Multi-shot feed divider for charging of tactic engine

A technology of engine and multi-engine, which is applied in the direction of rocket engine device, machine/engine, jet propulsion device, etc. It can solve the problems of low production efficiency, large feeding resistance, poor leveling of slurry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

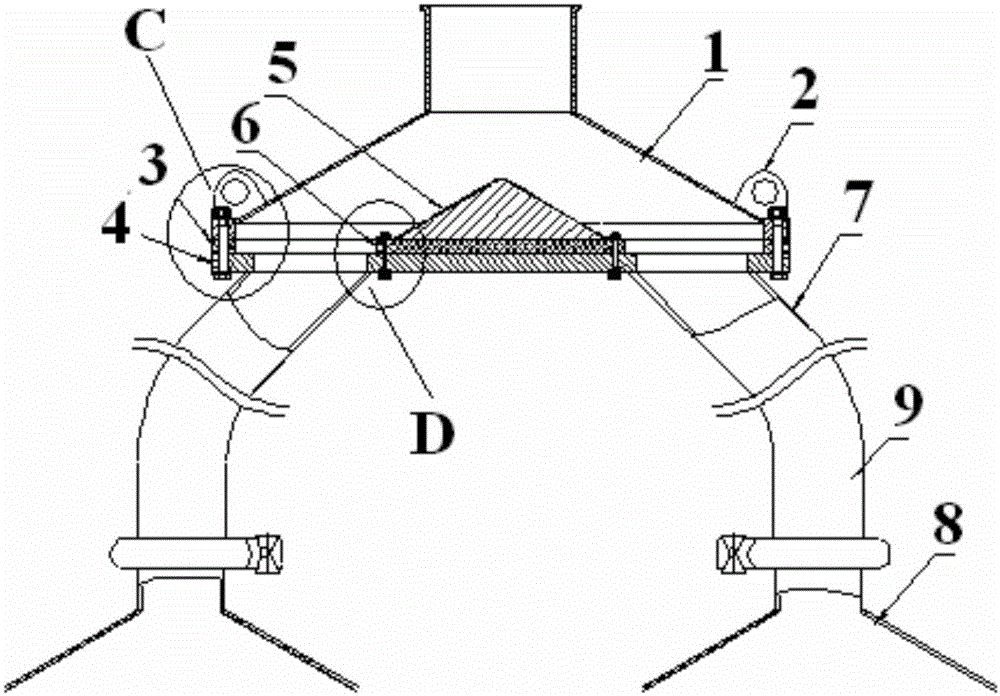

[0019] This embodiment is a multi-shot material distribution device for tactical engine charging, including a material distribution nozzle 1, a pressing plate 4, a material distribution cone 5, a material distribution pipe 7 and 6 feeding pipes 9. Such as figure 1 shown. in:

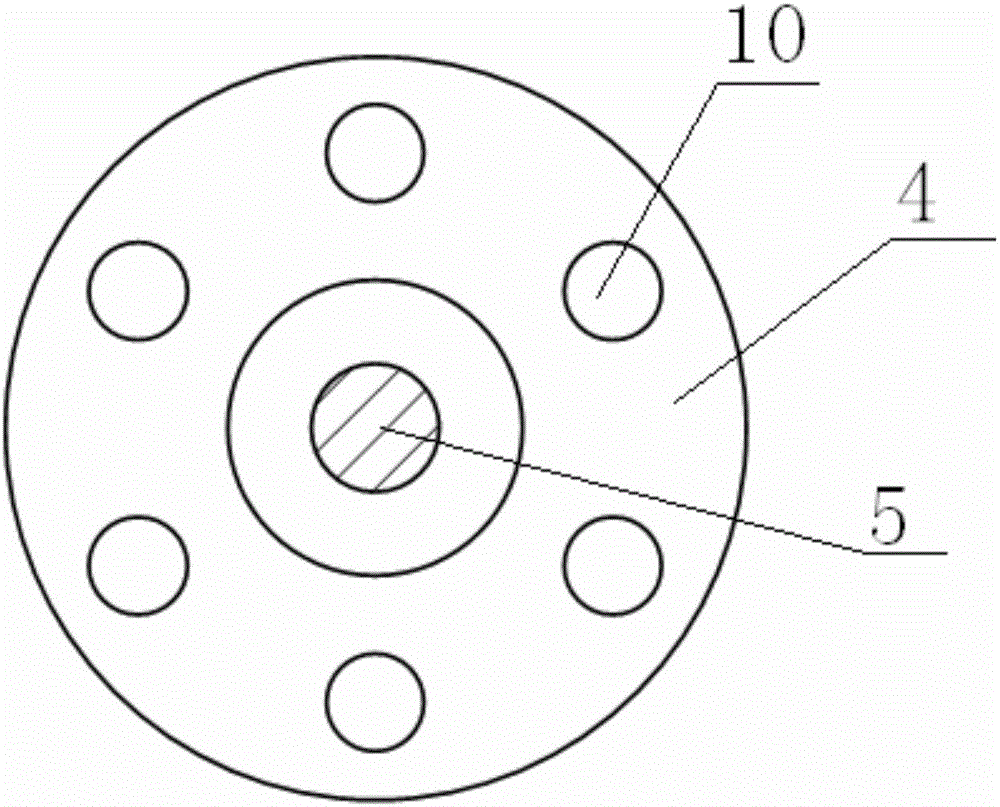

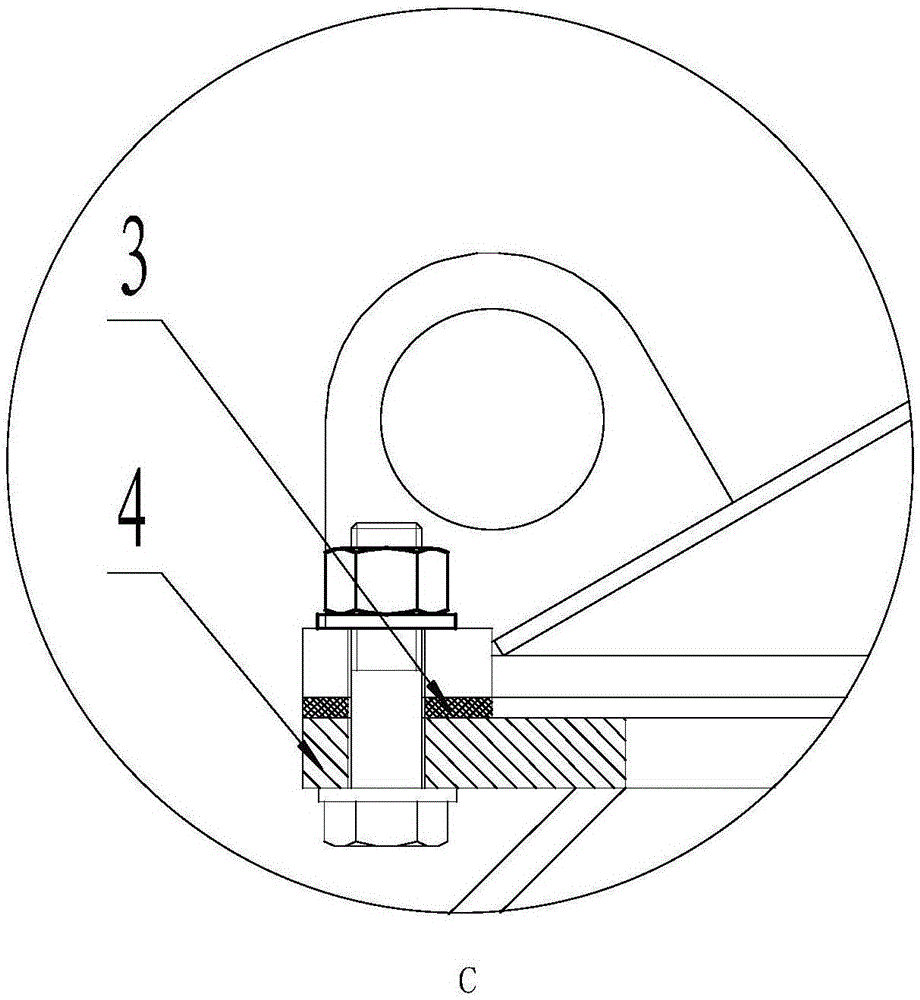

[0020] The edge of the material distribution nozzle 1 is fixed on the upper surface of the pressing plate 4 by bolts, and a large gasket 3 is arranged between the material distribution nozzle and the pressing plate. The lower end of the distribution cone 5 is placed in the distribution nozzle and corresponds to the central hole of the pressing plate. A small sealing gasket 6 is placed between the material distribution cone and the pressing plate. There are 6 distributing pipes 7 evenly distributed on the lower surface of the pressing plate 4 . The upper end of each feeding pipe 9 is fixedly connected with the distribution pipe 7 respectively, and the lower end of each feeding pipe is respectively con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com