Fabricated trolley for box culvert construction and construction method thereof

A prefabricated, box culvert technology, used in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of inability to use large-scale hoisting equipment, low box culvert construction efficiency, high labor costs, etc., and achieve a simple and compact overall structure. , The effect of convenient assembly and disassembly, and convenient equipment maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

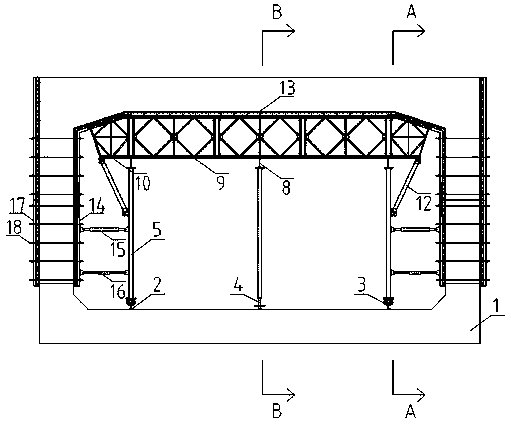

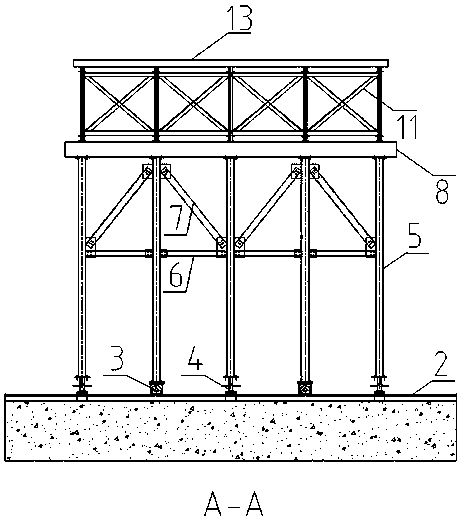

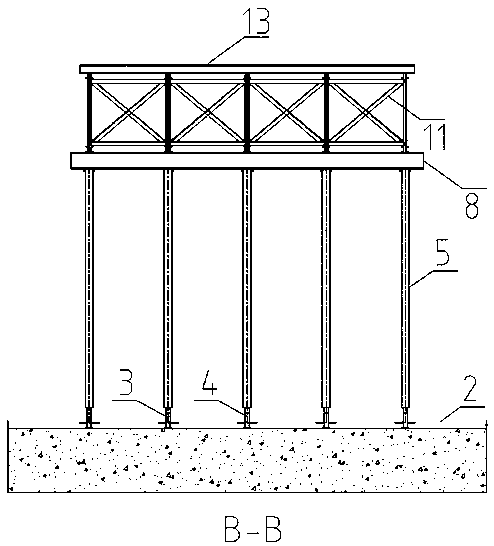

[0045] The prefabricated trolley for box culvert construction lays track 2 longitudinally on the poured box culvert bottom plate 1, above track 2 there are staggered uprights 5 with traveling wheels 3 and uprights 5 with adjustable bottom support A4, above the uprights 5 Support the longitudinal beam 8, several groups of Bailey beams 9 are erected above the longitudinal beam 8, and the top formwork 13 is supported above the Bailey beam 9; the left and right ends of the Bailey beam 9 are connected to the end truss 10; 15 connecting side templates;

[0046] The Bailey beams 9 of the adjacent row are connected as a whole by a support frame 11;

[0047] Described side formwork comprises that inner formwork 14 is connected with adjusting screw rod 16 and jack 15, and outer formwork 17 is connected with inner formwork 14 by pull rod 18;

[0048] The trolley has a relatively large span of 9m, and several rows of central columns 51 are arranged under the middle part of the trolley, a...

Embodiment 2

[0052] The difference from Embodiment 1 is that the span of the trolley is small, 6m, and the center column 51 and the center longitudinal beam 81 are not provided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com