Insulating paperboard tensile strength test fixture

A tensile strength and test fixture technology, applied in the direction of strength characteristics, the use of stable tension/pressure test material strength, instruments, etc., can solve the problems of cumbersome operation, occupying test time, affecting test work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to facilitate the understanding of the present invention, the present invention will be described more fully below with reference to the associated drawings. A preferred embodiment of the invention is shown in the drawings. However, the present invention can be embodied in many different forms and is not limited to the embodiments described herein. Rather, these embodiments are provided so that the disclosure of the present invention will be thorough and complete.

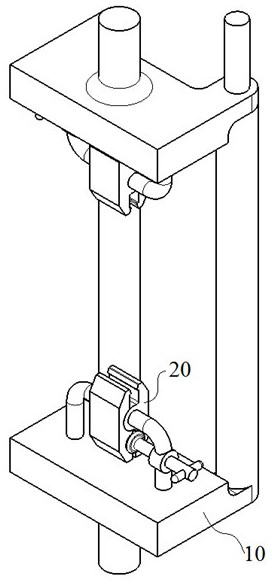

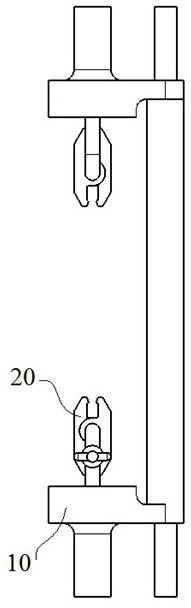

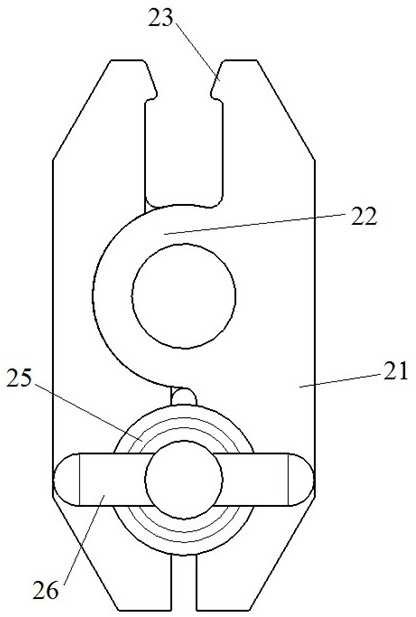

[0017] see Figure 1-Figure 4 The shown insulating cardboard tensile strength test fixture comprises a bracket 10 and a chuck 20, the chuck 20 is installed on the bracket 10, the bracket 10 is installed on a tensile machine, the bracket 10 and the chuck 20 have two groups, the bracket 10 and the clamp After the heads 20 are combined, they are respectively installed at the upper and lower ends of the tensile machine to form the upper clamping part and the lower clamping part of the sample.

[0018...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com