems of hidden safety hazards, low construction efficiency, and low precision of unloading points, so as to improve the accuracy of movement and achieve good construction effects , the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] Embodiment: door machine combined with GPS positioning technology concrete pouring method, on the basis of door machine and main control machine, GPS positioning control is carried out. Wherein the door machine and the main control machine can adopt the existing equipment.

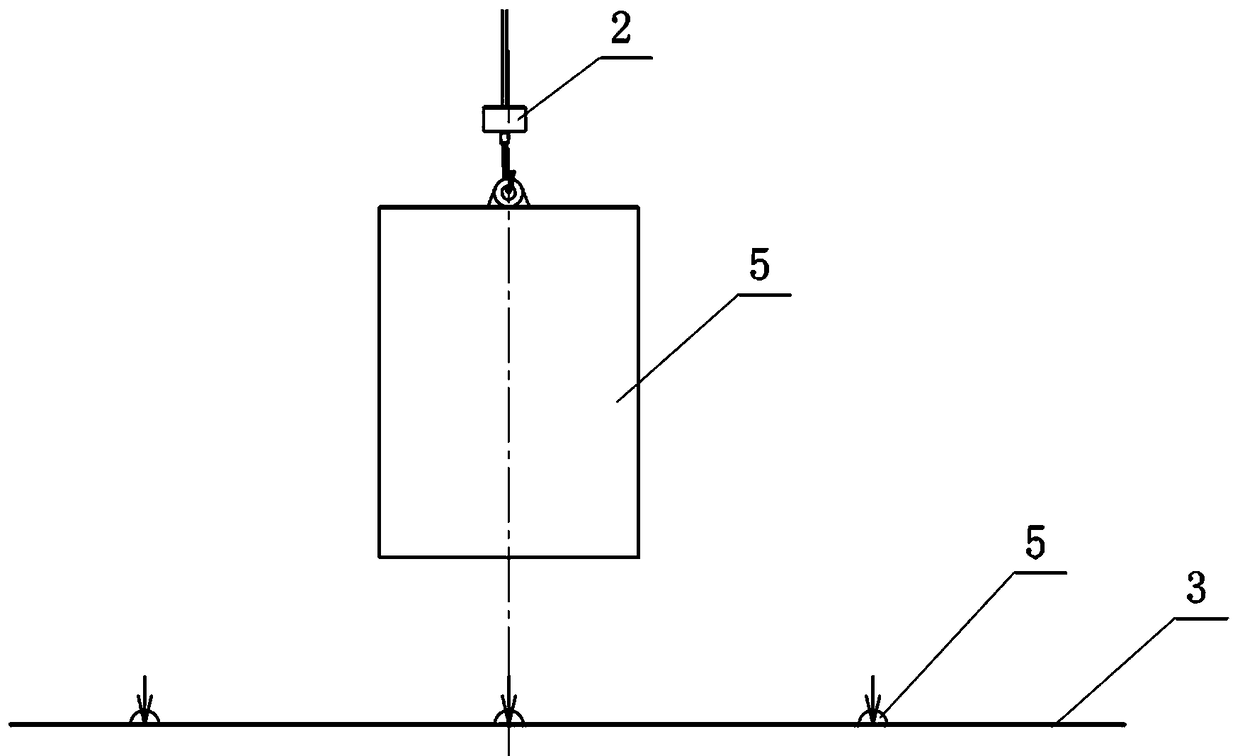

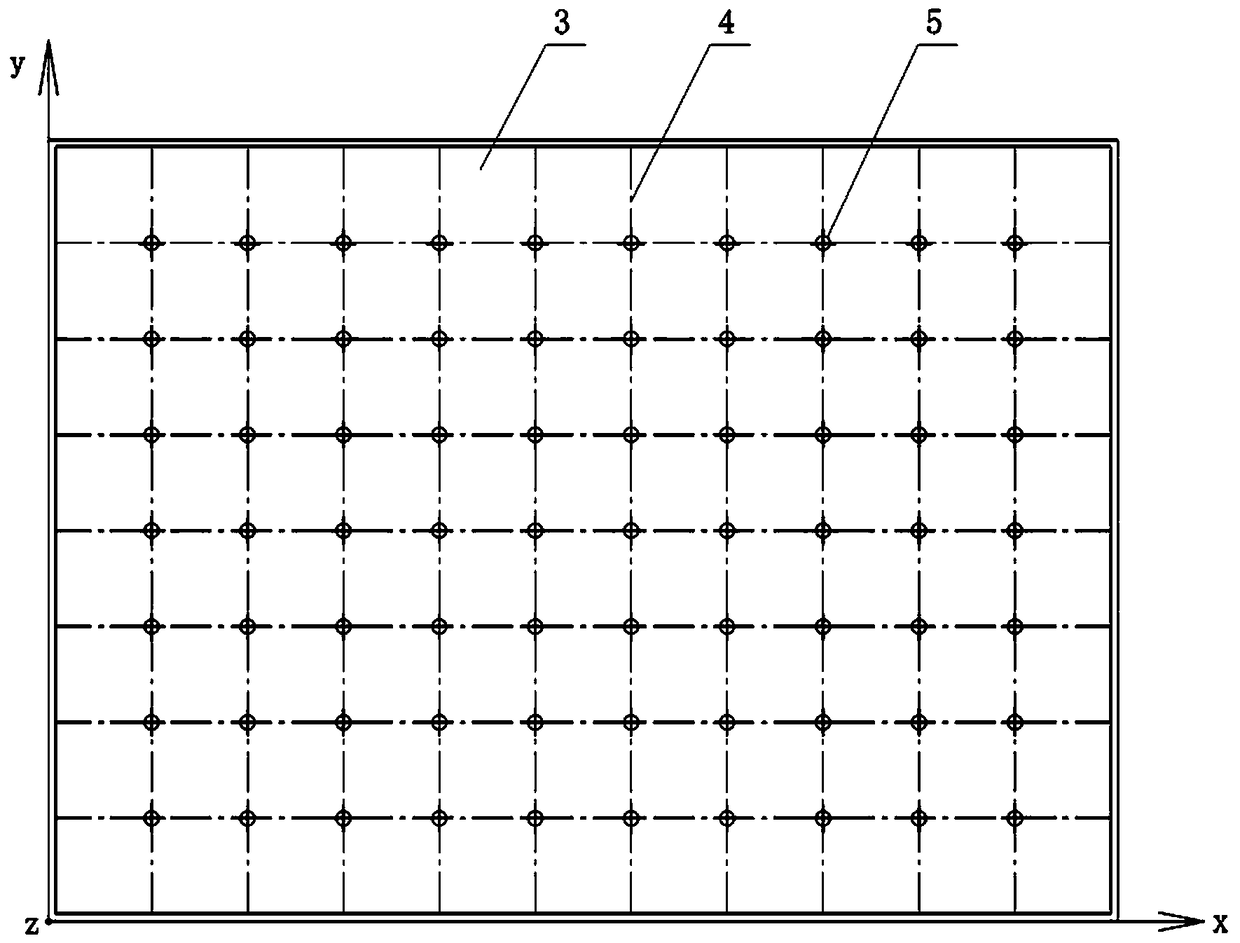

[0018] The surveying and mapping system plans the concrete pouring area according to the area and elevation of the concrete pre-casting area and forms a pouring area network (displayed in grid form), and calculates the pouring route plan at the same time. see figure 2 As shown, the pouring coordinates of each grid of the pouring area network are set to A (X, Y, Z). The method of surveying and mapping the target area to form a three-dimensional area network can be realized by various known technical means. For example, a surveying and mapping system is to take three-dimensional photographs of the concrete pre-casting area by means of multi-dimensional photography and determine the three-dimensiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com