Construction method for long-span hanging vestibule type template support system

A formwork support and construction method technology, applied in formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve problems such as large deformation of the support system, increase the construction time of key lines, collapse, etc. Low cost of sales

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

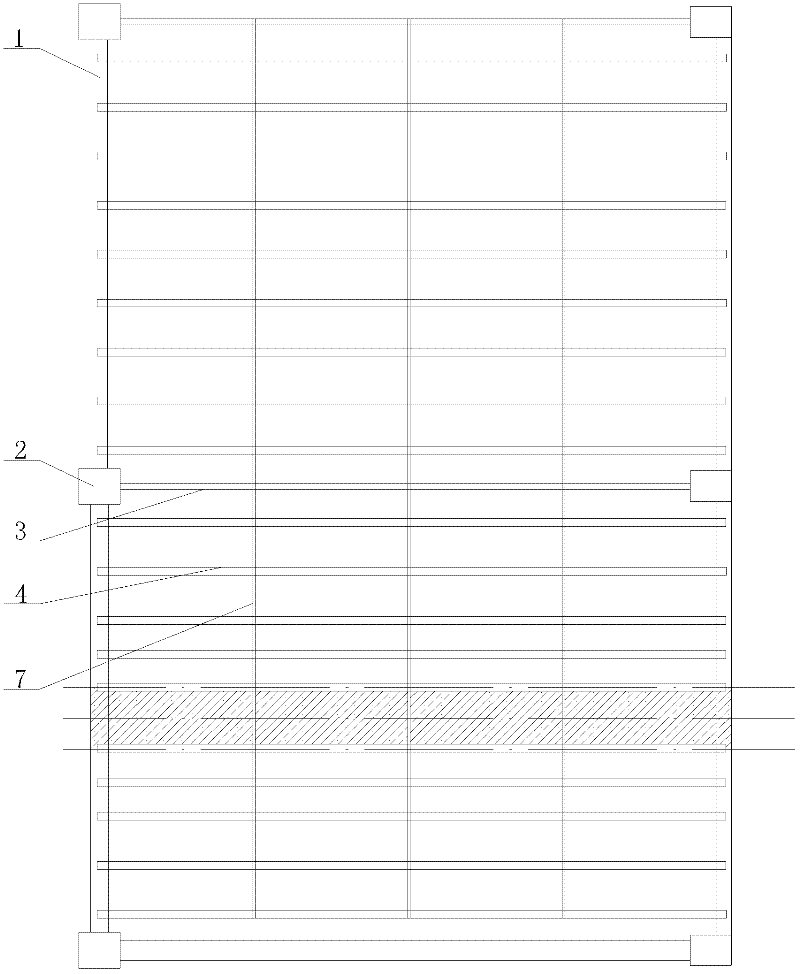

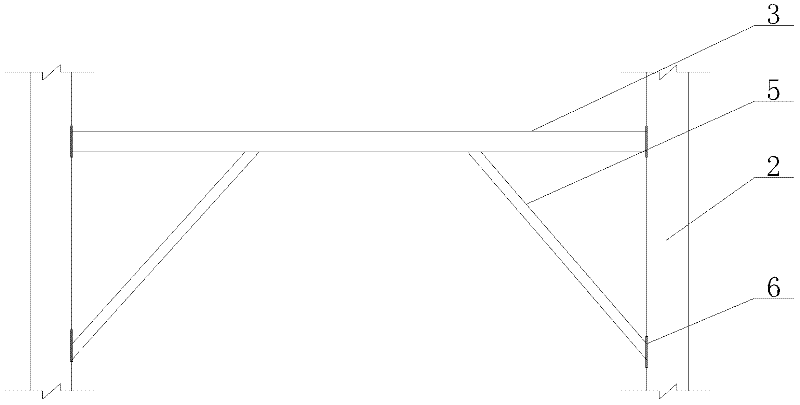

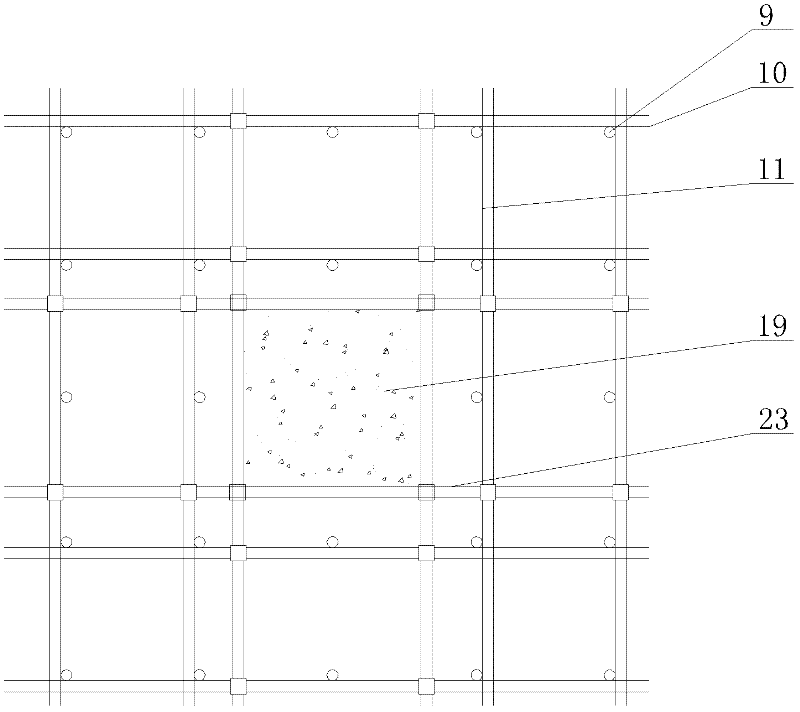

[0033] Such as Figure 1 to Figure 6 As shown, the construction method of the large-span suspended corridor formwork support system of the present invention takes the following steps:

[0034] (1) Select the position of the suspended steel beam: In the area without a floor of the building, use the longitudinal frame beam 1 on the first floor on both sides as the support for the suspended steel beam 4 under the continuous beam, and use the frame column 2 on the first floor as the support under the horizontal frame beam. The support of the suspended steel beam 3 is used to install the support system of the upper beam slab formwork;

[0035] (2) Positioning and setting out of suspended steel beams: pop up the positioning line of the suspended steel beams on the longitudinal frame beam 1 of the first floor, and draw the position lines of the suspended steel beams 3 under the horizontal frame beams and their connecting steel plates 6 on the frame column 2 of the first floor ;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com