Automatic movement type ladle pouring device

A technology of dumping device and automatic movement, which is applied in the direction of casting molten material container, metal processing equipment, casting equipment, etc., and can solve the problems of workpiece performance difference, increased scrap rate, temperature difference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

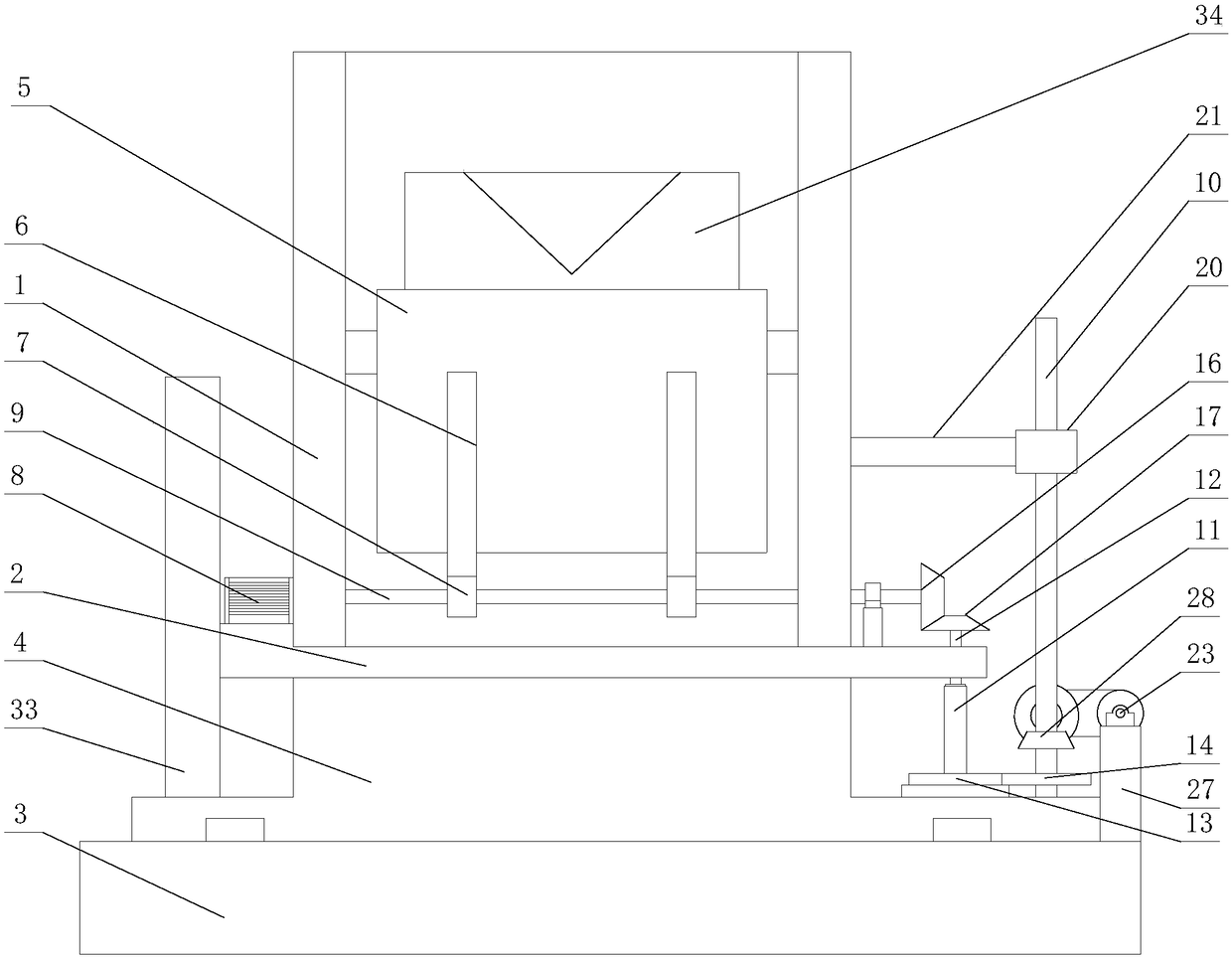

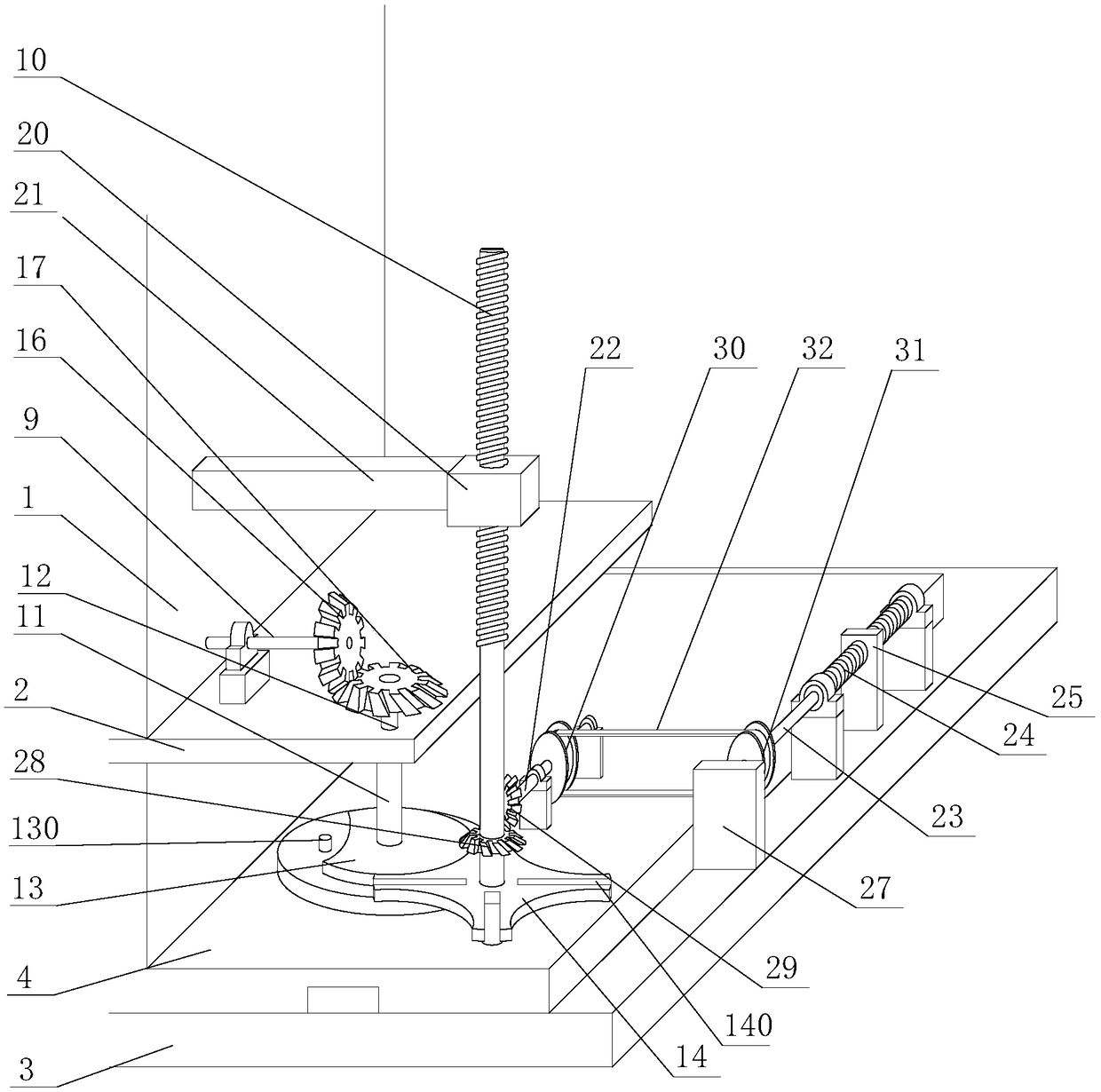

[0038] Such as Figure 1-9 The shown automatic moving ladle dumping device includes a bracket 1, a base 2, a mounting plate 4, a base 3, a fixed frame 5, a ladle 34, a transmission mechanism, a driving part 8, a transverse transmission shaft 9, a Three vertical transmission shafts 10, intermittent transmission assembly, up and down moving slider 20, forward and backward movement mechanism, third longitudinal transmission shaft 24 and front and rear moving slider 25;

[0039]The mounting plate 4 is slidingly installed on the base 3, the base 2 is arranged on the mounting plate 4, the support 1 is vertically fixedly installed on the base 2, the fixed frame 5 is rotatably installed on the support 1 and can rotate up and down relative to the support 1, and the ladle 34 is fixedly connected with the fixed frame 5, the transverse transmission shaft 9 is installed on the bracket 1 and is parallel to the axis of rotation of the fixed frame 5, the original moving part 8 is connected wi...

Embodiment 2

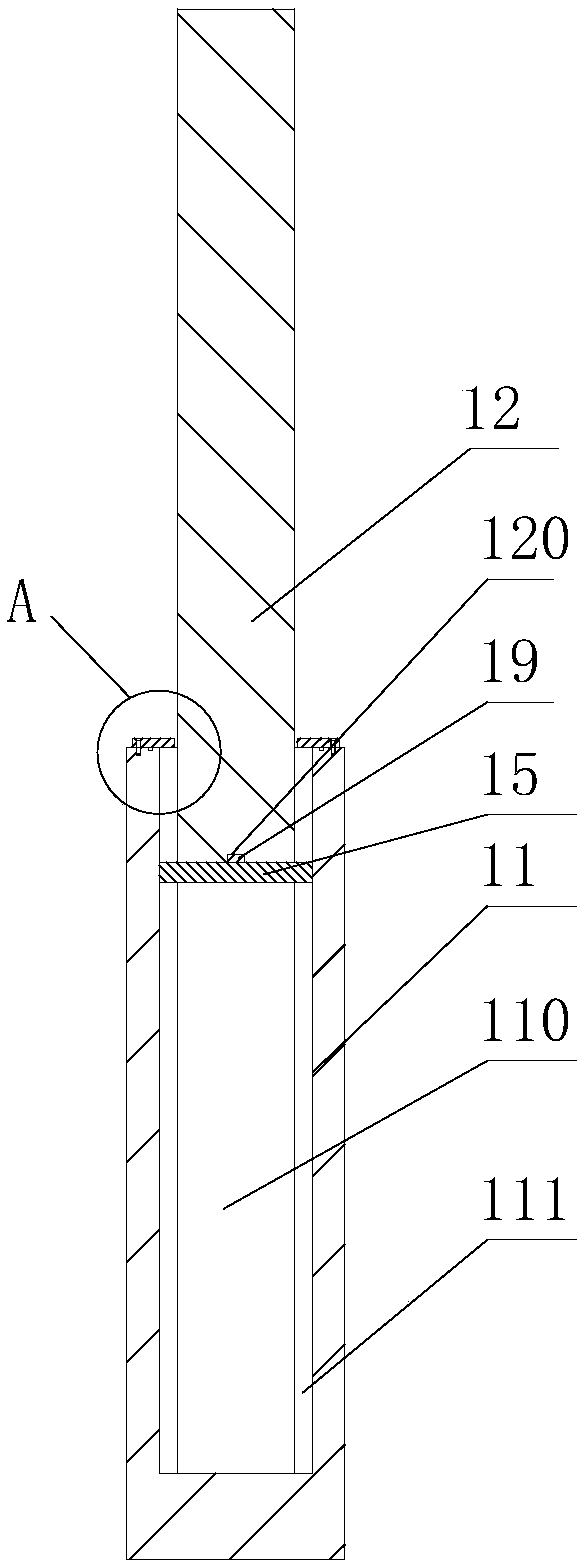

[0075] The difference between this embodiment and the first embodiment is that the first fixing groove 111 and the first mounting hole 110 form a spline groove, and the first fixing bar 15 is an external spline matching the spline groove, so that the connection and transmission are more stable.

Embodiment 3

[0077] The difference between this embodiment and the first embodiment is that the second fixing groove 241 and the second mounting hole 240 form a spline groove, and the second fixing bar 26 is an external spline matching the spline groove, so that the connection and transmission are more stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com